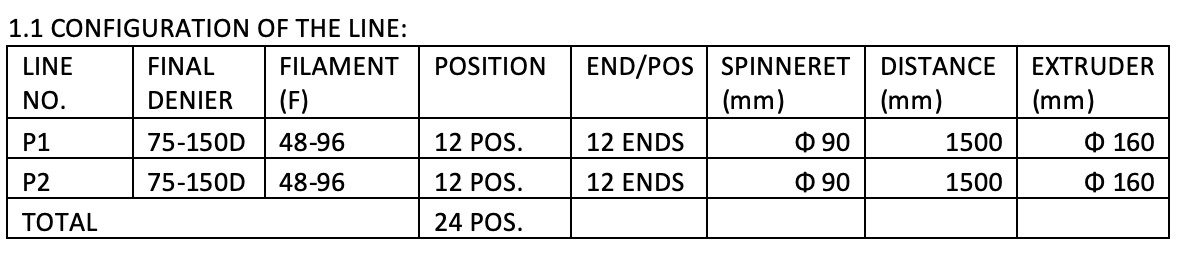

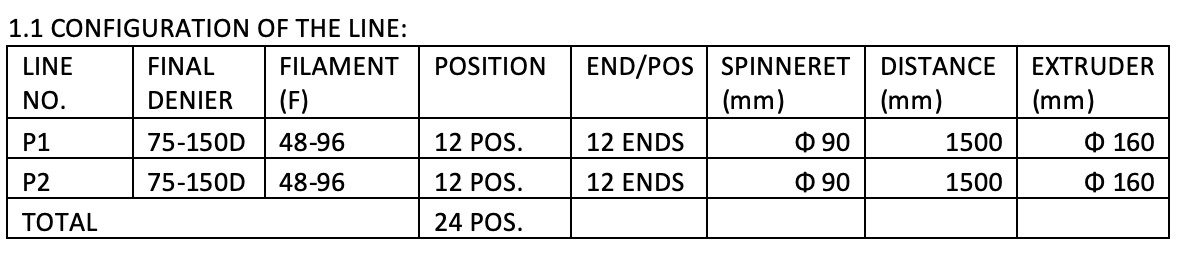

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES

T-7018

LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES

EXTRUDER Φ 160/25

PRODUCT TYPE PET-POY

END/POSITION 12 ENDS

POSITIONS 24 POSITIONS

POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM

POSITION DISTANCE (mm) 1500mm

SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED

SPINNERET DIAMETER (mm) Φ 90mm

CROSS BLOWING AREA 1430mm X 1380mm

GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV

GEAR PUMP QUANTITY/POSITION 1

OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV

OIL PUMP QUANTITY/ POSITION 1

DOWTHERM BOILER/LINE 600L/65KW

GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm

MIGRATION JET AWA. JAPAN

WINDER TWA1800-12ENDS

In stock

SKU

T-7018

REFERENCE NUMBER: T-7018

LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES

REQUIRED FLOORSPACE DIMENSIONS: 30 METERS x 120 METERS x 9 METERS HEIGHT

NOTE:

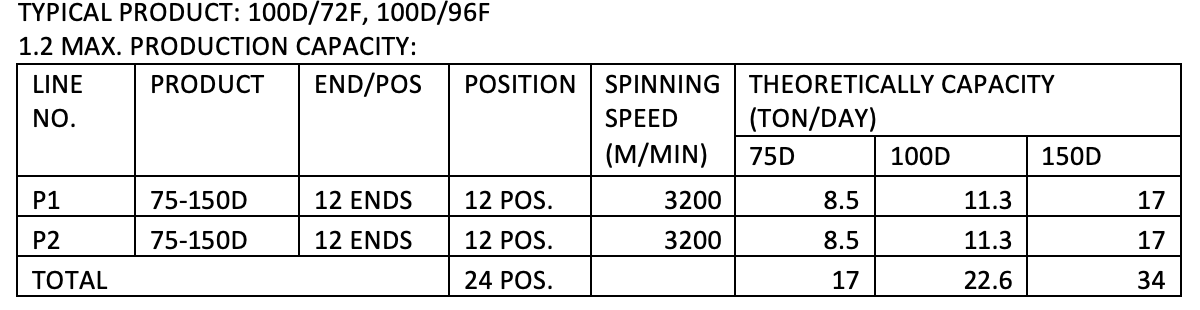

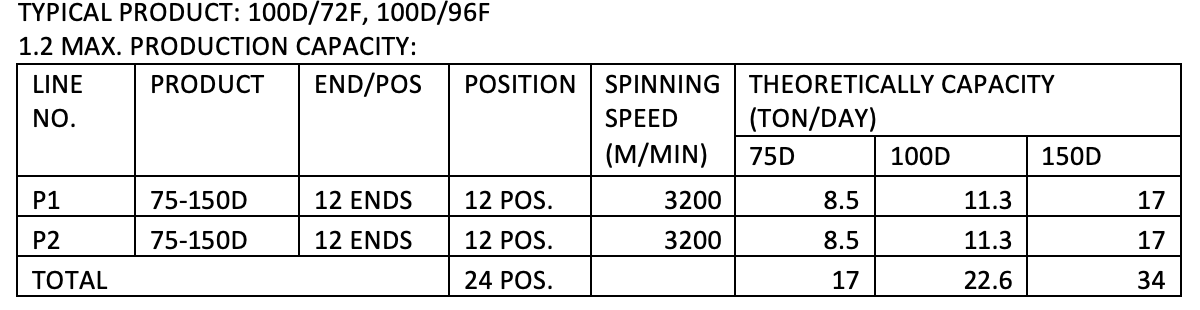

1. POY DRAWING TIME: 1.6

2. POY SPINNING SPEED: 3200M/MIN;

3. EFFICIENCY: 0.96

4. WORKING DAYS PER YEAR: 330 DAYS.

1.3 BASICS OF MACHINE DESIGN AND LAYOUT:

EXTRUDER Φ 160/25

PRODUCT TYPE PET-POY

END/POSITION 12 ENDS

POSITIONS 24 POSITIONS

POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM

POSITION DISTANCE (mm) 1500mm

SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED

SPINNERET DIAMETER (mm) Φ 90mm

CROSS BLOWING AREA 1430mm X 1380mm

GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV

GEAR PUMP QUANTITY/POSITION 1

OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV

OIL PUMP QUANTITY/ POSITION 1

DOWTHERM BOILER/LINE 600L/65KW

GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm

MIGRATION JET AWA. JAPAN

WINDER TWA1800-12ENDS

1.4 MAIN MATERIALS CONSUMPTION:

MAIN MATERIALS CONSUMPTION FOR PRODUCING 1000KGS OF PET-POY:

SERIAL 75D-150D

PET FLAKES (KG) 1045

OIL (KG) 6

REQUIRED FLAKES QUALITY:

INTRINSIC VISCOSITY: 0.74 TO 0.78 DL/G DEPEND ON BOTTLE'S I.V.

BULK DENSITY (MIN./AVG./MAX.): 250 TO 350 KG/M3

FLAKE SIZE: 2 TO 12mm

HUMIDITY: ≤ 1%

PE, PP: ≤ 10 PPM

PAPER: ≤ 15 PPM

GLUES/HOT MELTS: ≤ 20 PPM

ORGANICS: ≤ 20 PPM

METALS: ≤ 10 PPM

IN-ORGANICS: ≤ 20 PPM

PVC: ≤ 30 PPM

TOTAL IMPURITY: ≤ 80 PPM

1.5 PUBLIC ENGINEERING REQUIREMENTS:

1. ELECTRICITY

RATED VOLTAGE: V 380/220±5 %

PHASES: 3 PHASES/4 WIRES

RATED HERTZ: Hz 50±1.0%

2. COOLING WATER

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤32 °C

PH VALUE: 6.5-7

TOTAL SALT CONTENT: PPM ≤400

3. REFRIGERATED WATER (SUPPLIED BY THE REFRIGERATOR)

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤7.0-8.0°C

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤12

4. WATER FOR OIL (DISTILLED WATER OR DESALTED WATER)

PRESSURE: MPA ≥0.1MPA

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤1

SIO2 CONTENT: PPM ≤0.2

FUNGUS: NO

5. COMPRESSED AIR:

PRESSURE: MPA ≥0.5MPA

TEMPERATURE: °C NORMAL TEMPERATURE

CONDITIONS: NO OIL, NO WATER

6. COMPRESSED AIR FOR THE GAUGES:

PRESSURE: MPA 0.5-0.6MPA

TEMPERATURE: °C NORMAL TEMPERATURE

DEW POINT: °C -20°C

CONDITIONS: NO OIL, NO WATER, NO SOLID RESIDUES

7. COMPRESSED AIR FOR THE SUCTION GUN:

PRESSURE: MPA ≥0.7MPA

TEMPERATURE: °C NORMAL TEMPERATURE

8. CROSS BLOWING AIR:

AIR PRESSURE: 600PA

HUMIDITY: 75% ±3

TEMPERATURE: 22°C±1

1.6 PUBLIC UTILITIES (DETAIL DATA WILL BE CONFIRMED LATER)

1.7 TOTAL WEIGHT OF THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

1.8 TOTAL POWER NEEDED FOR THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

ANNEX 2:

PROJECT BOUNDARY AND SCOPE

3.1 SELLER:

1. PROVIDES THE BRAND NEW CONTRACTED MACHINES FROM THE MATERIAL INLET FLANGE OF THE SCREW EXTRUDER TILL THE WINDER.

2. PROVIDES THE TECHNICAL DOCUMENTS FOR THE CONTRACTED MACHINES.

3. WHEN THE MACHINES HAVE BEEN DELIVERED TO THE BUYER'S FACTORY, AND AFTER RECEIVING THE BUYER'S WRITTEN NOTICE, THE SELLER WILL SEND THE ELECTRIC ENGINEER AND MECHANICAL ENGINEER TO THE BUYER'S FACTORY FOR HELPING THE INSTALLATION AND PRODUCTION PREPARATION, AND THESE ENGINEERS WILL HELP TO INSTALL THE MACHINES PROVIDED BY THE SELLER AND CARRY OUT THE TESTING, AND THESE ENGINEERS WILL COOPERATE WITH THE BUYER TO PRODUCE THE QUALIFY PRODUCTS WITHIN THE TIME STIPULATED IN THE CONTRACT.

4. THE WELDING OF THE POLYMER PIPES AND THE SPECIAL WELDING MATERIALS SUCH AS THE ARC WELDING MACHINE AND

STAINLESS STEEL WELDING STICKS, WILL BE PROVIDED BY THE SELLER, THE BUYER SHALL PROVIDE THE COOPERATION BY PROVIDING THE ASSISTING PERSONNEL AND TOOLS.

5. PROVIDES THE SIGNAL WIRES, HIGH TEMPERATURE WIRES AND INSULATION WIRES FOR THE MACHINES THE SELLER SUPPLIED.

3.2 BUYER:

1. RESPONSIBLE FOR THE HEAT INSULATING MATERIAL FOR THE EQUIPMENT AND THE CONSTRUCTION OF THE HEAT INSULATING WORK.

2. RESPONSIBLE FOR THE FOOD AND LODGING FOR THE SELLER'S ENGINEERS AND PROVIDE THE GOOD WORKING CONDITIONS FOR THE SELLER'S ENGINEERS.

3. RESPONSIBLE FOR THE CABLE TRUNKING PREPARATION AND LAYING.

4. RESPONSIBLE FOR THE CABLE FOR THE EXTRUDER.

5. RESPONSIBLE FOR THE UNLOADING, UNPACKING, POSITIONING OF THE EQUIPMENT.

6. RESPONSIBLE FOR THE MATERIALS FOR THE INSTALLATION SUCH AS THE ACETYLENE, OXYGEN, WELDING STICK, GLOVES, LIFTING DEVICE, WATER, ELECTRICITY, COMPRESSED AIR AND ETC.

7. RESPONSIBLE FOR THE NORMAL CABLES FOR THE EXTRUDER HEATING, GEAR PUMP MOTOR, OIL PUMP MOTOR, CONTACTING WIRE, BUTTON WIRE, DOWTHERM STOVE, AND ETC.

