Search results for: 'wire drawing'

-

TT-8205 EUROLLS MULTIPLE WIRE DRAWING MACHINE - DRY, YEAR 2006TT-8205 EUROLLS MULTIPLE WIRE DRAWING MACHINE - DRY, YEAR 2006 1. BRAND: TEAM MECCANICA / EUROLLS 2. SECOND-HAND 3. TYPE: 6 BLOCKS 4. YEAR OF CONSTRUCTION 2006 Learn More

TT-8205 EUROLLS MULTIPLE WIRE DRAWING MACHINE - DRY, YEAR 2006TT-8205 EUROLLS MULTIPLE WIRE DRAWING MACHINE - DRY, YEAR 2006 1. BRAND: TEAM MECCANICA / EUROLLS 2. SECOND-HAND 3. TYPE: 6 BLOCKS 4. YEAR OF CONSTRUCTION 2006 Learn More -

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More -

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More -

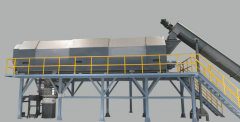

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More -

M-5221 NONWOVEN LINE WIDTH 2500mm

M-5221 NONWOVEN LINE WIDTH 2500mmREFERENCE NUMBER: M-5221 (1313565TNY12RX) L

NONWOVEN LINE WIDTH 2500mmCARD FEEDING

CARDINGQUANTITY AVAILABLE: 1

Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

TT-1885 MITSUI-ALSTOM STEAM TURBINE PLANT, 97.5MW 60HzTT-1885 MITSUI-ALSTOM STEAM TURBINE PLANT, 97.5MW 60Hz MITSUI-ALSTOM STEAM TURBINE PLANT NEVER-USED 13800V 97.5MW 60Hz AVAILABILITY IMMEDIATELY AVAILABLE QUANTITY: 1 Learn More

TT-1885 MITSUI-ALSTOM STEAM TURBINE PLANT, 97.5MW 60HzTT-1885 MITSUI-ALSTOM STEAM TURBINE PLANT, 97.5MW 60Hz MITSUI-ALSTOM STEAM TURBINE PLANT NEVER-USED 13800V 97.5MW 60Hz AVAILABILITY IMMEDIATELY AVAILABLE QUANTITY: 1 Learn More -

TT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTETT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTE MAXIMUM BUN SIZE: LENGTH 3000mm x WIDTH 2200mm x HEIGHT 1300mm MAIN FEATURES OF CONTOUR CUTTER: 1. ELIMINATES THE NEED TO MAKE, REPAIR AND STORE TEMPLATES; 2. INTEGRATED DESIGN & CUTTING PROGRAM. JUST DESIGN AND CUT; 3. COST SAVINGS BY AUTOMATICALLY ARRANGING THE PRODUCT (NESTING OF SHAPES TO MAXIMIZE MATERIAL USAGE) 4. SUPPORTS NUMERIC INSTRUMENTS; 5. HIGHER MATERIAL UTILIZATION RESULTING FROM COMPUTER AIDED NESTING OF SHAPES; 6. CUT SPEED CAN BE SET TO ARRIVE AT THE BEST CUT SPEED FOR DIFFERENT FOAMS; 7. CAN PRE-CUT ON THE COMPUTER TO CHECK CUTTING COURSE; Learn More

TT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTETT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTE MAXIMUM BUN SIZE: LENGTH 3000mm x WIDTH 2200mm x HEIGHT 1300mm MAIN FEATURES OF CONTOUR CUTTER: 1. ELIMINATES THE NEED TO MAKE, REPAIR AND STORE TEMPLATES; 2. INTEGRATED DESIGN & CUTTING PROGRAM. JUST DESIGN AND CUT; 3. COST SAVINGS BY AUTOMATICALLY ARRANGING THE PRODUCT (NESTING OF SHAPES TO MAXIMIZE MATERIAL USAGE) 4. SUPPORTS NUMERIC INSTRUMENTS; 5. HIGHER MATERIAL UTILIZATION RESULTING FROM COMPUTER AIDED NESTING OF SHAPES; 6. CUT SPEED CAN BE SET TO ARRIVE AT THE BEST CUT SPEED FOR DIFFERENT FOAMS; 7. CAN PRE-CUT ON THE COMPUTER TO CHECK CUTTING COURSE; Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

