Search results for: 'electric co'

- Related search terms

- electric con

- electric steam boiler

- electric'

- electric motor screw drive

- electric%27%27

-

T-6545 MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTER

T-6545 MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTERREFERENCE NUMBER: T-6545

MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTER

PRODUCT INTRODUCTION:

MASK BACTERIA FILTRATION EFFICIENCY KEY PERFORMANCE INDICATORS (BFE) DETECTOR TESTER NOT ONLY CONFORMS TO THE REQUIREMENTS OF MEDICAL SURGICAL MASKS TECHNOLOGY YY0469-2011 APPENDIX B IN THE TEST METHOD FOR FILTER EFFICIENCY (BFE) BACTERIA FIRST B. 1.1.1 TEST INSTRUMENT, BUT ALSO CONFORMS TO THE AMERICAN SOCIETY FOR TESTING MATERIAL ASTMF2100, ASTMF2101, THE REQUIREMENTS OF THE EUROPEAN EN14683 STANDARDS, INNOVATIVE IMPROVEMENTS WERE MADE ON THE BASIS OF THIS, WITH DOUBLE PNEUMATIC CONTRAST SAMPLING METHOD AT THE SAME TIME, IMPROVE THE PRECISION OF SAMPLING,IT IS SUITABLE FOR MEASURING AND TESTING DEPARTMENTS, SCIENTIFIC RESEARCH INSTITUTES, MASK MANUFACTURERS AND OTHER RELEVANT DEPARTMENTS TO TEST THE PERFORMANCE OF MASK BACTERIAL FILTRATION EFFICIENCY.

EXECUTION STANDARD:

Q/0212 ZRB003-2015 MEDICAL SURGICAL MASK

BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR RELATED INTELLECTUAL PROPERTY:

NO.: ZL200820224142.6 ELECTRIC FLOW CONTROL VALVE

NO.: ZL200820224143.0 GAS CAPACITY

NO.: ZL200920308391.8 AIR FILTRATIONMATERIAL FILTRATION EFFICIENCY DETECTOR

PRODUCT FEATURES:

NEGATIVE PRESSURE TEST SYSTEM TO ENSURE THE SAFETY OF OPERATORS;

BUILT -IN PERISTALTIC PUMP IN NEGATIVE PRESSURE CABINET, A, B TWO -WAY, SIX ANDERSEN; THE PERISTALTIC PUMP FLOW CAN BE SET;

THE FLOW RATE OF NIGHT SPRAY CAN BE SET AND THE ATOMIZATION EFFECT IS GOOD.

EMBEDDED HIGH SPEED INDUSTRIAL MICROCOMPUTER CONTROL; 10.4 INCHES INDUSTRIAL HIGH BRIGHTNESS COLOR TOUCH SCREEN;

USB INTERFACE, SUPPORT U DISK DATA STORAGE;

CABINET BUILT-IN HIGH BRIGHTNESS LIGHTS; BUILT-IN LEAKAGE PROTECTION SWITCH TO PROTECT THE SAFETY OF OPERATORS;

THE INNER LAYER OF THE CABINET IS MADE OF STAINLESS STEEL, THE OUTER LAYER IS SPRAYED WITH PLASTIC AND COLD-ROLLED, AND THE INNER AND OUTER LAYERS ARE INSULATED AND FLAME RETARDANT.

THE FRONT SWITCH TYPE GLASS DOOR IS CONVENIENT FOR THE EXPERIMENTER TO OBSERVE AND OPERATE.

DETACHABLE BRACKET, ADJUSTABLE BRACKET HEIGHT; SUPPORTING AND MOVING DUAL PURPOSE CASTERS.

QUANTITY: 1

Learn More -

T-6575 NON-INVASIVE VENTILATOR

T-6575 NON-INVASIVE VENTILATORNON-INVASIVE VENTILATOR

Learn More

CERTIFICATE: CE

MEDICAL VENTILATOR

TECHNICAL PARAMETERS OF DOUBLE LEVEL VENTILATOR

VENTILATOR TYPE: ELECTRIC CONTROL

SCOPE OF APPLICATION: TREATMENT AND TITRATION OF SLEEP APNEA HYPOPNEA SYNDROME, SEVERE SNORING, AND RESPIRATORY INSUFFICIENCY.