ANNEX 3:

SUPPLYING SCOPE

NOTE:

(S) — SELLER'S SUPPLYING SCOPE

(B) — BUYER'S SUPPLYING

SCOPE 4000 24 POSITION PET- POY SPINNING EQUIPMENT

ITEM 001

EXTRUDER

A. TYPE: HORIZONTAL

B. SCREW: Φ160mm L/D=25

C. DRIVING POWER: 132KW

D. HEATING POWER: 81KW

E. TEMP.DETECTING ELEMENT: PT100

F. AC FREQUENCY CONVERSION SPEED REGULATION, IMPORTED V BELT

G. 3 PHASES AC MOTOR, SIEMENS

QUANTITY: 2 SETS

ITEM 002

DETECTING HEAD

A. TYPE: JACKET TYPE HEATING

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

QUANTITY: 2 SETS

ITEM 003

POLYMER FILTER

A. TYPE: VERTICAL, TWO STAGES

D. FILTERING TYPE: CANDLE CORE

C. FILTERING AREA: 9.5-5.5

E. RATED FLOW: 700 TO 900KG/H

F. FILTERING PRECISION: ≤25μ

G. FILTERING CORE QUANTITY: 19X2, TOTALLY 38 PCS

QUANTITY: 2 SETS

ITEM 004

POLYMER PIPING

A. HEATING METHOD: JACKET TYPE

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

D. THE FLANGES' CONNECTION IS BY RED COPPER.

QUANTITY: 2 SETS

ITEM 005

SPINNING BEAM

A. TYPE: SINGLE SIDE OPERATION

B. POSITION: 2 POSITIONS /SPINNING BEAM

C. ENDS: 12 ENDS

D. DISTANCE: 1500mm

E. HEATING: DOWTHERM STOVE SYSTEM

F. DESIGNED TEMP.: 315°C

G. SPINNING BEAM SURFACE TEM. INCREASE: ≤60°C

H. SPINNING BEAM DESIGNED PRESSURE: 0.2MPA

I. DESIGNED PRESSURE FOR THE POLYMER PIPES:

BEFORE GEAR PUMP: 25MPA

AFTER GEAR PUMP: 35MPA

J. POLYMER VALVE: REFRIGERATED VALVE

QUANTITY: 12 SETS

ITEM 006

SPINNING BEAM RACK

A. MATERIAL: CARBON STEEL STRUCTURE

QUANTITY: 2 SETS

ITEM 007

GEAR PUMP

A. TYPE: PLANETARY TYPE

B. SPECIFICATIONS: 12X3.0CC/REV

C. INLET QUANTITY/OUTLET QUANTITY: 1/12

QUANTITY: 24 SETS

ITEM 008

GEAR PUMP DRIVING DEVICE

A. DRIVING METHOD: 1 SET OF DRIVING DEVICE FOR EACH POSITION

B. TYPE: VERTICAL SYNCHRONIZATION MOTOR + PLANETARY TYPE REDUCER + PULLING DRIVING SHAFT

C. MOTOR POWER: 2.2KW

D. SPEED RATIO: 1:43

QUANTITY: 24 SETS

ITEM 009

GEAR PUMP DRIVING FRAME

A. TYPE: CARBON STEEL STRUCTURE

B. U-STEEL FOR INSTALLING THE GEAR PUMP DRIVING WILL BE PROVIDED BY THE SELLER.

QUANTITY: 12 SETS

ITEM 010

SPIN PACK

A. TYPE: CYLINDER TYPE, BOTTOM MOUNTED

B. QUANTITY: 12 PCS PER POSITION

C. DIAMETER: Φ90mm

D. SPINNERET QUANTITY: 1 SPINNERET PER SPIN PACK

E. FILTERING TYPE: STEEL NET AND FILTER SAND TYPE

F. DESIGNED PRESSURE: 35MPA

G. NOT INCLUDING THE NET, WASHER AND GASKET

H. 288 SETS IN USING AND 2488 SETS FOR STAND BY

QUANTITY: 576 SETS

ITEM 011

SPINNERET

A. TYPE: ROUND

B. DIAMETER: Φ90mm

C. NO OF HOLE: 48 TO 96

QUANTITY: 576 PCS

ITEM 012

YARN DUCT

A. TYPE: RECTANGLE TYPE

B. MATERIAL: HIGH QUALITY ALUMINUM

QUANTITY: 24 SETS

ITEM 013

DOWTHERM BOILER

B. TYPE: ELECTRIC HEATING, CONTAINER TYPE

C. DESIGNED TEMP.: 350°C

D. DESIGNED PRESSURE: 0.2MPA

E. HEATING POWER: 65KW

E. VOLUME:600L

F. SAFETY DEVICE:

1) ELECTRIC CONTACT POINT PRESSURE GAUGE

2) EXPLOSION PREVENTION FILM PACK

3) DOUBLE SAFETY VALVE

4) OVER HEATING PREVENTION ALARM DEVICE

5) TIPPING PLATE TYPE LIQUID LEVEL GAUGE

QUANTITY: 2 SETS

ITEM 014

GENERAL PARTS FOR THE DOWTHERM PIPING

SEAMLESS STEEL PIPE, PIPING, ELBOW, TEE, STANDARD FITTING FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 015

SPECIAL PARTS FOR DOWTHERM SYSTEM

VALVE, FLANGE, GRAPHITE WINDED GASKET FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 016

DISCHARGE TANK

QUANTITY: 2 PCS

ITEM 017

QUENCHING CHAMBER

A. TYPE: CROSS BLOWING

B. BLOWING AREA: 1430mm X 1380mm

C. WITH HEAT INSULATION PLATE

D. WITH AIR FLOW REGULATION VALVE

E. WITH PLATE TYPE FILTER

F. WITH OIL FRAME SLIDING GROOVE

G. WITH QUENCHING CHAMBER DOOR

QUANTITY: 24 SETS

ITEM 018

QUENCHING CHAMBER FRAME

A. TYPE: CARBON STEEL STRUCTURE

QUANTITY: 24 SETS

ITEM 019

OILING DEVICE

A. OILING NOZZLE (12 PCS OF OILING NOZZLE PER POSITION)

B. YARN GUIDE HOOK (12 PCS OF YARN GUIDE HOOK PER POSITION)

QUANTITY: 24 SETS

ITEM 020

OIL PUMP

A. SPECIFICATIONS: 12X0.12CC/REV

B. INLET QUANTITY/OUTLET QUANTITY: 1/12

C. ORIGIN: SUZHOU HUAXI

QUANTITY: 24 SETS

ITEM 021

DRIVING DEVICE FOR OIL PUMP

A. INCLUDING MOTOR, REDUCER AND SUPPORT PLATE

QUANTITY: 24 SETS

ITEM 022

OIL TANK

A. WITH OIL FILTER

B. WITH PIPING, VALVE, DUPLEX FILTER, FILTERING PRECISION: 10UM

C. WITH FLOATING BALL VALVE, DISCHARGE VALVE, OVERFLOW

QUANTITY: 2 SETS

ITEM 023

PIPING AND WIRING OUTSIDE THE EQUIPMENT

SUCH AS THE PIPING AND ACCESSORIES FOR REFRIGERATED WATER, COMPRESSED AIR.

QUANTITY: 1 SET

ITEM 024

CONTROLLING PANEL FOR THE EXTRUDER

VOLTAGE, CURRENT, RPM, EXTRUDER PRESSURE BEFORE FILTER, ALARM, PRESSURE CONTROL, DISPLAY AND ALARM AFTER THE FILTER. THE EXTRUDER'S INVERTER IS FROM JAPAN YASKAWA.

QUANTITY: 2 SETS

ITEM 025

TEMP. CONTROLLING PANEL FOR SPINNING MACHINE

JAPANESE RKC TEMPERATURE GAUGE

QUANTITY: 2 PCS

ITEM 026

CONTROLLING PANEL FOR GEAR PUMP

THE CONTROLLING METHOD FOR THE GEAR PUMP INVERTER IS 1 CONTROLLING FOR EACH POSITION. THE INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 027

SWITCH BOX FOR GEAR PUMP

1 PIECE PER POSITION

QUANTITY: 24 PCS

ITEM 028

CONTROLLING CABINET FOR OIL PUMP

VERTICAL TYPE, DOORS CAN BE OPENED IN THE FRONT AND BACK, OIL PUMP INVERTER CONTROLLING METHOD: 1 CONTROLLING PER POSITION INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 029

POLYMER PRESSURE SENSOR (BEFORE FILTER)

0-25MAP (WITH SCENE DISPLAY)

QUANTITY: 2 PCS

ITEM 030

POLYMER PRESSURE SENSOR (AFTER FILTER)

0-35MPA (ITALY GEFRAN, WITH SCENE INDICATION)

QUANTITY: 2 PCS

ITEM 031

PRESSURE SENSOR FOR SPIN PACK

0-35MPA (WITH SCENE INDICATION, DIGITAL DISPLAY

QUANTITY: 2 PCS

ITEM 032

TEMPERATURE FOR DIFFERENT ZONES OF THE EXTRUDER

(TICA) PT100

QUANTITY: 12 PCS

ITEM 033

TEMP. SENSOR FOR EXTRUDER HEAD

(TIA) PT100

QUANTITY: 2 PCS

ITEM 034

TEMP.SENSOR FOR SPIN BEAM

(TIA) PT100

QUANTITY: 2 PCS

ITEM 035

PRESSURE SENSOR FOR DISCHARGE BOX

(TIA) PT100

QUANTITY: 2 PCS

ITEM 036

ELECTRIC CONTACT POINT PRESSURE GAUGE FOR DOWTHERM BOILER

(PICA) PT100, 0 TO 0.25MPA

QUANTITY: 2 PCS

ITEM 037

EXPLOSION FILM PACK

0-0.25MPA

QUANTITY: 2 SETS

ITEM 038

HIGH TEMPERATURE WIRE, SIGNAL WIRE

QUANTITY: 2 SETS

ITEM 039

NORMAL CABLE

QUANTITY: 1 SET

ITEM 040

TEMP. SENSOR FOR DOWTHERM STEAM

(TICA) PT100

QUANTITY: 2 PCS

ITEM 041

TEMP. SENSOR FOR DOWTHERM OVER HEATING PREVENTION

(TICA) PT100

QUANTITY: 2 PCS

ITEM 042

1800-12 AUTOMATIC WINDER

A. MECHANICAL SPEED: MAX: 4000M/MIN

B. PROCESSING SPEED: 2800 TO 3300M/MIN

C. 12 ENDS/PER WINDER

D. YARN PACKAGE: 15KG/BOBBIN

QUANTITY: 24 SETS

ITEM 043

COMPRESSED AIR TREATMENT SYSTEM

A. 24 POSITIONS PER SIDE, WITH PRECISE FILTER, EACH SIDE HAS 2 PCS PRESSURE RELEASE VALVES.

QUANTITY: 1 SIDE

ITEM 044

TAKE UP FRAME: NEW MOVABLE TYPE

A. DISTANCE: 1500mm

B. 2 POSITIONS PER SET, PROFILE STEEL STRUCTURE, SINGLE SIDE OPERATION, TAKE UP SWITCH BOX 1 PIECE, INCLUDING THE CONTACT FOR THE FIRST AND SECOND FLOORS AND TIMING AND LENGTH DISPLAY, 1 SET OF YARN GUIDE SYSTEM WITH A YARN BLOCKING PLATE.

QUANTITY: 12 SETS

ITEM 045

CR1 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 046

CR2 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 047

PRE-INTERMINGLING

A. 12 PCS PER POSITION

B. ORIGIN: AWA, JAPAN

24 SETS

ITEM 048

YARN ASPIRATOR

A. 1 PIECE PER SET

B. ORIGIN: CHINA

QUANTITY: 2 SETS

ITEM 049

YARN BREAK SENSOR

A. 12 PCS PER POSITION

B. ORIGIN: CHINA

QUANTITY: 24 SETS

ITEM 050

PNEUMATIC PIPING FOR TAKE UP

24 POSITIONS PER SET, QUICK CONNECTION TYPE

QUANTITY: 1 SET

ITEM 051

YARN DISTRIBUTION SUCTION GUN AND WASTE YARN PIPE

B. WATER YARN BASKET WILL BE PREPARED BY THE CUSTOMER

C. INCLUDING THE HIGH PRESSURE HOSE AND WASTE YARN PIPE

QUANTITY: 6 SETS

ITEM 052

COLD GODET CONTROLLING CABINET

A. VERTICAL, DOORS OPENED IN THE FRONT

B. 1 SET PER POSITION

C. JAPAN YASKAWA INVERTER

QUANTITY: 24 POS

ITEM 053

FREQUENCY CONVERSION CABINET FOR TAKE UP

BACK TO BACK, DOORS OPENED IN THE FRONT, 1 CONTROLLING FOR PER SET, INCLUDING ELECTRIC CONTROLLING BOX, INVERTER AND ETC.

QUANTITY: 24 SETS

ITEM 054

BASIC PLATE FOR WINDER

A. 1 POSITION PER SET

QUANTITY: 24 SETS

ITEM 055

CABLE

INSULATION CABLE

QUANTITY: 1 SET

CABLE FOR WINDER

QUANTITY: 1 SET

CABLE FROM THE CONTROLLING CABINET TO THE EQUIPMENT

QUANTITY: 1 SET

ITEM 056

BRIDGE FOR CABLE

QUANTITY: 1 SET

SPARE PARTS LIST

ITEM 057

SCREW DISMANTLE TOOLS FOR EXTRUDER

QUANTITY: 1 SET

ITEM 058

SPECIAL TOOLS FOR FILTER

QUANTITY: 1 SET

ITEM 059

WRENCH FOR GEAR PUMP

QUANTITY: 1 SET

ITEM 060

LIFTING ROD FOR SPIN PACK

QUANTITY: 2 SETS

ITEM 061

DISMANTLE TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 062

FASTENING TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 063

DISMANTLE TOOLS FOR YARN GUIDE DISC

QUANTITY: 1 SET

ITEM 064

DOFFING CART

QUANTITY: 1 SET

ITEM 065

TOOLS FOR INSTALLING THE SPIN PACK

QUANTITY: 1 SET

ITEM 066

TRANSPORTATION TROLLEY FOR WINDER

QUANTITY: 1 SET

ITEM 067

DISCHARGED YARN BLOCKING PLATE

QUANTITY: 24 PCS

ITEM 068

PUMP FOR DISCHARGE THE YARN

QUANTITY: 24 PCS

ITEM 069

SPECIAL TOOL FOR WINDER

QUANTITY: 1 SET

OTHER EQUIPMENT

UTILITIES

1 CRYSTALLIZER AND DRYER 1 SET

2 AHU 1 SET

3 COMPRESSOR 1 SET

4 CHILLER 1 SET

AUXILIARY EQUIPMENT LIST

1 VACUUM CLEANING OVEN 1 SET

2 ALKALI-WATER CLEANING TANK 1 SET

3 ULTRASONIC CLEANER 1 SET

4 PRE-HEATING FURNACE FOR SPIN PACK 1 SET

5 FINISH OIL PREPARING TANK 1 SET

6 FINISH OIL LEVEL TANK 1 SET

7 DISTILLED WATER GENERATOR 1 SET

8 DISTILLED WATER STORAGE TANK 1 SET

9 DISMOUNTING TOOL FOR SPIN PACK 1 SET

10 ASSEMBLING TOOL FOR SPIN PACK 1 SET

11 TRANSPORTATION CARRIAGE FOR SPIN PACK 1 SET

LAB EQUIPMENT LIST

1 SKEIN YARNS LENGTH TESTER 1 SET

2 SINGLE FIBER STRENGTH TESTER 1 SET

3 ELECTRICAL BALANCE 1 SET

4 ELECTRICAL OVEN 1 S ET

5 SPINNERET MICROSCOPE PROJECTOR 1 SET

6 DIGITAL YARN TENSION TESTER 1 S ET

7 DIFFERENTIAL PRESSURE MOISTURE TESTER 1 SET

8 FIBER OIL FAST EXTRACTOR 1 SET

9 STROBOSCOPE 1 SET

10 ANEMOGRAPH 1 SET

ANNEX 4:

TECHNICAL DOCUMENTS LIST

(1) MANUAL

(2) PID DIAGRAM FOR THE EQUIPMENT

(3) GENERAL DRAWING FOR THE EQUIPMENT

(4) ELECTRIC PRINCIPLE DIAGRAM

(5) ELECTRIC CONNECTION DIAGRAM

(6) EQUIPMENT LAYOUT DIAGRAM FOR DIFFERENT LAYER

(7) LIGHTING CONDITION DIAGRAM

(8) OILING SYSTEM DIAGRAM AND THE OILING PIPING DIAGRAM

(9) AIR CONDITIONER'S FLOW SYSTEM DIAGRAM AND PIPING DIAGRAM

(10) REFRIGERATED WATER AND REFRIGERATED WATER SYSTEM DIAGRAM AND PIPING DIAGRAM

(11) COMPRESSED AIR SYSTEM DIAGRAM AND PIPING DIAGRAM

ANNEX 5:

CHECKING STANDARD FOR THE PRODUCT QUALITY ASSURANCE

(1) CHECKING CATEGORY: 100D/72F

(2) SPINNING SPEED: 2500 TO 3300M/MIN

(3) CHECKING STANDARD: ACCORDING TO CHINA NATIONAL STANDARD ((FZ/T54003—2004)).

