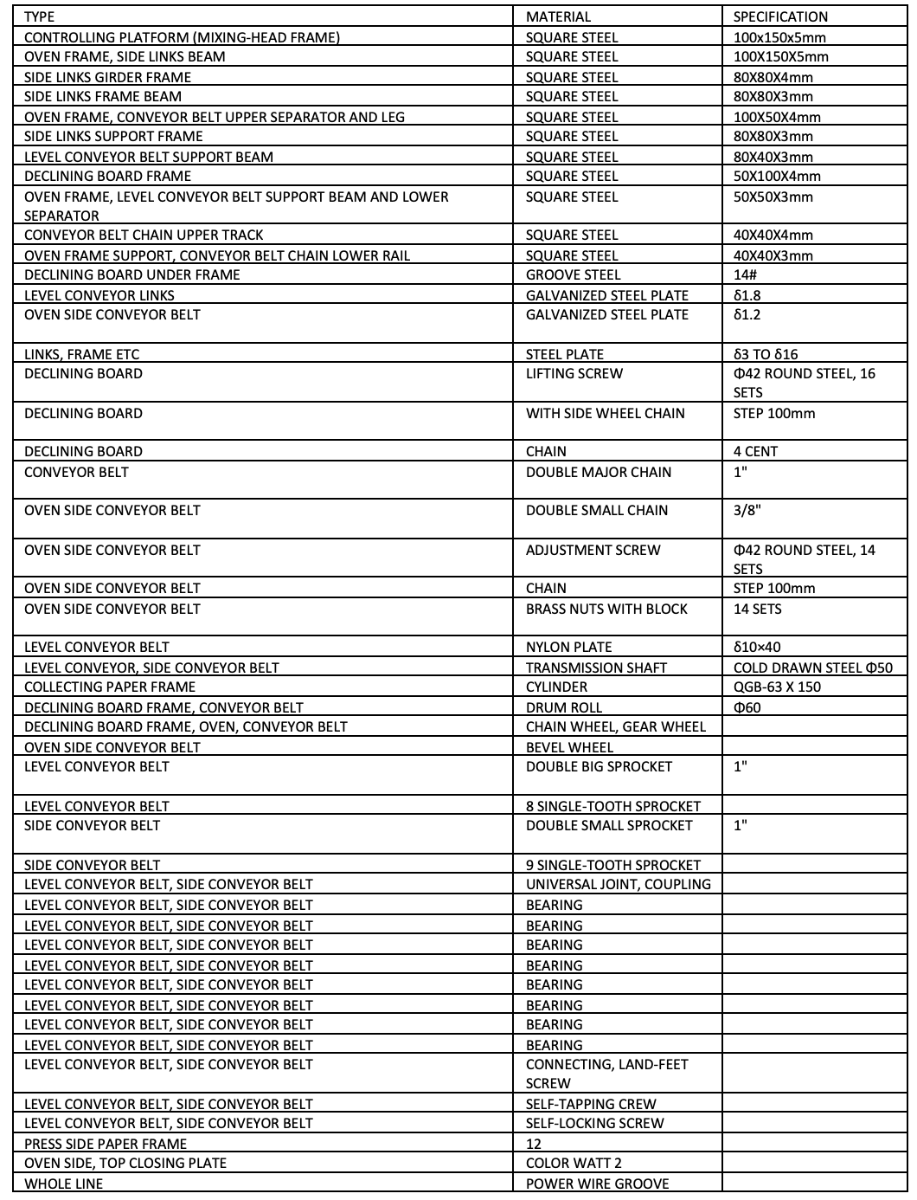

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR

YY-1357 HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR

MAIN TECHNICAL SPECIFICATION:

1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm

2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm

3.FOAMING HEIGHT: 1200mm

4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3

5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE

6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE

7.MATERIAL SPRAYING METHOD: TROUGH

8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS

9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY);

