Search results for: 'lab ste'

-

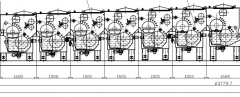

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

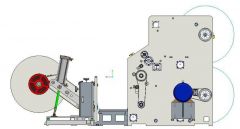

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

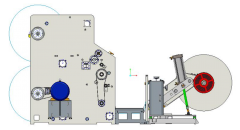

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

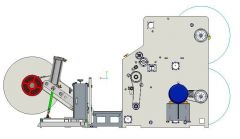

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

TT-6701 BOTTLING LINE IN PET AND GLASS FOR STILL WINE, UP TO 6000 BPH, YEAR 2014 TO 2024TT-6701 BOTTLING LINE IN PET AND GLASS FOR STILL WINE, UP TO 6000 BPH, YEAR 2014 TO 2024 1. IN STORAGE 2. SPEED: 6000 BOTTLES/HOUR 3. CONTAINERS: GLASS, PET 4. FORMATS: 0.187 L 5. PRODUCT: WINE (STILL) 6. FILL TYPE: GRAVITY/LIGHT DEPRESSION 7. NECK TYPE: 22mm QUANTITY: 1 Learn More

TT-6701 BOTTLING LINE IN PET AND GLASS FOR STILL WINE, UP TO 6000 BPH, YEAR 2014 TO 2024TT-6701 BOTTLING LINE IN PET AND GLASS FOR STILL WINE, UP TO 6000 BPH, YEAR 2014 TO 2024 1. IN STORAGE 2. SPEED: 6000 BOTTLES/HOUR 3. CONTAINERS: GLASS, PET 4. FORMATS: 0.187 L 5. PRODUCT: WINE (STILL) 6. FILL TYPE: GRAVITY/LIGHT DEPRESSION 7. NECK TYPE: 22mm QUANTITY: 1 Learn More -

TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022 WORKING CONDITION CONTAINER: 26/30 (DEPENDING FROM ACCESSORIES) Learn More

TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022 WORKING CONDITION CONTAINER: 26/30 (DEPENDING FROM ACCESSORIES) Learn More -

ADVANCED LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - DRUM COLLECTORREFERENCE NUMBER: A-2477 ADVANCED LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - DRUM COLLECTOR MACHINE IS A LABORATORY SCALE ELECTROSPINNING UNIT WITH A SINGLE NOZZLE. THE STANDARD MACHINES HAVE A 500 RPM ROTATING DRUM COLLECTOR AND A FLAT COLLECTOR. THERE ARE OPTIONAL ACCESSORIES UPON REQUEST FOR FUNCTIONALITY IMPROVEMENT. OPERATION PARAMETERS LIKE THE NEEDLE-COLLECTOR DISTANCE AND HIGH VOLTAGE VALUE COULD BE AUTOMATICALLY ADJUSTED FROM THE USER PANEL, WITH HIGH PRECISION. THE SYSTEM COMES WITH AN ENCLOSED CABINET MAKING IT POSSIBLE TO ADD TEMPERATURE AND RELATIVE HUMIDITY CONTROL SYSTEMS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRINGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 150 mm FIBER DEPOSITION AREA: 314 X 150 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More

ADVANCED LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - DRUM COLLECTORREFERENCE NUMBER: A-2477 ADVANCED LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - DRUM COLLECTOR MACHINE IS A LABORATORY SCALE ELECTROSPINNING UNIT WITH A SINGLE NOZZLE. THE STANDARD MACHINES HAVE A 500 RPM ROTATING DRUM COLLECTOR AND A FLAT COLLECTOR. THERE ARE OPTIONAL ACCESSORIES UPON REQUEST FOR FUNCTIONALITY IMPROVEMENT. OPERATION PARAMETERS LIKE THE NEEDLE-COLLECTOR DISTANCE AND HIGH VOLTAGE VALUE COULD BE AUTOMATICALLY ADJUSTED FROM THE USER PANEL, WITH HIGH PRECISION. THE SYSTEM COMES WITH AN ENCLOSED CABINET MAKING IT POSSIBLE TO ADD TEMPERATURE AND RELATIVE HUMIDITY CONTROL SYSTEMS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRINGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 150 mm FIBER DEPOSITION AREA: 314 X 150 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More -