(4) CHECKING TIME: WITHIN 15 DAYS AFTER THE EQUIPMENT HAS BEEN SUCCESSFULLY TESTED AND BEING RUNNING, BOTH PARTIES OF THE BUYER AND SELLER WILL CHECK THE CONTRACTED EQUIPMENT. IF THE CHECKING CAN NOT BE CARRIED OUT WITHIN ONE MONTH AFTER THE MACHINE IS BEING SUCCESSFULLY RUNNING, THEN THE MACHINE WILL BE REGARD AS PAST THE CHECKING. THE CHECKING PERIOD IS 72 HOURS CONTINUOUS CHECKING.

(5) METHOD OF TAKING CHECKING SAMPLE: EACH SHIFT WILL TAKE A BOBBIN FOR CHECKING THE MAIN

ITEMS, AND THE CHECKING WILL BE REGARDED AS PAST THE CHECKING IF 90% OF THE CHECKING ITEMS HAVE BEEN PAST, IN THE 72 HOURS CONTINUOUSLY CHECKING PERIOD, IF THERE IS ANY FAILURE HAPPENED, NO MATTER WHICH PARTY CAUSED THE FAILURE, THE CHECKING CAN BE DONE AGAIN.

ANNEX 6:

INSTALLATION AND AFTER SALES SERVICE

1. MACHINE INSTALLATION AND COMMISSIONING:

(1) THE SELLER WILL SEND HIS ELECTRIC AND MECHANICAL ENGINEER FOR HELPING THE INSTALLATION OF SPINNING AND WINDING MACHINES.

(2) THE SELLER WILL PROVIDE THE DRAWING AND DIMENSIONS GUIDANCE, AND THE BUYER WILL BE RESPONSIBLE FOR THE PREPARATION OF THE FOUNDATION.

(3) DURING THE COMMISSIONING PERIOD, THE SELLER HAS THE RIGHT TO MODIFY OR CHANGE THE MACHINE PARTS.

2. THE BUYER SHALL PROVIDE:

(1) COMPRESSED AIR FOR THE WINDER AND SUCTION GUN, THE COMPRESSED AIR PRESSURE SHALL NOT LESS THAN 0.8MPA, DEW DROP POINT OF THE COMPRESSED AIR IS RECOMMENDED TO BE MAX. -4°C, AND THE COMPRESSED AIR SHALL BE FILTERED FROM OIL AND WATER, THE FILTERING PRECISION IS RECOMMENDED TO BE 5μM

(2) OIL MIXING TANK, OIL TANK, OIL CONVEYING PIPE AND OIL RECYCLING PIPE AND ETC.

(3) CONNECTION FOR THE ELECTRIC BOX OF THE WINDER AND OILING DEVICE AND THE AUXILIARY MATERIALS.

(4) COMPRESSED AIR PIPING TO THE MACHINE AND THE WASTE YARN TANK.

(5) CLEANING AND PRE-HEATING EQUIPMENT FOR SPIN PACK AND SPINNERET.

(6) COOLING WATER PIPING FOR THE ETRUDER

(7) HIGH TEMPERATURE CONDUCTIVE OIL (DOWTHERM)

3. EXPLANATION:

(1) THE SELLER WILL PROVIDE THE GUARANTEE FOR THE MECHANICAL FEATURES OF THE CONTACTED EQUIPMENT. FOR THE POY SPINNING TECHNIQUE, THE BUYER SHALL HANDLE BY HIMSELF.

(2) THIS TECHNICAL SPECIFICATIONS IS AN INTEGRAL PART OF THE CONTRACT, IT HAS THE SAME LEGAL EFFECT LIKE THE CONTRACT. FOR THE TECHNICAL ISSUES AND SUPPLYING SCOPE MENTIONED IN THE CONTRACT, THIS TECHNICAL SPECIFICATIONS WILL BE REGARDED AS THE STANDARD.

4. AFTER SALES SERVICE

WHEN THE BUYER HAS SUCCESSFULLY RUN THE MACHINES, THE SELLER SHALL STILL PAY ATTENTION TO THE MACHINES. WITHIN THE 12 MONTHS AFTER THE MACHINE HAS BEEN ACCEPTED BY THE BUYER, IF THE MACHINE HAS A PROBLEM AND THIS PROBLEM IS NOT CAUSED BY THE BUYER, THE SELLER SHALL REPAIR OR CHANGE THIS DAMAGED PART. AND THE SELLER SHALL PROVIDE THE GUIDANCE FOR HOW TO USE THE MACHINE CORRECTLY, AND THE SELLER SHALL HELP THE BUYER TO SOLVE THE PROBLEMS TO ENSURE THAT THE MACHINE CAN BE OPERATED SMOOTHLY.

NOTE:

1. POY DRAWING TIME: 1.6

2. POY SPINNING SPEED: 3200M/MIN;

3. EFFICIENCY: 0.96

4. WORKING DAYS PER YEAR: 330 DAYS.

1.3 BASICS OF MACHINE DESIGN AND LAYOUT:

EXTRUDER Φ 160/25

PRODUCT TYPE PET-POY

END/POSITION 12 ENDS

POSITIONS 24 POSITIONS

POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM

POSITION DISTANCE (mm) 1500mm

SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED

SPINNERET DIAMETER (mm) Φ 90mm

CROSS BLOWING AREA 1430mm X 1380mm

GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV

GEAR PUMP QUANTITY/POSITION 1

OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV

OIL PUMP QUANTITY/ POSITION 1

DOWTHERM BOILER/LINE 600L/65KW

GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm

MIGRATION JET AWA. JAPAN

WINDER TWA1800-12ENDS

1.4 MAIN MATERIALS CONSUMPTION:

MAIN MATERIALS CONSUMPTION FOR PRODUCING 1000KGS OF PET-POY:

SERIAL 75D-150D

PET FLAKES (KG) 1045

OIL (KG) 6

REQUIRED FLAKES QUALITY:

INTRINSIC VISCOSITY: 0.74 TO 0.78 DL/G DEPEND ON BOTTLE'S I.V.

BULK DENSITY (MIN./AVG./MAX.): 250 TO 350 KG/M3

FLAKE SIZE: 2 TO 12mm

HUMIDITY: ≤ 1%

PE, PP: ≤ 10 PPM

PAPER: ≤ 15 PPM

GLUES/HOT MELTS: ≤ 20 PPM

ORGANICS: ≤ 20 PPM

METALS: ≤ 10 PPM

IN-ORGANICS: ≤ 20 PPM

PVC: ≤ 30 PPM

TOTAL IMPURITY: ≤ 80 PPM

1.5 PUBLIC ENGINEERING REQUIREMENTS:

1. ELECTRICITY

RATED VOLTAGE: V 380/220±5 %

PHASES: 3 PHASES/4 WIRES

RATED HERTZ: Hz 50±1.0%

2. COOLING WATER

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤32 °C

PH VALUE: 6.5-7

TOTAL SALT CONTENT: PPM ≤400

3. REFRIGERATED WATER (SUPPLIED BY THE REFRIGERATOR)

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤7.0-8.0°C

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤12

4. WATER FOR OIL (DISTILLED WATER OR DESALTED WATER)

PRESSURE: MPA ≥0.1MPA

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤1

SIO2 CONTENT: PPM ≤0.2

FUNGUS: NO

5. COMPRESSED AIR:

PRESSURE: MPA ≥0.5MPA

TEMPERATURE: °C NORMAL TEMPERATURE

CONDITIONS: NO OIL, NO WATER

6. COMPRESSED AIR FOR THE GAUGES:

PRESSURE: MPA 0.5-0.6MPA

TEMPERATURE: °C NORMAL TEMPERATURE

DEW POINT: °C -20°C

CONDITIONS: NO OIL, NO WATER, NO SOLID RESIDUES

7. COMPRESSED AIR FOR THE SUCTION GUN:

PRESSURE: MPA ≥0.7MPA

TEMPERATURE: °C NORMAL TEMPERATURE

8. CROSS BLOWING AIR:

AIR PRESSURE: 600PA

HUMIDITY: 75% ±3

TEMPERATURE: 22°C±1

1.6 PUBLIC UTILITIES (DETAIL DATA WILL BE CONFIRMED LATER)

1.7 TOTAL WEIGHT OF THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

1.8 TOTAL POWER NEEDED FOR THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

ANNEX 2:

PROJECT BOUNDARY AND SCOPE

3.1 SELLER:

1. PROVIDES THE BRAND NEW CONTRACTED MACHINES FROM THE MATERIAL INLET FLANGE OF THE SCREW EXTRUDER TILL THE WINDER.

2. PROVIDES THE TECHNICAL DOCUMENTS FOR THE CONTRACTED MACHINES.

3. WHEN THE MACHINES HAVE BEEN DELIVERED TO THE BUYER'S FACTORY, AND AFTER RECEIVING THE BUYER'S WRITTEN NOTICE, THE SELLER WILL SEND THE ELECTRIC ENGINEER AND MECHANICAL ENGINEER TO THE BUYER'S FACTORY FOR HELPING THE INSTALLATION AND PRODUCTION PREPARATION, AND THESE ENGINEERS WILL HELP TO INSTALL THE MACHINES PROVIDED BY THE SELLER AND CARRY OUT THE TESTING, AND THESE ENGINEERS WILL COOPERATE WITH THE BUYER TO PRODUCE THE QUALIFY PRODUCTS WITHIN THE TIME STIPULATED IN THE CONTRACT.

4. THE WELDING OF THE POLYMER PIPES AND THE SPECIAL WELDING MATERIALS SUCH AS THE ARC WELDING MACHINE AND

STAINLESS STEEL WELDING STICKS, WILL BE PROVIDED BY THE SELLER, THE BUYER SHALL PROVIDE THE COOPERATION BY PROVIDING THE ASSISTING PERSONNEL AND TOOLS.

5. PROVIDES THE SIGNAL WIRES, HIGH TEMPERATURE WIRES AND INSULATION WIRES FOR THE MACHINES THE SELLER SUPPLIED.

3.2 BUYER:

1. RESPONSIBLE FOR THE HEAT INSULATING MATERIAL FOR THE EQUIPMENT AND THE CONSTRUCTION OF THE HEAT INSULATING WORK.

2. RESPONSIBLE FOR THE FOOD AND LODGING FOR THE SELLER'S ENGINEERS AND PROVIDE THE GOOD WORKING CONDITIONS FOR THE SELLER'S ENGINEERS.

3. RESPONSIBLE FOR THE CABLE TRUNKING PREPARATION AND LAYING.

4. RESPONSIBLE FOR THE CABLE FOR THE EXTRUDER.

5. RESPONSIBLE FOR THE UNLOADING, UNPACKING, POSITIONING OF THE EQUIPMENT.

6. RESPONSIBLE FOR THE MATERIALS FOR THE INSTALLATION SUCH AS THE ACETYLENE, OXYGEN, WELDING STICK, GLOVES, LIFTING DEVICE, WATER, ELECTRICITY, COMPRESSED AIR AND ETC.

7. RESPONSIBLE FOR THE NORMAL CABLES FOR THE EXTRUDER HEATING, GEAR PUMP MOTOR, OIL PUMP MOTOR, CONTACTING WIRE, BUTTON WIRE, DOWTHERM STOVE, AND ETC.

