Search results for: 'Comp'

- Related search terms

- Complete

- complete no

- compo',))

- compo',)

- Complete aut

-

JENBACHER LMS612GS GAS POWER PLANT, 2 MW, 50 Hz, YEAR 2011REFERENCE NUMBER: T-6935 JENBACHER LMS612GS GAS POWER PLANT, 2 MW, 50 Hz, YEAR 2011 JENBACHER LMS612GS GAS POWER PLANT COMPLETE POWER PLANT 2,000 KW COP 11,000 V, 50 Hz AVK ALTERNATOR 1,500 RPM RADIATOR, SILENCER, EXHAUST, GAS CONTROL LINE YEAR 2011 APPROX 230 H ONLY QUANTITY: 1 Learn More

JENBACHER LMS612GS GAS POWER PLANT, 2 MW, 50 Hz, YEAR 2011REFERENCE NUMBER: T-6935 JENBACHER LMS612GS GAS POWER PLANT, 2 MW, 50 Hz, YEAR 2011 JENBACHER LMS612GS GAS POWER PLANT COMPLETE POWER PLANT 2,000 KW COP 11,000 V, 50 Hz AVK ALTERNATOR 1,500 RPM RADIATOR, SILENCER, EXHAUST, GAS CONTROL LINE YEAR 2011 APPROX 230 H ONLY QUANTITY: 1 Learn More -

SPINNBAU 3547 CARD, WORKING WIDTH 3000mm, YEAR 1989REFERENCE NUMBER: T-6856 SPINNBAU 3547 CARD, WORKING WIDTH 3000mm, YEAR 1989 BRAND: SPINNBAU MODEL: 3547 SHORT DESCRIPTION: CARD YEAR: 1989 WORKING WIDTH 3000mm WITH RANDOM ROLLER TWO DOFFER AND TWO COMPRESS ROLLER QUANTITY: 1 Learn More

SPINNBAU 3547 CARD, WORKING WIDTH 3000mm, YEAR 1989REFERENCE NUMBER: T-6856 SPINNBAU 3547 CARD, WORKING WIDTH 3000mm, YEAR 1989 BRAND: SPINNBAU MODEL: 3547 SHORT DESCRIPTION: CARD YEAR: 1989 WORKING WIDTH 3000mm WITH RANDOM ROLLER TWO DOFFER AND TWO COMPRESS ROLLER QUANTITY: 1 Learn More -

AUTEFA, DILO, TEMAFA NONWOVEN LINE, YEAR 1970REFERENCE NUMBER: T-6853 AUTEFA, DILO, TEMAFA NONWOVEN LINE, YEAR 1970 BRAND: AUTEFA, DILO, TEMAFA SHORT DESCRIPTION: NONWOVEN LINE YEAR 1970 SUITABLE FOR PRODUCTION: 1500 GRS/SQUARE METER COMPOSED OF: 1 BESSI CARD, WORKING WIDTH 2500mm -TEMAFA FEEDER -BREAST ROLLER DIAMETER 1500mm, 7 COUPLE OF WORKERS, DIAMETER 220/74 -DOFFER DIAMETER 1285mm -DRUM DIAMETER 1500mm, 6 COUPLE OF WORKERS -DOFFER DIAMETER 1500mm -FLY COMB 1 AUTEFA CROSS LAPPER MODEL MAK IN WORKING WIDTH 2500mm, DELIVERY 3000mm 1 DILO NFZ30DO PRE-NEEDLE/NEEDLE MACHINE, YEAR 1967, 5160 NEEDLES /METER 2 MACHI LONGITUDINAL CUTTERS 1 SPINBAU TRANSVERSAL CUTTER 1 WINDER ON WEIGHS (LOADING CELLS METTLER) QUANTITY: 1 Learn More

AUTEFA, DILO, TEMAFA NONWOVEN LINE, YEAR 1970REFERENCE NUMBER: T-6853 AUTEFA, DILO, TEMAFA NONWOVEN LINE, YEAR 1970 BRAND: AUTEFA, DILO, TEMAFA SHORT DESCRIPTION: NONWOVEN LINE YEAR 1970 SUITABLE FOR PRODUCTION: 1500 GRS/SQUARE METER COMPOSED OF: 1 BESSI CARD, WORKING WIDTH 2500mm -TEMAFA FEEDER -BREAST ROLLER DIAMETER 1500mm, 7 COUPLE OF WORKERS, DIAMETER 220/74 -DOFFER DIAMETER 1285mm -DRUM DIAMETER 1500mm, 6 COUPLE OF WORKERS -DOFFER DIAMETER 1500mm -FLY COMB 1 AUTEFA CROSS LAPPER MODEL MAK IN WORKING WIDTH 2500mm, DELIVERY 3000mm 1 DILO NFZ30DO PRE-NEEDLE/NEEDLE MACHINE, YEAR 1967, 5160 NEEDLES /METER 2 MACHI LONGITUDINAL CUTTERS 1 SPINBAU TRANSVERSAL CUTTER 1 WINDER ON WEIGHS (LOADING CELLS METTLER) QUANTITY: 1 Learn More -