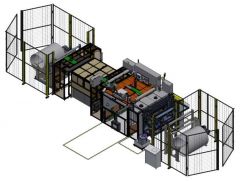

NANOSPIDER - ELECTROSPINREFERENCE NUMBER: A-2510 NANOSPIDER - ELECTROSPIN FIRST – (ROUNDED TANKS) NEW GENERATION NS PRODUCTION LINE ALLOWS NANOFIBERS TO BE PRODUCED ON A FULLY-INDUSTRIAL SCALE FOR A NUMBER OF APPLICATIONS FEATURES: • CONSTRUCTION USING SELF - EXTINGUISHING MATERIALS • VENTILATED SPINNING CHAMBER, PREVENTING THE ESCAPE OF SOLVENT FUMES • GROUNDING ROD FOR CHARGE DISSIPATION AND AUTOMATIC GROUNDING SYSTEM • FOUR EMERGENCY - STOP BUTTONS ARE PLACED ON THE CORNERS OF THE UNIT • ONE EMERGENCY - STOP BUTTON IS PLACED ON THE SERVICE CONTROL PANEL • THE TWO UPWARD SLIDING DOORS ARE EQUIPPED WITH AUTOMATIC DOOR LOCKS WITH LIMIT SWITCHES TO PREVENT ACCIDENTAL OPENING AND WILL ALSO SHUT DOWN THE UNIT IF A SLIDING DOOR IS ACCIDENTALLY OPENED • THE FOUR LOWER SWING OPEN DOORS HAVE LIMIT SWITCHES THAT WILL SHUT DOWN THE UNIT IF THE DOOR IS ACCIDENTALLY OPENED • FIRE SUPPRESSION SYSTEM FOR THE SPINNING CHAMBER WITH MANUAL ACTIVATION VIA BUTTON ON THE CONTROL PANELS • THE EQUIPMENT IS PRODUCED ACCORDING TO CE STANDARDS • RECOMMENDED ROOM LAYOUT: THE LAYOUT WILL BE OPTIMIZED ACCORDING TO BUYER NEEDS • LIGHTS ON THE FRONT AND BACK OF MACHINE SPECIFICATIONS: POLYMER (PROCESS) TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • CYLINDRICAL TANKS ON WHEELS, ONE FOR FRESH POLYMER • CYLINDRICAL TANKS ON WHEELS, ONE FOR WASTE • MIXING CAPABILITY (PNEUMATIC MIXTURE) FOR IN AND OUT TANKS - PNEUMATIC DRIVEN AGITATOR • CLEANING SHOWER FOR BOTH IN AND OUT TANK • TWO CYLINDRICAL SHAPED TANKS ON THE WHEELS IN ONE TUB • BURST DISK FOR EACH TANK • QUICK COUPLINGS STÄUBLI HCB 08 WORKING VOLUME OF TANKS IS 60 LITERS FOR EACH TANK CLEANING TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • TANK WITH VOLUME OF 60 LITERS WILL BE DIVIDED INTO TWO SECTIONS: 30 L FOR CLEAN,30 L USED CLEANING SOLUTION • CYLINDRICAL TANK ON WHEELS - SIZE ROUGHLY HALF OF THE PROCESS TANKS • BURST DISK FOR EACH TANK VOLUME 30 + 30 LITERS WILL BE POSSIBLE TO USE MULTIPLE TIMES FOR CLEANING SITE PREPARATION / CONNECTION REQUIREMENTS ALL POWER SUPPLY IS REALIZED FOR FULL LINE INCLUDING PERIPHERAL PARTS. IT IS JUST NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ AND 50/60Hz, MAIN CIRCUIT BREAKER 32 A POWER CONSUMPTION: UP TO 12 KW PRESSURE AIR: 5 TO 8 BAR, CONNECTION POINT CAPACITY 1000 L/min INERT GAS: 0.5 BAR, CONNECTION POINT CAPACITY 200 L/min PROCESS AIR INLET/OUTLET: UP TO 1000 M3/H PRODUCT SIZE AND WEIGHT LENGTH: APPROX. 2800 mm WIDTH: APPROX. 3300 mm HEIGHT: APPROX. 3000 mm WEIGHT: APPROX. 2500 KG SCOPE OF SUPPLY SPINNING CHAMBER • WITH WIRE COLLECTING ELECTRODE • LIFTING MECHANISM OF CART CAPABLE OF ADJUSTING THE DISTANCE BETWEEN THE COLLECTING AND SPINNING ELECTRODE BETWEEN 150 AND 250 mm VIA THE CONTROL PANEL • HV PROTECTING COVERS • SLIDING DOORS WITH ILLUMINATION • AIR INLET AND OUTLET WITH HOMOGENIZER AND FANS EXTINGUISHING SYSTEM • SWITCHBOARD SPINNING CART • 2 X PROCESS DOUBLE - TANKS (ONE CART ON WHEEL, EACH WITH IN AND OUT TANK) • CDS – CHEMICAL DISTRIBUTION SYSTEM • SEPARATE SPINNING MODULE EACH WITH MOVABLE CARRIAGE WITH SPINNING HEAD, ENERGY CHAIN • HV COVERS • WIRE SPINNING MECHANISM • WIRE ALIGNMENT MECHANISM • SET OF WIRE SPOOL 0.2 mm AND 0.3 mm MAIN OPERATOR PANEL – CONTROL SYSTEM HV POWER SUPPLIES SYSTEM (MAXIMUM AVAILABLE RATINGS + 80 KV DC / - 60 KV DC) SET OF SPINNING NOTCHES – FOR ROR 1 X CLEANING TANKS SERVICE OPERATION PANEL AUTOMATIC DISCHARGER R & D MODE ENABLE ELECTRO SPINNING FROM 4 WIRES ONLY – ONE MODULE PREPARATION FOR DRIVEN ENDLESS BELT COLLECTING ELECTRODE NOT IN SCOPE OF SUPPLY • SPARE WIRE FOR SPINNING • SPARE POLYMER CONTACT COMPONENT: CDS (PUMPS, VALVES, HOSES), SPINNING CARRIAGES WITH SPINNING HEADS, ENERGY CHAINS WITH POLYMER HOSES • SET OF SPINNING NOTCHES – NOT NECESSARY FOR ROR • ENDLESS BELT COLLECTING ELECTRODE REWINDING 1600 mm FULL THE NS LINE ALLOWS THE PRODUCTION OF NANOFIBERS ON A SUBSTRATE MATERIAL ONLY. THE SUBSTRATE MATERIAL MUST BE PRESENT IN THE SPINNING UNIT DURING THE SPINNING PROCESS. MOST NANOFIBER PRODUCTS USE TEXTILE, PAPER, OR FOIL SHEETS IN ROLLS AS A SUBSTRATE MATERIAL. UNWIND AND REWIND EQUIPMENT ALLOWS BIDIRECTIONAL REWINDING OF THE SUBSTRATE MATERIAL. THE ROLL GOODS EXCHANGE AND INSERTION IS MANUAL. MANIPULATION TOOLS ARE USUALLY NECESSARY BOTH UNWIND AND REWIND CONTAINS STEEL FRAMES WITH MOTORS, WHICH DRIVE THE UNWINDING AND WINDING PNEUMATIC SHAFTS SPEED IS CONTROLLED BY A SPECIAL RUBBER CYLINDER. THE PNEUMATIC SHAFTS