ANNEX 3:

SUPPLYING SCOPE

NOTE:

(S) — SELLER'S SUPPLYING SCOPE

(B) — BUYER'S SUPPLYING

SCOPE 4000 24 POSITION PET- POY SPINNING EQUIPMENT

ITEM 001

EXTRUDER

A. TYPE: HORIZONTAL

B. SCREW: Φ160mm L/D=25

C. DRIVING POWER: 132KW

D. HEATING POWER: 81KW

E. TEMP.DETECTING ELEMENT: PT100

F. AC FREQUENCY CONVERSION SPEED REGULATION, IMPORTED V BELT

G. 3 PHASES AC MOTOR, SIEMENS

QUANTITY: 2 SETS

ITEM 002

DETECTING HEAD

A. TYPE: JACKET TYPE HEATING

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

QUANTITY: 2 SETS

ITEM 003

POLYMER FILTER

A. TYPE: VERTICAL, TWO STAGES

D. FILTERING TYPE: CANDLE CORE

C. FILTERING AREA: 9.5-5.5

E. RATED FLOW: 700 TO 900KG/H

F. FILTERING PRECISION: ≤25μ

G. FILTERING CORE QUANTITY: 19X2, TOTALLY 38 PCS

QUANTITY: 2 SETS

ITEM 004

POLYMER PIPING

A. HEATING METHOD: JACKET TYPE

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

D. THE FLANGES' CONNECTION IS BY RED COPPER.

QUANTITY: 2 SETS

ITEM 005

SPINNING BEAM

A. TYPE: SINGLE SIDE OPERATION

B. POSITION: 2 POSITIONS /SPINNING BEAM

C. ENDS: 12 ENDS

D. DISTANCE: 1500mm

E. HEATING: DOWTHERM STOVE SYSTEM

F. DESIGNED TEMP.: 315°C

G. SPINNING BEAM SURFACE TEM. INCREASE: ≤60°C

H. SPINNING BEAM DESIGNED PRESSURE: 0.2MPA

I. DESIGNED PRESSURE FOR THE POLYMER PIPES:

BEFORE GEAR PUMP: 25MPA

AFTER GEAR PUMP: 35MPA

J. POLYMER VALVE: REFRIGERATED VALVE

QUANTITY: 12 SETS

ITEM 006

SPINNING BEAM RACK

A. MATERIAL: CARBON STEEL STRUCTURE

QUANTITY: 2 SETS

ITEM 007

GEAR PUMP

A. TYPE: PLANETARY TYPE

B. SPECIFICATIONS: 12X3.0CC/REV

C. INLET QUANTITY/OUTLET QUANTITY: 1/12

QUANTITY: 24 SETS

ITEM 008

GEAR PUMP DRIVING DEVICE

A. DRIVING METHOD: 1 SET OF DRIVING DEVICE FOR EACH POSITION

B. TYPE: VERTICAL SYNCHRONIZATION MOTOR + PLANETARY TYPE REDUCER + PULLING DRIVING SHAFT

C. MOTOR POWER: 2.2KW

D. SPEED RATIO: 1:43

QUANTITY: 24 SETS

ITEM 009

GEAR PUMP DRIVING FRAME

A. TYPE: CARBON STEEL STRUCTURE

B. U-STEEL FOR INSTALLING THE GEAR PUMP DRIVING WILL BE PROVIDED BY THE SELLER.

QUANTITY: 12 SETS

ITEM 010

SPIN PACK

A. TYPE: CYLINDER TYPE, BOTTOM MOUNTED

B. QUANTITY: 12 PCS PER POSITION

C. DIAMETER: Φ90mm

D. SPINNERET QUANTITY: 1 SPINNERET PER SPIN PACK

E. FILTERING TYPE: STEEL NET AND FILTER SAND TYPE

F. DESIGNED PRESSURE: 35MPA

G. NOT INCLUDING THE NET, WASHER AND GASKET

H. 288 SETS IN USING AND 2488 SETS FOR STAND BY

QUANTITY: 576 SETS

ITEM 011

SPINNERET

A. TYPE: ROUND

B. DIAMETER: Φ90mm

C. NO OF HOLE: 48 TO 96

QUANTITY: 576 PCS

ITEM 012

YARN DUCT

A. TYPE: RECTANGLE TYPE

B. MATERIAL: HIGH QUALITY ALUMINUM

QUANTITY: 24 SETS

ITEM 013

DOWTHERM BOILER

B. TYPE: ELECTRIC HEATING, CONTAINER TYPE

C. DESIGNED TEMP.: 350°C

D. DESIGNED PRESSURE: 0.2MPA

E. HEATING POWER: 65KW

E. VOLUME:600L

F. SAFETY DEVICE:

1) ELECTRIC CONTACT POINT PRESSURE GAUGE

2) EXPLOSION PREVENTION FILM PACK

3) DOUBLE SAFETY VALVE

4) OVER HEATING PREVENTION ALARM DEVICE

5) TIPPING PLATE TYPE LIQUID LEVEL GAUGE

QUANTITY: 2 SETS

ITEM 014

GENERAL PARTS FOR THE DOWTHERM PIPING

SEAMLESS STEEL PIPE, PIPING, ELBOW, TEE, STANDARD FITTING FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 015

SPECIAL PARTS FOR DOWTHERM SYSTEM

VALVE, FLANGE, GRAPHITE WINDED GASKET FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 016

DISCHARGE TANK

QUANTITY: 2 PCS

ITEM 017

QUENCHING CHAMBER

A. TYPE: CROSS BLOWING

B. BLOWING AREA: 1430mm X 1380mm

C. WITH HEAT INSULATION PLATE

D. WITH AIR FLOW REGULATION VALVE

E. WITH PLATE TYPE FILTER

F. WITH OIL FRAME SLIDING GROOVE

G. WITH QUENCHING CHAMBER DOOR

QUANTITY: 24 SETS

ITEM 018

QUENCHING CHAMBER FRAME

A. TYPE: CARBON STEEL STRUCTURE

QUANTITY: 24 SETS

ITEM 019

OILING DEVICE

A. OILING NOZZLE (12 PCS OF OILING NOZZLE PER POSITION)

B. YARN GUIDE HOOK (12 PCS OF YARN GUIDE HOOK PER POSITION)

QUANTITY: 24 SETS

ITEM 020

OIL PUMP

A. SPECIFICATIONS: 12X0.12CC/REV

B. INLET QUANTITY/OUTLET QUANTITY: 1/12

C. ORIGIN: SUZHOU HUAXI

QUANTITY: 24 SETS

ITEM 021

DRIVING DEVICE FOR OIL PUMP

A. INCLUDING MOTOR, REDUCER AND SUPPORT PLATE

QUANTITY: 24 SETS

ITEM 022

OIL TANK

A. WITH OIL FILTER

B. WITH PIPING, VALVE, DUPLEX FILTER, FILTERING PRECISION: 10UM

C. WITH FLOATING BALL VALVE, DISCHARGE VALVE, OVERFLOW

QUANTITY: 2 SETS

ITEM 023

PIPING AND WIRING OUTSIDE THE EQUIPMENT

SUCH AS THE PIPING AND ACCESSORIES FOR REFRIGERATED WATER, COMPRESSED AIR.

QUANTITY: 1 SET

ITEM 024

CONTROLLING PANEL FOR THE EXTRUDER

VOLTAGE, CURRENT, RPM, EXTRUDER PRESSURE BEFORE FILTER, ALARM, PRESSURE CONTROL, DISPLAY AND ALARM AFTER THE FILTER. THE EXTRUDER'S INVERTER IS FROM JAPAN YASKAWA.

QUANTITY: 2 SETS

ITEM 025

TEMP. CONTROLLING PANEL FOR SPINNING MACHINE

JAPANESE RKC TEMPERATURE GAUGE

QUANTITY: 2 PCS

ITEM 026

CONTROLLING PANEL FOR GEAR PUMP

THE CONTROLLING METHOD FOR THE GEAR PUMP INVERTER IS 1 CONTROLLING FOR EACH POSITION. THE INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 027

SWITCH BOX FOR GEAR PUMP

1 PIECE PER POSITION

QUANTITY: 24 PCS

ITEM 028

CONTROLLING CABINET FOR OIL PUMP

VERTICAL TYPE, DOORS CAN BE OPENED IN THE FRONT AND BACK, OIL PUMP INVERTER CONTROLLING METHOD: 1 CONTROLLING PER POSITION INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 029

POLYMER PRESSURE SENSOR (BEFORE FILTER)

0-25MAP (WITH SCENE DISPLAY)

QUANTITY: 2 PCS

ITEM 030

POLYMER PRESSURE SENSOR (AFTER FILTER)

0-35MPA (ITALY GEFRAN, WITH SCENE INDICATION)

QUANTITY: 2 PCS

ITEM 031

PRESSURE SENSOR FOR SPIN PACK

0-35MPA (WITH SCENE INDICATION, DIGITAL DISPLAY

QUANTITY: 2 PCS

ITEM 032

TEMPERATURE FOR DIFFERENT ZONES OF THE EXTRUDER

(TICA) PT100

QUANTITY: 12 PCS

ITEM 033

TEMP. SENSOR FOR EXTRUDER HEAD

(TIA) PT100

QUANTITY: 2 PCS

ITEM 034

TEMP.SENSOR FOR SPIN BEAM

(TIA) PT100

QUANTITY: 2 PCS

ITEM 035

PRESSURE SENSOR FOR DISCHARGE BOX

(TIA) PT100

QUANTITY: 2 PCS

ITEM 036

ELECTRIC CONTACT POINT PRESSURE GAUGE FOR DOWTHERM BOILER

(PICA) PT100, 0 TO 0.25MPA

QUANTITY: 2 PCS

ITEM 037

EXPLOSION FILM PACK

0-0.25MPA

QUANTITY: 2 SETS

ITEM 038

HIGH TEMPERATURE WIRE, SIGNAL WIRE

QUANTITY: 2 SETS

ITEM 039

NORMAL CABLE

QUANTITY: 1 SET

ITEM 040

TEMP. SENSOR FOR DOWTHERM STEAM

(TICA) PT100

QUANTITY: 2 PCS

ITEM 041

TEMP. SENSOR FOR DOWTHERM OVER HEATING PREVENTION

(TICA) PT100

QUANTITY: 2 PCS

ITEM 042

1800-12 AUTOMATIC WINDER

A. MECHANICAL SPEED: MAX: 4000M/MIN

B. PROCESSING SPEED: 2800 TO 3300M/MIN

C. 12 ENDS/PER WINDER

D. YARN PACKAGE: 15KG/BOBBIN

QUANTITY: 24 SETS

ITEM 043

COMPRESSED AIR TREATMENT SYSTEM

A. 24 POSITIONS PER SIDE, WITH PRECISE FILTER, EACH SIDE HAS 2 PCS PRESSURE RELEASE VALVES.

QUANTITY: 1 SIDE

ITEM 044

TAKE UP FRAME: NEW MOVABLE TYPE

A. DISTANCE: 1500mm

B. 2 POSITIONS PER SET, PROFILE STEEL STRUCTURE, SINGLE SIDE OPERATION, TAKE UP SWITCH BOX 1 PIECE, INCLUDING THE CONTACT FOR THE FIRST AND SECOND FLOORS AND TIMING AND LENGTH DISPLAY, 1 SET OF YARN GUIDE SYSTEM WITH A YARN BLOCKING PLATE.

QUANTITY: 12 SETS

ITEM 045

CR1 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 046

CR2 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 047

PRE-INTERMINGLING

A. 12 PCS PER POSITION

B. ORIGIN: AWA, JAPAN

24 SETS

ITEM 048

YARN ASPIRATOR

A. 1 PIECE PER SET

B. ORIGIN: CHINA

QUANTITY: 2 SETS

ITEM 049

YARN BREAK SENSOR

A. 12 PCS PER POSITION

B. ORIGIN: CHINA

QUANTITY: 24 SETS

ITEM 050

PNEUMATIC PIPING FOR TAKE UP

24 POSITIONS PER SET, QUICK CONNECTION TYPE

QUANTITY: 1 SET

ITEM 051

YARN DISTRIBUTION SUCTION GUN AND WASTE YARN PIPE

B. WATER YARN BASKET WILL BE PREPARED BY THE CUSTOMER

C. INCLUDING THE HIGH PRESSURE HOSE AND WASTE YARN PIPE

QUANTITY: 6 SETS

ITEM 052

COLD GODET CONTROLLING CABINET

A. VERTICAL, DOORS OPENED IN THE FRONT

B. 1 SET PER POSITION

C. JAPAN YASKAWA INVERTER

QUANTITY: 24 POS

ITEM 053

FREQUENCY CONVERSION CABINET FOR TAKE UP

BACK TO BACK, DOORS OPENED IN THE FRONT, 1 CONTROLLING FOR PER SET, INCLUDING ELECTRIC CONTROLLING BOX, INVERTER AND ETC.

QUANTITY: 24 SETS

ITEM 054

BASIC PLATE FOR WINDER

A. 1 POSITION PER SET

QUANTITY: 24 SETS

ITEM 055

CABLE

INSULATION CABLE

QUANTITY: 1 SET

CABLE FOR WINDER

QUANTITY: 1 SET

CABLE FROM THE CONTROLLING CABINET TO THE EQUIPMENT

QUANTITY: 1 SET

ITEM 056

BRIDGE FOR CABLE

QUANTITY: 1 SET

SPARE PARTS LIST

ITEM 057

SCREW DISMANTLE TOOLS FOR EXTRUDER

QUANTITY: 1 SET

ITEM 058

SPECIAL TOOLS FOR FILTER

QUANTITY: 1 SET

ITEM 059

WRENCH FOR GEAR PUMP

QUANTITY: 1 SET

ITEM 060

LIFTING ROD FOR SPIN PACK

QUANTITY: 2 SETS

ITEM 061

DISMANTLE TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 062

FASTENING TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 063

DISMANTLE TOOLS FOR YARN GUIDE DISC

QUANTITY: 1 SET

ITEM 064

DOFFING CART

QUANTITY: 1 SET

ITEM 065

TOOLS FOR INSTALLING THE SPIN PACK

QUANTITY: 1 SET

ITEM 066

TRANSPORTATION TROLLEY FOR WINDER

QUANTITY: 1 SET

ITEM 067

DISCHARGED YARN BLOCKING PLATE

QUANTITY: 24 PCS

ITEM 068

PUMP FOR DISCHARGE THE YARN

QUANTITY: 24 PCS

ITEM 069

SPECIAL TOOL FOR WINDER

QUANTITY: 1 SET

OTHER EQUIPMENT

UTILITIES

1 CRYSTALLIZER AND DRYER 1 SET

2 AHU 1 SET

3 COMPRESSOR 1 SET

4 CHILLER 1 SET

AUXILIARY EQUIPMENT LIST

1 VACUUM CLEANING OVEN 1 SET

2 ALKALI-WATER CLEANING TANK 1 SET

3 ULTRASONIC CLEANER 1 SET

4 PRE-HEATING FURNACE FOR SPIN PACK 1 SET

5 FINISH OIL PREPARING TANK 1 SET

6 FINISH OIL LEVEL TANK 1 SET

7 DISTILLED WATER GENERATOR 1 SET

8 DISTILLED WATER STORAGE TANK 1 SET

9 DISMOUNTING TOOL FOR SPIN PACK 1 SET

10 ASSEMBLING TOOL FOR SPIN PACK 1 SET

11 TRANSPORTATION CARRIAGE FOR SPIN PACK 1 SET

LAB EQUIPMENT LIST

1 SKEIN YARNS LENGTH TESTER 1 SET

2 SINGLE FIBER STRENGTH TESTER 1 SET

3 ELECTRICAL BALANCE 1 SET

4 ELECTRICAL OVEN 1 S ET

5 SPINNERET MICROSCOPE PROJECTOR 1 SET

6 DIGITAL YARN TENSION TESTER 1 S ET

7 DIFFERENTIAL PRESSURE MOISTURE TESTER 1 SET

8 FIBER OIL FAST EXTRACTOR 1 SET

9 STROBOSCOPE 1 SET

10 ANEMOGRAPH 1 SET

ANNEX 4:

TECHNICAL DOCUMENTS LIST

(1) MANUAL

(2) PID DIAGRAM FOR THE EQUIPMENT

(3) GENERAL DRAWING FOR THE EQUIPMENT

(4) ELECTRIC PRINCIPLE DIAGRAM

(5) ELECTRIC CONNECTION DIAGRAM

(6) EQUIPMENT LAYOUT DIAGRAM FOR DIFFERENT LAYER

(7) LIGHTING CONDITION DIAGRAM

(8) OILING SYSTEM DIAGRAM AND THE OILING PIPING DIAGRAM

(9) AIR CONDITIONER'S FLOW SYSTEM DIAGRAM AND PIPING DIAGRAM

(10) REFRIGERATED WATER AND REFRIGERATED WATER SYSTEM DIAGRAM AND PIPING DIAGRAM

(11) COMPRESSED AIR SYSTEM DIAGRAM AND PIPING DIAGRAM

ANNEX 5:

CHECKING STANDARD FOR THE PRODUCT QUALITY ASSURANCE

(1) CHECKING CATEGORY: 100D/72F

(2) SPINNING SPEED: 2500 TO 3300M/MIN

(3) CHECKING STANDARD: ACCORDING TO CHINA NATIONAL STANDARD ((FZ/T54003—2004)).