10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT

11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING

12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL

13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE

14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY

15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS

16. MIXING HEAD SIZE: Φ100mm

18.MIXING HEAD MOTOR: 30 KW

19.TOTAL POWER: ABOUT 80 KW

In stock

SKU

YY-1357

REFERENCE NUMBER: YY-1357

HORIZONTAL CONTINUOUS FOAMING MACHINE, 21000 KG PER HOUR

CAPACITY: 80 TO 350 KG PER MINUTE OR 4800 TO 21000 KG PER HOUR

DETAILS:

MAIN TECHNICAL PARAMETERS AND EQUIPMENT

COMPLETE MACHINE COMPONENT SPECIFICATIONS:

1. FOAMING CONTROLLING PLATFORM LENGTH 3200mm x WIDTH 2500mm x HEIGHT 600mm

2. OVEN DECLINING BOARD: LENGTH 6000mm x WIDTH 1100mm x 2300mm HEIGHT

3. OVEN SIDE LINKS: LENGTH 15000mm x WIDTH 2500mm x HEIGHT 1250mm

4. OVEN MACHINE FRAME LENGTH 15000mm x WIDTH 3200mm x HEIGHT 2850mm

5. OVEN INNER CONVEYOR LINE: LENGTH 16000mm x WIDTH 2400mm x HEIGHT 800mm

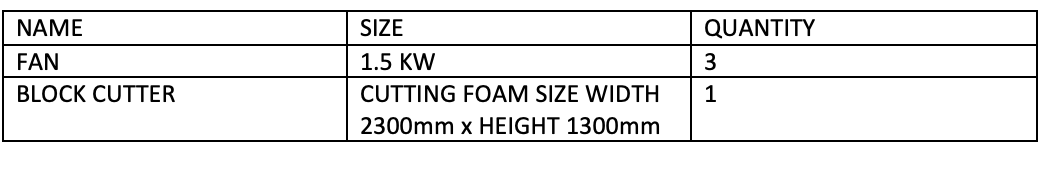

6. FOAM BLOCK CUTTING MACHINE FOR FOAM SIZE: WIDTH 2300mm x HEIGHT 1300mm

7. BACK ROLLER CONVEYOR LINE: LENGTH 3000mm x WIDTH 2400mm x HEIGHT 800mm

MAIN TECHNICAL SPECIFICATION:

1.TOTAL LENGTH: 35000mm × WIDTH 4500mm × HEIGHT 3000mm

2. FOAMING WIDTH 1000mm TO APPROXIMATELY 2300mm

3.FOAMING HEIGHT: 1200mm

4.FOAMING DENSITY: 8 KG PER m3 TO APPROXIMATELY 80 KG PER m3

5.FOAMING SPEED: 0 TO 6.8 METERS PER MINUTE

6.MAX TOTAL OUTPUT: 80 LITERS TO 350 LITERS PER MINUTE

7.MATERIAL SPRAYING METHOD: TROUGH

8.ALL KINDS OF VALVES, PIPES AND SPARE PARTS

9.THE MEMBRANE AUTOMATICALLY RECEIVES THE VOLUME INSTALLMENT (TO USE THE NEWEST INSTALLMENT, TO GUARANTEE THAT IT RECEIVES VOLUME SIDE PAPER SMOOTHLY);