ARE INFLATABLE AND SUITABLE FOR USE WITH PAPER CORES FEATURES: MAIN ROLL UNWINDER • THE SIDE-WALLS OF UNWINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE RUNNING ROLLERS ARE MACHINED • THE UNWINDER IS EQUIPPED SWINGING SPLICING TABLE. MAT SPLICING IS SOLVED BY THE CUSTOMER (E.G. DOUBLE STICKY TAPE) • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE UNWINDER. ON THE UNWINDER THERE IS PLACED STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE WINDER • THE SIDE-WALLS OF WINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE-RUNNING ROLLERS ARE MACHINED • COMPENSATOR SPLITS THE WINDING TENSION FROM PRODUCTION LINE AND THE WINDER. TO INCREASE THE FRICTION COEFFICIENT AND THUS TO PREVENT SLIDING OF THE WOUND MATERIAL, COMPENSATOR ROLLER SURFACE IS FINISHED WITH A GLUED TEXTILE STRAP WITH A LAYER OF THE RUBBER. THE WOUND MATERIAL CONTACTS THE OPPOSITE SIDE TO THAT ONE WITH NANOFIBERS • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE WINDER • ON THE WINDER THERE IS PLACED THE STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE BANANA ROLL • ROLL IS PLACED TO ADJUSTABLE BEARINGS FOR EASY SETTING OF CORRECT SPREADING EFFECT. ROLL SURFACE IS RUBBER COATED. THE BANANA ROLL IS DRIVEN TO SECURE ITS ROTATION AT LOW WINDING TENSIONS LONGITUDINAL CUTTING • INDIVIDUAL CUTTING HEADS CAN BE MANUALLY ADJUSTED TO THE DESIRED WIDTH. CUTTING IS CARRIED OUT BY PRESSURE AGAINST THE HARDENED CYLINDER - SHREDDER. CUTTING QUALITY IS RECOMMENDED TO TEST THE MATERIAL IN ADVANCE. THE EDGE TRIMS SLIDES ALLOW TO REDIRECT TRIMS TO CUSTOMER BIN OR TRIM WINDER WINDER EDGE GUIDING • THE EDGE GUIDING EQUIPMENT CONSIST OF WINDER BASE FRAME WITH TRANSVERSAL RAILS, ROLLERS MOUNTED ON WINDER MOVING FRAME, LINEAR ACTUATOR AND EDGE SENSOR INSTALLED ON ADJUSTABLE ARM. THE SENSOR MONITORS MATERIAL EDGE AND IN CASE OF EDGE POSITION DEVIATION THE WINDER FRAME IS MOVED RIGHT OR LEFT TO COMPENSATE THE MATERIAL PATH DEVIATION CONTROL SYSTEM • USER CONTROLS OF THE REWINDING IS SOLVED FROM THE MAIN CONTROL PANEL (HMI) OF NANOSPIDER LINE. SERVICE INTERVENTIONS ARE PERFORMED FROM THE SERVICE PANEL LOCATED ON THE DEVICE SPECIFICATIONS: WORKING WIDTH: 1650 mm SPEED: 0.4 TO 40 M/min +/- 1% CORES, INNER DIAMETER: 76 mm (3'') MAX. WINDING FORCE: 2000 N @ 90 mm MIN. WINDING FORCE: 80 N MAX. UNWINDING FORCE: 700 N MIN. UNWINDING FORCE: 40 N MAXIMUM DIAMETER OF ROLL: 1200 mm SAFETY FENCING • SAFETY FENCING IS NEEDED TO AVOID MECHANICAL HAZARDS IN THE CASE OF A RUNNING WINDING. FIRST THREATING OF THE SUBSTRATE IS PERFORMED WITH THE ENGINE DISCONNECTED, IE WITHOUT THE DANGER. ACCURATE FENCING DESIGN FOR COMPLETE SOS (SCOPE OF SUPPLY). VERY OFTEN IS IN SAFETY FENCING PLACE AIR PERMEABILITY TESTER OR OTHER EQUIPMENT BEFORE REWINDING. PROVIDED SAFETY FENCING COMPLIES WITH THE CURRENT MACHINERY DIRECTIVE 2006/42/EC HEIGHT: 1900 mm SAFETY DISTANCE: 120 mm PILLARS: 50 X 50 mm OR 70 X 70 mm MESH SIZE: 50 X 30 mm NUMBER OF DOORS: 1 X UNWINDER 2 X REWINDER SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THOUGHT NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASE OF ELECTRICAL POWER, SPACE AND PRESSURE AIR POWER: 10 KW VOLTAGE: 220 VOLTZ AND 50/60 Hz COMPRESSED AIR: 6 TO 8 BAR (CONNECTION POINT 60 L/min) PRODUCT SIZE AND WEIGHT UNWINDER - WITHOUT ROLL: 2800 X 2100 X 2300 mm WINDER - WITHOUT ROLL 2600 X 2200 X 1400 mm WEIGH – TOTAL 1000 KG (UNWINDER), 1800 KG (WINDER) SCOPE OF SUPPLY • RW SYSTEM • EDGE GUIDE CONTROL • BANANA ROLLER • SLITTING SYSTEM MECHANISM • 1 SLITTING KNIFE SYSTEM • SAFETY FENCING NOT IN SCOPE OF SUPPLY • SPARE PNEUMATIC SHAFT - 3" OR 6" • THE WAY OF MAT STICKING IS SOLVED BY THE BUYER AND IS NOT A PART OF DELIVERY • MACHINE FOUNDATIONS • FIRE PROTECTION • ROLL + SHAFT HANDLING • SUCTION SYSTEM FOR TRIMMED EDGES • THE LINE SPEED MEASURING DEVICE • LASER SENSOR FOR MEASURING OF PACKAGE DIAMETER FOR SIGNIFICANT INCREASING OF THE UN/WINDER CONTROL SENSITIVITY • COMPACTER ROLL ON THE WINDER • WASTE MATERIAL DISPOSAL ADHESION MODULE NS AM 1600 (WITH SHOWER) ADHESION MODULE IS DESIGNED TO ENSURE THAT THE NANOFIBER LAYER DEPOSITED ON A SUBSTRATE MATERIAL ADHERES PROPERLY TO IT WITHOUT ANY DELAMINATING FAILURES. THE EQUIPMENT IS INTENDED FOR APPLICATION OF LIQUID DISPERSION GLUES OR SIMILAR LIQUIDS ONTO THE SURFACE OF DIFFERENT SUBSTRATE MATERIALS WITH SMOOTH OR SLIGHTLY STRUCTURED SURFACES AS E.G. PAPER (FLAT AND CORRUGATED), PLASTIC FILMS, WOVEN OR NON-WOVEN TEXTILES ETC THE GLUE IS DEPOSITED ON A SUBSTRATE IN CONTACT WAY. A