(4) CHECKING TIME: WITHIN 15 DAYS AFTER THE EQUIPMENT HAS BEEN SUCCESSFULLY TESTED AND BEING RUNNING, BOTH PARTIES OF THE BUYER AND SELLER WILL CHECK THE CONTRACTED EQUIPMENT. IF THE CHECKING CAN NOT BE CARRIED OUT WITHIN ONE MONTH AFTER THE MACHINE IS BEING SUCCESSFULLY RUNNING, THEN THE MACHINE WILL BE REGARD AS PAST THE CHECKING. THE CHECKING PERIOD IS 72 HOURS CONTINUOUS CHECKING.

(5) METHOD OF TAKING CHECKING SAMPLE: EACH SHIFT WILL TAKE A BOBBIN FOR CHECKING THE MAIN

ITEMS, AND THE CHECKING WILL BE REGARDED AS PAST THE CHECKING IF 90% OF THE CHECKING ITEMS HAVE BEEN PAST, IN THE 72 HOURS CONTINUOUSLY CHECKING PERIOD, IF THERE IS ANY FAILURE HAPPENED, NO MATTER WHICH PARTY CAUSED THE FAILURE, THE CHECKING CAN BE DONE AGAIN.

ANNEX 6:

INSTALLATION AND AFTER SALES SERVICE

1. MACHINE INSTALLATION AND COMMISSIONING:

(1) THE SELLER WILL SEND HIS ELECTRIC AND MECHANICAL ENGINEER FOR HELPING THE INSTALLATION OF SPINNING AND WINDING MACHINES.

(2) THE SELLER WILL PROVIDE THE DRAWING AND DIMENSIONS GUIDANCE, AND THE BUYER WILL BE RESPONSIBLE FOR THE PREPARATION OF THE FOUNDATION.

(3) DURING THE COMMISSIONING PERIOD, THE SELLER HAS THE RIGHT TO MODIFY OR CHANGE THE MACHINE PARTS.

2. THE BUYER SHALL PROVIDE:

(1) COMPRESSED AIR FOR THE WINDER AND SUCTION GUN, THE COMPRESSED AIR PRESSURE SHALL NOT LESS THAN 0.8MPA, DEW DROP POINT OF THE COMPRESSED AIR IS RECOMMENDED TO BE MAX. -4°C, AND THE COMPRESSED AIR SHALL BE FILTERED FROM OIL AND WATER, THE FILTERING PRECISION IS RECOMMENDED TO BE 5μM

(2) OIL MIXING TANK, OIL TANK, OIL CONVEYING PIPE AND OIL RECYCLING PIPE AND ETC.

(3) CONNECTION FOR THE ELECTRIC BOX OF THE WINDER AND OILING DEVICE AND THE AUXILIARY MATERIALS.

(4) COMPRESSED AIR PIPING TO THE MACHINE AND THE WASTE YARN TANK.

(5) CLEANING AND PRE-HEATING EQUIPMENT FOR SPIN PACK AND SPINNERET.

(6) COOLING WATER PIPING FOR THE ETRUDER

(7) HIGH TEMPERATURE CONDUCTIVE OIL (DOWTHERM)

3. EXPLANATION:

(1) THE SELLER WILL PROVIDE THE GUARANTEE FOR THE MECHANICAL FEATURES OF THE CONTACTED EQUIPMENT. FOR THE POY SPINNING TECHNIQUE, THE BUYER SHALL HANDLE BY HIMSELF.

(2) THIS TECHNICAL SPECIFICATIONS IS AN INTEGRAL PART OF THE CONTRACT, IT HAS THE SAME LEGAL EFFECT LIKE THE CONTRACT. FOR THE TECHNICAL ISSUES AND SUPPLYING SCOPE MENTIONED IN THE CONTRACT, THIS TECHNICAL SPECIFICATIONS WILL BE REGARDED AS THE STANDARD.

4. AFTER SALES SERVICE

WHEN THE BUYER HAS SUCCESSFULLY RUN THE MACHINES, THE SELLER SHALL STILL PAY ATTENTION TO THE MACHINES. WITHIN THE 12 MONTHS AFTER THE MACHINE HAS BEEN ACCEPTED BY THE BUYER, IF THE MACHINE HAS A PROBLEM AND THIS PROBLEM IS NOT CAUSED BY THE BUYER, THE SELLER SHALL REPAIR OR CHANGE THIS DAMAGED PART. AND THE SELLER SHALL PROVIDE THE GUIDANCE FOR HOW TO USE THE MACHINE CORRECTLY, AND THE SELLER SHALL HELP THE BUYER TO SOLVE THE PROBLEMS TO ENSURE THAT THE MACHINE CAN BE OPERATED SMOOTHLY.

NOTE:

1. POY DRAWING TIME: 1.6

2. POY SPINNING SPEED: 3200M/MIN;

3. EFFICIENCY: 0.96

4. WORKING DAYS PER YEAR: 330 DAYS.

1.3 BASICS OF MACHINE DESIGN AND LAYOUT:

EXTRUDER Φ 160/25

PRODUCT TYPE PET-POY

END/POSITION 12 ENDS

POSITIONS 24 POSITIONS

POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM

POSITION DISTANCE (mm) 1500mm

SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED

SPINNERET DIAMETER (mm) Φ 90mm

CROSS BLOWING AREA 1430mm X 1380mm

GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV

GEAR PUMP QUANTITY/POSITION 1

OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV

OIL PUMP QUANTITY/ POSITION 1

DOWTHERM BOILER/LINE 600L/65KW

GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm

MIGRATION JET AWA. JAPAN

WINDER TWA1800-12ENDS

1.4 MAIN MATERIALS CONSUMPTION:

MAIN MATERIALS CONSUMPTION FOR PRODUCING 1000KGS OF PET-POY:

SERIAL 75D-150D

PET FLAKES (KG) 1045

OIL (KG) 6

REQUIRED FLAKES QUALITY:

INTRINSIC VISCOSITY: 0.74 TO 0.78 DL/G DEPEND ON BOTTLE'S I.V.

BULK DENSITY (MIN./AVG./MAX.): 250 TO 350 KG/M3

FLAKE SIZE: 2 TO 12mm

HUMIDITY: ≤ 1%

PE, PP: ≤ 10 PPM

PAPER: ≤ 15 PPM

GLUES/HOT MELTS: ≤ 20 PPM

ORGANICS: ≤ 20 PPM

METALS: ≤ 10 PPM

IN-ORGANICS: ≤ 20 PPM

PVC: ≤ 30 PPM

TOTAL IMPURITY: ≤ 80 PPM

1.5 PUBLIC ENGINEERING REQUIREMENTS:

1. ELECTRICITY

RATED VOLTAGE: V 380/220±5 %

PHASES: 3 PHASES/4 WIRES

RATED HERTZ: Hz 50±1.0%

2. COOLING WATER

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤32 °C

PH VALUE: 6.5-7

TOTAL SALT CONTENT: PPM ≤400

3. REFRIGERATED WATER (SUPPLIED BY THE REFRIGERATOR)

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤7.0-8.0°C

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤12

4. WATER FOR OIL (DISTILLED WATER OR DESALTED WATER)

PRESSURE: MPA ≥0.1MPA

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤1

SIO2 CONTENT: PPM ≤0.2

FUNGUS: NO

5. COMPRESSED AIR:

PRESSURE: MPA ≥0.5MPA

TEMPERATURE: °C NORMAL TEMPERATURE

CONDITIONS: NO OIL, NO WATER

6. COMPRESSED AIR FOR THE GAUGES:

PRESSURE: MPA 0.5-0.6MPA

TEMPERATURE: °C NORMAL TEMPERATURE

DEW POINT: °C -20°C

CONDITIONS: NO OIL, NO WATER, NO SOLID RESIDUES

7. COMPRESSED AIR FOR THE SUCTION GUN:

PRESSURE: MPA ≥0.7MPA

TEMPERATURE: °C NORMAL TEMPERATURE

8. CROSS BLOWING AIR:

AIR PRESSURE: 600PA

HUMIDITY: 75% ±3

TEMPERATURE: 22°C±1

1.6 PUBLIC UTILITIES (DETAIL DATA WILL BE CONFIRMED LATER)

1.7 TOTAL WEIGHT OF THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

1.8 TOTAL POWER NEEDED FOR THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

ANNEX 2:

PROJECT BOUNDARY AND SCOPE

3.1 SELLER:

1. PROVIDES THE BRAND NEW CONTRACTED MACHINES FROM THE MATERIAL INLET FLANGE OF THE SCREW EXTRUDER TILL THE WINDER.

2. PROVIDES THE TECHNICAL DOCUMENTS FOR THE CONTRACTED MACHINES.

3. WHEN THE MACHINES HAVE BEEN DELIVERED TO THE BUYER'S FACTORY, AND AFTER RECEIVING THE BUYER'S WRITTEN NOTICE, THE SELLER WILL SEND THE ELECTRIC ENGINEER AND MECHANICAL ENGINEER TO THE BUYER'S FACTORY FOR HELPING THE INSTALLATION AND PRODUCTION PREPARATION, AND THESE ENGINEERS WILL HELP TO INSTALL THE MACHINES PROVIDED BY THE SELLER AND CARRY OUT THE TESTING, AND THESE ENGINEERS WILL COOPERATE WITH THE BUYER TO PRODUCE THE QUALIFY PRODUCTS WITHIN THE TIME STIPULATED IN THE CONTRACT.

4. THE WELDING OF THE POLYMER PIPES AND THE SPECIAL WELDING MATERIALS SUCH AS THE ARC WELDING MACHINE AND

STAINLESS STEEL WELDING STICKS, WILL BE PROVIDED BY THE SELLER, THE BUYER SHALL PROVIDE THE COOPERATION BY PROVIDING THE ASSISTING PERSONNEL AND TOOLS.

5. PROVIDES THE SIGNAL WIRES, HIGH TEMPERATURE WIRES AND INSULATION WIRES FOR THE MACHINES THE SELLER SUPPLIED.

3.2 BUYER:

1. RESPONSIBLE FOR THE HEAT INSULATING MATERIAL FOR THE EQUIPMENT AND THE CONSTRUCTION OF THE HEAT INSULATING WORK.

2. RESPONSIBLE FOR THE FOOD AND LODGING FOR THE SELLER'S ENGINEERS AND PROVIDE THE GOOD WORKING CONDITIONS FOR THE SELLER'S ENGINEERS.

3. RESPONSIBLE FOR THE CABLE TRUNKING PREPARATION AND LAYING.

4. RESPONSIBLE FOR THE CABLE FOR THE EXTRUDER.

5. RESPONSIBLE FOR THE UNLOADING, UNPACKING, POSITIONING OF THE EQUIPMENT.

6. RESPONSIBLE FOR THE MATERIALS FOR THE INSTALLATION SUCH AS THE ACETYLENE, OXYGEN, WELDING STICK, GLOVES, LIFTING DEVICE, WATER, ELECTRICITY, COMPRESSED AIR AND ETC.

7. RESPONSIBLE FOR THE NORMAL CABLES FOR THE EXTRUDER HEATING, GEAR PUMP MOTOR, OIL PUMP MOTOR, CONTACTING WIRE, BUTTON WIRE, DOWTHERM STOVE, AND ETC.

