Search results for: 'and'

-

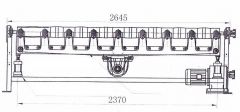

YY-3336 ELECTROTEK AUTOMATIC MATERIAL ALIGNING AND CENTRALIZING CONVEYOR, AUTOMATIC MATERIAL LIFTING AND CENTRALIZING SYSTEM, WORKING WIDTH 90 INCH, YEAR 2022YY-3336 ELECTROTEK AUTOMATIC MATERIAL ALIGNING AND CENTRALIZING CONVEYOR, AUTOMATIC MATERIAL LIFTING AND CENTRALIZING SYSTEM, WORKING WIDTH 90 INCH, YEAR 2022 QUANTITY: 1 Learn More

YY-3336 ELECTROTEK AUTOMATIC MATERIAL ALIGNING AND CENTRALIZING CONVEYOR, AUTOMATIC MATERIAL LIFTING AND CENTRALIZING SYSTEM, WORKING WIDTH 90 INCH, YEAR 2022YY-3336 ELECTROTEK AUTOMATIC MATERIAL ALIGNING AND CENTRALIZING CONVEYOR, AUTOMATIC MATERIAL LIFTING AND CENTRALIZING SYSTEM, WORKING WIDTH 90 INCH, YEAR 2022 QUANTITY: 1 Learn More -

TT-2978 COMPOSED OF TWO SHREDDERS WITH FEED AND CONNECTING CONVEYOR INCLUDING ONE SET OF MACHINES, ONE DOUBLE SHAFT AND ONE FOUR SHAFT, BOTH ARE 2000mm (80 INCHES WORKING WIDTH), CAPACITY 500 PASSENGER TIRES PER HOUR, OUTPUT IS 25mm x 25mm PARTICLETT-2978 COMPOSED OF TWO SHREDDERS WITH FEED AND CONNECTING CONVEYOR INCLUDING ONE SET OF MACHINES, ONE DOUBLE SHAFT AND ONE FOUR SHAFT, BOTH ARE 2000mm (80 INCHES WORKING WIDTH), CAPACITY 500 PASSENGER TIRES PER HOUR, OUTPUT IS 25mm x 25mm PARTICLE Learn More

TT-2978 COMPOSED OF TWO SHREDDERS WITH FEED AND CONNECTING CONVEYOR INCLUDING ONE SET OF MACHINES, ONE DOUBLE SHAFT AND ONE FOUR SHAFT, BOTH ARE 2000mm (80 INCHES WORKING WIDTH), CAPACITY 500 PASSENGER TIRES PER HOUR, OUTPUT IS 25mm x 25mm PARTICLETT-2978 COMPOSED OF TWO SHREDDERS WITH FEED AND CONNECTING CONVEYOR INCLUDING ONE SET OF MACHINES, ONE DOUBLE SHAFT AND ONE FOUR SHAFT, BOTH ARE 2000mm (80 INCHES WORKING WIDTH), CAPACITY 500 PASSENGER TIRES PER HOUR, OUTPUT IS 25mm x 25mm PARTICLE Learn More -

TT-8345 VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS, YEAR 2004 TO 2024TT-8345 VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS, YEAR 2004 TO 2024 1. SYSTEM TITLE: VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS 2. HEADING YEAR FOR SHREDDER: 2004 3. HEADING YEAR FOR GRANULATOR: 2013 Learn More

TT-8345 VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS, YEAR 2004 TO 2024TT-8345 VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS, YEAR 2004 TO 2024 1. SYSTEM TITLE: VECOPLAN VAZ1300 SHREDDER WITH RAPID 500 GRANULATOR AND CONVEYORS 2. HEADING YEAR FOR SHREDDER: 2004 3. HEADING YEAR FOR GRANULATOR: 2013 Learn More -

TT-5448 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING, 150 HP, YEAR 2020TT-5448 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING, 150 HP, YEAR 2020 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING BRAND VECOPLAN MODEL V-ECO 1300 QUANTITY: 1 Learn More

TT-5448 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING, 150 HP, YEAR 2020TT-5448 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING, 150 HP, YEAR 2020 VECOPLAN V-ECO 1300 SHREDDER SYSTEM WITH INFEED CONVEYOR, HOPPER FEED, BLOWER AND PIPING BRAND VECOPLAN MODEL V-ECO 1300 QUANTITY: 1 Learn More -

TT-8344 VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS, YEAR 2008 TO 2018TT-8344 VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS, YEAR 2008 TO 2018 1. SYSTEM TITLE: VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS 2. SHREDDER MAKE: VECOPLAN 3. SHREDDER MODEL: VAZ 1600M 4. SHREDDER YEAR: 2018 Learn More

TT-8344 VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS, YEAR 2008 TO 2018TT-8344 VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS, YEAR 2008 TO 2018 1. SYSTEM TITLE: VECOPLAN VAZ 1600 COMPLETE SHRED LINE WITH HERBOLD GRANULATOR AND CONVEYORS 2. SHREDDER MAKE: VECOPLAN 3. SHREDDER MODEL: VAZ 1600M 4. SHREDDER YEAR: 2018 Learn More -