P-5047 STA IMPIANTI ROASTER 10 KILOS

P-5047 STA IMPIANTI ROASTER 10 KILOSP-5047 STA IMPIANTI ROASTER 10 KILOS

STA

MODEL: IMPIANTI

ROASTER

10 KILOS

ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISANAL LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER ( AVAILABLE ALSO BY ELECTRIC RESISTANCES ) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.TECHNICAL DATA:

ROASTER CAPACITY: 10 KG. / MAX. 13 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 40 KG. ÷ 60

INSTALLED ELECTRIC POWER: 1,5 KW, SINGLEPHASE: 220 VOLT, 50 HZ | SPECIAL TRIPLEPHASE: 220 VOLT, 60 HZ

THERMAL POWER (NATURAL GAS OR LPG): 16000 KCAL/HMAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT

POSSIBLE RECORDING OF ROASTING PARAMETERS

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS).

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD ACCORDING CE RULES INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC-FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

P-5044 STA IMPIANTI ROASTER 5 KILOS

P-5044 STA IMPIANTI ROASTER 5 KILOSP-5044 STA IMPIANTI ROASTER 5 KILOS

STA

MODEL: IMPIANTI

ROASTER

5 KILOS

STA IS A MANUFACTURING GROUP IN ITALY - THAT IS MADE UP OF SEASONED ENGINEERS FROM MOST OF THE BIG OLD ITALIAN ROASTING MACHINE MAKERS - SO THEIR SCOPE OF KNOWLEDGE AND HISTORY IS FANTASTIC. BASICALLY - THEIR CLAIM TO FAME IS HOT AIR INTRODUCED INTO THE TOP OF THE ROASTING CHAMBER . . . BEING PULLED THROUGH THE TURBULATING COFFEE AND EXITING THROUGH DRUM PERFORATIONS INTO THE BOTTOM. FIRST, THAT MAKES IT REALLY FRIENDLY TO BLENDING FORMULAS AND SECOND IT MAKES FOR SMALLER CHAFF - AS THE TURNING COFFEE BEATS IT UP A LITTLE AND THUS THE ROAST COMES OUT MORE CLEAN THAN THE OLD DAYS OF SOME SOLID DRUMS . . . SO IT IS DIFFERENT - WHICH DOES NOT MAKE IT BETTER - BUT IF YOU HAVE A BACKGROUND ON JABEZ BURNS . . THEN YOU WILL REALLY LOVE THIS PRODUCTION. BIG NATURALLY DEVELOPED BEANS - VERY EVEN ROAST. FOLLOWING IS THE MANUFACTURERS SPECS AND WE WILL BE GLAD TO DISCUSS MORE IN-DEPTH AS YOU HAVE QUESTIONS.ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISAN LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER (AVAILABLE ALSO BY ELECTRIC RESISTANCES) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.

TECHNICAL DATA:

ROASTER CAPACITY: 5 KG. - MAX. 7 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 20 KG. ÷ 30

INSTALLED ELECTRIC POWER: 0.9 KW | SINGLEPHASE 220 VOLTS 50 HZ

THERMAL POWER (NATURAL GAS OR LPG): 8000 KCAL/H

MAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD MADE ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTING

DETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOORUNLOADING SYSTEM.

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, THE PRODUCT UNLOADING IS ALLOWED BY A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM.

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE COMPONENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD FOR MACHINE MANAGEMENT ACCORDING CE RULES INTEGRATED. COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING.

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC –FAN FOR COOLING TANK.QUANTITY: 1

Learn More