Search results for: 'Machine+f'

- Related search terms

- machine+foam

- machine+fly

- Machine+fiber

- Machine+fe'

- machine+foam'

-

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More -

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

M-7912 MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

M-7912 MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)REFERENCE NUMBER: M-7912

MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

FAST MACHINERY, QUICK CHANGEOVERS – DUAL FILM REEL WITH AUTO FILM SPLICE

STAINLESS STEEL CONSTRUCTION IS STANDARD

Learn More -

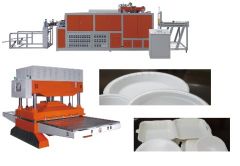

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINE

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINEREFERENCE NUMBER: L-5818

POLYSTYRENE FOAM PLATE FORMING MACHINE

RATED POWER: 90 KW

SHEET WIDTH: 800 TO 1080mm

MAX FORMING AREA: 1000 X 1300mm

WORKING SPEED: 17 TO 22 TIMES PER MINUTE

This machine is semi-automatic.

After forming, hydraulic cutting machine will be needed to cut out each product.

QUANTITY: 1

Learn More -

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOUR

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURREFERENCE NUMBER: M-6423

AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURAUTOMATIC CUP FILLING AND SEALING MACHINE – FILLING YOGURT

ROTARY TYPE

DIAMETER: 9.5 CM

OUTPUT: 800 TO 1,000 CUPS PER HOUR

ROLL FILMQUANTITY: 1

Learn More -

Z-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINEZ-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINE CAPACITY (KG/BATCH): 2 ROTARY SPEED(R/MIN): 46 MOTOR POWER (KW): 0.37 FAN POWER (KW): 0.15 HEATER POWER (KW): 0.75 SHELL SIZE (LXWXH) mm: 500X350X700 WEIGHT (KG): 37 QUANTITY: 1 Learn More

Z-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINEZ-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINE CAPACITY (KG/BATCH): 2 ROTARY SPEED(R/MIN): 46 MOTOR POWER (KW): 0.37 FAN POWER (KW): 0.15 HEATER POWER (KW): 0.75 SHELL SIZE (LXWXH) mm: 500X350X700 WEIGHT (KG): 37 QUANTITY: 1 Learn More -

M-7908 TETRA PAK A3/FLEX PRISMA 500ML FILLING MACHINE YEAR 2004

M-7908 TETRA PAK A3/FLEX PRISMA 500ML FILLING MACHINE YEAR 2004REFERENCE NUMBER: M-7908

TETRA PAK A3/FLEX PRISMA 500ML FILLING MACHINE YEAR 2004

FILLING MACHINE

MAKE: TETRA PAK

MODEL: A3/FLEX

VOLUME: 500ML PRISMA

YEAR: 2004

WORKING HOURS: 7,700 HOURS

Learn More -

G-4425 CHICKEN SLAUGHTER LINE 1500 PER HOURREFERENCE NUMBER: G-4425 CHICKEN SLAUGHTER LINE 1500 PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-4425 CHICKEN SLAUGHTER LINE 1500 PER HOURREFERENCE NUMBER: G-4425 CHICKEN SLAUGHTER LINE 1500 PER HOUR QUANTITY AVAILABLE: 1 Learn More -

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINEREFERENCE NUMBER: L-5827

AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

EFFECTIVE FORMING AREA: 1100 X 1400mm

HEATING OVEN LENGTH: 4400mm

HYDRAULIC CYLINDER BORE: 220mm

QUANTITY: 1

Learn More