TT-8651 HARRIS CENTURION 150 TWO RAM BALER AND INFEED CONVEYOR, YEAR 2018TT-8651 HARRIS CENTURION 150 TWO RAM BALER AND INFEED CONVEYOR, YEAR 2018 QUANTITY: 1 Learn More

TT-8651 HARRIS CENTURION 150 TWO RAM BALER AND INFEED CONVEYOR, YEAR 2018TT-8651 HARRIS CENTURION 150 TWO RAM BALER AND INFEED CONVEYOR, YEAR 2018 QUANTITY: 1 Learn More -

M-5322 90-DEGREE TURN UNIT TO PUT IN A CONVEYOR LINE AND CHANGE THE DIRECTION OF THE ROLL BUN FOR FOAM INDUSTRYREFERENCE NUMBER: M-5322 (22073CK1U) L 90-DEGREE TURN UNIT TO PUT IN A CONVEYOR LINE AND CHANGE THE DIRECTION OF THE ROLL BUN FOR FOAM INDUSTRY WIDTH: 2600MMx2600MM Including 2 motors each 1.5 kw QUANTITY AVAILABLE: 1 Learn More

M-5322 90-DEGREE TURN UNIT TO PUT IN A CONVEYOR LINE AND CHANGE THE DIRECTION OF THE ROLL BUN FOR FOAM INDUSTRYREFERENCE NUMBER: M-5322 (22073CK1U) L 90-DEGREE TURN UNIT TO PUT IN A CONVEYOR LINE AND CHANGE THE DIRECTION OF THE ROLL BUN FOR FOAM INDUSTRY WIDTH: 2600MMx2600MM Including 2 motors each 1.5 kw QUANTITY AVAILABLE: 1 Learn More -

YY-2222 CONVEYOR + AGGLOMERATOR + SCREW LOADERYY-2222 CONVEYOR + AGGLOMERATOR + SCREW LOADER TECHNICAL PARAMETERS: 1. BELT CONVEYOR MOTOR POWER: 2.2KW WIDTH OF BELT: 800mm MATERIAL OF BELT: PVC SPEED CONTROL BY: FREQUENCY INVERTER MOUNTED ON CASTERS, EASY TO MOVE: YES 2. AGGLOMERATOR TANK VOLUME (LITER): 800 WORKING VOLUME (LITER): 600 CAPACITY(KG/H): 450 TO 600 MOTOR POWER (KW): 132 ROTATING BLADES SPEED (R/MIN): 750 ROTATING BLADE QUANTITY (PCS): 4 FIXED BLADE QUANTITY (PCS): 8 BEARING BRAND: SKF MATERIAL OF BLADE: SKD11 FROM JAPAN MATERIAL OF INNER PART OF POT: STAINLESS STEEL DISCHARGING MODEL: PNEUMATIC WATER SPRAYING WAY: AUTOMATIC MACHINE DIMENSION L×W×H (mm): 2170×1510×2145 MACHINE WEIGHT (KG): 2800 3. SCREW LOADER MAIN MOTOR: 1.5KW SECOND MOTOR: 0.55KW SCREW DIAMETER: 133mm VOLUME OF HOPPER: 100KG MATERIAL OF HOPPER: STAINLESS STEEL 4. ELECTRICAL CABINET ELECTRICAL COMPONENT BRAND: SIEMENS AND DELIXI TEMPERATURE CONTROLLER: OMRON FROM JAPAN ELECTRICITY: 220, 60Hz, 3PHASE (CAN CUSTOMIZED) QUANTITY: 1 SET Learn More

YY-2222 CONVEYOR + AGGLOMERATOR + SCREW LOADERYY-2222 CONVEYOR + AGGLOMERATOR + SCREW LOADER TECHNICAL PARAMETERS: 1. BELT CONVEYOR MOTOR POWER: 2.2KW WIDTH OF BELT: 800mm MATERIAL OF BELT: PVC SPEED CONTROL BY: FREQUENCY INVERTER MOUNTED ON CASTERS, EASY TO MOVE: YES 2. AGGLOMERATOR TANK VOLUME (LITER): 800 WORKING VOLUME (LITER): 600 CAPACITY(KG/H): 450 TO 600 MOTOR POWER (KW): 132 ROTATING BLADES SPEED (R/MIN): 750 ROTATING BLADE QUANTITY (PCS): 4 FIXED BLADE QUANTITY (PCS): 8 BEARING BRAND: SKF MATERIAL OF BLADE: SKD11 FROM JAPAN MATERIAL OF INNER PART OF POT: STAINLESS STEEL DISCHARGING MODEL: PNEUMATIC WATER SPRAYING WAY: AUTOMATIC MACHINE DIMENSION L×W×H (mm): 2170×1510×2145 MACHINE WEIGHT (KG): 2800 3. SCREW LOADER MAIN MOTOR: 1.5KW SECOND MOTOR: 0.55KW SCREW DIAMETER: 133mm VOLUME OF HOPPER: 100KG MATERIAL OF HOPPER: STAINLESS STEEL 4. ELECTRICAL CABINET ELECTRICAL COMPONENT BRAND: SIEMENS AND DELIXI TEMPERATURE CONTROLLER: OMRON FROM JAPAN ELECTRICITY: 220, 60Hz, 3PHASE (CAN CUSTOMIZED) QUANTITY: 1 SET Learn More -

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More