Search results for: 'steam+ca''

-

TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023 COMPLETE DENIM TEXTILE MILL EQUIPMENT: WEAVING, SIZING, TWISTING, WINDING, AND FINISHING MACHINERY - INCLUDING CONTINUOUS WASHING, MERCERIZING, AND SANFORIZING. Learn More

TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023TT-7165 COMPLETE TEXTILE MILL EQUIPMENT, YEAR 1986 TO 2023 COMPLETE DENIM TEXTILE MILL EQUIPMENT: WEAVING, SIZING, TWISTING, WINDING, AND FINISHING MACHINERY - INCLUDING CONTINUOUS WASHING, MERCERIZING, AND SANFORIZING. Learn More -

YY-3556 4 X 60 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE POWER PLANTYY-3556 4 X 60 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE POWER PLANT HISTORY: THE POWER PLANT CONSISTS OF X 50 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE, ALL OF YEAR: 2011, 7000 HRS SINCE NEW EACH, 3000 RPM, 50 Hz, X 13 MW SIEMENS SST 300 STEAM TURBINE WITH 5000 HOURS EACH. PLANT WAS COMMISSIONED AND PUT INTO OPERATION IN 2012. QUNATITY: 1 Learn More

YY-3556 4 X 60 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE POWER PLANTYY-3556 4 X 60 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE POWER PLANT HISTORY: THE POWER PLANT CONSISTS OF X 50 MW GE LM6000 PD 15PPM SPRINT GAS TURBINE, ALL OF YEAR: 2011, 7000 HRS SINCE NEW EACH, 3000 RPM, 50 Hz, X 13 MW SIEMENS SST 300 STEAM TURBINE WITH 5000 HOURS EACH. PLANT WAS COMMISSIONED AND PUT INTO OPERATION IN 2012. QUNATITY: 1 Learn More -

M-5380 CONE DYEING PLANTREFERENCE NUMBER: M-5380 (220DBLMXX1) L CONE DYEING PLANT QUANTITY AVAILABLE: 1 Learn More

M-5380 CONE DYEING PLANTREFERENCE NUMBER: M-5380 (220DBLMXX1) L CONE DYEING PLANT QUANTITY AVAILABLE: 1 Learn More -

K-8158 COAL FIRED STEAM POWER PLANT 330 MW YEAR 1983

K-8158 COAL FIRED STEAM POWER PLANT 330 MW YEAR 1983K-8158 COAL FIRED STEAM POWER PLANT 330 MW YEAR 1983

COAL FIRED STEAM POWER PLANT 330 MW

PLANT FOR RELOCATION

EQUIPMENT AND AUXILIARIES IN EXCELLENT CONDITIONSUMMARY OF MAIN ADVANTAGES:

THE STEAM PLANT IS AVAILABLE NOW AND CAN BE REINSTALLED IN SHORT TIME

POWER AVAILABLE IN SHORT TIME

THE EQUIPMENT IS OFFERED AT ATTRACTIVE CONDITIONS

LOW INVESTMENT COST

THE MAIN EQUIPMENT IS BASED ON STATE OF THE ART DESIGN & EMISSION CONTROL

COMMERCIAL LIFE TIME FOR MANY YEARS TO COME

RELOCATION IN COOPERATION WITH OEM SUPERVISING AND GUARANTEES OVERALL CONCEPTTECHNICAL DATA OF BOILER:

OEM

STEAM OUTPUT DESIGN PRESSURE LIVE STEAM REHEAT TEMP FUEL980 T/H

203 BAR

184 BAR / GRAD CBROWN COAL, APPROXIMATELY 9,000 KJ/KG

HARD COAL POSSIBLE AS WELL (24,000 - 28,000 KJ/KG)CONSUMPTION APPROXIMATELY 280 T/H AT FULL LOAD WITH BROWN COAL

APPROXIMATELY 110 T/H AT FULL LOAD WITH HARD COALGRINDING MILLS: 6

EMISSION SO2 200 MG/NM3 X 200 MG/NM3 ASHES 50 MG/NM3 EXHAUST TEMP 70°C

TECHNICAL DATA STEAM TURBINE:

OEM

OUTPUT

LIVE STEAM: 330/345 MW, 177.5 BAR, 535°CGENERAL REMARKS:

PLANT HAS GONE IN COMMERCIAL OPERATION IN 1983

PLANT AND EQUIPMENT HAS BEEN IN OPERATION BASICALLY DURING THE WINTER PERIOD AND HAS 84,300 HOURS ACCUMULATED ONLY

ALL EQUIPMENT IS IN EXCELLENT CONDITION AND PROFESSIONALLY PRESERVEDENTIRE PLANT WITH ALL AUXILIARIES IS AVAILABLE FOR RELOCATION

SCOPE AND CONDITIONS:

DISASSEMBLED, PACKED, AND SHIPPED OR TURNKEY SOLUTION CAN BE NEGOTIATED

RELOCATION WILL BE INCOORDINATION WITH THE OEM WHO IS WILLING TO GIVE A CERTAIN LEVEL OF GUARANTEE FOR THE RELOCATED PLANTQUANTITY: 1

Learn More -

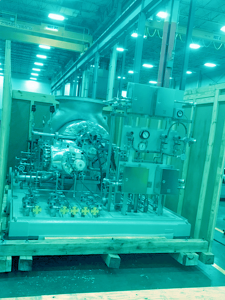

TT-6997 ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET - NEW, YEAR 2016TT-6997 ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET - NEW, YEAR 2016 1. ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET 2. NEW, NEVER USED 3. MODEL: 2 DYR6 4. CAPACITY: 7MW QUANTITY: 1 Learn More

TT-6997 ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET - NEW, YEAR 2016TT-6997 ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET - NEW, YEAR 2016 1. ELLIOTT STEAM TURBINE PAIRED WITH HYUNDAI-IDEAL ELECTRIC GENERATOR SET 2. NEW, NEVER USED 3. MODEL: 2 DYR6 4. CAPACITY: 7MW QUANTITY: 1 Learn More -

TT-6830 SIEMENS/RENTECH CONDENSING STEAM TURBINE-GENERATOR PACKAGE, 24.5MW, UNUSED, YEAR 2013 TO 2014, 50 HzTT-6830 SIEMENS/RENTECH CONDENSING STEAM TURBINE-GENERATOR PACKAGE, 24.5MW, UNUSED, YEAR 2013 TO 2014, 50 Hz ALREADY DISMANTLED THE PACKAGE AND CAN MAKE IT AVAILABLE FOR DELIVERY IN 2 WEEKS Learn More

TT-6830 SIEMENS/RENTECH CONDENSING STEAM TURBINE-GENERATOR PACKAGE, 24.5MW, UNUSED, YEAR 2013 TO 2014, 50 HzTT-6830 SIEMENS/RENTECH CONDENSING STEAM TURBINE-GENERATOR PACKAGE, 24.5MW, UNUSED, YEAR 2013 TO 2014, 50 Hz ALREADY DISMANTLED THE PACKAGE AND CAN MAKE IT AVAILABLE FOR DELIVERY IN 2 WEEKS Learn More -

TT-6970 BENNINGER BEN MACHINE-INDIGO, YEAR 2008TT-6970 BENNINGER BEN MACHINE-INDIGO, YEAR 2008 Learn More

TT-6970 BENNINGER BEN MACHINE-INDIGO, YEAR 2008TT-6970 BENNINGER BEN MACHINE-INDIGO, YEAR 2008 Learn More -

TT-4373 JEMONT ELECTRIC BACK PRESSURE STEAM TURBINE GENERATOR, 16MW, 50Hz, YEAR 2007 TO 2008TT-4373 JEMONT ELECTRIC BACK PRESSURE STEAM TURBINE GENERATOR, 16MW, 50Hz, YEAR 2007 TO 2008 GENERATOR: JEMONT ELECTRIC 2008 MANUFACTURING YEAR 2007 (TURBINE) 2008 (ALTERNATOR) TURBINE ENGINE MAN MARC 4B 2008 16,230KW 8120 RPM FRESH STEAM 99 BAR Learn More

