Search results for: 'Electric dia'

- Related search terms

- electric co

- Electrical

- electric steam boiler

- Electrical mas

- electric motor screw drive

-

F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm QUANTITY: ONE PRODUCTION LINE Learn More

F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm QUANTITY: ONE PRODUCTION LINE Learn More -

M-3471 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: M-3471 (880OKRSHH7) L NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm TECHNICAL DATA: RAW MATERIALS: NYLON, POLYESTER, POLYPROPYLENE, GLASS FIBER, ETC. FINENESS OF FIBER: 2.5 TO 10DENIER LENGTH OF FIBER: 38 TO 76mm MIXING RATIO BETWEEN TWO FIBERS: 20 TO 100% SPEED: 6m/min (PER 2.5-6D× 38-51mm) MAX. 5000 KG/DAY (PER 22 HOURS/DAY) RANGE OF GRAM WEIGHT: 100 TO 250g/m2 CARDING MACHINE FEATURES ARE ACCORDING GRAM WEIGHT: 250G/M², 300G/M² PROCESS FLOW CHART: BALE OPENER---PER-OPENER—FINE OPENER--FEEDER---CARDING MACHINE-- CROSSLAPPER--TRANSIT APRON---HIGH-SPEED PRE-NEEDLE LOOM---(2) HIGH-SPEED MAIN NEEDLE LOOM--CALENDER---CUTTER AND REWINDER QUANTITY AVAILABLE: 1 Learn More

M-3471 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: M-3471 (880OKRSHH7) L NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm TECHNICAL DATA: RAW MATERIALS: NYLON, POLYESTER, POLYPROPYLENE, GLASS FIBER, ETC. FINENESS OF FIBER: 2.5 TO 10DENIER LENGTH OF FIBER: 38 TO 76mm MIXING RATIO BETWEEN TWO FIBERS: 20 TO 100% SPEED: 6m/min (PER 2.5-6D× 38-51mm) MAX. 5000 KG/DAY (PER 22 HOURS/DAY) RANGE OF GRAM WEIGHT: 100 TO 250g/m2 CARDING MACHINE FEATURES ARE ACCORDING GRAM WEIGHT: 250G/M², 300G/M² PROCESS FLOW CHART: BALE OPENER---PER-OPENER—FINE OPENER--FEEDER---CARDING MACHINE-- CROSSLAPPER--TRANSIT APRON---HIGH-SPEED PRE-NEEDLE LOOM---(2) HIGH-SPEED MAIN NEEDLE LOOM--CALENDER---CUTTER AND REWINDER QUANTITY AVAILABLE: 1 Learn More -

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More -

M-5956 SLAUGHTERING EQUIPMENT – 1,000 BIRDS PER HOURREFERENCE NUMBER: M-5956 (7707V4QB6UX) L SLAUGHTERING EQUIPMENT – 1,000 BIRDS PER HOUR SLAUGHTERING EQUIPMENT PRODUCT: WHOLE BIRDS & CUT-UP PLANT TYPE: SEMI-AUTO KIND OF BIRDS: BROILER MINIMUM LIVE WEIGHT: 1.2 KG MAXIMUM LIVE WEIGHT: 2.2 KG AVERAGE LIVE WEIGHT: 1.7 KG CAPACITY PER HOUR: 1,000 BIRDS BLEEDING TIME: 4 MINUTES SCALDING TEMPERATURE: 58 TO 63 °C SCALDING TIME: 90 SECONDS PRE-CHILLING TIME: 45 MINUTES TOTAL TIME OF WORK PER DAY: 10 HOURS Learn More

M-5956 SLAUGHTERING EQUIPMENT – 1,000 BIRDS PER HOURREFERENCE NUMBER: M-5956 (7707V4QB6UX) L SLAUGHTERING EQUIPMENT – 1,000 BIRDS PER HOUR SLAUGHTERING EQUIPMENT PRODUCT: WHOLE BIRDS & CUT-UP PLANT TYPE: SEMI-AUTO KIND OF BIRDS: BROILER MINIMUM LIVE WEIGHT: 1.2 KG MAXIMUM LIVE WEIGHT: 2.2 KG AVERAGE LIVE WEIGHT: 1.7 KG CAPACITY PER HOUR: 1,000 BIRDS BLEEDING TIME: 4 MINUTES SCALDING TEMPERATURE: 58 TO 63 °C SCALDING TIME: 90 SECONDS PRE-CHILLING TIME: 45 MINUTES TOTAL TIME OF WORK PER DAY: 10 HOURS Learn More -

TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974 MODEL: LABORATORY NEEDLEPUNCH LINE CONDITION: USED ELECTRICITY: 440/3/60 & 380/3/50 WIDTH: 800mm Learn More

TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974 MODEL: LABORATORY NEEDLEPUNCH LINE CONDITION: USED ELECTRICITY: 440/3/60 & 380/3/50 WIDTH: 800mm Learn More -

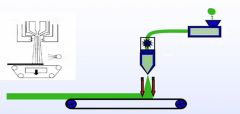

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More -

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More -

TT-3594 SML 3-LAYER COEXTRUSION CAST FILM LINE, WIDTH 3100mmTT-3594 SML 3-LAYER COEXTRUSION CAST FILM LINE, WIDTH 3100mm BRAND: SML EXTRUDERS CONDITION: USED QUANTITY: 1 Learn More

TT-3594 SML 3-LAYER COEXTRUSION CAST FILM LINE, WIDTH 3100mmTT-3594 SML 3-LAYER COEXTRUSION CAST FILM LINE, WIDTH 3100mm BRAND: SML EXTRUDERS CONDITION: USED QUANTITY: 1 Learn More -

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More