COMPACT FOAMING LINES

-

TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014 1. HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE 2. YEAR OF CONSTRUCTION 2014 3. MACHINE TYPE: BLOCK FOAMING LINE 4. BRAND: HENNECKE GMBH 5. MODEL: BFM COMPACT 6. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More

TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014 1. HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE 2. YEAR OF CONSTRUCTION 2014 3. MACHINE TYPE: BLOCK FOAMING LINE 4. BRAND: HENNECKE GMBH 5. MODEL: BFM COMPACT 6. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More -

J-4921 HENNECKE POLYURETHANE TECHNOLOGY BFM COMPACT (BLOCFOAMAT – BATCH TYPE) FOAMING MACHINE, YEAR 2009J-4921 HENNECKE POLYURETHANE TECHNOLOGY BFM COMPACT (BLOCFOAMAT – BATCH TYPE) FOAMING MACHINE, YEAR 2009 MAKE: HENNECKE POLYURETHANE TECHNOLOGY MODEL: BFM COMPACT (BLOCFOAMAT) QUANTITY: 1 Learn More

J-4921 HENNECKE POLYURETHANE TECHNOLOGY BFM COMPACT (BLOCFOAMAT – BATCH TYPE) FOAMING MACHINE, YEAR 2009J-4921 HENNECKE POLYURETHANE TECHNOLOGY BFM COMPACT (BLOCFOAMAT – BATCH TYPE) FOAMING MACHINE, YEAR 2009 MAKE: HENNECKE POLYURETHANE TECHNOLOGY MODEL: BFM COMPACT (BLOCFOAMAT) QUANTITY: 1 Learn More -

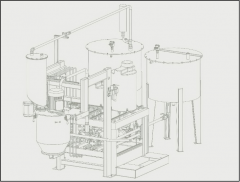

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More