Search results for: 'Automatic d'

- Related search terms

- automatic V''

- AUTOMATIC'

- Automatic+d

- AUTOMATIC''

- AUTOMATIC P'

-

TT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESSTT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESS QUANTITY: 1 Learn More

TT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESSTT-3916 MARGASA TEARING LINE, WORKING WIDTH 2000mm, 5 DRUMS, YEAR 2010 COMPLETE PLANT WITH MIXING ROOMS AND FILTRATION, ALL PIPING INCLUDED. WITH AUTEFA AUTOMATIC BALE PRESS QUANTITY: 1 Learn More -

YY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mmYY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mm SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS TECHNICAL FEATURE OF THE LOOM: 1. MAXIMUM WEAVING WIDTH: 2140mm – MIN. 1000mm (ON REQUEST BE POSSIBLE ALL WEAVING WIDTH); 2. THE LOOM IS SUITABLE FOR WEAVING TUBULAR FABRICS AND FLATS; 3. ADJUSTABLE WIRE/CM. MAX. 200 – MIN. 5; 4. MAX SPEED FROM 150 RPM; 5. MAXIMUM WARP TENSION: DAN/M 1500. QUANTITY: 1 Learn More

YY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mmYY-3533 SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS, WORKING WIDTH 2140mm SHUTTLE LOOMS WITH AUTOMATIC CHANGE SPOOL DEVICE FOR TECHNICAL FABRICS, DENIM, AND OTHER FABRICS TECHNICAL FEATURE OF THE LOOM: 1. MAXIMUM WEAVING WIDTH: 2140mm – MIN. 1000mm (ON REQUEST BE POSSIBLE ALL WEAVING WIDTH); 2. THE LOOM IS SUITABLE FOR WEAVING TUBULAR FABRICS AND FLATS; 3. ADJUSTABLE WIRE/CM. MAX. 200 – MIN. 5; 4. MAX SPEED FROM 150 RPM; 5. MAXIMUM WARP TENSION: DAN/M 1500. QUANTITY: 1 Learn More -

C-1222 SAVIO AUTOMATIC CONE WINDER, MODEL ORION E, YEAR 2005, WITH WAXING DEVICE, N.44 POSITIONS – YEAR 2005REFERENCE NUMBER: C-1222 SAVIO AUTOMATIC CONE WINDER, MODEL ORION E, YEAR 2005, WITH WAXING DEVICE, N.44 POSITIONS – YEAR 2005 DETAILS: AUTOMATIC CONE WINDER SAVIO ORION E N.44 HEADS YEAR OF CONSTRUCTION 2005 AUTOMATIC LOADER OF THE SPOOLS AUTOMATIC TOP SEARCH MAIN UNIT SX LOADED DX DELIVERY 6"(152 mm) CONICITY 4°20' 2 TURNS DRUM DIAMETER 94 mm VARIABLE STEP SPLICER MESDAN MOD.690 U ELECTRONIC CLEARERS LOEPFE ZENIT FC WITH INTERCEPTING FOREIGN FIBERS WAXING DEVICE N.1 TROLLEY FOR AUTOMATIC DOFFING N.1 CONES RESERVE SINGLE BASKET LIGHTING ON THE MACHINE TROLLEY BLOWER MAGITEX WITH DRAIN ON THE MAIN UNIT QUANTITY AVAILABLE: 1 Learn More