10.USES ENVIRONMENTALLY-FRIENDLY EQUIPMENT TO PURIFY EXHAUST GAS, NO POLLUTION PRESENT

11. RESPONSIBLE FOR ELECTRICAL, MECHANICAL MAINTENANCE PERSONNEL TRAINING

12.THE BLOCK CUTTER MACHINE CUTS THE BUN LENGTH USING ROTARY ENCODER AND THICKNESS GAUGE TO SETUP AND CONTROL

13. MIXING HEAD FRAME PLUS OVERHAUL STAND, LADDER AND BARRICADE

14.MIXING HEAD IS GERMAN PRECISION TECHNOLOGY

15.FOAMING OVEN, DECLINING BOARD AND OVEN INNER CONVEYOR MACHINE PARTS

16. MIXING HEAD SIZE: Φ100mm

18.MIXING HEAD MOTOR: 30 KW

19.TOTAL POWER : ABOUT 80 KW

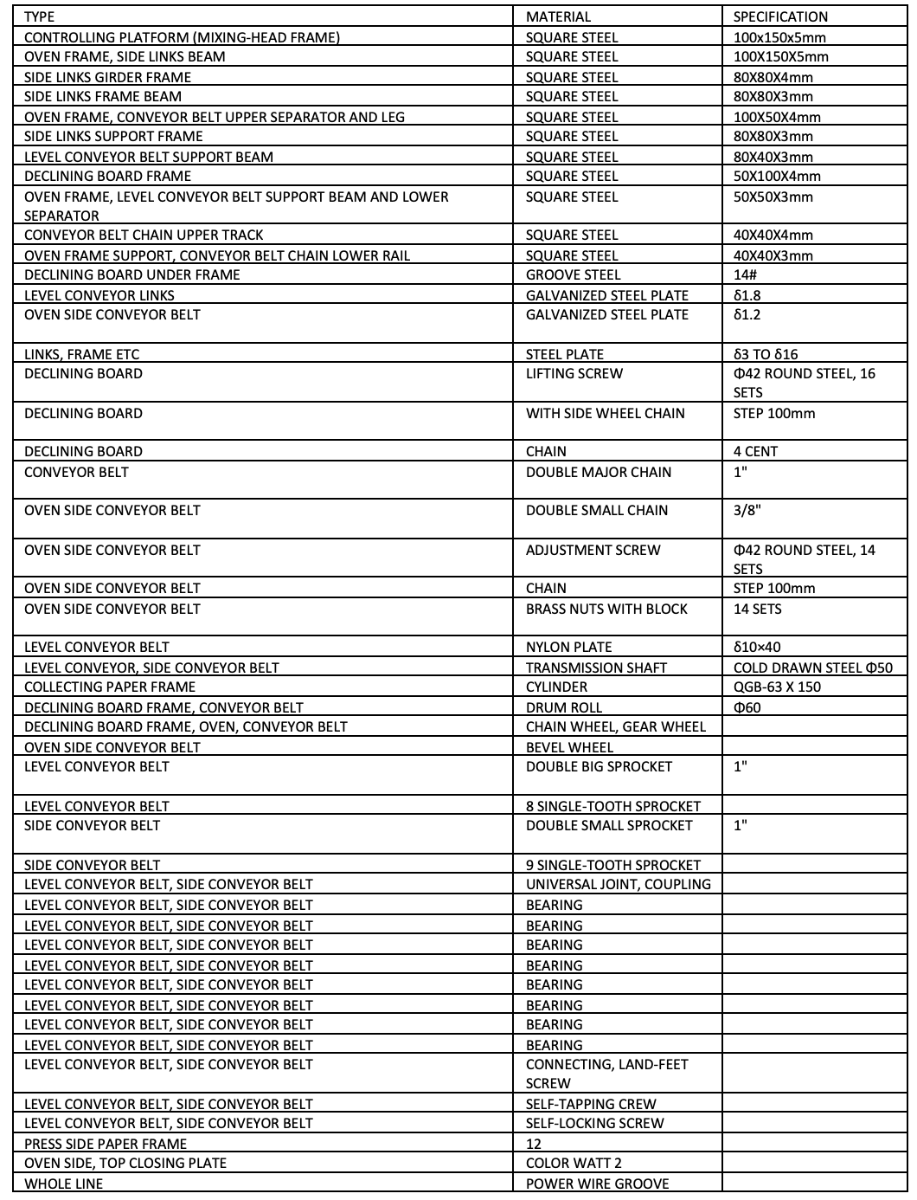

MAIN COLLOCATIONS AND MATERIAL CHOSE:

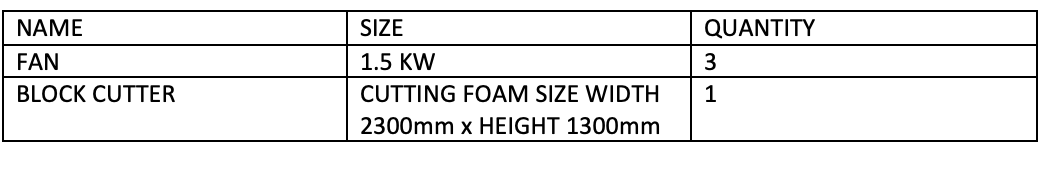

1. METAL MATERIAL AND OTHER ASSISTANT MATERIAL:

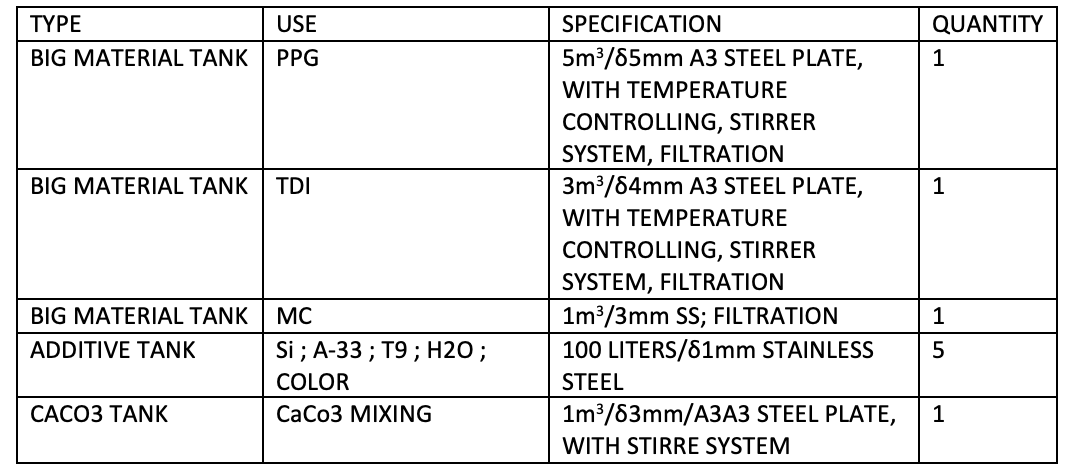

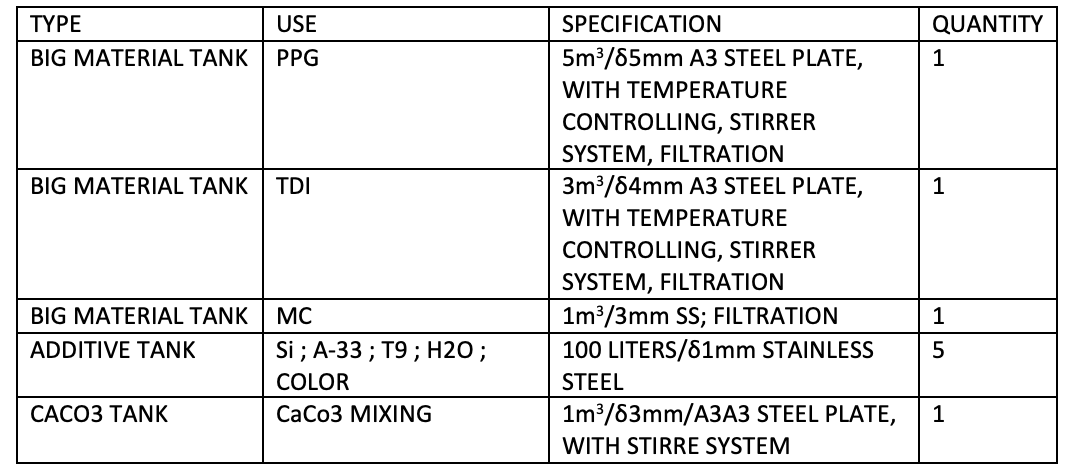

2. MATERIAL POT TYPES: (THE WORK PRESSURE IN THE POT IS NORMAL PRESSURE)

2. MATERIAL POT TYPES: (THE WORK PRESSURE IN THE POT IS NORMAL PRESSURE)

3. INVERTOR TYPES

3. INVERTOR TYPES

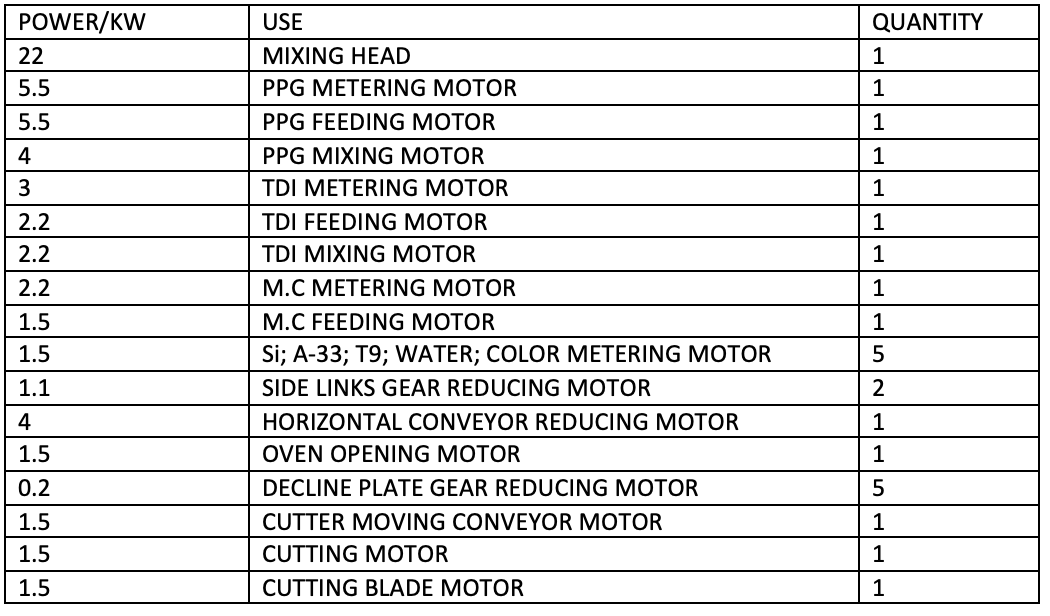

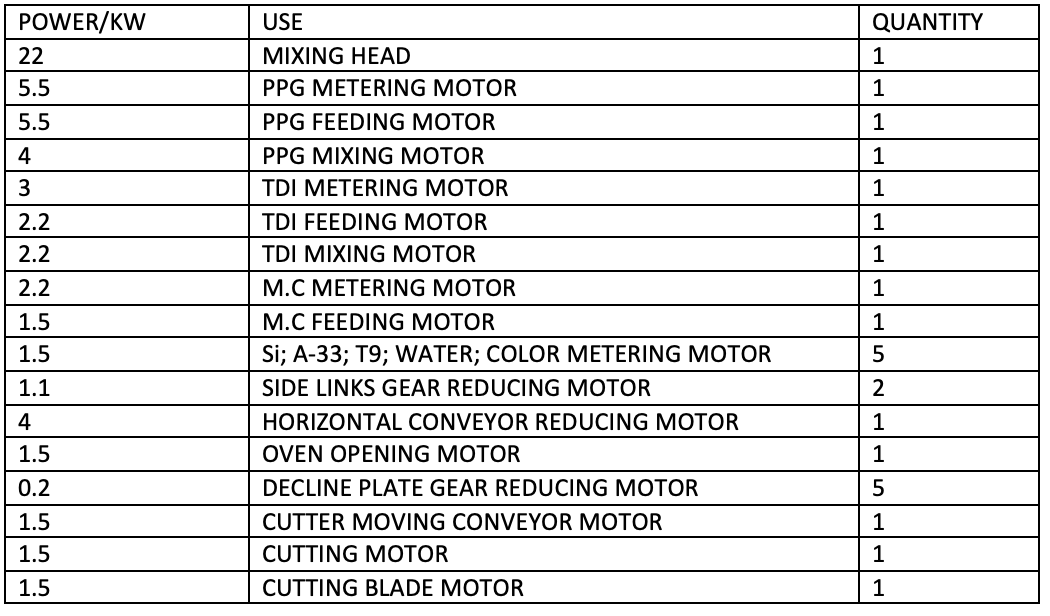

4. MOTOR TYPES

4. MOTOR TYPES

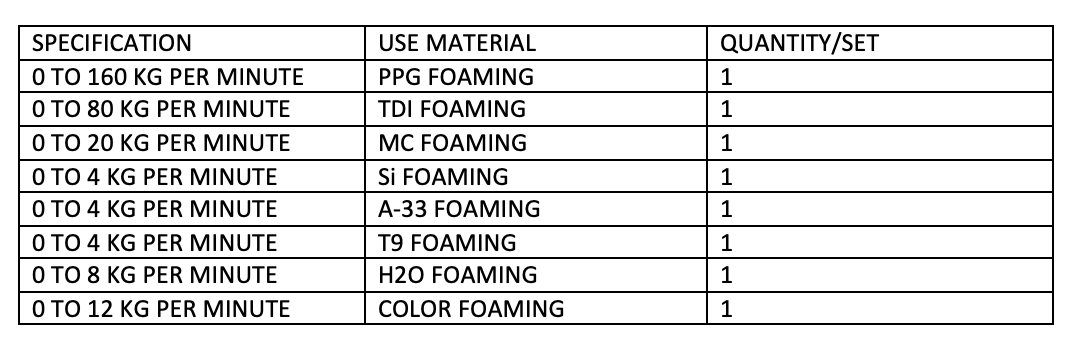

