Search results for: 'for'

-

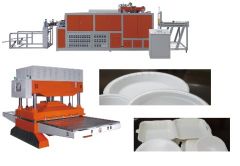

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINE

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINEREFERENCE NUMBER: L-5818

POLYSTYRENE FOAM PLATE FORMING MACHINE

RATED POWER: 90 KW

SHEET WIDTH: 800 TO 1080mm

MAX FORMING AREA: 1000 X 1300mm

WORKING SPEED: 17 TO 22 TIMES PER MINUTE

This machine is semi-automatic.

After forming, hydraulic cutting machine will be needed to cut out each product.

QUANTITY: 1

Learn More -

M-7912 MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

M-7912 MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)REFERENCE NUMBER: M-7912

MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

MACHINERY TO FORM FILL AND SEAL POUCHES WITH A CORNER SPOUT (NEW)

FAST MACHINERY, QUICK CHANGEOVERS – DUAL FILM REEL WITH AUTO FILM SPLICE

STAINLESS STEEL CONSTRUCTION IS STANDARD

Learn More -

Z-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINEZ-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINE CAPACITY (KG/BATCH): 2 ROTARY SPEED(R/MIN): 46 MOTOR POWER (KW): 0.37 FAN POWER (KW): 0.15 HEATER POWER (KW): 0.75 SHELL SIZE (LXWXH) mm: 500X350X700 WEIGHT (KG): 37 QUANTITY: 1 Learn More

Z-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINEZ-1683 COATING PAN CHOCOLATE BEAN FORMING MACHINE CAPACITY (KG/BATCH): 2 ROTARY SPEED(R/MIN): 46 MOTOR POWER (KW): 0.37 FAN POWER (KW): 0.15 HEATER POWER (KW): 0.75 SHELL SIZE (LXWXH) mm: 500X350X700 WEIGHT (KG): 37 QUANTITY: 1 Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINEREFERENCE NUMBER: L-5827

AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

EFFECTIVE FORMING AREA: 1100 X 1400mm

HEATING OVEN LENGTH: 4400mm

HYDRAULIC CYLINDER BORE: 220mm

QUANTITY: 1

Learn More -

G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD)REFERENCE NUMBER: G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD) QUANTITY AVAILABLE: 1 Learn More

G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD)REFERENCE NUMBER: G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD) QUANTITY AVAILABLE: 1 Learn More -

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More

M-4690 FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINEREFERENCE NUMBER: M-4690 (11111B176Y10UF) L FULL AUTOMATIC SINGLE HEAD CHOCOLATE PRODUCTION LINE TOTAL ELECTRIC POWER: 21KW AIR COMPRESSOR: CONSUMPTION: 0.22M3/MIN, PRESSURE: 0.7MPA WORKING CNDITION: TEMPERATURE: 20 TO 25°C CHOCOLATE WEIGHT: PURE CHOCOLATE: 2.5 TO 512 G, CENTRE FILLED CHOCOLATE: 15 TO 40G TOTAL MACHINE WEIGHT: 5,250KGS TOTAL MACHINE SIZE: 16.7 x 1.21 x 2.5 M MOULD SIZE: 280 x 200 x 30mm AND 300 x 225 x 30mm THE FOOD CONTACT SPARE PARTS ARE ALL PLATED WITH NICKEL. DOUGH HOPPER INSIDE SURFACE IS MADE OF STAINLESS STEEL 304, BEAUTIFUL AND CLEAN. TO MEET THE STANDARD OF FOOD STANDARD. COCOA BUTTER MELTING TANK (1SET) SUGAR GRINDING MACHINE (1SET) 500L CHOCOLATE CONCH (REFINER) (2SET) 500L CHOCOLATE HOLDING TANK (2SET) QH320 CHOCOLATE SYRUP PUMP (2SET) QH25CHOCOLATE SYRUP PUMP (2SET) QH-I SINGLE HEAD CHOCOLATE DEPOSITING AND COOLING TUNNEL (1SET) CHOCOLATE MOULDS (280PCS) CONTROL PANEL BOX (1PCS) OTHER OPTIONAL EQUIPMENTS: (CHOOSE WHEN USE NATURAL COCOA BUTTER) 250KG CHOCOLATE TEMPERING MACHINE 1SET QUANTITY AVAILABLE: 1 Learn More -

R-9572 COMPLETE DANGER FLAT WAFER OVEN LINE, YEAR AROUND 1975-1980 (WITH HEBENSTREIT CREAM LINE)

R-9572 COMPLETE DANGER FLAT WAFER OVEN LINE, YEAR AROUND 1975-1980 (WITH HEBENSTREIT CREAM LINE)REFERENCE NUMBER: R-9572

COMPLETE DANGER FLAT WAFER OVEN LINE, YEAR AROUND 1975-1980 (WITH HEBENSTREIT CREAM LINE)

COMPLETE FLAT WAFER LINE

CONSITING OF:

DANGER WM 52 FLAT WAFER OVEN

DANGER WM 36 FLAT WAFER OVEN

HEBENSTREIT WZ-EM WAFER SPREAD CREAM LINE

POSSIBLY WITH SUBSEQUENT COOLING CHANNEL

AND SIG SB HORICONTAL FLOW WRAPPER INCL

WAFER CUTTER TABLE

MACHINE IS OFFERED IN ‘AS IS’ CONDITION, WITHOUT WARRANTY

QUANTITY: 1

Learn More -

M-7882 TETRA PAK A/3 FLEX 100V ASEPTIC FILLING LINE, 1000ML SLIM, YEAR 2004

M-7882 TETRA PAK A/3 FLEX 100V ASEPTIC FILLING LINE, 1000ML SLIM, YEAR 2004REFERENCE NUMBER: M-7882

TETRA PAK A/3 FLEX 100V ASEPTIC FILLING LINE, 1000ML SLIM, YEAR 2004

ASEPTIC FILLING LINE

1000ML SLIM

MAKE: TETRA PAK

MODEL: A/3 FLEX 100V

WITH DIMC (100V AND FIRST GENERATION):

YEAR: 2004

VERSION: 100V

PRODUCTION HOURS: 43,156

CAP TYPE: LIGHT CAP

CONDITION: USED

QUANTITY: 1

Learn More -

R-8165 MULTIVAC R245 VACUUM PACKING MACHINE, YEAR 2011

R-8165 MULTIVAC R245 VACUUM PACKING MACHINE, YEAR 2011MULTIVAC R245 VACUUM PACKING MACHINE

Learn More

YEAR 2011

MANUFACTURED BY MULTIVAC

MODEL R245

400VOLTS

50HZ

3PHASE

13.5KW MOTOR

THE R 245 IS A FREELY CONFIGURABLE THERMOFORMING PACKAGING MACHINE IN THE MID-

PERFORMANCE RANGE

IT PROVIDES A HIGH DEGREE OF EFFICIENCY DUE TO ITS EFFICIENT PACKAGING MATERIAL AND ENERGY

CONSUMPTION

MULTIVAC PROCESS FLEXIBLE AND RIGID FILM

AS WELL AS ALUMINIUM AND OTHER PACKAGING MATERIALS

WITH A THICKNESS OF UP TO 1,000 μM AND A FILM WIDTH UP TO 560 mm

THEY PROVIDE A MAXIMUM FORMING DEPTH OF UP TO 150 mm AND A MAXIMUM CUT-OFF LENGTH

OF UP TO 700 mm

QUANTITY: 1