Search results for: 'machine de fa'

- Related search terms

- Machine fl

- machine tr'A=0

- machine can

- Machine+ope

- machine de''

-

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATEREFERENCE NUMBER: T-6549

CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

TESTING METER (WITH MOISTURE PERMEABLE CUP)

TECHNICAL DESCRIPTION OF THE INSTRUMENT:

IT IS MAINLY USED TO MEASURE THE MOISTURE PERMEABILITY OF ALL KINDS OF FABRICS, INCLUDING PERMEABLE COATED FABRICS. STRUCTURE PRINCIPLE: ADOPT COMPUTER CONTROL, CREATING A CONSTANT TEMPERATURE, AND HUMIDITY TEST ENVIRONMENT, TEST ENVIRONMENT IN THE CONSTANT TEMPERATURE, AND HUMIDITY, MOISTURE VAPOR TRANSMISSION CUP, PLACED 6 SAMPLE INTO THE GLASS AND THE RUBBER GASKET SEAL, THE CONTAINING HYGROSCOPIC AGENT OR WATER SEAL IS SPECIFIED BY THE WET CUP PLACED IN THE FABRIC SAMPLE TEMPERATURE AND HUMIDITY OF THE ENVIRONMENT, THE SEAL MOISTURE VAPOR TRANSMISSION CUP ACCORDING TO A CERTAIN TIME (INCLUDING SAMPLE AND HYGROSCOPIC AGENT OR WATER) TO CALCULATE THE MOISTURE TRANSMISSION QUALITY CHANGE.

TESTING STANDARD:

GB19082-2009 MEDICAL PRIMARY PROTECTIVE CLOTHING

TECHNICAL REQUIREMENTS GUIDELINES FOR THE SELECTION OF YY-T1498-2016 MEDICAL PROTECTIVE CLOTHING

GB/T12704.1 DETERMINATION OF MOISTURE PERMEABILITY OF FABRICS --HYGROSCOPIC METHOD

DETAILED TECHNICAL SPECIFICATIONS AND CONFIGURATION:

TECHNICAL INDICATORS:

1. TEMPERATURE CONTROL RANGE: -40°C ~ 150°C;RESOLUTION; 0.1 °C

2. HUMIDITY CONTROL RANGE: 50%RH ~ 95% RH±5%

3. SPEED RANGE: 2mm ~ 60mm/MIN

4. CONTROL PRECISION: TEMPERATURE <0.1°C; HUMIDITY + / -1% RH OR LESS

5. CYCLIC WIND SPEED: 0.02 ~ 0.5M/S, 0.3 ~ 0.5M/S

6. TIME CONTROL: 1 ~ 9999H

7. MOISTURE PERMEABLE AREA: 2827 mm 2 (DIAMETER IS 60 mm --NATIONAL STANDARD)

8. QUANTITY OF PERMEABLE CUPS: 6 GB;

9. DRYING BOX CONTROL TEMPERATURE: ROOM TEMPERATURE ~ 199 °C

10. TEST TIME: 1 ~ 999H

11. DRYING BOX STUDIO SIZE: 490 X 400 X 215mm

INSTRUMENT CONFIGURATION:

1. ONE MAIN MACHINE

QUANTITY: 1

Learn More -

M-4144 BIELLA SHRUNK DECATIZING MACHINE TYPE VULCANO YEAR 1997 WIDTH 1800MM

M-4144 BIELLA SHRUNK DECATIZING MACHINE TYPE VULCANO YEAR 1997 WIDTH 1800MMREFERENCE NUMBER: M-4144

BIELLA SHRUNK DECATIZING MACHINE TYPE VULCANO YEAR 1997 WIDTH 1800MM

BIELLA SHRUNK DECATIZING MACHINE

TYPE VULCANO

YEAR 1997

WIDTH 1800 MM

HIGH FABRIC FEEDING FRAME WITH TENSIONER

HUMIDIFYING MACHINE, TYPE IGROFAST

CORINO PIN WHEEL TYPE WEFT STRAIGHTNER TYPE FLC-3

CORINO OPENING AND CENTERING DEVICE WITH SCROLL ROLLERS

BIELLA CONTINOUS DECATIZING MACHINE TYPE VULCANO, STEAM HEATED DRUM WITH FELT

FABRIC EXIT WITH PLAITER

380V, 50HZ, PLC

QUANTITY AVAILABLE: 1

Learn More -

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell Individually

M-4089 COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES - Will Sell IndividuallyREFERENCE NUMBER: M-4089 (990DJSKXX8) L

COMPLETE RIETER RING SPINNING & YARN DYE FACTORY – 37,056 SPINDLES- will sell individually

FACTORY WAS PRODUCING VARIOUS SPECIALTY YARNS FOR USE IN APPAREL AND TECHNICAL TEXTILES

ALL RING FRAMES SHORT STAPLE FOR FIBERS UP TO 40mm, 220mm TUBES, APPROXIMATELY HALF OF THE RING FRAMES ARE WITH PINTER CORE DEVICE OR AMSLER SLUBBING DEVICE. AMSLER AND PINTER AVAILABLE TO SELL SEPARATELY.

COMPLETE YARN DYE HOUSE & DYE LAB

QUANTITY AVAILABLE: 1

Learn More -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More -

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEAR

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEARTILE FACTORY DESIGNED BY SACMI / ITALY

YEAR ESTABLISHED 2014 TO 2016

THIS PLANT IS AN ENVIRONMENTALLY FRIENDLY ENTERPRISE, WHEN IT RECYCLES 100% OF ITS EFFLUENTS AND PERFORMS HEAT RECOVERY, THEREBY SAVING ENERGY

See all pictures:

https://www.flickr.com/photos/183869481@N08/albums/72157710649767958THE PLANT:

COVERS AN AREA OF 22 THOUSAND SQUARE METERS

THE PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

CERAMIC FLOOR TILES

CERAMIC WALL TILES

BMR POLISHING LINE

BMR SQUARING & CHANFERING LINE

THE MAIN RAW MATERIALS ARE CLAY (DB-4) - 31 %, ALBITE (STD5) - 60 %

NEPHAIIN (PN9595) - 2.5 %, KAOLIN (RHB1) - 6.5 %

ON TOP OF IT THEY ARE USING GLAZE MATERIALS AND PAINTS

•FROM THE MOMENT THE MATERIAL IS PREPARED IT IS BEING DRIED PRESSED ON ONE OF FOUR (4) PRODUCTION LINES.

•TWO (2) LINES ARE WITH SACMI PRESSES OF PH 7,500 TON EACH AND HORIZONTAL DRYERS SACMI

•TWO LINES ARE WITH SACMI PRESSES OF PH 3,590 TON EACH AND VERTICAL DRYERS SACMI

•ALL FOUR (4) LINES HAVE THEIR OWN DIGITAL PRINTING MACHINE INCORPORATED

•ALL PRODUCTS ARE BEING GLAZED AND FIRED ON 1200 DEGREES IN ONE OF THE TWO (2) KILNS, SACMI

FOUR (4) SORTING, PACKING AND PALLETIZING LINES

GLAZE PREPARATION LINE

COMPLETE INSTALLATION FOR SMALL PRODUCTION CAPACITIES

COMPLETE FOILING LINE

COMPLETE ELECTRIC INSTALLATION

POWER GENERATOR UNIT

COMPRESSED AIR INSTALLATIONMACHINES ARE MADE BY:

SACMI: ITALY

NUOVA ERA / ROBOBOX: ITALY

BMR: ITALY

IN.TE.SA: ITALY

CUCCOLINI: ITALY

SYSTEM CERAMICS: ITALY

TGMAC SR.L: ITALY

DURST: GERMANY

ROTOCOLOR MAG: ITALY

NUOVA FIMA: ITALY

OMS: ITALY

MARPAK OMS: ITALY

MESSERSI PACK: ITALYTILE SIZES

THE FACTORY MANUFACTURES TILES OF VARIOUS SIZES FROM 300 X 300 TO 1200 X 1200mm IN VARIOUS TEXTURES AND DESIGNS USING DIGITAL PRINTING MACHINES

PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

THE FACTORY IS FULLY AUTOMATED AND USING ADVANCED CONTROL SYSTEMS!HUGE AMOUNT OF ORIGINAL SPARE PARTS AVAILABLE WITH THIS PLANT

THIS PLANT IS AVAILABLE WITH THE COMPLETE ELECTRIC, AIR, GAS, RECYCLING INSTALLATIONTHIS PLANT CAN BE SOLD: WITH 4 LINES OR 2 AND 2 LINES

Learn More -

E-4906 FRANZ MULLER TYPE PRN-32 TIGER BRUSHING MACHINEINVENTORY NUMBER: E-4906 FRANZ MULLER TYPE PRN-32 TIGER BRUSHING MACHINE FOR BLANKETS FOR SALE: ROLLERS WIDTH 260 CM FABRIC SPEED INFINATLY VARIABLE BETWEEN 2.5 - 20 M/MIN., AJUSTABLE DISTANCE BETWEEN FABRIC AND BRUSHING CYLINDER AJUSTABLE ROTATION SPEED FOR BRUSHING CYLINDER AJUSTABLE FABRIC TENSION BETWEEN FRONT AND REAR SEAM DETECTOR WITH AUTOMATIC SEAM PASSAGE DEVICE BRUSHING CYLINDER SPEED 300 - 750 M/MIN. BACKSIDE BRUSH WITH ARC FOR ADJUSTING CLOTH ARC EXIT WITH PLAITER AIR PRESSURE FOR PNEUMATIC SYSTEM 7 BAR INDICATED SPECIALY FOR BRUSHING HIGH PILE FABRICS, AS BLANKETS, FALSE FURE, ETC. (PICTURES AVAILABLE) QUANTITY: 1 Learn More

E-4906 FRANZ MULLER TYPE PRN-32 TIGER BRUSHING MACHINEINVENTORY NUMBER: E-4906 FRANZ MULLER TYPE PRN-32 TIGER BRUSHING MACHINE FOR BLANKETS FOR SALE: ROLLERS WIDTH 260 CM FABRIC SPEED INFINATLY VARIABLE BETWEEN 2.5 - 20 M/MIN., AJUSTABLE DISTANCE BETWEEN FABRIC AND BRUSHING CYLINDER AJUSTABLE ROTATION SPEED FOR BRUSHING CYLINDER AJUSTABLE FABRIC TENSION BETWEEN FRONT AND REAR SEAM DETECTOR WITH AUTOMATIC SEAM PASSAGE DEVICE BRUSHING CYLINDER SPEED 300 - 750 M/MIN. BACKSIDE BRUSH WITH ARC FOR ADJUSTING CLOTH ARC EXIT WITH PLAITER AIR PRESSURE FOR PNEUMATIC SYSTEM 7 BAR INDICATED SPECIALY FOR BRUSHING HIGH PILE FABRICS, AS BLANKETS, FALSE FURE, ETC. (PICTURES AVAILABLE) QUANTITY: 1 Learn More -

C-1169 BRUCKNER STENTER , WORKING WIDTH 2400MM,YEAR 1995REFERENCE NUMBER: C-1169 BRUCKNER STENTER , WORKING WIDTH 2400MM,YEAR 1995 QUANTITY AVAILABLE: 1 Learn More

C-1169 BRUCKNER STENTER , WORKING WIDTH 2400MM,YEAR 1995REFERENCE NUMBER: C-1169 BRUCKNER STENTER , WORKING WIDTH 2400MM,YEAR 1995 QUANTITY AVAILABLE: 1 Learn More -

