Search results for: 'Comp'

-

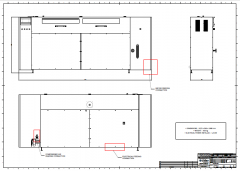

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE3 LAYER MASKS CONSTRUCTED OF NONWOVEN AND MELTBLOWN FABRIC

MASK DIMENSIONS: 175 x 95mm (ADULT) & 145 x 90mm (CHILD)---COMPOSED OF TWO MACHINES, AS BELOW

1) AUTOMATIC MASK LAYER MAKING AND CUTTING MACHINE

CAPACITY: 200 TO 300 PIECES PER MINUTE

INCLUDES

• MATERIAL FEEDING FRAME

• MACHINE FRAME

• ALUMINUM NOSE STRIP INSERTION

• ULTRASONIC WELDING

• CONVEYOR

DIMENSIONS: 4600 x 500 x 2100mm

WEIGHT: 300 KGS

POWER: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER)

2) MANUAL EAR BAND WELDING MACHINE

CAPACITY: 30 TO 40 PIECES PER MINUTE

INCLUDES

• WORKBENCH

• LIGHT

• AIR CYLINDER

• ULTRASONIC GENERATOR

• CONTROL SYSTEM

DIMENSIONS: 800 x 500 x 1000mm

WEIGHT: 43 KGS

POWER: 380 VOLTS, 50 Hz (OR AS PER CUSTOMER)WARRANTY: 1 YEAR FOR MAJOR COMPONENTS, LIFELONG SERVICE FOR THE USER

QUANTITY: 1 COMPLETE SEMI-AUTOMATIC LINE

Learn More -

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS• Air permeable

The mesh openings on two sides and the porous structure allow free air flow and vapor emission from all six sides, effectively inhibiting the growth of molds, bacteria and mites and thus preventing skin itches.• Stress-relieving and body-fitting

The hardness is moderate to reduce the body stress so that human body can fully relax without feeling any compression, avoiding blocking blood flow. There are 40 supporting points per square centimeter, providing meticulous support and fitting the material to the natural curve of human body.• Easy-to-wash and fast-dry

The material is made from functional fiber, which neither absorbs moisture nor easily reacts chemically with oil and dirt. Water stays no more than one second on the material, while sweat, dirt, and dust can be washed away easily. Therefore, the surface can be cleaned with minimum effort, preventing the growth of mites and bacteria.• Eco-friendly and non-toxic

The pure fabric can be fully recycled upon disposal. The combustion products of sponge are cyanides, which are highly toxic; on the contrary, the products of complete combustion of 3D spacer material are water and carbon dioxide, which are non-toxic and totally safe.• Rollable and portable.

With superior rollability, it can be easily carried into and out of an elevator, taken to outdoor activities, or stores easily when the seasons change.

Learn More

CONSTRUCTED OF 100% POLYESTER

FEATURES: AIR-PERMEABLE, WATER-PERMEABLE, ECO-FRIENDLY, NON-TOXIC, 100% RECYCLED, ANTI-STATIC, ANTI-MITE, ELASTIC, FLAME-RETARDANT, ETC.

NET “X” STRUCTURE

FOR UPHOLSTERY, MATTRESS TOPPERS, MATS, SEAT CUSHIONS, ETC.

NO# NAME LENGTH x WIDTH DIMENSIONS APPROX. INCHES THICKNESS

1 CUSHION 450x450mm 17.7 x 17.7 8 INCHES

2 BABY BED 600x1200mm 23.6 x 47.2 8 INCHES

3 STUDENT BED 1000x2000mm 39.3 x 78.7 8 INCHES

4 1.2 METER BED 1200x2000mm 47.2 x 78.7 8 INCHES

5 1.5 METER BED 1500x2000mm 59 x 78.7 8 INCHES

6 1.8 METER BED 1800x2000mm 70.8 x 78.7 8 INCHES

7 QUEEN BED 1524 x 2032mm 60 x 80 8 INCHES -

J-2640 DYEING AND FINISHING PLANT FOR SALE

J-2640 DYEING AND FINISHING PLANT FOR SALEREFERENCE NUMBER: J-2640

DYEING AND FINISHING PLANT FOR SALEITEM 001

THIES SAMPLE DYEING MACHINE

MODEL: MINISOFT SAMPLE

CAPACITY: 50 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 002

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

3 PORT SPLIT/SPLIT

CAPACITY: 900 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 003

THIES DYEING MACHINE

MODEL: ECOSOFT PLUS

2 PORT SPLIT/SPLIT

CAPACITY: 600 KGS

YEAR: 1999

MICROPROCESSOR CONTROL

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 004

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

1 PORT SPLIT/SPLIT

CAPACITY: 300 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: A460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 005