TT-4373 JEMONT ELECTRIC BACK PRESSURE STEAM TURBINE GENERATOR, 16MW, 50Hz, YEAR 2007 TO 2008TT-4373 JEMONT ELECTRIC BACK PRESSURE STEAM TURBINE GENERATOR, 16MW, 50Hz, YEAR 2007 TO 2008 GENERATOR: JEMONT ELECTRIC 2008 MANUFACTURING YEAR 2007 (TURBINE) 2008 (ALTERNATOR) TURBINE ENGINE MAN MARC 4B 2008 16,230KW 8120 RPM FRESH STEAM 99 BAR Learn More -

M-4007 NITRIC ACID PLANT -1,000 TONS PER DAY & 500 TONS PER DAY

M-4007 NITRIC ACID PLANT -1,000 TONS PER DAY & 500 TONS PER DAYREFERENCE NUMBER: M-4007

NITRIC ACID PLANT -1,000 TONS PER DAY & 500 TONS PER DAY

UNUSED 1,000 TON/DAY NITRIC ACID PLANT

(SEE 500 TON/DAY NITRIC ACID PLANT BELOW)- PRODUCT: WEAK NITRIC ACID

- MAJOR EQUIPMENT:

(CONTACT IPP FOR A COMPLETE LIST) - ABSORBER COLUMN:

- 304LSS CONSTRUCTION

- (37) SIEVE TRAYS

- AIR COMPRESSOR:

- 201,100 NM³/HR (DRY)

- TYPE AV63-14, AXIAL

- 14.3 MW

- 5,199 RPM

- NOX COMPRESSOR:

- 181,000 NM³/HR

- TYPE E90-3, CENTRIFUGAL

- 8.6 MW

- 5,820 RPM

- EXPANDER:

- 161,000 NM³/HR (DRY)

- TYPE WP15.5-870/380, CENTRIFUGAL

- 5,200 RPM

- STEAM TURBINE:

- 48.96 TON/HR

- TYPE NK40/45/40, CONDENSING

- 9.1 MW

- AMMONIA BURNER

- CONTACT IPP FOR A COMPLETE PROCESS DESCRIPTION AND FLOW DIAGRAM

- COMPLETE DOCUMENTATION AVAILABLE

500 TON/DAY NITRIC ACID PLANT

- PRODUCES 65% CONCENTRATED NITRIC ACID

- TURN-DOWN CAPABILITIES AS LOW AS 300 TON/DAY

- TECHNOLOGY: WEATHERLY MEDIUM-PRESSURE

- THIS PLANT IS A NET STEAM EXPORTER WITH 550, 175, AND 60 PSIG STEAM BEING PRODUCED ON THE WASTE HEAT BOILERS AND 520 PSIG STEAM BEING CONSUMED BY THE AIR COMPRESSOR STEAM TURBINE DRIVE

- MAJOR EQUIPMENT:

(CONTACT IPP FOR A COMPLETE LIST) - ABSORBER COLUMN:

- 11' DIA. X 127'

- 304LSS CONSTRUCTION

- (49) SIEVE TRAYS

- OPERATES AT 98% EFFICIENCY

- AIR COMPRESSOR:

- INGERSOLL RAND 2-STAGE CENTRIFUGAL

- INCLUDES 520 PSIG TERRY STEAM TURBINE DRIVE ASSISTED BY A DRESSER-RAND TAIL GAS TURBINE DRIVE

- CONVERTER:

- 304LSS CONSTRUCTION WITH AN INCONEL 617 BASKET

- CATALYST COMPOSITION IS 90% PLATINUM, 5% RHODIUM AND 5% PALLADIUM

- HEAT TRAIN:

- CONTACT IPP FOR COMPONENT DETAILS

- INCLUDES EXPANDER GAS HEATER, MEDIUM-PRESSURE WASTE HEAT BOILER, TAIL GAS HEATER, FILTER AND LOW-PRESSURE WASTE HEAT BOILER

- CONTACT IPP FOR A COMPLETE PROCESS DESCRIPTION AND FLOW DIAGRAM

COMPLETE DOCUMENTATION AVAILABLE

Learn More -

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More