Search results for: 'Band f'

-

PP-1135 FR INVENTORY FROM MATTRESS PLANT

PP-1135 FR INVENTORY FROM MATTRESS PLANT.60 OZ FR BARRIER (HLO54404FRC) (100 YARDS/ROLL) (RED BAND)

QUANTITY: 1,44045” TIETEX FR SOCK #5898 (90yrds/roll) 9.5oz / LINEAR YARD

QUANTITY: 1,000.9oz FR BARRIER (HL0724FR (80 YARDS /ROLL) (RED BAG, BLUE BAND)

QUANTITY: 7203/3-3/3XL TIGHT GRIP FR SOCK (TG-FR-SOCK-01)

QUANTITY: 36FR FILLER C267 82” SILVER (945294) 110YD/ROLL

QUANTITY: 1,320ACCORD-110 WHT HVY WT QUILT BACKER 92”

QUANTITY: 1,000ACCORD104 WHT LT WT QUILT BACKER 92”

QUANTITY: 2,000DUOTEX 24W 84” ROLLS 250YDS/ROLL

QUANTITY: 250ACCORD 2531 GREY 82” FOUNDATIONS 250 YRDS PER ROLL

Learn More

QUANTITY: 1,000 -

M-6440 WARPING MACHINE FOR MEDICAL BANDAGE PLANT

M-6440 WARPING MACHINE FOR MEDICAL BANDAGE PLANTREFERENCE NUMBER: M-6440

WARPING MACHINE FOR MEDICAL BANDAGE PLANT

WARPING MACHINE

ADJUST SPEED BY FREQUENCY CONVERTER, EASY TO ADJUST, SAVES ENERGY

TIGHT PRESS AUTOMATICALLY, PRESSURE IS ADJUSTABLE, EVEN WARPING

COUNT LENGTH AUTOMATICALLY, WARPING LENGTH CAN BE PRE-SET

COMB TYPE EXPANSION REED, OPEN IN TOP, EASY TO ROW LINE AND CONVENIENT TO ADJUST WIDTH

ON BOTH MACHINE HEAD AND CREEL OF YARNS, THERE ARE CONTROL DEVICES FOR STOPPING THE MACHINE WHEN THE YARN BREAKS, TO ENSURE THE MACHINE WILL STOP WHEN THE YARN BREAKS

WARPING SPEED: UP TO 350 METERS PER MINUTE

REMOTE CONTROL TO START AND STOP MACHINE AUTOMATICALLY, AVAILABLE DISTANCE 20M

AVAILABLE WARP ROLL: Ø300mm TO 410mm, INSIDE WARP BEAM LENGTH IS 255mm TO 260mm, IT CAN BE MADE ON CUSTOMERS’ DIFFERENT REQUESTS

MOTOR POWER: 1.5KW

ONE WARPING MACHINE CAN WORK FOR 20 BANDAGE WEAVING MACHINES

QUANTITY: 1

Learn More -

V-1471 AUTOMATIC CORELESS ROLL WINDER

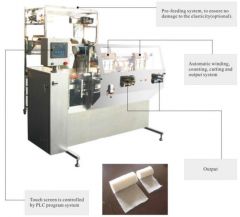

V-1471 AUTOMATIC CORELESS ROLL WINDERREFERENCE NUMBER: V-1471

AUTOMATIC CORELESS ROLL WINDER

THE MACHINE IS SUITABLE TO PROCESS CORELESS ELASTIC BANDAGE ROLLS.

HAS PRE-FEEDING SYSTEM, TO ENSURE NO DAMAGE TO THE ELASTICITY (OPTIONAL).

WITH AUTOMATIC WINDING, COUNTING, CUTTING, AND OUTPUT SYSTEM.

TOUCH SCREEN IS CONTROLLED BY PLC PROGRAM SYSTEM.