GASTON COUNTY DYEING MACHINE

MODEL: AQUAFLOW

2 PORT

CAPACITY; 250 KGS

YEAR: 1987

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING AND UNLOADING REEL

QUANTITY: 1ITEM 006

THIES DYEING MACHINE

MODEL: SOFT TRD

2 TUBE

CAPACITY: 700 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 007 (also our J-2647)

LAFER OPEN WIDTH COMPACTOR MACHINE

MODEL: KSA 500 2400/2200

YEAR: 1998

LAFER TEXEN CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY, VERTICAL PIN CHAIN, WITH PLATE GUIDES, RAIL OPENING, PINNING BRUSHES, PINS ONLY, WITH SUPPORT SECTION FOR THE FABRIC IN THE CENTER, AT 10’ THERE IS A STEAMING SECTION, TOTAL LENGTH OF THE TENTER IS 30’, WITH AUTOMATIC LUBRICATION FOR THE CHAIN

• KSA 500 COMPACTOR BENCH WITH TEXEN CONTROLS

• TENSIONLESS FABRIC CONVEYOR

• PLAITOR AND FABRIC SCRAY WITH OPTICAL LOAD SENSOR

• INLINE INSPECTION BATCHER MACHINE, WITHH A BACK LIGHTED BOARD, MANUAL CUT

• SCALE TO WEIGHT THE FABRIC

QUANTITY: 1ITEM 008 (also our J-2648)

SANTEX TUBULAR 4-ROLL EXTRACTION PAD

MODEL: SANTASTRETCH PLUS 140

YEAR: 1998

COMPOSED OF TURNTABLE, DETWISTER, TUBULAR 4-ROLL PAD WITH WET SPREADERS, PLAITOR

WITH ADDITION TANKS FOR SOFTENER

REEL FABRIC PLAITOR EXIT

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 009

SANTEX CONVEYOR DRYER FOR OPEN WIDTH AND TUBULAR FABRIC

MODEL: SANTASHRINK 4/5240

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER TO

• (2) SANTEX 2-ROLL PADS, RUBBER OVER RUBBER, 102” WIDE x 12” DIAMETER, STAINLESS STEEL PAN, 10-TON PAD, SWING-AWAY PAN, TENSION BAR WITH 2 STAINLESS STEEL MIXING TANKS, 75 GALLONS EACH

• DRIVEN SCROLL ROLLS WITH EDGE GUIDE CONTROL, WIDTH 95”

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY 45°, YEAR 1998, VERTICAL PIN CHAIN, 30’ LONG WITH TANDEMATIC PLATE GUIDES, RAIL GUIDES, PINNING BRUSHES, GUIDE SUPPORT FOR THE FABRIC, FABRIC CONVEYOR TO ENTER BOTH TUBULAR OR OPEN WIDTH FABRIC TO