SPINNBAU FBK DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1983REFERENCE NUMBER: T-6842 SPINNBAU FBK DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1983 BRAND: SPINNBAU MODEL: FBK SHORT DESCRIPTION: DOUBLE DOFFER CARDING MACHINE YEAR: 1983 WORKING WIDTH: 2500mm QUANTITY: 1 Learn More

SPINNBAU FBK DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1983REFERENCE NUMBER: T-6842 SPINNBAU FBK DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1983 BRAND: SPINNBAU MODEL: FBK SHORT DESCRIPTION: DOUBLE DOFFER CARDING MACHINE YEAR: 1983 WORKING WIDTH: 2500mm QUANTITY: 1 Learn More -

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More -

AUTEFA, TEMAFA NONWOVEN LINE, YEAR 1970REFERENCE NUMBER: T-6839 AUTEFA, TEMAFA NONWOVEN LINE, YEAR 1970 BRAND: AUTEFA, TEMAFA SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1970 SUITABLE FOR A PRODUCTION OF: 700/800 GRS/SQUARE METER COMPOSED OF: 1 BESSI CARDING MACHINE, WORKING WIDTH 2500mm -TEMAFA FEEDER -BREAST ROLLER DIAMETER 1500mm, 7 COUPLE OF WORKERS, DIAMETER 220/74 -DOFFER DIAMETER 1285mm -DRUM DIAMETER 1500mm, 6 COUPLE OF WORKERS -DOFFER DIAMETER 1500mm -FLY COMB 1 AUTEFA CROSS LAPPER MODEL MAK IN WORKING WIDTH 2500mm, DELIVERY 3000mm 1 DILO NFZ25 PRE-NEEDLING MACHINE, YEAR 1965, 2580 NEEDLES /METER 2 MACCHI LONGITUDINAL CUTTERS 1 SPINBAU TRANSVERSAL CUTTER 1 WINDER ON WEIGHS (LOADING CELLS METTLER) QUANTITY: 1 Learn More

AUTEFA, TEMAFA NONWOVEN LINE, YEAR 1970REFERENCE NUMBER: T-6839 AUTEFA, TEMAFA NONWOVEN LINE, YEAR 1970 BRAND: AUTEFA, TEMAFA SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1970 SUITABLE FOR A PRODUCTION OF: 700/800 GRS/SQUARE METER COMPOSED OF: 1 BESSI CARDING MACHINE, WORKING WIDTH 2500mm -TEMAFA FEEDER -BREAST ROLLER DIAMETER 1500mm, 7 COUPLE OF WORKERS, DIAMETER 220/74 -DOFFER DIAMETER 1285mm -DRUM DIAMETER 1500mm, 6 COUPLE OF WORKERS -DOFFER DIAMETER 1500mm -FLY COMB 1 AUTEFA CROSS LAPPER MODEL MAK IN WORKING WIDTH 2500mm, DELIVERY 3000mm 1 DILO NFZ25 PRE-NEEDLING MACHINE, YEAR 1965, 2580 NEEDLES /METER 2 MACCHI LONGITUDINAL CUTTERS 1 SPINBAU TRANSVERSAL CUTTER 1 WINDER ON WEIGHS (LOADING CELLS METTLER) QUANTITY: 1 Learn More -

P-8701 MEDICAL PROTECTIVE CLOTHING

P-8701 MEDICAL PROTECTIVE CLOTHINGREFERENCE NUMBER: P-8701

MEDICAL PROTECTIVE CLOTHING

ADVANTAGES: MOISTURE PERMEABILITY,ANTI TEARING, ANTI-STATIC,ANTI PENETRATIONVIRUS BARRIERAND HIGH STRENGTH OF ANTIBACTERIAL FILM COMPOSITE FABRIC.