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More -

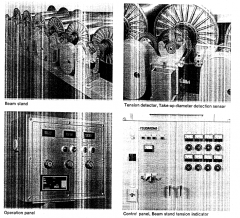

R-4681 SUCKER MULLER HACOBA SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 1999

R-4681 SUCKER MULLER HACOBA SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 1999REFERENCE NUMBER: R-4681

Learn More

SUCKER MULLER HACOBA SIZING MACHINE

YEAR: 1999

WORKING WIDTH: 1800mm

QUANTITY: 1 -

C-2171 BRAZZOLI HT ROPE DYEING MACHINE, CAPACITY 800 KGS, YEAR 2001REFERENCE NUMBER: C-2171 BRAZZOLI HT ROPE DYEING MACHINE, CAPACITY 800 KGS, YEAR 2001 DETAILS: BRAZZOLI 140°C HT ROPE DYEING MACHINE 4.5 BAR LOW LIQUOR RATIO (FROM 1/6 TO 1/8) TYPE SIRIO HT 800 4 TUBES CAPACITY: 800 KGS YEAR: 2001 TURBOVARIO DEVICE VARIABLE BATH PASSAGE CROSS SECTION THAT GUARANTEES HIGH PRODUCTION SPEEDS AT VERY LOW OPERATING PRESSURE SEAM DETECTOR 2 DYE STUFF TANKS AUXILIARY CHEMICAL PRODUCT TANK ANALOG DOSING SYSTEM MAGNETIC LEVEL CONTROL LITRE COUNTER HIGH THERMAL GRADIENT HEAT EXCHANGER MICROPROCESSOR FOR COMPLETE TREATMENT CYCLE CONTROL REMOVABLE FILTER MODULAR CONTROL BOARD MAXIMUM FABRIC SPEED 600 MTS/MIN EXTREME VERSATILITY OF THIS MACHINE ALLOWS TO PROCESS ANY KIND OF FABRIC BOTH WOVEN AND KNITTED FROM A WEIGHT OF 50 GRMS/MT TO 800 GRMS/MT PROGRAMMER APC504 BY AREL NOZZLES: 80 TO 90mm QUANTITY AVAILABLE: 2 Learn More

C-2171 BRAZZOLI HT ROPE DYEING MACHINE, CAPACITY 800 KGS, YEAR 2001REFERENCE NUMBER: C-2171 BRAZZOLI HT ROPE DYEING MACHINE, CAPACITY 800 KGS, YEAR 2001 DETAILS: BRAZZOLI 140°C HT ROPE DYEING MACHINE 4.5 BAR LOW LIQUOR RATIO (FROM 1/6 TO 1/8) TYPE SIRIO HT 800 4 TUBES CAPACITY: 800 KGS YEAR: 2001 TURBOVARIO DEVICE VARIABLE BATH PASSAGE CROSS SECTION THAT GUARANTEES HIGH PRODUCTION SPEEDS AT VERY LOW OPERATING PRESSURE SEAM DETECTOR 2 DYE STUFF TANKS AUXILIARY CHEMICAL PRODUCT TANK ANALOG DOSING SYSTEM MAGNETIC LEVEL CONTROL LITRE COUNTER HIGH THERMAL GRADIENT HEAT EXCHANGER MICROPROCESSOR FOR COMPLETE TREATMENT CYCLE CONTROL REMOVABLE FILTER MODULAR CONTROL BOARD MAXIMUM FABRIC SPEED 600 MTS/MIN EXTREME VERSATILITY OF THIS MACHINE ALLOWS TO PROCESS ANY KIND OF FABRIC BOTH WOVEN AND KNITTED FROM A WEIGHT OF 50 GRMS/MT TO 800 GRMS/MT PROGRAMMER APC504 BY AREL NOZZLES: 80 TO 90mm QUANTITY AVAILABLE: 2 Learn More