• CONVEYOR DRYER 100” WIDE, 5 ZONES, 3-PASS WITH MAXON BURNERS, 5 CIRCULATING FANS TO CONVEYOR BELT TO PLAITOR

• ALL MOTORS AND SANTEX CONTROLS AND MONITORS

QUANTITY: 1ITEM 010

SANTEX AG TUBULAR COMPACTOR MACHINE

MODEL: SANTASPREAD 140

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSIONS BAR ENTRY

• OPERATOR’S PLATFORM

• TENSION DEVICE

• DRIVEN SPREADER BARS

• STEAMING DEVICE

• TUBULAR COMPACTING BENCH

• FELT BLANKET ONTO THE CONVEYOR BELT

• PRECISION PLAITOR

• TABELTOP ELECTRONIC SCALE

QUANTITY: 1ITEM 011

COMET NAPPER

MODEL: PEGSO-X4

YEAR: 1998

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

24 ROLLS WITH TURNING BARS FOR TUBULAR 90” WIDE

XYCOM CONTROLS

12-BAG COLLECTION SYSTEM AND PLAITOR

YEAR: 1996

QUANTITY: 1ITEM 012

STENTEX TENTER FRAME

MODEL: STENTOTHERM 3300

YEAR: 1999

STENTEX CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION ENTRY TO TEXT-STAR TYPE GUIDER TO 2 ROLL PAD

• ADDITION TANK TOP SCRAY PAD TO TEXT-STAR TYPE GUIDER

• TWO ROLL PAD R/R 10 TON

• OPERATOR’S PLATFORM

• WORKING WIDTH 1800mm

• HORIZONTAL PIN CHAIN, KNIT ENTRY

• TANDEMATIC SPLITLEVEL DECURLERS

• OVERFEED

• PINNING BRUSHES

• STEAM BOX

• RAIL GUIDERS, 20 FEET ENTRY, 8 ZONES

• 80 FEET HOUSING

• SCREEN MONITORS

• GAS FIRED, MAXON OVEPAK 408 BURNERS

• HONEYWELL CONTROLS

• 3 FEET COOLING ZONE

• 2 COOLING CANS, SELVEDGE TRIMMERS

• PLIATOR, SCRAY

• ZONE IN LINE INSPECTION BATCHER

QUANTITY: 1ITEM 013

ZIMMER ROTARY SCREEN PRINTING MACHINE

MODEL: R92-S153

YEAR: 1993

COMPOSED OF:

• TENSION BAR SKY ENTRY

• SCRAY

• CORINO BRUSH

• CORINO PRINT GUIDER

• ZIMMER PRINTER, 8 COLOR, 86” BLANEKT

• PRINT CONVEYOR DRYER, 30’ LONG, 3-ZONE, GAS FIRED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 014

Learn More

SAFETY SWITCH BULLET NOSE SLITTER

MODEL: CUTTING

WITH REEL FABRIC PLIATOR

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1 -

J-2365 HERBOLD DENSIFICATION LINES, DENSIFIER MODEL HV70

J-2365 HERBOLD DENSIFICATION LINES, DENSIFIER MODEL HV70EACH LINE WITH

PRE-GRINDER

DENSIFIER, MODEL HV70

REGRINDING

COOLING

DOFFINGTHERE IS A PULVERIZER AT THE END OF ONE OF THE LINES THAT IS AVAILABLE

HERBOLD RECENTLY INSPECTED AND INFORMED ALL BIG COMPONENTS ARE IN GOOD CONDITION, SOME SMALLER SPARE PARTS ARE ADVISED

QUANTITY: 2 LINES

Learn More -

J-2380 LUMMUS AND ARMA BALERS, BALE SIZE 48 x 27 INCHES

J-2380 LUMMUS AND ARMA BALERS, BALE SIZE 48 x 27 INCHESMAKE: LUMMUS

ONE OF THE LUMMUS BALERS (WHITE) HAS MORE AUTOMATION THAN THE OTHERS

QUANTITY: 3MAKE: ARMA

THIS BALER HAS A LARGER CYLINDER THAN THE LUMMUS BALERS FOR MAKING MORE COMPACT BALES OF THE SAME DIMENSIONS

QUANTITY: 1SIZE OF BALE: 48 x 27 INCHES (FOR ALL BALERS ABOVE)

QUANTITY: 4

Learn More -

J-2184 HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEW

J-2184 HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEWREFERENCE NUMBER: J-2184

HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEWMOTORIZED BELT-DRIVEN CONVEYOR

CONVEYING LENGTH: 90 METERS

CONVEYING WIDTH: 2400mm

CONVEYOR HEIGHT: 800mm

CONVEYING SPEED: 0 TO APPROXIMATELY 40 METERS PER MINUTE

BELTS: 200mm WIDTH x 6 PIECES, EACH 90 METERS LONG

DRIVING ROLL DIAMETER: 157mm

DRIVEN ROLL DIAMETER: 75mm

CENTER TO CENTER SPACING OF 2 ROLLS: 500mm

2 MOTORS, EACH 5.5 KW (CONVEYOR IS COMPOSED OF A TOTAL OF 4 SECTIONS. ONE 5.5 KW MOTOR DRIVES TWO SECTIONS)

1 INVERTER, 11 KW (DRIVES BOTH OF THE 5.5 KW MOTORS)

VOLTAGE: 220 VOLTS, 3-PHASE, 60 HzLEAD TIME: 45 WEEKDAYS FROM RECEIPT OF DEPOSIT

QUANTITY: 1

Learn More -

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILL

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILLFOR FILLING DOWN FEATHER PILLOWS

FILLING RANGE: 1 TO 120 GRAMS (70% FEATHER & 30% DOWN)

WEIGHING SYSTEM: 4 SETS

POWER: 4.5 KW

VOLTAGE: 220 / 380 V, 3-PHASE

AIR PRESSURE: 0.5 TO 0.7 MPA

ACCURATE WEIGHING RESULTS WITH TOLERANCE OF ONLY 1 GRAM

WORKING TABLE DIMENSIONS: 1200 x 2400mm (FOR CUSTOMERS FILLING PILLOWS AND QUILTS)

WORKING TABLE DIMENSIONS FOR PILLOWS ONLY: 1200 x 1200mm (EASIER TO FIT IN A 20 FOOT CONTAINER)