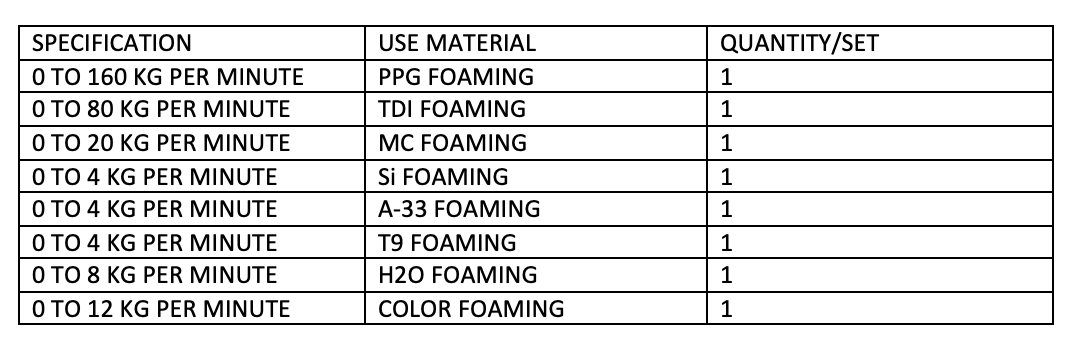

5. GEAR PUMP TYPES

5. GEAR PUMP TYPES

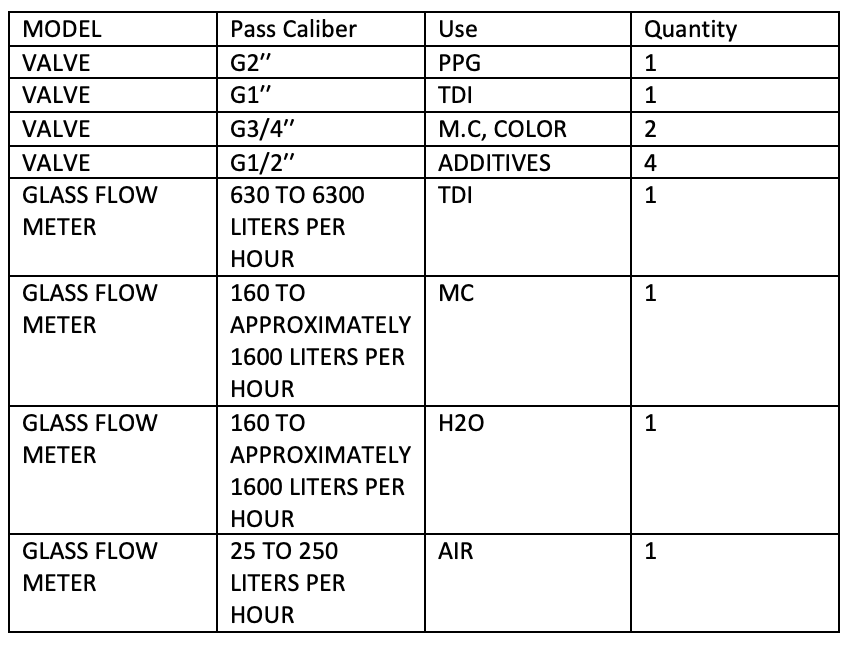

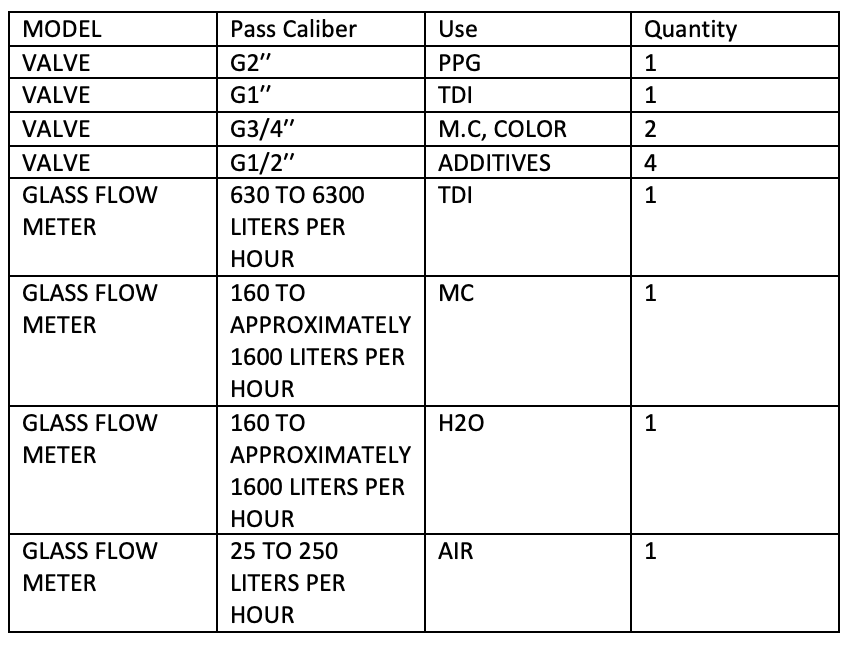

6. PNEUMATIC VALVE, FLOW METER EQUIPMENT TYPES

6. PNEUMATIC VALVE, FLOW METER EQUIPMENT TYPES

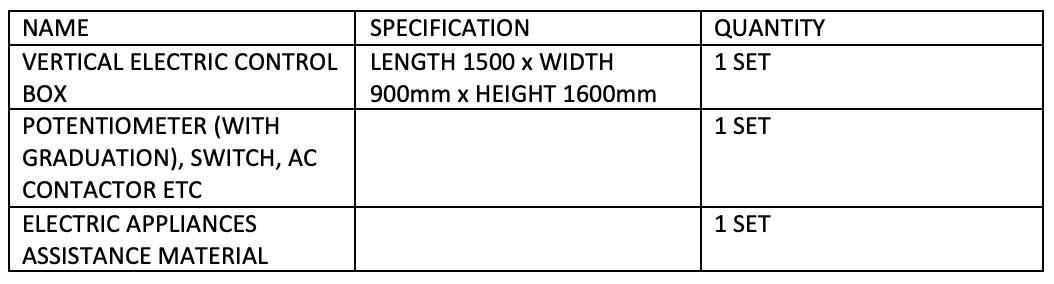

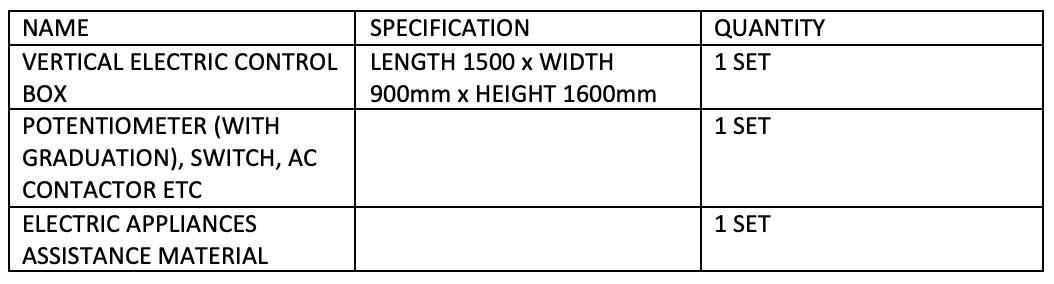

7. ELECTRONIC CONTROL, PNEUMATIC EQUIPMENTS TYPES

7. ELECTRONIC CONTROL, PNEUMATIC EQUIPMENTS TYPES

8. OTHER ASSISTANT EQUIPMENTS

8. OTHER ASSISTANT EQUIPMENTS

