Search results for: 'edge w'

-

YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS)YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS) DETAILS: MACHINE FEATURES: 1. NEW COMPUTER CONTROL SYSTEM, FRIENDLY HMI, FLEXIBLE CONTROL AND LARGE CAPACITY, ENSURING HIGH-PRECISION RUNNING OF THE MACHINE. 2. LONGITUDINAL SEWING: DOUBLE THREADS CHAINSTITCH (OPTIONAL LOCKSTITCH OR OVERLOCK STITCH). 3. TRAVERSE SEWING: MULTI-NEEDLE CHAINSTITCH SEWING. 4. FULL SERVO MOTOR CONTROL SYSTEM, PROVIDING STRONG AND ACCURATE DRIVING POWER. 5. WITH SCRAP COLLECTION DEVICE TO KEEP THE WORKSHOP CLEAN. QUANTITY: 1 Learn More

YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS)YY-2047 AUTOMATIC FOUR-SIDED SEWING MACHINE (BOTH FOR TURN-OVER QUILT PROCESS) DETAILS: MACHINE FEATURES: 1. NEW COMPUTER CONTROL SYSTEM, FRIENDLY HMI, FLEXIBLE CONTROL AND LARGE CAPACITY, ENSURING HIGH-PRECISION RUNNING OF THE MACHINE. 2. LONGITUDINAL SEWING: DOUBLE THREADS CHAINSTITCH (OPTIONAL LOCKSTITCH OR OVERLOCK STITCH). 3. TRAVERSE SEWING: MULTI-NEEDLE CHAINSTITCH SEWING. 4. FULL SERVO MOTOR CONTROL SYSTEM, PROVIDING STRONG AND ACCURATE DRIVING POWER. 5. WITH SCRAP COLLECTION DEVICE TO KEEP THE WORKSHOP CLEAN. QUANTITY: 1 Learn More -

T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004 QUANTITY: 1 Learn More

T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004 QUANTITY: 1 Learn More -

T-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MINT-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MIN CARTON SET: WOODEN BOX CTN SIZE: 1270, 540, 1200mm QUANTITY/CTN: 1 CBM: 0.82 SINGLE MOTOR OUTPUT POWER: 2500W WPOWER INPUT: 220V OUTPUT FREQUENCY: 20KHz WORKING TEMPERATURE: -10-28C WORKING SPEED: 0 TO 26M/MIN EQUIPPED PATTERN MOULD: 0 TO 200mm WEIGHT OF MACHINE: 95KG QUANTITY: 1 Learn More

T-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MINT-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MIN CARTON SET: WOODEN BOX CTN SIZE: 1270, 540, 1200mm QUANTITY/CTN: 1 CBM: 0.82 SINGLE MOTOR OUTPUT POWER: 2500W WPOWER INPUT: 220V OUTPUT FREQUENCY: 20KHz WORKING TEMPERATURE: -10-28C WORKING SPEED: 0 TO 26M/MIN EQUIPPED PATTERN MOULD: 0 TO 200mm WEIGHT OF MACHINE: 95KG QUANTITY: 1 Learn More -

TT-3553 HEIDELBERG CD 102 6LX, 28” X 40”, YEAR 2003, 6 COLORSTT-3553 HEIDELBERG CD 102 6LX, 28” X 40”, YEAR 2003, 6 COLORS HEIDELBERG CD 102 6LX YEAR 2003 28” X 40” 6 COLORS EXTENDED DELIVERY COATER STILL HOOKED TO POWER ABLE TO BE INSPECTED. CAN ASK ABOUT SCHEDULING A TIME. VERY CLEAN PRESS. EXCELLENT CONDITION. QUANTITY: 1 Learn More

TT-3553 HEIDELBERG CD 102 6LX, 28” X 40”, YEAR 2003, 6 COLORSTT-3553 HEIDELBERG CD 102 6LX, 28” X 40”, YEAR 2003, 6 COLORS HEIDELBERG CD 102 6LX YEAR 2003 28” X 40” 6 COLORS EXTENDED DELIVERY COATER STILL HOOKED TO POWER ABLE TO BE INSPECTED. CAN ASK ABOUT SCHEDULING A TIME. VERY CLEAN PRESS. EXCELLENT CONDITION. QUANTITY: 1 Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

TT-2176 BRUCKNER HIGH-PERFORMANCE STENTER, WORKING WIDTH 1300 TO 4200mm, YEAR 2018TT-2176 BRUCKNER HIGH-PERFORMANCE STENTER, WORKING WIDTH 1300 TO 4200mm, YEAR 2018 BRUCKNER HIGH-PERFORMANCE STENTER TYPE: POWER-FRAME SPLIT FLOW YEAR 2018 ROLLER WIDTH 4400mm WORKING WIDTH 1300 TO 4200mm SPEED 80 M/MIN MACHINE IS IN EXCELLENT CONDITION AND ONLY FEW RUNNING HOURS QUANTITY: 1 Learn More

TT-2176 BRUCKNER HIGH-PERFORMANCE STENTER, WORKING WIDTH 1300 TO 4200mm, YEAR 2018TT-2176 BRUCKNER HIGH-PERFORMANCE STENTER, WORKING WIDTH 1300 TO 4200mm, YEAR 2018 BRUCKNER HIGH-PERFORMANCE STENTER TYPE: POWER-FRAME SPLIT FLOW YEAR 2018 ROLLER WIDTH 4400mm WORKING WIDTH 1300 TO 4200mm SPEED 80 M/MIN MACHINE IS IN EXCELLENT CONDITION AND ONLY FEW RUNNING HOURS QUANTITY: 1 Learn More -

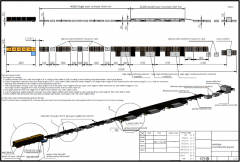

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More -

TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010 1. DILO NEEDLELOOM NONWOVEN LINE 2. BRAND: TEMAFA / TRUTZSCHLER / FOR / AUTEFA / DILO / ETF/ MENZEL 3. WORKING WIDTH: 5000mm 4. YEAR: 1999 TO 2010 QUANTITY: 1 Learn More

TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010 1. DILO NEEDLELOOM NONWOVEN LINE 2. BRAND: TEMAFA / TRUTZSCHLER / FOR / AUTEFA / DILO / ETF/ MENZEL 3. WORKING WIDTH: 5000mm 4. YEAR: 1999 TO 2010 QUANTITY: 1 Learn More -

TT-6007 SRC SYSTEMS MODEL 610 COMPACT - STOCK MACHINE - 2 WEEKS UNTIL SHIPMENT – NEW, 63”, YEAR 2024TT-6007 SRC SYSTEMS MODEL 610 COMPACT - STOCK MACHINE - 2 WEEKS UNTIL SHIPMENT – NEW, 63”, YEAR 2024 QUANTITY: 1 Learn More

TT-6007 SRC SYSTEMS MODEL 610 COMPACT - STOCK MACHINE - 2 WEEKS UNTIL SHIPMENT – NEW, 63”, YEAR 2024TT-6007 SRC SYSTEMS MODEL 610 COMPACT - STOCK MACHINE - 2 WEEKS UNTIL SHIPMENT – NEW, 63”, YEAR 2024 QUANTITY: 1 Learn More -

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More