WORKING SPEED: 7 TO 11 BEATS PER MINUTE

END SURFACE TOLERANCE OF FINAL ROLLS (DEPENDS ON MATERIAL): ±2 TO 3.5mm

ROLLING TENSION: ADJUSTABLE

MAX. DIAMETER OF FINISHED BANDAGE: 6cm

QUANTITY: 1

Learn More -

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More -

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More -

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More -

M-3973 HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mmREFERENCE NUMBER: M-3973 (99016AVEZ8RX)-D HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mm 1.LAMINATING LINE : MAKE : VILLARS (CH) ACTUALLY SANTEX YEAR: 1993 WORKING WIDTH : 2200mm (NOMINAL WIDTH 2M10) VOLTAGE: 3X380(400)V TOTAL POWER : 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION : INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997) : 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS : 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED 2.ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM : MAKE : MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR: 1999 OPERATING VOLTAGE : 3X380V CAPACITY ACCUMULATOR : +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) 3. SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE : MAKE: MENZEL YEAR: 2000 OPERATING VOLTAGE : 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT KNOWN PROBLEM : PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) 4.MISCELLANEOUS : SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS Learn More

M-3973 HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mmREFERENCE NUMBER: M-3973 (99016AVEZ8RX)-D HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mm 1.LAMINATING LINE : MAKE : VILLARS (CH) ACTUALLY SANTEX YEAR: 1993 WORKING WIDTH : 2200mm (NOMINAL WIDTH 2M10) VOLTAGE: 3X380(400)V TOTAL POWER : 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION : INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997) : 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS : 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED 2.ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM : MAKE : MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR: 1999 OPERATING VOLTAGE : 3X380V CAPACITY ACCUMULATOR : +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) 3. SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE : MAKE: MENZEL YEAR: 2000 OPERATING VOLTAGE : 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT KNOWN PROBLEM : PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) 4.MISCELLANEOUS : SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS Learn More -

YY-2279 SML FILM EXTRUSION LINE, FILM WIDTH 2000mm, YEAR 2010YY-2279 SML FILM EXTRUSION LINE, FILM WIDTH 2000mm, YEAR 2010 MANUFACTURER: SML; YEAR: 2010 ; NUMBER OF LAYERS: 3; FILM STRUCTURE: ABC; MATERIAL: STRETCH FILM; FILM WIDTH (mm): 2000; OUTPUT (KG/H): 1000; QUANTITY: 1 Learn More

YY-2279 SML FILM EXTRUSION LINE, FILM WIDTH 2000mm, YEAR 2010YY-2279 SML FILM EXTRUSION LINE, FILM WIDTH 2000mm, YEAR 2010 MANUFACTURER: SML; YEAR: 2010 ; NUMBER OF LAYERS: 3; FILM STRUCTURE: ABC; MATERIAL: STRETCH FILM; FILM WIDTH (mm): 2000; OUTPUT (KG/H): 1000; QUANTITY: 1 Learn More -

TT-3658 SML STARLINGER STRETCH FILM LINE, WIDTH 2000mm, YEAR 2010, 3 LAYERSTT-3658 SML STARLINGER STRETCH FILM LINE, WIDTH 2000mm, YEAR 2010, 3 LAYERS BRAND: SML EXTRUDERS CONDITION: USED YEAR: 2010 QUANTITY: 1 Learn More

TT-3658 SML STARLINGER STRETCH FILM LINE, WIDTH 2000mm, YEAR 2010, 3 LAYERSTT-3658 SML STARLINGER STRETCH FILM LINE, WIDTH 2000mm, YEAR 2010, 3 LAYERS BRAND: SML EXTRUDERS CONDITION: USED YEAR: 2010 QUANTITY: 1 Learn More -

TT-3055 VERTICAL FOAM CUTTING MACHINE, WIDTH 1300mm, YEAR 2021 - NEWTT-3055 VERTICAL FOAM CUTTING MACHINE, WIDTH 1300mm, YEAR 2021 - NEW MACHINE TYPE: FOAM CUTTING MACHINE, AUTOMATIC MODEL SIMILAR TO: V D2 YEAR OF CONSTRUCTION: 2021 CONDITION: NEW QUANTITY: 1 Learn More

TT-3055 VERTICAL FOAM CUTTING MACHINE, WIDTH 1300mm, YEAR 2021 - NEWTT-3055 VERTICAL FOAM CUTTING MACHINE, WIDTH 1300mm, YEAR 2021 - NEW MACHINE TYPE: FOAM CUTTING MACHINE, AUTOMATIC MODEL SIMILAR TO: V D2 YEAR OF CONSTRUCTION: 2021 CONDITION: NEW QUANTITY: 1 Learn More