9. ALL KINDS OF VALVE, PIPE AND SPARE PARTS.

10. PLC AND HMI CONTROL.

11. 20 HP CHILLER FOR COOLING AND HEATING.

12. SILICON PRE-MIXER.

REQUIRES 1 TO 2 40 FOOT HQ CONTAINERS (DEPENDING ON IF ADDITIONAL CUTTING MACHINERY IS ALSO PURCHASED)

9. ALL KINDS OF VALVE, PIPE AND SPARE PARTS.

10. PLC AND HMI CONTROL.

11. 20 HP CHILLER FOR COOLING AND HEATING.

12. SILICON PRE-MIXER.

REQUIRES 1 TO 2 40 FOOT HQ CONTAINERS (DEPENDING ON IF ADDITIONAL CUTTING MACHINERY IS ALSO PURCHASED)

2. MATERIAL POT TYPES: (THE WORK PRESSURE IN THE POT IS NORMAL PRESSURE)

2. MATERIAL POT TYPES: (THE WORK PRESSURE IN THE POT IS NORMAL PRESSURE)

3. INVERTOR TYPES

3. INVERTOR TYPES

4. MOTOR TYPES

4. MOTOR TYPES

5. GEAR PUMP TYPES

5. GEAR PUMP TYPES

6. PNEUMATIC VALVE, FLOW METER EQUIPMENT TYPES

6. PNEUMATIC VALVE, FLOW METER EQUIPMENT TYPES

7. ELECTRONIC CONTROL, PNEUMATIC EQUIPMENTS TYPES

7. ELECTRONIC CONTROL, PNEUMATIC EQUIPMENTS TYPES

8. OTHER ASSISTANT EQUIPMENTS

8. OTHER ASSISTANT EQUIPMENTS

9. ALL KINDS OF VALVE, PIPE AND SPARE PARTS.

10. PLC AND HMI CONTROL.

11. 20 HP CHILLER FOR COOLING AND HEATING.

12. SILICON PRE-MIXER.

REQUIRES 1 TO 2 40 FOOT HQ CONTAINERS (DEPENDING ON IF ADDITIONAL CUTTING MACHINERY IS ALSO PURCHASED)

9. ALL KINDS OF VALVE, PIPE AND SPARE PARTS.

10. PLC AND HMI CONTROL.

11. 20 HP CHILLER FOR COOLING AND HEATING.

12. SILICON PRE-MIXER.

REQUIRES 1 TO 2 40 FOOT HQ CONTAINERS (DEPENDING ON IF ADDITIONAL CUTTING MACHINERY IS ALSO PURCHASED)

Write Your Own Review