STEEL CYLINDER ROTATES IN A TUB FILLED WITH GLUE. GLUE IN THE TUB IS KEPT AT A CERTAIN LEVEL BY THE PERISTALTIC PUMP, WHICH ALSO KEEPS ITS CIRCULATION IN A CLOSED LOOP SPECIFICATION: WORKING WIDTH: ADJUSTABLE FROM 800 TO 1640 mm SUBSTRATE MATERIAL WIDTH UP TO 1700 mm SPEED: 1 TO 40 M/min (LIMIT DEPENDS ON THE TYPE OF SUBSTRATE AND WINDING SYSTEM PARAMETERS AND TYPE OF HOT AIR DRYER). COATING (DRY MASS): 0.5 TO 1.5 GSM (CHANGE BY 0.5 GSM PROVIDES A SIGNIFICANT CHANGE IN ADHESION) FEATURES: THE ADHESIVE MODULE CAN WORK IN TWO MODES • MODE 1 - STEEL CYLINDER IS IN CONTACT WITH A SOFT ROLLER AND THIS FOAM ROLLER COATS THE SUBSTRATE WITH A THIN LAYER OF GLUE – USED MAINLY FOR COATING OF CORRUGATED MEDIA. SOFT ROLLER IS A CONSUMABLE PART • MODE 2 - SUBSTRATE IS IN DIRECT CONTACT WITH STEEL CYLINDER, ADHESIVE IS TRANSFERRED DIRECTLY ONTO SUBSTRATE • SPEED IS THE CRUCIAL PARAMETER OF THE QUALITY OF THE ADHESION TREATMENT. OPERATING SPEED RANGE MUST BE TESTED WITH THE REQUIRED SUBSTRATE MATERIAL AND OPTIMIZED. AT TOO LOW SPEED THE ADHESIVE USUALLY DRIES OUT BEFORE IT REACHES THE SPINNING CHAMBER. ON THE OTHER HAND, TOO HIGH-SPEED LEADS TO INHOMOGENEOUS COATING. • THE HOT AIR DRYER IS USED IN COMBINATION WITH ADHESIVE MODULE. • ADHESION MODULE IS INTEGRATED TO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR THE OPERATION. SETTING OF ADHESION MODULE STRICTLY DEPENDS ON RECIPE OF RECORD, ADHESION MODULE DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF GLUE. • THE INSIDE OF THE MACHINE IS EQUIPPED WITH A TAP WITH INLET AND DRAINAGE FOR CLEANING. THE WATER IS HEATED IN THE MACHINE FOR BETTER DISSOLUTION OF THE ADHESIVE RESIDUE. THE DEVICE CONTAINS DRAIN PUMP FOR USED WATER. • BETWEEN THE ADHESION MODULE AND THE NANOSPIDER LINE IS A COVERED SINGLE-CYLINDER VENTILATED PORTER FOR BETTER MATERIAL GUIDANCE IN THE TECHNOLOGY. SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASED ELECTRICAL POWER, SPACE AND PRESSURE AIR • POWER: 7.5 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 6 TO 8 BARS (CONSUMPTION 100 L/min) • TAP WATER: G THREAD ½” TO CAPACITY 20 LITERS/min • DRAIN: WASTE WATER PUMP: ½“ HOSE. • MAXIMUM HOSE LENGTH 10000 mm MAX. RECOMMENDED HEAD 3000 mm PRODUCT SIZE AND WEIGHT DIMENSIONS: 2675 X 2430 X 1470 mm + 800 mm COVERS WEIGHT: 1300 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 2 MOTORS FOR MAIN AND SOFT ROLLERS • COVERS FOR SPACE BETWEEN NANOSPIDER UNIT AND ADHESION MODULE – TENT • CONTROL SYSTEM – SWITCHBOARD – OPERATOR PANEL IS USED FROM NS LINE • MECHANISM FOR WIPING THE ADHESIVE FROM THE MAIN CYLINDER • INITIAL SET OF SOFT ROLLERS (4X) • EXPANSION SHAFT FOR MOHAIR ROLLER WITH SAFETY CLAMPS • TANK WITH PNEUMATIC MIXER (75L) – NOISE APPROX. 75DB • MEASUREMENT OF THE AMOUNT OF COATING – WEIGHT PLATFORM/SCALE • AUTOMATIC LOCK FOR SLIDING DOOR WITH SWITCH LIMIT TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • THREE SWITCH LIMITS ON DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • TWO EMERGENCY-STOP BUTTONS ON THE CORNERS OF THE MODULE WATER HEATER • SHOWER • DRAIN NOT IN SCOPE OF SUPPLY • SPARE SOFT ROLLERS – CONSUMABLE PARTS • GLUE • OPERATORS PANEL (USE PANEL FROM LINE) • GLUE PREPARATION STATION • ANY OTHER EQUIPMENT OF CLEAN SOFT ROLLER • WATER AND DRAIN CONNECTION – PIPING OPERATION DESCRIPTION GLUE PREPARATION TYPICALITY IS GLUE DELIVERY FROM SUPPLIER IN CONCENTRATION APPROX. 50%. FOR ADHESION MODULE IS USED TYPICALLY CONCENTRATION VALUE BETWEEN 20-30%. IF NO GLUE WEIGHT STATION IS USED, THE FOLLOWING METHOD OF GLUE PREPARATION IS RECOMMENDED • FILL ORIGINAL CONCENTRATION OF GLUE TO GLUE TANK – FOR EXAMPLE MEASURING BY LABORATORY SCALE • FILL (HOT) WATER FOR DILUTING GLUE – MEASURED BY VOLUME (HOT WATER IS RECOMMENDED FOR FASTER MIXING) • MOVE TANK TO COMPRESS AIR SUPPLY AND MIX THE GLUE SOLUTION FOR 10-30 MINUTES BY INTEGRAL MIXER WE RECOMMEND PREPARING ONLY SUCH AMOUNT OF GLUE WHICH IS NECESSARY FOR PRODUCTION – AS APPROX. AFTER 3 DAYS THERE IS RISK OF BIODEGRADATION OF THE PREPARED UNUSED GLUE GLUE DEPOSITION MEASURING (CHECK) – SCALE METHOD TANK WITH GLUE IS PLACED ON WEIGHT PLATFORM (SCALE) AND MEASURE DECREASING OF MASS IN TIME = DEPOSITION ON SUBSTRATE. MEASURING IN TIME LONGER THAN 5 MINUTES IS REQUIRED – DEPENDS ON WEIGHT PLATFORM RESOLUTION AND SETTING OF ADHESION MODULE HOT AIR DRYER HAD 1600/2000 – FIRST FEATURES: • THE HOT AIR DRYER EQUIPMENT PROVIDES ADDITIONAL DRYING OF FINAL PRODUCT. NANOFIBER LAYERS WILL LEAVE THE SPINNING UNIT WITH SOME