ANNEX 3:

SUPPLYING SCOPE

NOTE:

(S) — SELLER'S SUPPLYING SCOPE

(B) — BUYER'S SUPPLYING

SCOPE 4000 24 POSITION PET- POY SPINNING EQUIPMENT

ITEM 001

EXTRUDER

A. TYPE: HORIZONTAL

B. SCREW: Φ160mm L/D=25

C. DRIVING POWER: 132KW

D. HEATING POWER: 81KW

E. TEMP.DETECTING ELEMENT: PT100

F. AC FREQUENCY CONVERSION SPEED REGULATION, IMPORTED V BELT

G. 3 PHASES AC MOTOR, SIEMENS

QUANTITY: 2 SETS

ITEM 002

DETECTING HEAD

A. TYPE: JACKET TYPE HEATING

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

QUANTITY: 2 SETS

ITEM 003

POLYMER FILTER

A. TYPE: VERTICAL, TWO STAGES

D. FILTERING TYPE: CANDLE CORE

C. FILTERING AREA: 9.5-5.5

E. RATED FLOW: 700 TO 900KG/H

F. FILTERING PRECISION: ≤25μ

G. FILTERING CORE QUANTITY: 19X2, TOTALLY 38 PCS

QUANTITY: 2 SETS

ITEM 004

POLYMER PIPING

A. HEATING METHOD: JACKET TYPE

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

D. THE FLANGES' CONNECTION IS BY RED COPPER.

QUANTITY: 2 SETS

ITEM 005

SPINNING BEAM

A. TYPE: SINGLE SIDE OPERATION

B. POSITION: 2 POSITIONS /SPINNING BEAM

C. ENDS: 12 ENDS

D. DISTANCE: 1500mm

E. HEATING: DOWTHERM STOVE SYSTEM

F. DESIGNED TEMP.: 315°C

G. SPINNING BEAM SURFACE TEM. INCREASE: ≤60°C

H. SPINNING BEAM DESIGNED PRESSURE: 0.2MPA

I. DESIGNED PRESSURE FOR THE POLYMER PIPES:

BEFORE GEAR PUMP: 25MPA

AFTER GEAR PUMP: 35MPA

J. POLYMER VALVE: REFRIGERATED VALVE

QUANTITY: 12 SETS

ITEM 006

SPINNING BEAM RACK

A. MATERIAL: CARBON STEEL STRUCTURE

QUANTITY: 2 SETS

ITEM 007

GEAR PUMP

A. TYPE: PLANETARY TYPE

B. SPECIFICATIONS: 12X3.0CC/REV

C. INLET QUANTITY/OUTLET QUANTITY: 1/12

QUANTITY: 24 SETS

ITEM 008

GEAR PUMP DRIVING DEVICE

A. DRIVING METHOD: 1 SET OF DRIVING DEVICE FOR EACH POSITION

B. TYPE: VERTICAL SYNCHRONIZATION MOTOR + PLANETARY TYPE REDUCER + PULLING DRIVING SHAFT

C. MOTOR POWER: 2.2KW

D. SPEED RATIO: 1:43

QUANTITY: 24 SETS

ITEM 009

GEAR PUMP DRIVING FRAME

A. TYPE: CARBON STEEL STRUCTURE

B. U-STEEL FOR INSTALLING THE GEAR PUMP DRIVING WILL BE PROVIDED BY THE SELLER.

QUANTITY: 12 SETS

ITEM 010

SPIN PACK

A. TYPE: CYLINDER TYPE, BOTTOM MOUNTED

B. QUANTITY: 12 PCS PER POSITION

C. DIAMETER: Φ90mm

D. SPINNERET QUANTITY: 1 SPINNERET PER SPIN PACK

E. FILTERING TYPE: STEEL NET AND FILTER SAND TYPE

F. DESIGNED PRESSURE: 35MPA

G. NOT INCLUDING THE NET, WASHER AND GASKET

H. 288 SETS IN USING AND 2488 SETS FOR STAND BY

QUANTITY: 576 SETS

ITEM 011

SPINNERET

A. TYPE: ROUND

B. DIAMETER: Φ90mm

C. NO OF HOLE: 48 TO 96

QUANTITY: 576 PCS

ITEM 012

YARN DUCT

A. TYPE: RECTANGLE TYPE

B. MATERIAL: HIGH QUALITY ALUMINUM

QUANTITY: 24 SETS

ITEM 013

DOWTHERM BOILER

B. TYPE: ELECTRIC HEATING, CONTAINER TYPE

C. DESIGNED TEMP.: 350°C

D. DESIGNED PRESSURE: 0.2MPA

E. HEATING POWER: 65KW

E. VOLUME:600L

F. SAFETY DEVICE:

1) ELECTRIC CONTACT POINT PRESSURE GAUGE

2) EXPLOSION PREVENTION FILM PACK

3) DOUBLE SAFETY VALVE

4) OVER HEATING PREVENTION ALARM DEVICE

5) TIPPING PLATE TYPE LIQUID LEVEL GAUGE

QUANTITY: 2 SETS

ITEM 014

GENERAL PARTS FOR THE DOWTHERM PIPING

SEAMLESS STEEL PIPE, PIPING, ELBOW, TEE, STANDARD FITTING FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 015

SPECIAL PARTS FOR DOWTHERM SYSTEM

VALVE, FLANGE, GRAPHITE WINDED GASKET FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 016

DISCHARGE TANK

QUANTITY: 2 PCS

ITEM 017

QUENCHING CHAMBER

A. TYPE: CROSS BLOWING

B. BLOWING AREA: 1430mm X 1380mm

C. WITH HEAT INSULATION PLATE

D. WITH AIR FLOW REGULATION VALVE

E. WITH PLATE TYPE FILTER

F. WITH OIL FRAME SLIDING GROOVE

G. WITH QUENCHING CHAMBER DOOR

QUANTITY: 24 SETS

ITEM 018

QUENCHING CHAMBER FRAME

A. TYPE: CARBON STEEL STRUCTURE

QUANTITY: 24 SETS

ITEM 019

OILING DEVICE

A. OILING NOZZLE (12 PCS OF OILING NOZZLE PER POSITION)

B. YARN GUIDE HOOK (12 PCS OF YARN GUIDE HOOK PER POSITION)

QUANTITY: 24 SETS

ITEM 020

OIL PUMP

A. SPECIFICATIONS: 12X0.12CC/REV

B. INLET QUANTITY/OUTLET QUANTITY: 1/12

C. ORIGIN: SUZHOU HUAXI

QUANTITY: 24 SETS

ITEM 021

DRIVING DEVICE FOR OIL PUMP

A. INCLUDING MOTOR, REDUCER AND SUPPORT PLATE

QUANTITY: 24 SETS

ITEM 022

OIL TANK

A. WITH OIL FILTER

B. WITH PIPING, VALVE, DUPLEX FILTER, FILTERING PRECISION: 10UM

C. WITH FLOATING BALL VALVE, DISCHARGE VALVE, OVERFLOW

QUANTITY: 2 SETS

ITEM 023

PIPING AND WIRING OUTSIDE THE EQUIPMENT

SUCH AS THE PIPING AND ACCESSORIES FOR REFRIGERATED WATER, COMPRESSED AIR.

QUANTITY: 1 SET

ITEM 024

CONTROLLING PANEL FOR THE EXTRUDER

VOLTAGE, CURRENT, RPM, EXTRUDER PRESSURE BEFORE FILTER, ALARM, PRESSURE CONTROL, DISPLAY AND ALARM AFTER THE FILTER. THE EXTRUDER'S INVERTER IS FROM JAPAN YASKAWA.

QUANTITY: 2 SETS

ITEM 025

TEMP. CONTROLLING PANEL FOR SPINNING MACHINE

JAPANESE RKC TEMPERATURE GAUGE

QUANTITY: 2 PCS

ITEM 026

CONTROLLING PANEL FOR GEAR PUMP

THE CONTROLLING METHOD FOR THE GEAR PUMP INVERTER IS 1 CONTROLLING FOR EACH POSITION. THE INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 027

SWITCH BOX FOR GEAR PUMP

1 PIECE PER POSITION

QUANTITY: 24 PCS

ITEM 028

CONTROLLING CABINET FOR OIL PUMP

VERTICAL TYPE, DOORS CAN BE OPENED IN THE FRONT AND BACK, OIL PUMP INVERTER CONTROLLING METHOD: 1 CONTROLLING PER POSITION INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 029

POLYMER PRESSURE SENSOR (BEFORE FILTER)

0-25MAP (WITH SCENE DISPLAY)

QUANTITY: 2 PCS

ITEM 030

POLYMER PRESSURE SENSOR (AFTER FILTER)

0-35MPA (ITALY GEFRAN, WITH SCENE INDICATION)

QUANTITY: 2 PCS

ITEM 031

PRESSURE SENSOR FOR SPIN PACK

0-35MPA (WITH SCENE INDICATION, DIGITAL DISPLAY

QUANTITY: 2 PCS

ITEM 032

TEMPERATURE FOR DIFFERENT ZONES OF THE EXTRUDER

(TICA) PT100

QUANTITY: 12 PCS

ITEM 033

TEMP. SENSOR FOR EXTRUDER HEAD

(TIA) PT100

QUANTITY: 2 PCS

ITEM 034

TEMP.SENSOR FOR SPIN BEAM

(TIA) PT100

QUANTITY: 2 PCS

ITEM 035

PRESSURE SENSOR FOR DISCHARGE BOX

(TIA) PT100

QUANTITY: 2 PCS

ITEM 036

ELECTRIC CONTACT POINT PRESSURE GAUGE FOR DOWTHERM BOILER

(PICA) PT100, 0 TO 0.25MPA

QUANTITY: 2 PCS

ITEM 037

EXPLOSION FILM PACK

0-0.25MPA

QUANTITY: 2 SETS

ITEM 038

HIGH TEMPERATURE WIRE, SIGNAL WIRE

QUANTITY: 2 SETS

ITEM 039

NORMAL CABLE

QUANTITY: 1 SET

ITEM 040

TEMP. SENSOR FOR DOWTHERM STEAM

(TICA) PT100

QUANTITY: 2 PCS

ITEM 041

TEMP. SENSOR FOR DOWTHERM OVER HEATING PREVENTION

(TICA) PT100

QUANTITY: 2 PCS

ITEM 042

1800-12 AUTOMATIC WINDER

A. MECHANICAL SPEED: MAX: 4000M/MIN

B. PROCESSING SPEED: 2800 TO 3300M/MIN

C. 12 ENDS/PER WINDER

D. YARN PACKAGE: 15KG/BOBBIN

QUANTITY: 24 SETS

ITEM 043

COMPRESSED AIR TREATMENT SYSTEM

A. 24 POSITIONS PER SIDE, WITH PRECISE FILTER, EACH SIDE HAS 2 PCS PRESSURE RELEASE VALVES.

QUANTITY: 1 SIDE

ITEM 044

TAKE UP FRAME: NEW MOVABLE TYPE

A. DISTANCE: 1500mm

B. 2 POSITIONS PER SET, PROFILE STEEL STRUCTURE, SINGLE SIDE OPERATION, TAKE UP SWITCH BOX 1 PIECE, INCLUDING THE CONTACT FOR THE FIRST AND SECOND FLOORS AND TIMING AND LENGTH DISPLAY, 1 SET OF YARN GUIDE SYSTEM WITH A YARN BLOCKING PLATE.

QUANTITY: 12 SETS

ITEM 045

CR1 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 046

CR2 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 047

PRE-INTERMINGLING

A. 12 PCS PER POSITION

B. ORIGIN: AWA, JAPAN

24 SETS

ITEM 048

YARN ASPIRATOR

A. 1 PIECE PER SET

B. ORIGIN: CHINA

QUANTITY: 2 SETS

ITEM 049

YARN BREAK SENSOR

A. 12 PCS PER POSITION

B. ORIGIN: CHINA

QUANTITY: 24 SETS

ITEM 050

PNEUMATIC PIPING FOR TAKE UP

24 POSITIONS PER SET, QUICK CONNECTION TYPE

QUANTITY: 1 SET

ITEM 051

YARN DISTRIBUTION SUCTION GUN AND WASTE YARN PIPE

B. WATER YARN BASKET WILL BE PREPARED BY THE CUSTOMER

C. INCLUDING THE HIGH PRESSURE HOSE AND WASTE YARN PIPE

QUANTITY: 6 SETS

ITEM 052

COLD GODET CONTROLLING CABINET

A. VERTICAL, DOORS OPENED IN THE FRONT

B. 1 SET PER POSITION

C. JAPAN YASKAWA INVERTER

QUANTITY: 24 POS

ITEM 053

FREQUENCY CONVERSION CABINET FOR TAKE UP

BACK TO BACK, DOORS OPENED IN THE FRONT, 1 CONTROLLING FOR PER SET, INCLUDING ELECTRIC CONTROLLING BOX, INVERTER AND ETC.

QUANTITY: 24 SETS

ITEM 054

BASIC PLATE FOR WINDER

A. 1 POSITION PER SET

QUANTITY: 24 SETS

ITEM 055

CABLE

INSULATION CABLE

QUANTITY: 1 SET

CABLE FOR WINDER

QUANTITY: 1 SET

CABLE FROM THE CONTROLLING CABINET TO THE EQUIPMENT

QUANTITY: 1 SET

ITEM 056

BRIDGE FOR CABLE

QUANTITY: 1 SET

SPARE PARTS LIST

ITEM 057

SCREW DISMANTLE TOOLS FOR EXTRUDER

QUANTITY: 1 SET

ITEM 058

SPECIAL TOOLS FOR FILTER

QUANTITY: 1 SET

ITEM 059

WRENCH FOR GEAR PUMP

QUANTITY: 1 SET

ITEM 060

LIFTING ROD FOR SPIN PACK

QUANTITY: 2 SETS

ITEM 061

DISMANTLE TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 062

FASTENING TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 063

DISMANTLE TOOLS FOR YARN GUIDE DISC

QUANTITY: 1 SET

ITEM 064

DOFFING CART

QUANTITY: 1 SET

ITEM 065

TOOLS FOR INSTALLING THE SPIN PACK

QUANTITY: 1 SET

ITEM 066

TRANSPORTATION TROLLEY FOR WINDER

QUANTITY: 1 SET

ITEM 067

DISCHARGED YARN BLOCKING PLATE

QUANTITY: 24 PCS

ITEM 068

PUMP FOR DISCHARGE THE YARN

QUANTITY: 24 PCS

ITEM 069

SPECIAL TOOL FOR WINDER

QUANTITY: 1 SET

OTHER EQUIPMENT

UTILITIES

1 CRYSTALLIZER AND DRYER 1 SET

2 AHU 1 SET

3 COMPRESSOR 1 SET

4 CHILLER 1 SET

AUXILIARY EQUIPMENT LIST

1 VACUUM CLEANING OVEN 1 SET

2 ALKALI-WATER CLEANING TANK 1 SET

3 ULTRASONIC CLEANER 1 SET

4 PRE-HEATING FURNACE FOR SPIN PACK 1 SET

5 FINISH OIL PREPARING TANK 1 SET

6 FINISH OIL LEVEL TANK 1 SET

7 DISTILLED WATER GENERATOR 1 SET

8 DISTILLED WATER STORAGE TANK 1 SET

9 DISMOUNTING TOOL FOR SPIN PACK 1 SET

10 ASSEMBLING TOOL FOR SPIN PACK 1 SET

11 TRANSPORTATION CARRIAGE FOR SPIN PACK 1 SET

LAB EQUIPMENT LIST

1 SKEIN YARNS LENGTH TESTER 1 SET

2 SINGLE FIBER STRENGTH TESTER 1 SET

3 ELECTRICAL BALANCE 1 SET

4 ELECTRICAL OVEN 1 S ET

5 SPINNERET MICROSCOPE PROJECTOR 1 SET

6 DIGITAL YARN TENSION TESTER 1 S ET

7 DIFFERENTIAL PRESSURE MOISTURE TESTER 1 SET

8 FIBER OIL FAST EXTRACTOR 1 SET

9 STROBOSCOPE 1 SET

10 ANEMOGRAPH 1 SET

ANNEX 4:

TECHNICAL DOCUMENTS LIST

(1) MANUAL

(2) PID DIAGRAM FOR THE EQUIPMENT

(3) GENERAL DRAWING FOR THE EQUIPMENT

(4) ELECTRIC PRINCIPLE DIAGRAM

(5) ELECTRIC CONNECTION DIAGRAM

(6) EQUIPMENT LAYOUT DIAGRAM FOR DIFFERENT LAYER

(7) LIGHTING CONDITION DIAGRAM

(8) OILING SYSTEM DIAGRAM AND THE OILING PIPING DIAGRAM

(9) AIR CONDITIONER'S FLOW SYSTEM DIAGRAM AND PIPING DIAGRAM

(10) REFRIGERATED WATER AND REFRIGERATED WATER SYSTEM DIAGRAM AND PIPING DIAGRAM

(11) COMPRESSED AIR SYSTEM DIAGRAM AND PIPING DIAGRAM

ANNEX 5:

CHECKING STANDARD FOR THE PRODUCT QUALITY ASSURANCE

(1) CHECKING CATEGORY: 100D/72F

(2) SPINNING SPEED: 2500 TO 3300M/MIN

(3) CHECKING STANDARD: ACCORDING TO CHINA NATIONAL STANDARD ((FZ/T54003—2004)).

