Search results for: 'Pillow r'

- Related search terms

- pillow

- pillow co

- pillow+co

- pillow machine

- pillow c

-

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More -

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFT

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFTPILLOW DIMENSIONS (MAXIMUM): 800 x 600 x 200mm (ONCE COMPRESSED, HEIGHT IS 30mm)

Learn More

CAPACITY: 2 PILLOWS PER MINUTE (960 PILLOWS PER 8 HOUR SHIFT)

EXIT DIAMETER: 80 TO 200mm (CUSTOMIZED PER CUSTOMER, PLEASE SPECIFY WHEN ORDERING)

PRESSURE: 1.2 TONS

POWER: 6.37 KW

WEIGHT: 400 KGS

DIMENSIONS: 1850 x 2940 x 2100mm -

K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBSREFERENCE NUMBER: K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBS QUANTITY AVAILABLE: 1 Learn More

K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBSREFERENCE NUMBER: K-1332 PILLOW BLOWING, PILLOW SEWING AND ROUND STORAGE TUBS QUANTITY AVAILABLE: 1 Learn More -

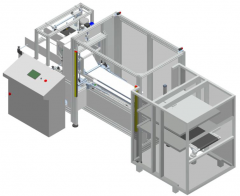

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

G-4840 PILLOW ROLL PACK MACHINE (NEW)REFERENCE NUMBER: G-4840 PILLOW ROLL PACK MACHINE (NEW) MAXIMUM PILLOW SIZE: 480mm x 74mm ROLLING OUTLET DIAMETER: 150mm PLASTIC BAG DIAMETER: 160mm DIMENSIONS: 1350 x 1120 x 1000mm AIRPRESSURE: 0.5 TO 0.8 MPa POWER: .75 kw PILLOW WIDTH: 400mm OR UPON CUSTOMER REQUEST WEIGHT: 400mm CYLINDER DIAMETER: 150mm MAXIMUM WEIGHT OF PILLOW: 750g QUANTITY AVAILABLE: 1 Learn More

G-4840 PILLOW ROLL PACK MACHINE (NEW)REFERENCE NUMBER: G-4840 PILLOW ROLL PACK MACHINE (NEW) MAXIMUM PILLOW SIZE: 480mm x 74mm ROLLING OUTLET DIAMETER: 150mm PLASTIC BAG DIAMETER: 160mm DIMENSIONS: 1350 x 1120 x 1000mm AIRPRESSURE: 0.5 TO 0.8 MPa POWER: .75 kw PILLOW WIDTH: 400mm OR UPON CUSTOMER REQUEST WEIGHT: 400mm CYLINDER DIAMETER: 150mm MAXIMUM WEIGHT OF PILLOW: 750g QUANTITY AVAILABLE: 1 Learn More -

YY-2078 AUTOMATIC ROLL PACKING MACHINE FOR PILLOW AND QUILTSYY-2078 AUTOMATIC ROLL PACKING MACHINE FOR PILLOW AND QUILTS PACKING SIZE: 2618 X 1540 X 1812 mm, 7.31 CBM QUANTITY: 1 Learn More

YY-2078 AUTOMATIC ROLL PACKING MACHINE FOR PILLOW AND QUILTSYY-2078 AUTOMATIC ROLL PACKING MACHINE FOR PILLOW AND QUILTS PACKING SIZE: 2618 X 1540 X 1812 mm, 7.31 CBM QUANTITY: 1 Learn More -

J-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTEJ-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTE POWER: 11.2 KW WEIGHT: 1000 KG AIR PRESSURE: 0.4 TO 0.8 Mpa FRONT BELT CONVEYOR: 750 x 1430 x 700mm PRESSING PLATE BELT: 650 x 1100mm PRESSING PLATE: 750 x 950mm STROKE HEIGHT: 300mm MIDDLE BELT CONVEYOR: 800 x 1800 x 750mm WRAPPING MACHINE: 620 x 2800 x 1200mm ELECTRIC CABINET: 450 x 800 x 1000mm OVERALL DIMENSIONS: 2800 x 5100 x 2050mm OVERALL VOLUME: 13 CUBIC METERS QUANTITY: 1 Learn More

J-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTEJ-4026 FLAT PILLOW ROLLER, FLATTENING AND ROLLING MACHINE – 6 PIECES PER MINUTE POWER: 11.2 KW WEIGHT: 1000 KG AIR PRESSURE: 0.4 TO 0.8 Mpa FRONT BELT CONVEYOR: 750 x 1430 x 700mm PRESSING PLATE BELT: 650 x 1100mm PRESSING PLATE: 750 x 950mm STROKE HEIGHT: 300mm MIDDLE BELT CONVEYOR: 800 x 1800 x 750mm WRAPPING MACHINE: 620 x 2800 x 1200mm ELECTRIC CABINET: 450 x 800 x 1000mm OVERALL DIMENSIONS: 2800 x 5100 x 2050mm OVERALL VOLUME: 13 CUBIC METERS QUANTITY: 1 Learn More -

M-3007 ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOP

M-3007 ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOPREFERENCE NUMBER: M-3007

ATLANTA ATTACHMENT RUFFLER FLANGER FOR PILLOW TOP

ATLANTA ATT. MODEL #1335

PILLOW TOP MACHINE RUFFLER

BRAND: ATLANTA ATTACHMENT

MODEL: 1335MF

NEEDLE: SN 62×5721

INCLUDES:

-S.S. TABLE WITH AIR FLOTATION ON IT

-SEWING TABLE, MOTOR AND ELECTRICAL BOXES

-METAL FRAME FOR MATERIAL FEEDING

NOTE: THE SEWING HEAD HAS (4) EYELETS FOR THREAD

AUTOMATIC FLANGER

Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More