C-1222 SAVIO AUTOMATIC CONE WINDER, MODEL ORION E, YEAR 2005, WITH WAXING DEVICE, N.44 POSITIONS – YEAR 2005REFERENCE NUMBER: C-1222 SAVIO AUTOMATIC CONE WINDER, MODEL ORION E, YEAR 2005, WITH WAXING DEVICE, N.44 POSITIONS – YEAR 2005 DETAILS: AUTOMATIC CONE WINDER SAVIO ORION E N.44 HEADS YEAR OF CONSTRUCTION 2005 AUTOMATIC LOADER OF THE SPOOLS AUTOMATIC TOP SEARCH MAIN UNIT SX LOADED DX DELIVERY 6"(152 mm) CONICITY 4°20' 2 TURNS DRUM DIAMETER 94 mm VARIABLE STEP SPLICER MESDAN MOD.690 U ELECTRONIC CLEARERS LOEPFE ZENIT FC WITH INTERCEPTING FOREIGN FIBERS WAXING DEVICE N.1 TROLLEY FOR AUTOMATIC DOFFING N.1 CONES RESERVE SINGLE BASKET LIGHTING ON THE MACHINE TROLLEY BLOWER MAGITEX WITH DRAIN ON THE MAIN UNIT QUANTITY AVAILABLE: 1 Learn More -

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More -

TT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICETT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICE QUANTITY: 1 Learn More

TT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICETT-3053 SCHLAFHORST 338 AUTOMATIC WINDING WITH 60 SPINDLES, YEAR 2007 WITH THERMO-SPLICER DEVICE QUANTITY: 1 Learn More -

P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mmREFERENCE NUMBER: P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1982 WIDTH: 2500mm TYPE: GALAXY AS.202 QUANTITY AVAILABLE: 1 Learn More

P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mmREFERENCE NUMBER: P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1982 WIDTH: 2500mm TYPE: GALAXY AS.202 QUANTITY AVAILABLE: 1 Learn More -

P-1467 HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH 2500mmREFERENCE NUMBER: P-1467 HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH: 2500mm WITH 4 SWIFTS CONSTR. TYPE: EUROPE QUANTITY AVAILABLE: 1 Learn More

P-1467 HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH 2500mmREFERENCE NUMBER: P-1467 HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING WIDTH: 2500mm WITH 4 SWIFTS CONSTR. TYPE: EUROPE QUANTITY AVAILABLE: 1 Learn More -

TT-7666 HOUGET DUESBERG BOSSON AUTOMATIC CARDING SET WITH 2 SWIFTS, WORKING WIDTH 2200mmTT-7666 HOUGET DUESBERG BOSSON AUTOMATIC CARDING SET WITH 2 SWIFTS, WORKING WIDTH 2200mm 1. AUTOMATIC CARDING SET WITH 2 SWIFTS 2. BRAND: HOUGET DUESBERG BOSSON 3. WORKING WIDTH 2200mm QUANTITY: 1 Learn More

TT-7666 HOUGET DUESBERG BOSSON AUTOMATIC CARDING SET WITH 2 SWIFTS, WORKING WIDTH 2200mmTT-7666 HOUGET DUESBERG BOSSON AUTOMATIC CARDING SET WITH 2 SWIFTS, WORKING WIDTH 2200mm 1. AUTOMATIC CARDING SET WITH 2 SWIFTS 2. BRAND: HOUGET DUESBERG BOSSON 3. WORKING WIDTH 2200mm QUANTITY: 1 Learn More -

M-5131 DIGITAL CONTROL AUTOMATIC COILERREFERENCE NUMBER: M-5131 (121234ZGW11UF) L DIGITAL CONTROL AUTOMATIC COILER DIGITAL CONTROL AUTOMATIC COILER MODEL: CL-80A PRODUCTION: 80 SPRINGS PER MINUTE SPRING TYPE: BONNELL QUANTITY AVAILABLE: 1 Learn More

M-5131 DIGITAL CONTROL AUTOMATIC COILERREFERENCE NUMBER: M-5131 (121234ZGW11UF) L DIGITAL CONTROL AUTOMATIC COILER DIGITAL CONTROL AUTOMATIC COILER MODEL: CL-80A PRODUCTION: 80 SPRINGS PER MINUTE SPRING TYPE: BONNELL QUANTITY AVAILABLE: 1 Learn More -

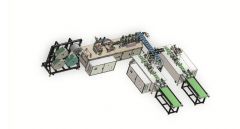

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More