(4) CHECKING TIME: WITHIN 15 DAYS AFTER THE EQUIPMENT HAS BEEN SUCCESSFULLY TESTED AND BEING RUNNING, BOTH PARTIES OF THE BUYER AND SELLER WILL CHECK THE CONTRACTED EQUIPMENT. IF THE CHECKING CAN NOT BE CARRIED OUT WITHIN ONE MONTH AFTER THE MACHINE IS BEING SUCCESSFULLY RUNNING, THEN THE MACHINE WILL BE REGARD AS PAST THE CHECKING. THE CHECKING PERIOD IS 72 HOURS CONTINUOUS CHECKING.

(5) METHOD OF TAKING CHECKING SAMPLE: EACH SHIFT WILL TAKE A BOBBIN FOR CHECKING THE MAIN

ITEMS, AND THE CHECKING WILL BE REGARDED AS PAST THE CHECKING IF 90% OF THE CHECKING ITEMS HAVE BEEN PAST, IN THE 72 HOURS CONTINUOUSLY CHECKING PERIOD, IF THERE IS ANY FAILURE HAPPENED, NO MATTER WHICH PARTY CAUSED THE FAILURE, THE CHECKING CAN BE DONE AGAIN.

ANNEX 6:

INSTALLATION AND AFTER SALES SERVICE

1. MACHINE INSTALLATION AND COMMISSIONING:

(1) THE SELLER WILL SEND HIS ELECTRIC AND MECHANICAL ENGINEER FOR HELPING THE INSTALLATION OF SPINNING AND WINDING MACHINES.

(2) THE SELLER WILL PROVIDE THE DRAWING AND DIMENSIONS GUIDANCE, AND THE BUYER WILL BE RESPONSIBLE FOR THE PREPARATION OF THE FOUNDATION.

(3) DURING THE COMMISSIONING PERIOD, THE SELLER HAS THE RIGHT TO MODIFY OR CHANGE THE MACHINE PARTS.

2. THE BUYER SHALL PROVIDE:

(1) COMPRESSED AIR FOR THE WINDER AND SUCTION GUN, THE COMPRESSED AIR PRESSURE SHALL NOT LESS THAN 0.8MPA, DEW DROP POINT OF THE COMPRESSED AIR IS RECOMMENDED TO BE MAX. -4°C, AND THE COMPRESSED AIR SHALL BE FILTERED FROM OIL AND WATER, THE FILTERING PRECISION IS RECOMMENDED TO BE 5μM

(2) OIL MIXING TANK, OIL TANK, OIL CONVEYING PIPE AND OIL RECYCLING PIPE AND ETC.

(3) CONNECTION FOR THE ELECTRIC BOX OF THE WINDER AND OILING DEVICE AND THE AUXILIARY MATERIALS.

(4) COMPRESSED AIR PIPING TO THE MACHINE AND THE WASTE YARN TANK.

(5) CLEANING AND PRE-HEATING EQUIPMENT FOR SPIN PACK AND SPINNERET.

(6) COOLING WATER PIPING FOR THE ETRUDER

(7) HIGH TEMPERATURE CONDUCTIVE OIL (DOWTHERM)

3. EXPLANATION:

(1) THE SELLER WILL PROVIDE THE GUARANTEE FOR THE MECHANICAL FEATURES OF THE CONTACTED EQUIPMENT. FOR THE POY SPINNING TECHNIQUE, THE BUYER SHALL HANDLE BY HIMSELF.

(2) THIS TECHNICAL SPECIFICATIONS IS AN INTEGRAL PART OF THE CONTRACT, IT HAS THE SAME LEGAL EFFECT LIKE THE CONTRACT. FOR THE TECHNICAL ISSUES AND SUPPLYING SCOPE MENTIONED IN THE CONTRACT, THIS TECHNICAL SPECIFICATIONS WILL BE REGARDED AS THE STANDARD.

4. AFTER SALES SERVICE

WHEN THE BUYER HAS SUCCESSFULLY RUN THE MACHINES, THE SELLER SHALL STILL PAY ATTENTION TO THE MACHINES. WITHIN THE 12 MONTHS AFTER THE MACHINE HAS BEEN ACCEPTED BY THE BUYER, IF THE MACHINE HAS A PROBLEM AND THIS PROBLEM IS NOT CAUSED BY THE BUYER, THE SELLER SHALL REPAIR OR CHANGE THIS DAMAGED PART. AND THE SELLER SHALL PROVIDE THE GUIDANCE FOR HOW TO USE THE MACHINE CORRECTLY, AND THE SELLER SHALL HELP THE BUYER TO SOLVE THE PROBLEMS TO ENSURE THAT THE MACHINE CAN BE OPERATED SMOOTHLY.

NOTE:

1. POY DRAWING TIME: 1.6

2. POY SPINNING SPEED: 3200M/MIN;

3. EFFICIENCY: 0.96

4. WORKING DAYS PER YEAR: 330 DAYS.

1.3 BASICS OF MACHINE DESIGN AND LAYOUT:

EXTRUDER Φ 160/25

PRODUCT TYPE PET-POY

END/POSITION 12 ENDS

POSITIONS 24 POSITIONS

POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM

POSITION DISTANCE (mm) 1500mm

SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED

SPINNERET DIAMETER (mm) Φ 90mm

CROSS BLOWING AREA 1430mm X 1380mm

GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV

GEAR PUMP QUANTITY/POSITION 1

OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV

OIL PUMP QUANTITY/ POSITION 1

DOWTHERM BOILER/LINE 600L/65KW

GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm

MIGRATION JET AWA. JAPAN

WINDER TWA1800-12ENDS

1.4 MAIN MATERIALS CONSUMPTION:

MAIN MATERIALS CONSUMPTION FOR PRODUCING 1000KGS OF PET-POY:

SERIAL 75D-150D

PET FLAKES (KG) 1045

OIL (KG) 6

REQUIRED FLAKES QUALITY:

INTRINSIC VISCOSITY: 0.74 TO 0.78 DL/G DEPEND ON BOTTLE'S I.V.

BULK DENSITY (MIN./AVG./MAX.): 250 TO 350 KG/M3

FLAKE SIZE: 2 TO 12mm

HUMIDITY: ≤ 1%

PE, PP: ≤ 10 PPM

PAPER: ≤ 15 PPM

GLUES/HOT MELTS: ≤ 20 PPM

ORGANICS: ≤ 20 PPM

METALS: ≤ 10 PPM

IN-ORGANICS: ≤ 20 PPM

PVC: ≤ 30 PPM

TOTAL IMPURITY: ≤ 80 PPM

1.5 PUBLIC ENGINEERING REQUIREMENTS:

1. ELECTRICITY

RATED VOLTAGE: V 380/220±5 %

PHASES: 3 PHASES/4 WIRES

RATED HERTZ: Hz 50±1.0%

2. COOLING WATER

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤32 °C

PH VALUE: 6.5-7

TOTAL SALT CONTENT: PPM ≤400

3. REFRIGERATED WATER (SUPPLIED BY THE REFRIGERATOR)

PRESSURE: MPA ≥0.2MPA

WATER INLET TEMPERATURE: °C ≤7.0-8.0°C

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤12

4. WATER FOR OIL (DISTILLED WATER OR DESALTED WATER)

PRESSURE: MPA ≥0.1MPA

PH VALUE: 6.5-7

GENERAL HARDNESS: DH ≤1

SIO2 CONTENT: PPM ≤0.2

FUNGUS: NO

5. COMPRESSED AIR:

PRESSURE: MPA ≥0.5MPA

TEMPERATURE: °C NORMAL TEMPERATURE

CONDITIONS: NO OIL, NO WATER

6. COMPRESSED AIR FOR THE GAUGES:

PRESSURE: MPA 0.5-0.6MPA

TEMPERATURE: °C NORMAL TEMPERATURE

DEW POINT: °C -20°C

CONDITIONS: NO OIL, NO WATER, NO SOLID RESIDUES

7. COMPRESSED AIR FOR THE SUCTION GUN:

PRESSURE: MPA ≥0.7MPA

TEMPERATURE: °C NORMAL TEMPERATURE

8. CROSS BLOWING AIR:

AIR PRESSURE: 600PA

HUMIDITY: 75% ±3

TEMPERATURE: 22°C±1

1.6 PUBLIC UTILITIES (DETAIL DATA WILL BE CONFIRMED LATER)

1.7 TOTAL WEIGHT OF THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

1.8 TOTAL POWER NEEDED FOR THE MACHINE (DETAIL DATA WILL BE CONFIRMED LATER)

ANNEX 2:

PROJECT BOUNDARY AND SCOPE

3.1 SELLER:

1. PROVIDES THE BRAND NEW CONTRACTED MACHINES FROM THE MATERIAL INLET FLANGE OF THE SCREW EXTRUDER TILL THE WINDER.

2. PROVIDES THE TECHNICAL DOCUMENTS FOR THE CONTRACTED MACHINES.

3. WHEN THE MACHINES HAVE BEEN DELIVERED TO THE BUYER'S FACTORY, AND AFTER RECEIVING THE BUYER'S WRITTEN NOTICE, THE SELLER WILL SEND THE ELECTRIC ENGINEER AND MECHANICAL ENGINEER TO THE BUYER'S FACTORY FOR HELPING THE INSTALLATION AND PRODUCTION PREPARATION, AND THESE ENGINEERS WILL HELP TO INSTALL THE MACHINES PROVIDED BY THE SELLER AND CARRY OUT THE TESTING, AND THESE ENGINEERS WILL COOPERATE WITH THE BUYER TO PRODUCE THE QUALIFY PRODUCTS WITHIN THE TIME STIPULATED IN THE CONTRACT.

4. THE WELDING OF THE POLYMER PIPES AND THE SPECIAL WELDING MATERIALS SUCH AS THE ARC WELDING MACHINE AND

STAINLESS STEEL WELDING STICKS, WILL BE PROVIDED BY THE SELLER, THE BUYER SHALL PROVIDE THE COOPERATION BY PROVIDING THE ASSISTING PERSONNEL AND TOOLS.

5. PROVIDES THE SIGNAL WIRES, HIGH TEMPERATURE WIRES AND INSULATION WIRES FOR THE MACHINES THE SELLER SUPPLIED.

3.2 BUYER:

1. RESPONSIBLE FOR THE HEAT INSULATING MATERIAL FOR THE EQUIPMENT AND THE CONSTRUCTION OF THE HEAT INSULATING WORK.

2. RESPONSIBLE FOR THE FOOD AND LODGING FOR THE SELLER'S ENGINEERS AND PROVIDE THE GOOD WORKING CONDITIONS FOR THE SELLER'S ENGINEERS.

3. RESPONSIBLE FOR THE CABLE TRUNKING PREPARATION AND LAYING.

4. RESPONSIBLE FOR THE CABLE FOR THE EXTRUDER.

5. RESPONSIBLE FOR THE UNLOADING, UNPACKING, POSITIONING OF THE EQUIPMENT.

6. RESPONSIBLE FOR THE MATERIALS FOR THE INSTALLATION SUCH AS THE ACETYLENE, OXYGEN, WELDING STICK, GLOVES, LIFTING DEVICE, WATER, ELECTRICITY, COMPRESSED AIR AND ETC.

7. RESPONSIBLE FOR THE NORMAL CABLES FOR THE EXTRUDER HEATING, GEAR PUMP MOTOR, OIL PUMP MOTOR, CONTACTING WIRE, BUTTON WIRE, DOWTHERM STOVE, AND ETC.

