Search results for: 'A-1'

- Related search terms

- A-12

- A-125

- A-128

- A-1152

- A-1 Automotive

-

TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998 QUANTITY: 1 Learn More

TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998 QUANTITY: 1 Learn More -

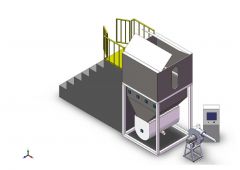

V-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALINGV-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALING

V-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALINGV-1212-A PILLOW COMPRESSION/PACKING MACHINE – new model Aug 2020 (800 x 800 mm) {31.5 x 31.5”} WITH DOUBLE BAND SEALING DIMENSIONS: 1200 x 1150 x 1600mm

SHIPPING DIMENSIONS: 1220 WIDTH x 1110 LENGTH x 2060mm HEIGHT

NET WEIGHT: 110 KGS

GROSS WEIGHT 320 KG

PRESSURE: 0.6 MPa = 87 PSI

VIDEO AVAILABLE

QUANTITY: 1

Learn More

DIMENSIONS: 1200 x 1150 x 1600mm

SHIPPING DIMENSIONS: 1220 WIDTH x 1110 LENGTH x 2060mm HEIGHT

NET WEIGHT: 110 KGS

GROSS WEIGHT 320 KG

PRESSURE: 0.6 MPa = 87 PSI

VIDEO AVAILABLE

QUANTITY: 1

Learn More

-

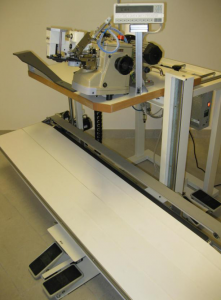

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More

K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: K-1428 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS FOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) QUANTITY AVAILABLE: 1 Learn More -

V-1376 AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTH

V-1376 AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTHREFERENCE NUMBER: V-1376

AKAB MACHINES, COMFORTER SHELL MAKERS, YEAR 1992, WIDTH 115” AND UNLIMITED LENGTHAKAB MACHINES

COMFORTER SHELL MAKERS

MAXIMUM WIDTH: 115”

YEAR: 1992

WIDTH: 115 INCHESQUANTITY: 2

Learn More -

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

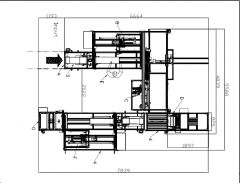

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBSREFERENCE NUMBER: K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBS QUANTITY AVAILABLE: 1 Learn More

K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBSREFERENCE NUMBER: K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBS QUANTITY AVAILABLE: 1 Learn More -

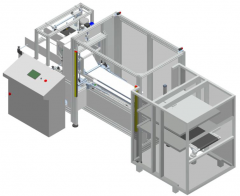

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More