Search results for: 'Winder machine se'

- Related search terms

- machine can

- Machine+f'

- Machine ope

- Machine fe

- machine de''

-

K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mmREFERENCE NUMBER: K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mm MODEL F26 LOADING CONVEYOR 2100 X 2100mm UNLOADING CONVEYOR 2100 X 2100mm MAX. DRILLING WIDTH 2100mm MAXIJMUM LENGTH 2100mm MAX. DRILLING HEIGHT 180mm HOLE DIAMETER 6-30mm QUANTITY AVAILABLE: 1 Learn More

K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mmREFERENCE NUMBER: K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mm MODEL F26 LOADING CONVEYOR 2100 X 2100mm UNLOADING CONVEYOR 2100 X 2100mm MAX. DRILLING WIDTH 2100mm MAXIJMUM LENGTH 2100mm MAX. DRILLING HEIGHT 180mm HOLE DIAMETER 6-30mm QUANTITY AVAILABLE: 1 Learn More -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

TT-3992 SCHLAFHORST AUTOCONER X5 SPINNING MACHINE TIED WITH A LINKED WINDER, 70 SPINDLES, YEAR 2010 TO 2011TT-3992 SCHLAFHORST AUTOCONER X5 SPINNING MACHINE TIED WITH A LINKED WINDER, 70 SPINDLES, YEAR 2010 TO 2011 QUANTITY: 2 SETS Learn More

TT-3992 SCHLAFHORST AUTOCONER X5 SPINNING MACHINE TIED WITH A LINKED WINDER, 70 SPINDLES, YEAR 2010 TO 2011TT-3992 SCHLAFHORST AUTOCONER X5 SPINNING MACHINE TIED WITH A LINKED WINDER, 70 SPINDLES, YEAR 2010 TO 2011 QUANTITY: 2 SETS Learn More -

TT-1817 HACOBA SEWING THREAD WINDER KSA, YEAR 2000 TO 2002TT-1817 HACOBA SEWING THREAD WINDER KSA, YEAR 2000 TO 2002 ITEM 001 HACOBA SEWING THREAD WINDER KSA YEAR: 2000 ELECTRONIC QUANTITY: 1 ITEM 002 HACOBA SEWING THREAD WINDER KSA YEAR: 2002 QUANTITY: 1 Learn More

TT-1817 HACOBA SEWING THREAD WINDER KSA, YEAR 2000 TO 2002TT-1817 HACOBA SEWING THREAD WINDER KSA, YEAR 2000 TO 2002 ITEM 001 HACOBA SEWING THREAD WINDER KSA YEAR: 2000 ELECTRONIC QUANTITY: 1 ITEM 002 HACOBA SEWING THREAD WINDER KSA YEAR: 2002 QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More -

L-4955 BENNINGER SIZETEC SIZING MACHINE, EXIT WIDTH 2200mm, YEAR 1994 – ONE SIZE BOX 2200mm

L-4955 BENNINGER SIZETEC SIZING MACHINE, EXIT WIDTH 2200mm, YEAR 1994 – ONE SIZE BOX 2200mmREFERENCE NUMBER: L-4955

Learn More

BRAND: BENNINGER

MODEL: SIZETEC

TYPE: BB-S/ZT4/4TKD

YEAR: 1994 -

P-3307 VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMS

P-3307 VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMSREFERENCE NUMBER: P-3307

VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMS

3 PICANOL

TYPE: TERRY PLUS

AIRJET TERRY LOOMS

YEAR: 2005 to 2006

CONDITION: ALMOST NEW

3 VAMATEX

TYPE: DYNA TERRY

RAPIER WEAVING MACHINES FOR TERRY FABRICS

YEAR: 2007

REED WIDTH: 2600mm

DOBBY FIMTESILE 7P, 20 SHHAFTS

8 COLORS

4 BEAMS 800+1000mm

2650 DROPPERS

6 PRE FEEDERS

2 CLOTH ROLLERS

16 HEALD FRAMES

3 PICANOL

TYPE: TERRY PLUS

AIRJET TERRY LOOMS

2 DOBBY and 1 JACQUARD

PICANOL

TYPE: TERRY PLUS 800-6-R

AIRJET LOOMS

YEAR: 2005

REED SPACE: 2600mm

6 COLORS

6 PICANOL 1131 CAN PLUS WEFT ACCUMULATORS

STAUBLI DOBBY TYPE 2861-16K FOR 16 SHAFTS

14 SHAFTS PROVIDED – DRC30 DRIVE HARNESS CONNECTION

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WRAP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIAMETER

1 GROUND WARP BEAMS, TYPE 190

1 PILE WARP BEAM

2 ADAPTERS

1 CLOTH ROLLER

APPROXIMATELY 5000 DROPPERS, 5000 HEALD WIRES

380 VOLTS, 50 HERTZ

PICANOL

TYPE: TERRY PLUS 800-6-R

AIRJET TERRY LOOM

YEAR: 2006

REED SPACE: 2300mm

6 COLORS

6 WEFT ACCUMULATORS

STAUBLI DOBBY TYPE 2861-A6K FOR 16 SHAFTS

14 SHAFTS PROVIDED – DRC DRIVE HARNESS ONNECTION

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WARP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIMAETER

1 GROUND WARP BEAM 805mm, TYPE 190

1 PILE WARP BEAM

2 ADAPTERS

1 CLOTH ROLLER

380 VOLTS, 50 HERTZ

PICANOL

TYPE: TERRY PLUS 800-8-J

AIRJET LOOMS

YEAR: 2006

REED SPACE: 2600mm

6 COLORS, 6 WEFT ACCUMULATORS

STAUBLI ELECTRONIC JACQUARD TYPE LX1602 FOR 3072 HOOKS AND HARNESS WITH SPRINGS AND 5756 ENDS

LIETTI STEEL JACQUARD GANTRY

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WARP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIAMETER

1 GROUND WARP BEAM 805mm DIAMETER

1 PILE WARP BEAM 1000mm DIAMETER

2 ADAPTERS FOR WORKING FROM BEAMS, TYPE 190

1 CLOTH ROLLER

APPROXIMATELY 5000 DROPPERS

3 VAMATEX

TYPE: DYNA-TERRY

RAPIER WEAVING MACHINES FOR TERRY FABRICS

YEAR: 2007

REED WIDTH: 2600mm

DOBBY FIMTESILE 7P-20 SHAFTS

8 COLORS

4 BEAMS 800+1000mm

6250 DROPPERS

6 PRE FEEDERS and 2 CLOTH ROLLERS

16 HEALD FRAMES

QUANTITY: 15

Learn More -

GEO-TEXTILE NON-WOVEN PUNCH LINE 5500mm MODEL T-550KB-110 BALE OPENER (2 SETS) KS-130 PRE OPENER (1 SET) HM-200 BIG CAPACITY BLENDER (1 SET) KS-130 FINE OPENER (1 SET) GM-220 VIBRATING HOPPER (1 SET) SL-250 CARDING MACHINE (C2D2) (1 SET) PW-600 CROSS LAPPER (1 SET) JL-590 BATT FEEDER (1 SET) GY-580 HIGH SPEED PRE-NEEDLE LOOM (1 SET) GS-570 HIGH SPEED UPWARD PUNCH NEEDLE LOOM (1 SET) GX-570 HIGH SPEED DOWNWARD PUNCH NEEDLE LOOM (1 SET) CJ-550 WINDER (1 SET) ELECTRIC CONTROL CABINET (1 SET) MOTORS: TECO (TAIWAN) INVERTERS: EMERSON PLC+TOUCH SCREEN: MITSUBISHI Learn More

GEO-TEXTILE NON-WOVEN PUNCH LINE 5500mm MODEL T-550KB-110 BALE OPENER (2 SETS) KS-130 PRE OPENER (1 SET) HM-200 BIG CAPACITY BLENDER (1 SET) KS-130 FINE OPENER (1 SET) GM-220 VIBRATING HOPPER (1 SET) SL-250 CARDING MACHINE (C2D2) (1 SET) PW-600 CROSS LAPPER (1 SET) JL-590 BATT FEEDER (1 SET) GY-580 HIGH SPEED PRE-NEEDLE LOOM (1 SET) GS-570 HIGH SPEED UPWARD PUNCH NEEDLE LOOM (1 SET) GX-570 HIGH SPEED DOWNWARD PUNCH NEEDLE LOOM (1 SET) CJ-550 WINDER (1 SET) ELECTRIC CONTROL CABINET (1 SET) MOTORS: TECO (TAIWAN) INVERTERS: EMERSON PLC+TOUCH SCREEN: MITSUBISHI Learn More -

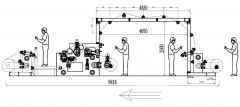

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More