ANNEX 3:

SUPPLYING SCOPE

NOTE:

(S) — SELLER'S SUPPLYING SCOPE

(B) — BUYER'S SUPPLYING

SCOPE 4000 24 POSITION PET- POY SPINNING EQUIPMENT

ITEM 001

EXTRUDER

A. TYPE: HORIZONTAL

B. SCREW: Φ160mm L/D=25

C. DRIVING POWER: 132KW

D. HEATING POWER: 81KW

E. TEMP.DETECTING ELEMENT: PT100

F. AC FREQUENCY CONVERSION SPEED REGULATION, IMPORTED V BELT

G. 3 PHASES AC MOTOR, SIEMENS

QUANTITY: 2 SETS

ITEM 002

DETECTING HEAD

A. TYPE: JACKET TYPE HEATING

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

QUANTITY: 2 SETS

ITEM 003

POLYMER FILTER

A. TYPE: VERTICAL, TWO STAGES

D. FILTERING TYPE: CANDLE CORE

C. FILTERING AREA: 9.5-5.5

E. RATED FLOW: 700 TO 900KG/H

F. FILTERING PRECISION: ≤25μ

G. FILTERING CORE QUANTITY: 19X2, TOTALLY 38 PCS

QUANTITY: 2 SETS

ITEM 004

POLYMER PIPING

A. HEATING METHOD: JACKET TYPE

B. DESIGNED TEMP.: 310°C

C. DESIGNED PRESSURE:

JACKET: 0.2MPA

POLYMER PIPE: 25MPA

D. THE FLANGES' CONNECTION IS BY RED COPPER.

QUANTITY: 2 SETS

ITEM 005

SPINNING BEAM

A. TYPE: SINGLE SIDE OPERATION

B. POSITION: 2 POSITIONS /SPINNING BEAM

C. ENDS: 12 ENDS

D. DISTANCE: 1500mm

E. HEATING: DOWTHERM STOVE SYSTEM

F. DESIGNED TEMP.: 315°C

G. SPINNING BEAM SURFACE TEM. INCREASE: ≤60°C

H. SPINNING BEAM DESIGNED PRESSURE: 0.2MPA

I. DESIGNED PRESSURE FOR THE POLYMER PIPES:

BEFORE GEAR PUMP: 25MPA

AFTER GEAR PUMP: 35MPA

J. POLYMER VALVE: REFRIGERATED VALVE

QUANTITY: 12 SETS

ITEM 006

SPINNING BEAM RACK

A. MATERIAL: CARBON STEEL STRUCTURE

QUANTITY: 2 SETS

ITEM 007

GEAR PUMP

A. TYPE: PLANETARY TYPE

B. SPECIFICATIONS: 12X3.0CC/REV

C. INLET QUANTITY/OUTLET QUANTITY: 1/12

QUANTITY: 24 SETS

ITEM 008

GEAR PUMP DRIVING DEVICE

A. DRIVING METHOD: 1 SET OF DRIVING DEVICE FOR EACH POSITION

B. TYPE: VERTICAL SYNCHRONIZATION MOTOR + PLANETARY TYPE REDUCER + PULLING DRIVING SHAFT

C. MOTOR POWER: 2.2KW

D. SPEED RATIO: 1:43

QUANTITY: 24 SETS

ITEM 009

GEAR PUMP DRIVING FRAME

A. TYPE: CARBON STEEL STRUCTURE

B. U-STEEL FOR INSTALLING THE GEAR PUMP DRIVING WILL BE PROVIDED BY THE SELLER.

QUANTITY: 12 SETS

ITEM 010

SPIN PACK

A. TYPE: CYLINDER TYPE, BOTTOM MOUNTED

B. QUANTITY: 12 PCS PER POSITION

C. DIAMETER: Φ90mm

D. SPINNERET QUANTITY: 1 SPINNERET PER SPIN PACK

E. FILTERING TYPE: STEEL NET AND FILTER SAND TYPE

F. DESIGNED PRESSURE: 35MPA

G. NOT INCLUDING THE NET, WASHER AND GASKET

H. 288 SETS IN USING AND 2488 SETS FOR STAND BY

QUANTITY: 576 SETS

ITEM 011

SPINNERET

A. TYPE: ROUND

B. DIAMETER: Φ90mm

C. NO OF HOLE: 48 TO 96

QUANTITY: 576 PCS

ITEM 012

YARN DUCT

A. TYPE: RECTANGLE TYPE

B. MATERIAL: HIGH QUALITY ALUMINUM

QUANTITY: 24 SETS

ITEM 013

DOWTHERM BOILER

B. TYPE: ELECTRIC HEATING, CONTAINER TYPE

C. DESIGNED TEMP.: 350°C

D. DESIGNED PRESSURE: 0.2MPA

E. HEATING POWER: 65KW

E. VOLUME:600L

F. SAFETY DEVICE:

1) ELECTRIC CONTACT POINT PRESSURE GAUGE

2) EXPLOSION PREVENTION FILM PACK

3) DOUBLE SAFETY VALVE

4) OVER HEATING PREVENTION ALARM DEVICE

5) TIPPING PLATE TYPE LIQUID LEVEL GAUGE

QUANTITY: 2 SETS

ITEM 014

GENERAL PARTS FOR THE DOWTHERM PIPING

SEAMLESS STEEL PIPE, PIPING, ELBOW, TEE, STANDARD FITTING FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 015

SPECIAL PARTS FOR DOWTHERM SYSTEM

VALVE, FLANGE, GRAPHITE WINDED GASKET FOR THE DOWTHERM CIRCULATION SYSTEM.

QUANTITY: 2 SETS

ITEM 016

DISCHARGE TANK

QUANTITY: 2 PCS

ITEM 017

QUENCHING CHAMBER

A. TYPE: CROSS BLOWING

B. BLOWING AREA: 1430mm X 1380mm

C. WITH HEAT INSULATION PLATE

D. WITH AIR FLOW REGULATION VALVE

E. WITH PLATE TYPE FILTER

F. WITH OIL FRAME SLIDING GROOVE

G. WITH QUENCHING CHAMBER DOOR

QUANTITY: 24 SETS

ITEM 018

QUENCHING CHAMBER FRAME

A. TYPE: CARBON STEEL STRUCTURE

QUANTITY: 24 SETS

ITEM 019

OILING DEVICE

A. OILING NOZZLE (12 PCS OF OILING NOZZLE PER POSITION)

B. YARN GUIDE HOOK (12 PCS OF YARN GUIDE HOOK PER POSITION)

QUANTITY: 24 SETS

ITEM 020

OIL PUMP

A. SPECIFICATIONS: 12X0.12CC/REV

B. INLET QUANTITY/OUTLET QUANTITY: 1/12

C. ORIGIN: SUZHOU HUAXI

QUANTITY: 24 SETS

ITEM 021

DRIVING DEVICE FOR OIL PUMP

A. INCLUDING MOTOR, REDUCER AND SUPPORT PLATE

QUANTITY: 24 SETS

ITEM 022

OIL TANK

A. WITH OIL FILTER

B. WITH PIPING, VALVE, DUPLEX FILTER, FILTERING PRECISION: 10UM

C. WITH FLOATING BALL VALVE, DISCHARGE VALVE, OVERFLOW

QUANTITY: 2 SETS

ITEM 023

PIPING AND WIRING OUTSIDE THE EQUIPMENT

SUCH AS THE PIPING AND ACCESSORIES FOR REFRIGERATED WATER, COMPRESSED AIR.

QUANTITY: 1 SET

ITEM 024

CONTROLLING PANEL FOR THE EXTRUDER

VOLTAGE, CURRENT, RPM, EXTRUDER PRESSURE BEFORE FILTER, ALARM, PRESSURE CONTROL, DISPLAY AND ALARM AFTER THE FILTER. THE EXTRUDER'S INVERTER IS FROM JAPAN YASKAWA.

QUANTITY: 2 SETS

ITEM 025

TEMP. CONTROLLING PANEL FOR SPINNING MACHINE

JAPANESE RKC TEMPERATURE GAUGE

QUANTITY: 2 PCS

ITEM 026

CONTROLLING PANEL FOR GEAR PUMP

THE CONTROLLING METHOD FOR THE GEAR PUMP INVERTER IS 1 CONTROLLING FOR EACH POSITION. THE INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 027

SWITCH BOX FOR GEAR PUMP

1 PIECE PER POSITION

QUANTITY: 24 PCS

ITEM 028

CONTROLLING CABINET FOR OIL PUMP

VERTICAL TYPE, DOORS CAN BE OPENED IN THE FRONT AND BACK, OIL PUMP INVERTER CONTROLLING METHOD: 1 CONTROLLING PER POSITION INVERTER IS FROM JAPAN YASKAWA

QUANTITY: 2 PCS

ITEM 029

POLYMER PRESSURE SENSOR (BEFORE FILTER)

0-25MAP (WITH SCENE DISPLAY)

QUANTITY: 2 PCS

ITEM 030

POLYMER PRESSURE SENSOR (AFTER FILTER)

0-35MPA (ITALY GEFRAN, WITH SCENE INDICATION)

QUANTITY: 2 PCS

ITEM 031

PRESSURE SENSOR FOR SPIN PACK

0-35MPA (WITH SCENE INDICATION, DIGITAL DISPLAY

QUANTITY: 2 PCS

ITEM 032

TEMPERATURE FOR DIFFERENT ZONES OF THE EXTRUDER

(TICA) PT100

QUANTITY: 12 PCS

ITEM 033

TEMP. SENSOR FOR EXTRUDER HEAD

(TIA) PT100

QUANTITY: 2 PCS

ITEM 034

TEMP.SENSOR FOR SPIN BEAM

(TIA) PT100

QUANTITY: 2 PCS

ITEM 035

PRESSURE SENSOR FOR DISCHARGE BOX

(TIA) PT100

QUANTITY: 2 PCS

ITEM 036

ELECTRIC CONTACT POINT PRESSURE GAUGE FOR DOWTHERM BOILER

(PICA) PT100, 0 TO 0.25MPA

QUANTITY: 2 PCS

ITEM 037

EXPLOSION FILM PACK

0-0.25MPA

QUANTITY: 2 SETS

ITEM 038

HIGH TEMPERATURE WIRE, SIGNAL WIRE

QUANTITY: 2 SETS

ITEM 039

NORMAL CABLE

QUANTITY: 1 SET

ITEM 040

TEMP. SENSOR FOR DOWTHERM STEAM

(TICA) PT100

QUANTITY: 2 PCS

ITEM 041

TEMP. SENSOR FOR DOWTHERM OVER HEATING PREVENTION

(TICA) PT100

QUANTITY: 2 PCS

ITEM 042

1800-12 AUTOMATIC WINDER

A. MECHANICAL SPEED: MAX: 4000M/MIN

B. PROCESSING SPEED: 2800 TO 3300M/MIN

C. 12 ENDS/PER WINDER

D. YARN PACKAGE: 15KG/BOBBIN

QUANTITY: 24 SETS

ITEM 043

COMPRESSED AIR TREATMENT SYSTEM

A. 24 POSITIONS PER SIDE, WITH PRECISE FILTER, EACH SIDE HAS 2 PCS PRESSURE RELEASE VALVES.

QUANTITY: 1 SIDE

ITEM 044

TAKE UP FRAME: NEW MOVABLE TYPE

A. DISTANCE: 1500mm

B. 2 POSITIONS PER SET, PROFILE STEEL STRUCTURE, SINGLE SIDE OPERATION, TAKE UP SWITCH BOX 1 PIECE, INCLUDING THE CONTACT FOR THE FIRST AND SECOND FLOORS AND TIMING AND LENGTH DISPLAY, 1 SET OF YARN GUIDE SYSTEM WITH A YARN BLOCKING PLATE.

QUANTITY: 12 SETS

ITEM 045

CR1 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 046

CR2 SYSTEM

A. DIMENSIONS: φ160 X 160mm

B. SURFACE TREATMENT: CERAMIC COATING

C. MOTOR POWER: 0.3KW

QUANTITY: 24 SETS

ITEM 047

PRE-INTERMINGLING

A. 12 PCS PER POSITION

B. ORIGIN: AWA, JAPAN

24 SETS

ITEM 048

YARN ASPIRATOR

A. 1 PIECE PER SET

B. ORIGIN: CHINA

QUANTITY: 2 SETS

ITEM 049

YARN BREAK SENSOR

A. 12 PCS PER POSITION

B. ORIGIN: CHINA

QUANTITY: 24 SETS

ITEM 050

PNEUMATIC PIPING FOR TAKE UP

24 POSITIONS PER SET, QUICK CONNECTION TYPE

QUANTITY: 1 SET

ITEM 051

YARN DISTRIBUTION SUCTION GUN AND WASTE YARN PIPE

B. WATER YARN BASKET WILL BE PREPARED BY THE CUSTOMER

C. INCLUDING THE HIGH PRESSURE HOSE AND WASTE YARN PIPE

QUANTITY: 6 SETS

ITEM 052

COLD GODET CONTROLLING CABINET

A. VERTICAL, DOORS OPENED IN THE FRONT

B. 1 SET PER POSITION

C. JAPAN YASKAWA INVERTER

QUANTITY: 24 POS

ITEM 053

FREQUENCY CONVERSION CABINET FOR TAKE UP

BACK TO BACK, DOORS OPENED IN THE FRONT, 1 CONTROLLING FOR PER SET, INCLUDING ELECTRIC CONTROLLING BOX, INVERTER AND ETC.

QUANTITY: 24 SETS

ITEM 054

BASIC PLATE FOR WINDER

A. 1 POSITION PER SET

QUANTITY: 24 SETS

ITEM 055

CABLE

INSULATION CABLE

QUANTITY: 1 SET

CABLE FOR WINDER

QUANTITY: 1 SET

CABLE FROM THE CONTROLLING CABINET TO THE EQUIPMENT

QUANTITY: 1 SET

ITEM 056

BRIDGE FOR CABLE

QUANTITY: 1 SET

SPARE PARTS LIST

ITEM 057

SCREW DISMANTLE TOOLS FOR EXTRUDER

QUANTITY: 1 SET

ITEM 058

SPECIAL TOOLS FOR FILTER

QUANTITY: 1 SET

ITEM 059

WRENCH FOR GEAR PUMP

QUANTITY: 1 SET

ITEM 060

LIFTING ROD FOR SPIN PACK

QUANTITY: 2 SETS

ITEM 061

DISMANTLE TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 062

FASTENING TOOLS FOR SPIN PACK

QUANTITY: 1 SET

ITEM 063

DISMANTLE TOOLS FOR YARN GUIDE DISC

QUANTITY: 1 SET

ITEM 064

DOFFING CART

QUANTITY: 1 SET

ITEM 065

TOOLS FOR INSTALLING THE SPIN PACK

QUANTITY: 1 SET

ITEM 066

TRANSPORTATION TROLLEY FOR WINDER

QUANTITY: 1 SET

ITEM 067

DISCHARGED YARN BLOCKING PLATE

QUANTITY: 24 PCS

ITEM 068

PUMP FOR DISCHARGE THE YARN

QUANTITY: 24 PCS

ITEM 069

SPECIAL TOOL FOR WINDER

QUANTITY: 1 SET

OTHER EQUIPMENT

UTILITIES

1 CRYSTALLIZER AND DRYER 1 SET

2 AHU 1 SET

3 COMPRESSOR 1 SET

4 CHILLER 1 SET

AUXILIARY EQUIPMENT LIST

1 VACUUM CLEANING OVEN 1 SET

2 ALKALI-WATER CLEANING TANK 1 SET

3 ULTRASONIC CLEANER 1 SET