RESIDUAL HUMIDITY (OR SOLVENT CONTENT) AND THE LAYER MUST BE DRIED BEFORE WINDING. THE HOT AIR DRYER IS NEEDED, WHENEVER THE ADHESION MODULE (APPLYING WATER-BASED GLUES) IS IN OPERATION OR THICKER NANOFIBER LAYERS ARE PRODUCED OF LOW VOLATILE SOLVENT SYSTEMS ARE GENERATED. THE DRYER ALSO REDUCES THE POLLUTION OF THE AMBIENT AIR AS IT IS VENTILATED • THE HOT AIR DRYER MAY NOT PROVIDE COMPLETE DRYING OF PRODUCED NANOFIBER LAYER IF THEY ARE TOO THICK, DENSE OR THE SPEED OF THE LINE IS TOO HIGH, THEREFORE ITS PERFORMANCE MUST BE TESTED ON PARTICULAR NANOFIBER PRODUCTS • THE EQUIPMENT IS PLACED BEHIND THE SPINNING UNIT. THE DRYER CAN USE ADDITIONAL HEATING TO SPEED UP THE DRYING PROCESS. AIR FLOW RATE AND HEATING TEMPERATURE CAN BE SET DIRECTLY FROM THE CONTROL SYSTEM AS REQUIRED BASED ON THE POLYMER SOLUTION AND AMOUNT OF ADHESIVE USED AND ON THE SPEED OF THE WHOLE NS LINE • THE HOT AIR DRYER INCLUDES A CHAMBER WITH NOZZLES, EXHAUST FAN AND RECOVERY FAN AND HEATERS. THE PROCESS AIR IS SUCKED FROM THE ROOM, PARTIALLY RECIRCULATED INSIDE THE CHAMBER AND THEN EXHAUSTED • HOT AIR DRYER IS INTEGRATED INTO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR ITS OPERATION. SETTING OF HOT AIR DRYER IS STRICTLY DEPENDENT ON RECIPE OF RECORD, ESPECIALLY ON SETTING OF ADHESION MODULE AND TYPE OF SUBSTRATE MATERIAL. EQUIPMENT DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF RESIDUAL WATER • HOT AIR DRYER CONTAINS SUPPORTING ROLLERS. GEOMETRICAL SHAPE OF THIS ROLLER IS SIMILAR TO LETTER “OMEGA”. PURPOSE OF OMEGA CYLINDER IS REDUCTION OF UNSUPPORTED LENGTH OF MATERIAL. SUPPORT OF THE MATERIAL IS TYPICALLY NEEDED EACH 2 TO 3 METERS. IF MATERIAL IS NOT SUPPORTED BY OTHER EQUIPMENT (LIKE REWINDING ADHESION MODULE) IT IS NECESSARY TO USE THESE 3 CYLINDERS. CYLINDER WHICH IS IN CONTACT WITH NANOFIBERS HAS PTFE COATING. CYLINDER IN STANDARD IS NOT DRIVEN (DRIVEN ONE IS ON THE REQUEST FOR SOFT MATERIAL – CAN BE ASSEMBLED AFTER INSTALLATION) • PURPOSE OF USAGE OF TENT AROUND OMEGA CYLINDERS IS DRIVEN BY MECHANICAL SAFETY AND WITH AMBIENT ATMOSPHERE AROUND TECHNOLOGY (REDUCED ODORS, IMPROVED STABILITY OF AMBIENT ATMOSPHERE IN SPINNING CHAMBER). SPECIFICATION: WORKING WIDTH: 1600 mm SUBSTRATE MATERIAL WIDTH: UP TO 1700 mm HEATING TEMPERATURE: UP TO 80 °C POWER HEATING: UP TO 15 KW NOMINAL LENGTH OF DRYING: 2000 mm AIR CHANGE/EXHAUST: MAXIMUM UP TO 500M3/H SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ 50/60 Hz 24 KW EXHAUST: UP TO 500 M3/H (DN 160) PRODUCT SIZE AND WEIGHT DIMENSIONS: 2200 X 1800 X 2700 mm + 900 mm FOR SUPPORTING ROLLER WEIGHT: 1500 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 1 PROCESS FAN, INLET AND OUTLET FAN • CONTROL SYSTEM – SWITCHBOARD • TENT WITH NONDRIVEN SUPPORTING ROLLERS • TWO EMERGENCY - STOP BUTTONS (ONE ON FRONT, ONE ON BACK OF HAD) • SIX SWITCH LIMITS ON THE DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED NOT IN SCOPE OF SUPPLY • OPERATORS PANEL (USE MAIN PANEL FROM LINE) DATA STORAGE AND REMOTE ACCESS FEATURES: THIS SYSTEM IS PERIODICALLY SAVING SPECIFIC PROCESS DATA AND SETTINGS FROM THE MACHINE. NO DATA STORAGE FROM WINDING SYSTEM. DATA IS ACCESSIBLE BY HTTP PROTOCOL IN LOCAL NETWORK. THIS UNIT ALSO REALIZES REMOTE ACCESS (PRIVATE AND SECURED VPN). WE ARE RECOMMENDING PERMANENT INTERNET CONNECTION FOR BETTER SERVICE CAPABILITY. ALL COMPONENTS ARE PLACED IN 19” RACK FLAT BOX – 9 UNIT TYPE. FOR RIGHT FUNCTION IS NECESSARY PERMANENT POWER SUPPLY 230V/10/16A – STANDARD PLUG. REMOTE CONTROL ENABLES DIAGNOSIS OF MOTOR FUNCTIONS, UPLOADING NEW SOFTWARE VERSIONS, ONLINE DIAGNOSIS OF THE TECHNOLOGY PARAMETERS. FURTHERMORE, THE ONLINE TROUBLESHOOTING WILL BE POSSIBLE TO SPEED UP AND MINIMIZE DOWNTIME IN THE CASE OF BREAKAGE OR MISUSE. ETHERNET COMMUNICATION IS BASED ON: SPECIFICATION: RACK: 19” RACK FLAT BOX COMPUTER: SIEMENS INDUSTRIAL PC OPERATION SYSTEM: WINDOWS + WEB ACCESS (TOSI BOX) SITE PREPARATION / CONNECTION REQUIREMENTS POWER CONSUMPTION: UP TO 1.5 KW VOLTAGE: 230V/10/16A TO STANDARD PLUG CEE7 TO PERMANENTLY CONNECT INTERNET CONNECTION: CONNECTED TO THE BUYER`S INTERNAL NETWORK OR, IF SECURITY IS CONCERN, BUYER`S DMZ (DE-MILITARIZED ZONE) IN ORDER TO GET CONNECTIVITY TO THE INTERNET NETWORK. THE RECOMMENDED SPEED IS AT LEAST 512 KBPS / 512 KBPS. PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 1000 X 1000 mm (19” RACK FLAT BOX) WEIGHT: 50 KG SCOPE OF SUPPLY • 19” RACK FLAT BOX (OR PLACE IN SWITCHBOARD OF MACHINE) • VPN ROUTER • DATA STORAGE MEMORY • WEB ACCESS