OPERATION CAN BE HANDLED BY ONLY 1 EMPLOYEE

INCLUDES ONE AUTOMATIC FILLING TABLE WITH FOOT SWITCH AND CLAMP DEVICE

THE WORKER STEPS ON THE FOOT SWITCH AND THE CLAMP DEVICE WILL RUN TO CLAMP THE PILLOW BAG

THE FILLING PROCESS AUTOMATICALLY STARTS TO FILL THE PILLOW AND AFTER FINISHING THE CLAMP DEVICE WILL RESET

DURING THIS PERIOD, THE WORKER MAY SEAL THE PILLOW WITH SEWING MACHINE

FOUR HOPPER SYSTEM FOR CONSTANT SUPPLY

ONE KEY FOR CHARGE AND RECHARGE REDUCES WASTED TIME

HIGH-QUALITY, RELIABLE ELECTRICAL COMPONENTS

PREPROGRAMMABLE FOR UP TO 50 GROUPS OF RECIPES WITH EACH RECIPE CONTAINING UP TO 60 SETS OF DIFFERENT FILLING PARTS FOR THE SAME PRODUCTION

FULLY ENCLOSED DESIGN TO KEEP ENVIRONMENT CLEAN AND REDUCE MATERIAL WASTE

AUTOMATIC, ACCURATE WEIGHING WITH LOAD CELL TO ENSURE PRODUCTION QUALITY

CE CERTIFICATE INCLUDED

FLOORSPACE 4000mm LONG X 3000mm WIDE X 2500mm HIGH

TABLE FOR PILLOWS IS 1200 X 1200mm

Learn More

QUANTITY: 1 -

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

2 BAR , 150m DISTANCE BETWEEN BARS

WIDTH UP TO 2700mm = 106 INCHESMAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER

YEAR: 2014

96 SEPARATELY CONTROLLABLE NEEDLES

FULLY AUTOMATIC NEEDLE PLAN CHANGE

TOP AND BOTTOM THREAD CUTTER AT EACH SEWING POSITION

MATERIAL WIDTH UP TO 2700mm

TWO NEEDLE BARS

150mm SPACING

HANDWHEEL ADJUSTMENT OF HEIGHT OF PRESSER PLATE

ELECTRONIC THREAD BREAK DETECTOR FOR TOP AND BOTTOM THREADS

MATERIAL UNWIND DEVICE

RACKS FOR TOP AND BOTTOM THREAD

ONE CATWALK EACH ON FRONT AND REAR OPERATING SITE

TROUGH INFEED FOR UPPER MATERIAL WITH MOTOR-DRIVEN ROLLER SYSTEM

AUTOMATIC MARKING AND DETECTING UNIT FOR PATTERN CONFORM LATERAL CUT

ELECTRONICS AND MOTORS 400V, 3 PHASES

CONCRETE BASES AND VIBRATION DAMPERS

Learn More -

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEM

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEMMAKE: CIBITEX

THE MOST INNOVATIVE, VERSATILE AND COMPACT SYSTEM FOR PROFESSIONAL WASHING DESIGNED FOR SMALL AND MEDIUM VOLUMES OF DIGITALLY PRINTED FABRICS

UNIT COMES WITH 3 STAGE BOILER

VOLTAGE: 400 V 50/60Hz

MAXIMUM WORKING WIDTH: 2200mm

MAXIMUM WATER TEMPERATURE: 95 °C

MAXIMUM INTERNAL CONTENT (DEPENDING ON FABRIC): 200 METERS

MAXIMUM WATER CONSUMPTION: 5 L/MIN

AVERAGE ELECTRICAL CONSUMPTION: 5,6kWh

DIMENSIONS: 3270 X 560 X 1380mm

WEIGHT: 400kgQUANTITY: 1

Learn More -

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNIT

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNITMAKE: CIBITEX

COMPACT UNIT FOR PRE-TREATMENT AND DRYING OF FABRICS PRINTED USING BOTH ACID, REACTIVE OR PIGMENTED INKS

MAXIMUM WORKING WIDTH: 1800mm

POWER INSTALLED: 82 Kw

VOLTAGE: 400 V 50Hz

MAXIMUM CYLINDERS TEMPERATURE: 210 °C

INTERNAL CONTENT (DEPENDING ON FABRIC): 300 M

MAX LOAD: 280 KG

COATING BASIC CAPACITY: 40 L

DIMENSIONS: 3500 X 4600 X 1890mm

WEIGHT: 4,935 KGQUANTITY: 1

Click here to watch the videos of this machine on YouTube.

Learn More