DISPLAY INTERFACE: 3.5-INCH LED SCREEN, CHINESE OPERATING SYSTEM

*VENTILATION MODE: CPAP, S, S/T, T

PRESSURE RANGE:

PRESSURE RANGE: 4-30CMH2O (±0.5CMH2O)

PRESSURE ACCURACY: + 0.5CMH2O

PARAMETER SETTING:

DELAYED BOOST: 0-60MIN, SET THE DIVISION INTERVAL 5MIN

INITIAL PRESSURE: 4CMH2O TREATMENT PRESSURE / RESPIRATORY PRESSURE SETTING

THERAPEUTIC PRESSURE: 4-20CMH2O (IN CPAP MODE)

TARGET TIDAL VOLUME: 150ML - 1500ML, ON/ OFF

MAXIMUM SUCTION PRESSURE: 4-30CMH2O, (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

MINIMUM SUCTION PRESSURE: 4-30CMH2O (NOT HIGHER THAN THE SUCTION PRESSURE), (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

INSPIRATORY PHASE PRESSURE: 4-30CMH2O

EXPIRATORY PRESSURE: 4-30CMH2O

EXPIRATORY DECOMPRESSION: PATIENT, OFF, 1-3, THREE ADJUSTABLE

MANUAL VOLTAGE REGULATION: 0-2 GEAR, 0-2CMH2O (ONLY AVAILABLE IN CPAP MODE)

INSPIRATORY SENSITIVITY: 1-8 STALLS

EXPIRATORY SENSITIVITY: 1-8 STALLS

RESPIRATORY FREQUENCY: 3-40 TIMES / MIN

INSPIRATORY TIME: 0.3-3.0S

BACKUP RATE: ON / OFF, DEFAULT 10

PRESSURE RISE TIME: 1-4 STALLS

HUMIDIFIER: 1-5 ADJUSTABLE IN 5 GEARS

*TITRATION FUNCTION: SUPPORT MANUAL AND AUTOMATIC PRESSURE TITRATION, BUILT-IN REMOTE WIRELESS COMMUNICATION MODULE, COMPLETE THE RANDOM SWITCHING OF SINGLE AND DOUBLE LEVEL MODES IN THE TITRATION PROCESS, AND CONTROL MORE THAN 11 VENTILATOR PARAMETERS AT THE SAME TIME.

AUXILIARY FUNCTION: AUTOMATIC AIR LEAKAGE COMPENSATION, AUTOMATIC STARTUP, AUTOMATIC SHUTDOWN, DELAYED SHUTDOWN, SCREEN BACKLIGHT ADJUSTMENT

MONITORING PARAMETERS: PRESSURE, TIDAL VOLUME, RESPIRATORY RATE, MINUTE VENTILATION VOLUME, AIR LEAKAGE VOLUME, INSPIRATORY TIME, BLOOD OXYGEN SATURATION

WAVY CURVE: PRESSURE TIME WAVEFORM, FLOW RATE TIME WAVEFORM

ALARM PROMPT: PIPELINE AND MASK FALLING OFF, AIR LEAKAGE PROMPT, POWER INTERRUPTION, TREATMENT MACHINE FAILURE, HUMIDIFIER FAILURE, LOW VOLTAGE, HIGH RESPIRATORY RATE, LOW RESPIRATORY RATE, LOW MINUTE VENTILATION VOLUME, LOW BLOOD OXYGEN, REPLACEMENT OF FILTER COTTON, FULL SD CARD, RE INSERTION OF SD CARD

*DATA MANAGEMENT:

NETWORK DATA: BMC + RESPIRATORY HEALTH MANAGEMENT CLOUD PLATFORM

SD CARD DATA: RESART NPAP DATA ANALYSIS SOFTWARE

PARTS:

SD CARD: STANDARD

SD CARD SLOT: STANDARD

PIPING: 9 22MM, 1.8M LONG

FACE SHIELD: F2 NOSE MASK AS STANDARD

NOISE: LESS THAN 30DB

ENVIRONMENT CONDITION:

TEMPERATURE:

(WHEN USED) 5 -35 C

(DURING TRANSPORTATION AND STORAGE) -20 C -55 C

ATMOSPHERIC PRESSURE:

(WHEN USED) 760-1060HPA

(DURING TRANSPORTATION AND STORAGE) 760-1060HPA

WORKING HOURS: MORE THAN 8 HOURS

POWER SUPPLY REQUIREMENTS:

AC VOLTAGE: 100-240V

FREQUENCY: 50HZ/60HZ

INPUT POWER: LESS THAN 2A

WATERPROOF LEVEL: IP22 - DRIP PROOF EQUIPMENT

INSTRUMENT SIZE: 290mm X 180mm X 134mm

WEIGHT: 1.5KG (EXCLUDING HUMIDIFIER) 2.5KG (INCLUDING HUMIDIFIER)

ITEM 001

QUANTITY: 10 SETS-999 SETS

ITEM 002

QUANTITY: 1,000 SETS-9,999SETS

ITEM 003

QUANTITY: ≥10,000 SETS -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

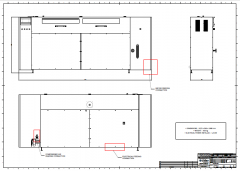

H-2239 MAMMUT QUILTER – MODEL P2 S240 QS28/PA – YEAR 2011

H-2239 MAMMUT QUILTER – MODEL P2 S240 QS28/PA – YEAR 2011BRAND: MAMMUT

MODEL: P2 S240 QS28/PA

YEAR 2011GENERAL MACHINE DATA

UP TO 3,100 STITCHES / MINUTE

MAX. SEWING AREA 2,400 X 2,600mm

STITCH LENGTH 2-8mmMECHANICAL DATA

DIMENSIONS (L X W): 4100 X 7500mm

WEIGHT: APPROXIMATELY 2,300 KG

AIR CONNECTION: 6 BAR

AIR CONSUMPTION: 250 L / MINELECTRICAL DATA

3 PHASES / 400 V

50-60 HZ

3.5 KWQUANTITY: 1

Learn More -

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILL

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILLFOR FILLING DOWN FEATHER PILLOWS

FILLING RANGE: 1 TO 120 GRAMS (70% FEATHER & 30% DOWN)

WEIGHING SYSTEM: 4 SETS

POWER: 4.5 KW

VOLTAGE: 220 / 380 V, 3-PHASE

AIR PRESSURE: 0.5 TO 0.7 MPA

ACCURATE WEIGHING RESULTS WITH TOLERANCE OF ONLY 1 GRAM

WORKING TABLE DIMENSIONS: 1200 x 2400mm (FOR CUSTOMERS FILLING PILLOWS AND QUILTS)

WORKING TABLE DIMENSIONS FOR PILLOWS ONLY: 1200 x 1200mm (EASIER TO FIT IN A 20 FOOT CONTAINER)

OPERATION CAN BE HANDLED BY ONLY 1 EMPLOYEE

INCLUDES ONE AUTOMATIC FILLING TABLE WITH FOOT SWITCH AND CLAMP DEVICE

THE WORKER STEPS ON THE FOOT SWITCH AND THE CLAMP DEVICE WILL RUN TO CLAMP THE PILLOW BAG

THE FILLING PROCESS AUTOMATICALLY STARTS TO FILL THE PILLOW AND AFTER FINISHING THE CLAMP DEVICE WILL RESET

DURING THIS PERIOD, THE WORKER MAY SEAL THE PILLOW WITH SEWING MACHINE

FOUR HOPPER SYSTEM FOR CONSTANT SUPPLY

ONE KEY FOR CHARGE AND RECHARGE REDUCES WASTED TIME

HIGH-QUALITY, RELIABLE ELECTRICAL COMPONENTS

PREPROGRAMMABLE FOR UP TO 50 GROUPS OF RECIPES WITH EACH RECIPE CONTAINING UP TO 60 SETS OF DIFFERENT FILLING PARTS FOR THE SAME PRODUCTION

FULLY ENCLOSED DESIGN TO KEEP ENVIRONMENT CLEAN AND REDUCE MATERIAL WASTE

AUTOMATIC, ACCURATE WEIGHING WITH LOAD CELL TO ENSURE PRODUCTION QUALITY

CE CERTIFICATE INCLUDED

FLOORSPACE 4000mm LONG X 3000mm WIDE X 2500mm HIGH

TABLE FOR PILLOWS IS 1200 X 1200mm

Learn More

QUANTITY: 1 -

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEW

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEWFLATTEN ALL TYPES OF MATTRESSES AND ROLL UP THE FLAT POCKET SPRING MATTRESSES.