TO DOWNLOAD DATA NOT IN SCOPE OF SUPPLY • CONNECTION TO INTERNET • OTHER TOSI BOX KEY PMS 60 L– PELLETS ONLY • THE POLYMER MIX STATION (PMS) IS DESIGNED TO PREPARE POLYMER SOLUTIONS SUITABLE FOR FURTHER USE IN THE SPINNING UNIT. THE MIX STATION CONSISTS OF THE MIXER, STAIRS, SWITCHBOARD CABINET, WITH HEATING AND COOLING UNIT, STORAGE TANK AND CONNECTION POINT • THE MIXER IS A DOUBLE WALL VESSEL, WHERE A PREPARED SOLUTION IS STIRRED AND CAN BE HEATED OR COOLED DURING PREPARATION. THE MIXER IS PLACED ON A WEIGHING PLATFORM - SCALE. THE SOLVENTS ARE DELIVERED VIA FIXED PIPING FROM EXTERNAL DRUMS, BARRELS OR CANISTERS, SOLID POLYMERS ARE FILLED IN THROUGH A FUNNEL • THE OPERATION IS ALMOST FULLY AUTOMATED, SO THAT THE OPERATOR NEEDS TO ENTER ONLY A POLYMER SOLUTION RECIPE INTO THE CONTROL SYSTEM VIA A TOUCH SCREEN. SINCE THE MIXING PROCESS IS INITIATED, THE SOLVENTS ARE DOSED AUTOMATICALLY. THE SOLID POLYMER MUST BE ADDED THROUGH A FUNNEL MANUALLY • CONTACT OF OPERATORS AND CHEMICALS USED IS ELIMINATED, AS THE POLYMER MIX STATION AND THE FILLING AND CLEANING STATION ARE CONNECTED STEADILY AND FOR ANY CHANGES IN CONFIGURATION ONLY SAFETY QUICK COUPLINGS NEED TO BE DISCONNECTED AND CONNECTED • THE SPINNING SOLUTION USED IN THE ELECTROSPINNING PROCESS CAN BE REUSED FOR PREPARATION OF A NEW BATCH OF THE SPINNING SOLUTION BY UTILIZING THE STORAGE TANK. THE DEVICE IS DESIGNED FOR OPERATION IN EX ENVIRONMENT AND COMPLIES WITH ATEX DIRECTIVE 2014/34/EU. INSIDE THE MIXING VESSEL IS ZONE 0, ABOVE THE MIXING VESSEL IS ZONE 1, AND WITHIN A 1.5 M RADIUS (SHOWN AS CIRCLE IN ABOVE DRAWING) FROM THE OUTER SURFACE (BODY) OF THE MIXING VESSEL IS ZONE • THE POLYMER MIX STATION SHOULD BE ALWAYS PLACED INTO A SEPARATE EXHAUSTED ROOM EQUIPPED WITH EMERGENCY VENTILATION, AS IT WORKS WITH HIGHER AMOUNT OF CHEMICALS. THE VENTILATION SHOULD BE DESIGNED ACCORDING TO THE LOCAL LEGISLATION REQUIREMENTS, ESPECIALLY TO THE AMOUNT AND TYPE OF CHEMICALS SUPPOSED TO BE USED. DESIGN OF THE ROOMS FOR ATEX COMPLIANCE AND VENTILATING SYSTEM IS NOT INCLUDED IN THE SCOPE OF SUPPLY SPECIFICATION: WORKING VOLUME: 60 LITERS OPERATING TEMPERATURE: 20 TO 80°C MAXIMUM VISCOSITY OF FINAL SOLUTION OF POLYMER: 1000 MPAS MAXIMUM VISCOSITY OF SOURCE COMPONENTS – LIQUIDS: 500 MPAS ACCURACY OF AUTOMATIC DOSING SOURCE CHEMICALS: ± 0.100 KG FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS ROOM - SIZE DEFINED IN LAYOUT (ROUGHLY 40 M2) - VENTILATION OF ROOM RECOMMENDED 6X PER HOUR (ACCORDING TO LOCAL REGULATION) - SPACE AROUND MIXING VESSEL (1.5 M) IS IN EX ZONE • POWER: 15 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 5 TO 8 BAR (CONSUMPTION 600 L/min) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 2000 X 1000 mm INCL. WEIGHING PLATFORM DIMENSIONS - STAIRS: 1150 X 2000 X 1150 mm DIMENSIONS - CABINET: 1150 X 2050 X 1050 mm INCL. THE BUILT - IN HEATING / COOLING UNIT DIMENSIONS - STORAGE TANK: 800 X 1000 X 1000 mm WEIGHT MIXER AND STAIRS: 1000 KG WEIGHT - CABINET: 400 KG SCOPE OF SUPPLY MIXING VESSEL • INLET FOR PELLETS • 3X INLET FOR LIQUID (SOLVENTS OR USED POLYMER SOLUTION) • LIGHT AND SIGHT GLASS IN LID • MATERIAL IN CONTACT WITH POLYMER SOLUTION – AISI 316L CONTROL PANEL STORAGE TANK – 60 L STAIRS ARE COMPLIANT WITH EN131 FILLING AND CLEANING STATION ALL CONNECTIONS AND PIPING FOR MANIPULATION OF POLYMER SOLUTION AND SOLVENTS BETWEEN SELLER PROVIDED EQUIPMENT NOT IN SCOPE OF SUPPLY PIPING CONNECTION TO CHILLER (PRODUCTION OF COLD WATER) BARRELS FOR FRESH AND WASTE CHEMICALS VENTILATION OF ROOM FIRE EXTINGUISHER CAPABILITY FOR POLYMERS IN POWDER FORM FILLING AND CLEANING STATION + SWITCHBOARD FILLING AND CLEANING STATION IS DESIGNED TO REDUCE CONTACT OF OPERATORS WITH ANY CHEMICALS DURING PROCESSES OF FILLING AND CLEANING. THE EQUIPMENT HAS THE FOLLOWING FUNCTIONS • FILL THE RESERVOIR TANKS WITH A FRESH SPINNING SOLUTION FOR FURTHER USE IN THE SPINNING UNIT • DRAIN THE RESERVOIR TANKS AND REMOVE THE SPINNING SOLUTION AFTER BEING USED IN THE SPINNING UNIT • CLEAN THE RESERVOIR TANKS • CLEAN THE SPINNING CARRIAGE THE FILLING AND CLEANING STATION CONSISTS OF THE EXHAUSTED CHAMBER WITH A TUB FOR CLEANING CHEMICALS FOR MANUAL CLEANING OF SPINNING CARRIAGES AND A SET OF PUMPS. A SCALE FOR MIXING VESSEL IS USED FOR CONTROL OF PRECISE FILLING OF THE RESERVOIR TANKS. OTHER OPERATIONS CAN BE CONTROLLED BY TIMERS. THE EQUIPMENT MUST BE CONNECTED TO AN EXHAUST DESIGN OF FILLING AND CLEANING STATION VARY ACCORDING TO SUPPLIED NANOSPIDER LINE CONFIGURATION