STRUCTURE: CONSISTS OF HOODED TOP AND TROUSERS

RANGE: PROVIDE BARRIER AND PROTECTION

PRODUCT SIZE: 165,170,175,180,185

CARTON SIZE: 56X41X36mm

ONE CARTON:30PCS

GROSS WEIGHT: 9.5KG

PACKAGE: PACKED BY PLASTIC, BAG INSIDE AND NORMAL CARTON OUTSIDENO SHOES INCLUDED-NO STOCK

QUANTITY: 1

Learn More -

T-6543 MEDICAL UNIVERSAL TENSILE TESTING EQUIPMENT

T-6543 MEDICAL UNIVERSAL TENSILE TESTING EQUIPMENTREFERENCE NUMBER: T-6543

MEDICAL UNIVERSAL TENSILE TESTING EQUIPMENT

SHANDONG INDEPENDENTLY RESEARCH AND DEVELOPMENT THIS COMPREHENSIVE TESTING MACHINE FOR SURGICAL MASK & PROTECTIVE CLOTHING, IT IS WIDELY USED IN A VARIETY OF MASK STRENGTH DETECTION PROJECTS.FEATURES:COMPLY WITH NATIONAL STANDARDS, MEDICAL STANDARDS TESTING REQUIREMENTS, AUTOMATIC SOFTWARE CONTROL SYSTEM, MEET THE REQUIREMENTS OF DATA STORAGE, PRINTING, COMPARISON. THE IMPORTED SERVO MOTOR IS EQUIPPED WITH PRECISION SCREW DRIVE SYSTEM TO ENSURE THE STABILITY OF TEST DATA.

TEST STANDARDS:

GB 19082-2009 TECHNICAL REQUIREMENTS FOR DISPOSABLE PROTECTIVE CLOTHING FOR MEDICAL USE (4.5 BREAKING STRENGTH -THE BREAKING STRENGTH OF MATERIALS IN KEY PARTS OF PROTECTIVE CLOTHING SHOULD NOT BE LESS THAN 45N)

(4.6 ELONGATION AT BREAK -THE ELONGATION AT BREAK OF KEY PARTS OF PROTECTIVE CLOTHING SHOULD NOT BE LESS THAN 15%)

SELF-PRIMING FILTER RESPIRATOR FOR RESPIRATORY PROTECTION ARTICLES5.6.2 BREATHING BONNET -BREATHING BONNET SHALL BE SUBJECT TO AXIAL TENSION"DISPOSABLE MASK: 10N FOR 10S" "REPLACEABLE MASK: 50N FOR 10S"

(5.9 HEADBAND -HEADBAND SHOULD BEAR THE TENSION "DISPOSABLE MASK: 10N, 10S" "REPLACEABLE HALF MASK: 50N FOR 10S" "FULL MASK: 150N FOR 10S")

5.10 JOINTS AND CONNECTING PARTS -JOINTS AND CONNECTING PARTS SHALL BE SUBJECT TO AXIAL TENSION

"REPLACEABLE HALF MASK: 50N FOR 10S" "FULL COVER 250N FOR 10S"

GB/T 32610-2016 TECHNICAL SPECIFICATION FOR DAILY PROTECTIVE MASKS

(6.9 BREAKING STRENGTH OF THE MASK BELT AND THE CONNECTION BETWEEN THE MASK BELT ANDTHE MASK BODY ≥ 20N)

(6.10 FASTNESS TO BREATHING BONNET: NO SLIPPAGE, BREAKAGE OR DEFORMATION SHALL OCCUR)

YY/T 0699-2013 DISPOSABLE SURGICAL MASK

(4.4 MASK BELT -THE BREAKING FORCE AT THE CONNECTION POINT BETWEEN EACH MASK BELT AND THE MASK BODY IS NOT LESS THAN 10N)

YY 0469-2011 SURGICAL MASK FOR MEDICAL USE (5.4.2 MASK BELT)

GB/T 3923.1-1997 DETERMINATION OF BREAKING STRENGTH AND ELONGATION AT BREAK OF FABRICS (STRIP METHOD)

DISPOSABLE RUBBER INSPECTION GLOVES (6.3 TENSILE PROPERTIES)

INSTRUMENT TECHNICAL PARAMETERS:

SPECIFICATION: 200N (STANDARD) 50N, 100N, 500N, 1000N (OPTIONAL)

ACCURACY: BETTER THAN 0.5RESOLUTION OF FORCE VALUE: 0.1N

DEFORMATION RESOLUTION: 0.001mm

TEST SPEED: 0.01mm/MIN ~ 2000mm/MIN (STEPLESS SPEED REGULATION)

WIDTH OF SAMPLE: 30mm (STANDARD FIXTURE) 50mm (OPTIONAL FIXTURE)

CLAMPING OF SAMPLES: MANUAL (PNEUMATIC CLAMPING CAN BE CHANGED)

STROKE: 700mm (STANDARD) 400mm, 1000mm (OPTIONAL)

QUANTITY: 1

Learn More -

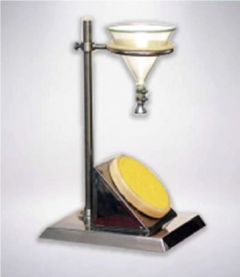

T-6548 FABRIC SURFACE WETTING TESTER

T-6548 FABRIC SURFACE WETTING TESTERREFERENCE NUMBER: T-6548

FABRIC SURFACE WETTING TESTER

INSTRUMENT TECHNICAL DESCRIPTION:

WATER TESTER IS TO INSTALL THE SAMPLE ON THE SAMPLE HOLDER AND MAKE AN ANGLE OF 45 ° WITH THE LEVEL. THE CENTER OF THE SAMPLE IS LOCATED AT A SPECIFIED DISTANCE BELOW THE NOZZLE. THE SAMPLE IS SPRAYED WITH A SPECIFIED VOLUME OF DISTILLED OR DEIONIZED WATER. BY COMPARING THE APPEARANCE OF THE SAMPLE WITH THE EVALUATION STANDARDS AND PICTURES TO DETERMINE ITS WATER-SOAKING GRADE, IT IS SUITABLE FOR MEASURING VARIOUS WATER-SOAKING TESTS ON THE SURFACE OF FABRICS WITH OR WITHOUT WATER RESISTANCE AND WATER REPELLENT FINISHING. THIS INSTRUMENT IS NOT SUITABLE FOR MEASURING THE WATER PERMEABILITY OF FABRICS, SO IT CANNOT BE USED TO PREDICT THE RAINPROOF PERMEABILITY OF FABRICS.

STANDARD:

GB19082-2009 TECHNICAL REQUIREMENTS FOR MEDICAL PRIMARY PROTECTIVE CLOTHINGGB / T4745 SURFACE MOISTURE RESISTANCE TEST

THE MAIN TECHNICAL INDICATORS OF THE INSTRUMENT:

GLASS FUNNEL: φ150mm

MEASURING CUP: 500ML

SAMPLE SUPPORT ANGLE: 45 °

INSTRUMENT CONFIGURATION:

1. ONE HOST

2. A GLASS FUNNEL

3. 500ML MEASURING CUP

QUANTITY: 1

Learn More -

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATEREFERENCE NUMBER: T-6549

CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

TESTING METER (WITH MOISTURE PERMEABLE CUP)

TECHNICAL DESCRIPTION OF THE INSTRUMENT:

IT IS MAINLY USED TO MEASURE THE MOISTURE PERMEABILITY OF ALL KINDS OF FABRICS, INCLUDING PERMEABLE COATED FABRICS. STRUCTURE PRINCIPLE: ADOPT COMPUTER CONTROL, CREATING A CONSTANT TEMPERATURE, AND HUMIDITY TEST ENVIRONMENT, TEST ENVIRONMENT IN THE CONSTANT TEMPERATURE, AND HUMIDITY, MOISTURE VAPOR TRANSMISSION CUP, PLACED 6 SAMPLE INTO THE GLASS AND THE RUBBER GASKET SEAL, THE CONTAINING HYGROSCOPIC AGENT OR WATER SEAL IS SPECIFIED BY THE WET CUP PLACED IN THE FABRIC SAMPLE TEMPERATURE AND HUMIDITY OF THE ENVIRONMENT, THE SEAL MOISTURE VAPOR TRANSMISSION CUP ACCORDING TO A CERTAIN TIME (INCLUDING SAMPLE AND HYGROSCOPIC AGENT OR WATER) TO CALCULATE THE MOISTURE TRANSMISSION QUALITY CHANGE.

TESTING STANDARD:

GB19082-2009 MEDICAL PRIMARY PROTECTIVE CLOTHING

TECHNICAL REQUIREMENTS GUIDELINES FOR THE SELECTION OF YY-T1498-2016 MEDICAL PROTECTIVE CLOTHING

GB/T12704.1 DETERMINATION OF MOISTURE PERMEABILITY OF FABRICS --HYGROSCOPIC METHOD

DETAILED TECHNICAL SPECIFICATIONS AND CONFIGURATION:

TECHNICAL INDICATORS:

1. TEMPERATURE CONTROL RANGE: -40°C ~ 150°C;RESOLUTION; 0.1 °C

2. HUMIDITY CONTROL RANGE: 50%RH ~ 95% RH±5%

3. SPEED RANGE: 2mm ~ 60mm/MIN

4. CONTROL PRECISION: TEMPERATURE <0.1°C; HUMIDITY + / -1% RH OR LESS

5. CYCLIC WIND SPEED: 0.02 ~ 0.5M/S, 0.3 ~ 0.5M/S

6. TIME CONTROL: 1 ~ 9999H

7. MOISTURE PERMEABLE AREA: 2827 mm 2 (DIAMETER IS 60 mm --NATIONAL STANDARD)

8. QUANTITY OF PERMEABLE CUPS: 6 GB;

9. DRYING BOX CONTROL TEMPERATURE: ROOM TEMPERATURE ~ 199 °C

10. TEST TIME: 1 ~ 999H

11. DRYING BOX STUDIO SIZE: 490 X 400 X 215mm

INSTRUMENT CONFIGURATION:

1. ONE MAIN MACHINE

QUANTITY: 1

Learn More