FLATTENING AND ROLLING MATTRESSES HAS THE ADVANTAGE OF MINIMIZING THE STORAGE AREA AND

FACILITATE THE TRANSPORTATION AND LOWER TRANSPORTATION COSTS.

PRODUCTION CAPACITY: 3 MATTRESSES PER MINUTE FOR NORMAL PACKING.

MATTRESS SIZE: MIN. 700 X 1900mm TO MAX. 2100 X 2100mm

MATTRESS HEIGHT: 50mm TO 400mm

PRESSING SYSTEM: PNEUMATIC FOR NORMAL PACKING, HYDRAULIC SYSTEM FOR FLATTENING AND ROLL PACKING

PNEUMATIC PRESSURE: 482 KGS (8 BARS)

HYDRAULIC PRESSURE: 65 TON

WIDTH OF FILM ROLLS: MIN. 2200 mm TO MAX. 2650 mm

MAX. DIAMETER OF FILM ROLLS: 320mm

MAX. WEIGHT OF FILM ROLLS: 200 KGS

TYPE OF NYLON: PE FILM

THICKNESS OF FILM: 50 TO 150 MICRON (5 TO 15)

POWER REQUIREMENTS: 3 PHASE 380 V OR AS PER CUSTOMER

TOTAL ELECTRIC DRAW: 20 KW

WEIGHT: APPROX. 10 TONS

NUMBER OF OPERATORS: 1

QUALITY STANDARD: CE

WARRANTY: 2 YEARS

FINAL ROLL PACKING TUBE DIAMETER: 250 TO 400 mm

YouTube Video 1: https://youtu.be/7e3-3FtaQdE

YouTube Video 2: https://youtu.be/LrmcQ18A1zM

QUANTITY: 1

Learn More -

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEM

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEMMAKE: CIBITEX

THE MOST INNOVATIVE, VERSATILE AND COMPACT SYSTEM FOR PROFESSIONAL WASHING DESIGNED FOR SMALL AND MEDIUM VOLUMES OF DIGITALLY PRINTED FABRICS

UNIT COMES WITH 3 STAGE BOILER

VOLTAGE: 400 V 50/60Hz

MAXIMUM WORKING WIDTH: 2200mm

MAXIMUM WATER TEMPERATURE: 95 °C

MAXIMUM INTERNAL CONTENT (DEPENDING ON FABRIC): 200 METERS

MAXIMUM WATER CONSUMPTION: 5 L/MIN

AVERAGE ELECTRICAL CONSUMPTION: 5,6kWh

DIMENSIONS: 3270 X 560 X 1380mm

WEIGHT: 400kgQUANTITY: 1

Learn More -

T-1138 LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016

T-1138 LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016REFERENCE NUMBER: T-1138

LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016

HANKS CABINET DYEING MACHINE

UNDER PRESSURE TEMPERATURE 110°C

WITH EXTRACTABLES BASKETS

MODEL LORIS BELLINI APPC/LV 150

YEAR 1988 FULLY RECONDITIONED 2016

QUANTITY: 1

Learn More -

T-1139 OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017

T-1139 OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017REFERENCE NUMBER: T-1139

OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017

HANKS CABINET DYEING MACHINE

UNDER PRESSURE TEMPERATURE 110°C

WITH EXTRACTABLES BASKETS

BRAND OBEM

TYPE MBC 350/06/CE

YEAR 1989 FULLY RECONDITIONED 2017

QUANTITY: 1

Learn More -

M-7728 ISOTEX PLANT FOR PRINTING ON PAPER OR SKIN 1800mm

M-7728 ISOTEX PLANT FOR PRINTING ON PAPER OR SKIN 1800mmREFERENCE NUMBER: M-7728

ISOTEX PLANT FOR PRINTING ON PAPER OR SKIN 1800mm

COATING LINE FOR PVC WITH PAPER BASE

2 COLORS ISOTEX H.1800mm

PLANT FOR PRINTING ON PAPER OR ON SKIN

MAKE: ISOTEX

COLORS: 2

H.1800mm

QUANTITY: 1

Learn More