DIMENSIONS: 650 (EXCLUDING RAMP) X 2650 X 800 mm WEIGHT: UP TO 400 KG AIR CONDITIONING UNIT • THE ATMOSPHERE IN THE SPINNING CHAMBER IS ONE OF THE MOST IMPORTANT FACTORS, INFLUENCING BOTH FIBER MORPHOLOGY AND PROCESS THROUGHPUT. THE RELATIVE HUMIDITY IN THE RANGE 20 TO 50% AND TEMPERATURE IN THE RANGE 18 TO 30°C IS TARGET FOR MOST POLYMER SOLUTION RECIPES. THE OPTIMAL RELATIVE HUMIDITY AND TEMPERATURE OF THE AMBIENT AIR DIFFER FOR EACH POLYMER SYSTEM AND BOTH FACTORS ARE OPTIMIZED EMPIRICALLY. WHILE FOR ONE POLYMER SYSTEM, THE MOST SUITABLE RH CAN BE 20%, FOR ANOTHER ONE, 35% CAN BE MUCH BETTER. USUALLY, EVEN IF THE ROOMS THE LINE IS INSTALLED IN ARE AIR CONDITIONED, THE PRECISE CONTROL IS NOT EASY AND IS USUALLY TOO EXPENSIVE. THEREFORE, IT IS NECESSARY TO HAVE THE HUMIDITY CONTROL EQUIPMENT CONNECTED DIRECTLY TO THE SPINNING UNIT TO CONTROL RELATIVE HUMIDITY (AND TEMPERATURE) INSIDE THE SPINNING CHAMBER • THE AIR CONDITIONING UNIT IS DESIGNED TO PROVIDE PRECISE CONTROL OF TEMPERATURE AND RELATIVE HUMIDITY OF THE SPINNING UNIT INLET AIR. IT IS POSSIBLE TO SET UP TEMPERATURE AND HUMIDITY INDEPENDENTLY AND KEEP BOTH OUTPUT VALUES IN QUITE NARROW RANGE • THERE ARE TWO MAIN TECHNOLOGICAL COMPONENTS OF THE A/C UNIT: DEHUMIDIFIER AND HUMIDIFIER. THE AIR THAT SHOULD BE DEHUMIDIFIED (PROCESS AIR) ENTERS THE ROTOR. THE WATER MOLECULES ARE ADSORBED IN THE SILICA GEL ROTOR. THE ROTOR IS REACTIVATED THROUGH ANOTHER AIR STREAM WHICH IS HEATED UP TO 100 TO 120 °C. THE MOISTURE LEAVES THE A/C AS WARM WET AIR • THE A/C UNIT IS ABLE TO COVER VERY LOW HUMIDITY AND IS SUBSTANTIALLY MORE EFFECTIVE THAN STANDARD DEHUMIDIFIER WORKING ON CONDENSATION PRINCIPLE. THE A/C UNIT USES CROSS FLOW RECUPERATOR OF WASTE HEAT DURING THE DEHUMIDIFYING PROCESS. IN CASE OF REMOTE ACCESS, WE OFFER REAL-TIME SERVICE SCAN OF THE A/C UNIT AT CUSTOMER’S SITE SPECIFICATION: PROCESS SIDE • PROCESS AIR FLOW (FRESH AIR): (VPA)1000 M3/H • MIN. INLET TEMPERATURE: (TIMIN) 8 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • OUTLET TEMPERATURE: (TO) 20 TO 25 °C • MIN. OUTLET HUMIDITY: (ABSHOMIN) 2 G / KG • MAX. OUTLET HUMIDITY: (ABSHOMAX) 9 G / KG • HUMIDITY ACCURACY: (ΔRH) + / - 3,0 % • TEMPERATURE ACCURACY: (ΔT) + / - 1,0 °C • EXTERNAL PRESSURE: (PEXT) 250 PA REGENERATION SIDE • PROCESS AIR FLOW (FRESH AIR): (VRA) 400 M3 / H • MIN. INLET TEMPERATURE: (TIMIN) 18 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • EXTERNAL PRESSURE: (PEXT) 150 PA • REACTIVATION HEATER: (QHEL) 10 KW FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS VOLTAGE: 3 / N / PE 3 X 400 V 50 HZ, 57A COMPRESSED AIR: N/A WATER CONNECTION: TAP WATER, 1 TO 8 BAR, 10 L/HOUR AIR DUCT CONNECTION: PROCESS AIR DN200 – SEE PARAMETERS ABOVE (PROCESS SIDE) WASTE AIR DN160 (< 60°C, <90% RH) COOLING WATER CONNECTION: WATER / GLYCOL MIXTURE RECOMMENDED (MEG 30%), IN / OUT G 1 1/2” WASTEWATER CONNECTION: DN32 (PVC PIPING) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1400 X 2000 X 6000 mm WEIGHT: 2000 KG SCOPE OF SUPPLY MAIN AIR CONDITIONING UNIT TECHNICAL GUIDE CHILLED WATER ACCUMULATOR 400 L (INCLUDED) CIRCULATION PUMP (INCLUDED) REVERSE OSMOSIS SYSTEM (INCLUDED) WATER DRAIN PUMP (INCLUDED) NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL 30% (-15°C) - APPROX. 1000 L DUCTING BETWEEN THE AC AND NS LINE PIPING BETWEEN AC UNIT AND CHILLER (OR OTHER COOLING SYSTEM) - SEE HYDRAULIC FLOW PLAN BELOW CHILLER (CAN BE OFFERED) OPTIONAL EQUIPMENT AND PARTS REQUIRED FOR THE OPERATION OF NS AC1000 CHILLER – NECESSARY EQUIPMENT IF BUYER DOES NOT HAVE ANOTHER USABLE COOLING SYSTEM ALREADY INSTALLED! • TEMPERATURE STABILITY (± 2°C BY THE SET POINT) • COOLING CAPACITY MIN 20 KW • TEMPERATURE SET POINT OUT 2,0/ IN 5,0 °C ETHYLENE GLYCOL 30% (-15°C) ADDITIONAL SUPPORTIVE VENTILATOR (ACCORDING TO LOCAL NEEDS) SELLER IS NOT RESPONSIBLE FOR SUPPLY OF ANY EXTRA PARTS, WHICH ARE NOT INCLUDED IN THE SCOPE OF SUPPLY, AND WHICH DEPENDS ON EXACT PLACEMENT OF EACH PERIPHERAL PARTS NEEDED FOR THE INSTALLATION ROOM CONDITIONS INTENDED SCOPE OF POLYMERS TO BE USED, RH AND TEMPERATURE OF AMBIENT AIR ARE AMONG THE MOST IMPORTANT ASPECTS. PRIOR TO PURCHASE OF THE UNIT BY THE SELLER THE CUSTOMER MUST AGREE AND SIGN A PROTOCOL CONFIRMING THAT ALL REQUIREMENTS THAT NEED TO BE MET BY THE BUYER WILL BE FULFILLED PRIOR TO INSTALLATION. IF THE REQUIREMENTS ARE NOT MET PRIOR TO INSTALLATION, THE SELLER CANNOT GUARANTEE MEETING THE PROCESS PARAMETERS CHILLER CHILLER IS A MACHINE TO PRODUCE CHILLED WATER, WHICH IS USED FOR TAKING OUT THE HEAT DEVELOPED IN VARIOUS INDUSTRIAL PROCESSES IN NS TECHNOLOGY, CHILLED WATER IS DISTRIBUTED INTO HEAT EXCHANGERS IN NS AC UNIT AND THEN THE WATER IS RE-CIRCULATED BACK TO THE CHILLER TO BE COOLED AGAIN. THE FIRST HEAT EXCHANGER IS USED TO COOL AND DEHUMIDIFY THE INLET AIR (1ST DEHUMIDIFYING STEP) AND THE SECOND HEAT EXCHANGER IS USED FOR FINAL ADJUSTMENT OF THE REQUIRED OUTPUT TEMPERATURE OF THE AIR. DUE TO THE AIR-COOLING PRINCIPLE, THE CHILLER IS PRIMARILY INTENDED FOR OUTDOOR INSTALLATION AND OPERATION. CHILLER MIGHT BE INSTALLED ALSO INSIDE OF BUILDINGS WHERE IT BECOMES THE SOURCE OF NON-NEGLIGIBLE AMOUNT OF WASTE HEAT SPECIFICATION: COOLING CAPACITY: (QC) 25.69 KW AMBIENT TEMPERATURE MAX: 46.0 °C OUTLET / INLET WATER TEMPERATURE: (TO/TI) 2.0/5.0 °C CHILLED WATER ACCUMULATOR TANK: 100 L FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 11.18 KW (400V/ 3 PH / 50HZ) SURROUNDINGS: OUTSIDE PRODUCT SIZE AND WEIGHT DIMENSIONS: 75 X 1450 X 1750 mm (THE CHILLER NEEDS A FREE SPACE OF ABOUT 1.5 M FROM ALL SIDES FOR PROPER OPERATION) NET WEIGHT: 293 KG SCOPE OF SUPPLY MAIN UNIT EC FANS NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL - 30% (-15°C) PIPING BETWEEN AC UNIT AND CHILLER REGENERATIVE CATALYTIC OXIDIZER 3000-GAS EMISSION LIMITS IN MOST REGIONS DO NOT ALLOW DISCHARGE OF THESE CONCENTRATIONS DIRECTLY INTO THE ATMOSPHERE. COMBUSTION IS CHOSEN AS A UNIVERSAL WASTE AIR TREATMENT METHOD. THE EQUIPMENT SHOULD ALWAYS BE CHOSEN WITH RESPECT TO: PROCESS PARAMETERS • FLOW RATE • CONCENTRATION LOCAL REGULATIONS • EMISSION LIMITS • OTHER CONDITION FINAL FACTORY INSTALLATION • AVAILABLE ENERGY • SPACE – INSIDE OUTSIDE THIS TECHNICAL EQUIPMENT IS ONE OF POSSIBLE SOLUTION, FOR FINAL OFFER WE RECOMMENDED SPECIFIED MORE PRECISELY CATALYTIC OXIDATION WITH REGENERATION / RECUPERATION OF WASTE HEAT (RCO/CO) IN THE CASE OF EXACT PRE-DEFINED CONDITIONS AND CHARACTERISTICS OF THE WASTE GAS, IT IS POSSIBLE TO SUPPLEMENT THE RTO AND TO TECHNOLOGIES WITH CATALYST. THANKS TO THIS CATALYST, OXIDATION OF VOCS OCCURS AT LOWER TEMPERATURES, WHICH REDUCES OPERATING COSTS. TECHNOLOGIES WITH CATALYST REACH AUTOTHERMAL OPERATION AT LOWER CONCENTRATIONS OF VOCS IN THE WASTE GAS. THERMAL OXIDIZER (WITH HEAT RECUPERATION) (TO) THE TECHNOLOGY OF DIRECT COMBUSTION IS ESPECIALLY SUITABLE FOR WASTE GASES WITH HIGHER CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS. IN ORDER TO REDUCE FUEL CONSUMPTION, A TUBULAR HEAT EXCHANGER FOR PREHEATING THE WASTE AND COMBUSTION AIR IS ADDED. REGENERATIVE THERMAL OXIDIZER (RTO) RTO SYSTEMS UTILIZE THE TECHNOLOGY OF REGENERATION OF WASTE HEAT CONTAINED IN THE EXHAUST CLEANED OFF-GAS. THERMAL EFFICIENCY OF UP TO 95 % TRANSLATES INTO LOW CONSUMPTION OF AUXILIARY FUEL EVEN FOR RELATIVELY LOW CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS IN THE OFF-GAS. RTO TECHNOLOGIES ARE DISTINGUISHED BY THE FOLLOWING CHARACTERISTICS: • LOW CONSUMPTION OF AUXILIARY ENERGY • WIDE TURNDOWN RATIO • OPTIONAL AUTOTHERMAL OPERATION (WITHOUT CONSUMPTION OF AUXILIARY ENERGY) • LONG LIFETIME OF CERAMIC LINING • EASY OPERATION AND MAINTENANCE SPECIFICATIONS: PROCESS AIR VOLUME MAXIMUM: 3000 NM3/H MINIMUM: 1500 NM3/H PRINCIPLE: REGENERATIVE CATALYTIC OXIDIZER ENERGY FOR HEATING: NATURAL GAS 70 KW LOCATION INSIDE (FROM +3°C TO 30°C) ESTIMATED CONSUMPTION: 3000 M3 / H CONCENTRATION: 0 MG TOC / NM3 48 KW CONCENTRATION: 0.5 G / NM3 - DMAC 42 KW EMISSION TOC <20 MG / NM3 CO <100 MG/NM3 NOX <100 MG / NM3 FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 10 KW (400V @ 50HZ) PRESSURE AIR: DEW POINT +3°C (OUTSIDE -40°C) 6 BAR 4 NM3 / H NATURAL GAS: 150 MBAR CALORIFIC / HEATING / ENERGY VALUE: 10.2 KWH/NM3 70KW PRODUCT SIZE AND WEIGHT DIMENSIONS: 3300 mm X 3300 mm X 3400 mm (LOCATION OUTSIDE OR INSIDE) EXTERNAL SWITCHBOARD (APPROX. 1200 X 500 X 2000 mm) NET WEIGHT: 7500 KG SCOPE OF SUPPLY PROCESS CENTRIFUGAL FAN AND MOTOR COMBUSTION CHAMBER WITH CATALYTIC DAMPER SYSTEM – TO CHANGE PROSS AND REGENERATION CATALYTIC HEATER SUPPORTING STEEL STRUCTURE STACK / CHIMNEY Ø300M - 7M – FREE STANDING EXTERNAL SWITCHBOARD + CABLE UP TO 1000 mm NOT IN SCOPE OF SUPPLY CIVIL WORKS AND ANCHORING CONNECTION DUCTWORKS BETWEEN PRODUCTION NANOSPIDER LINE AND WAT CONNECTION TO UTILITIES UP TO THE BATTERY LIMITS PROCESS FLUIDS (FUEL, COMPRESSED AIR) WASTE DISPOSAL LIFTING EQUIPMENT • START-UP EMISSION ANALYSIS CONTINUOUS ANALYZER EMISSION. CABLE TRACE FOR CONNECTION BURNING UNIT AND SWITCHBOARD Learn More