Search results for: 'Roll e'

- Related search terms

- roll pa

- roller p,"()(),'.,

- roller+d

- roll-mac'

- roller+p'

-

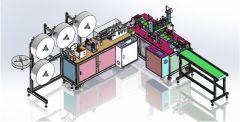

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

T-6545 MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTER

T-6545 MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTERREFERENCE NUMBER: T-6545

MASK BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR TESTER

PRODUCT INTRODUCTION:

MASK BACTERIA FILTRATION EFFICIENCY KEY PERFORMANCE INDICATORS (BFE) DETECTOR TESTER NOT ONLY CONFORMS TO THE REQUIREMENTS OF MEDICAL SURGICAL MASKS TECHNOLOGY YY0469-2011 APPENDIX B IN THE TEST METHOD FOR FILTER EFFICIENCY (BFE) BACTERIA FIRST B. 1.1.1 TEST INSTRUMENT, BUT ALSO CONFORMS TO THE AMERICAN SOCIETY FOR TESTING MATERIAL ASTMF2100, ASTMF2101, THE REQUIREMENTS OF THE EUROPEAN EN14683 STANDARDS, INNOVATIVE IMPROVEMENTS WERE MADE ON THE BASIS OF THIS, WITH DOUBLE PNEUMATIC CONTRAST SAMPLING METHOD AT THE SAME TIME, IMPROVE THE PRECISION OF SAMPLING,IT IS SUITABLE FOR MEASURING AND TESTING DEPARTMENTS, SCIENTIFIC RESEARCH INSTITUTES, MASK MANUFACTURERS AND OTHER RELEVANT DEPARTMENTS TO TEST THE PERFORMANCE OF MASK BACTERIAL FILTRATION EFFICIENCY.

EXECUTION STANDARD:

Q/0212 ZRB003-2015 MEDICAL SURGICAL MASK

BACTERIAL FILTRATION EFFICIENCY (BFE) DETECTOR RELATED INTELLECTUAL PROPERTY:

NO.: ZL200820224142.6 ELECTRIC FLOW CONTROL VALVE

NO.: ZL200820224143.0 GAS CAPACITY

NO.: ZL200920308391.8 AIR FILTRATIONMATERIAL FILTRATION EFFICIENCY DETECTOR

PRODUCT FEATURES:

NEGATIVE PRESSURE TEST SYSTEM TO ENSURE THE SAFETY OF OPERATORS;

BUILT -IN PERISTALTIC PUMP IN NEGATIVE PRESSURE CABINET, A, B TWO -WAY, SIX ANDERSEN; THE PERISTALTIC PUMP FLOW CAN BE SET;

THE FLOW RATE OF NIGHT SPRAY CAN BE SET AND THE ATOMIZATION EFFECT IS GOOD.

EMBEDDED HIGH SPEED INDUSTRIAL MICROCOMPUTER CONTROL; 10.4 INCHES INDUSTRIAL HIGH BRIGHTNESS COLOR TOUCH SCREEN;

USB INTERFACE, SUPPORT U DISK DATA STORAGE;

CABINET BUILT-IN HIGH BRIGHTNESS LIGHTS; BUILT-IN LEAKAGE PROTECTION SWITCH TO PROTECT THE SAFETY OF OPERATORS;

THE INNER LAYER OF THE CABINET IS MADE OF STAINLESS STEEL, THE OUTER LAYER IS SPRAYED WITH PLASTIC AND COLD-ROLLED, AND THE INNER AND OUTER LAYERS ARE INSULATED AND FLAME RETARDANT.

THE FRONT SWITCH TYPE GLASS DOOR IS CONVENIENT FOR THE EXPERIMENTER TO OBSERVE AND OPERATE.

DETACHABLE BRACKET, ADJUSTABLE BRACKET HEIGHT; SUPPORTING AND MOVING DUAL PURPOSE CASTERS.

QUANTITY: 1

Learn More -

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

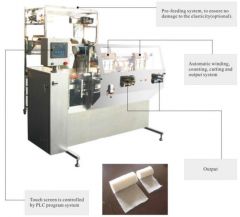

V-1471 AUTOMATIC CORELESS ROLL WINDER

V-1471 AUTOMATIC CORELESS ROLL WINDERREFERENCE NUMBER: V-1471

AUTOMATIC CORELESS ROLL WINDER

THE MACHINE IS SUITABLE TO PROCESS CORELESS ELASTIC BANDAGE ROLLS.

HAS PRE-FEEDING SYSTEM, TO ENSURE NO DAMAGE TO THE ELASTICITY (OPTIONAL).

WITH AUTOMATIC WINDING, COUNTING, CUTTING, AND OUTPUT SYSTEM.

TOUCH SCREEN IS CONTROLLED BY PLC PROGRAM SYSTEM.

WORKING SPEED: 7 TO 11 BEATS PER MINUTE

END SURFACE TOLERANCE OF FINAL ROLLS (DEPENDS ON MATERIAL): ±2 TO 3.5mm

ROLLING TENSION: ADJUSTABLE

MAX. DIAMETER OF FINISHED BANDAGE: 6cm

QUANTITY: 1

Learn More -

M-6095 GAUZE MACHINE PRODUCTION LINE

M-6095 GAUZE MACHINE PRODUCTION LINEREFERENCE NUMBER: M-6095

GAUZE MACHINE PRODUCTION LINEGAUZE SLITTING MACHINE

GAUZE FOLDING MACHINE

GAUZE PACKING MACHINE

ETHYLENE OXIDE STERILIZER

Learn More -

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More -

M-5143 ROUND COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5143 (1212YJJGXX11) L ROUND COTTON PAD MAKING MACHINE NONWOVEN ROUND COTTON PAD MAKING MACHINE MODEL: RD MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: DERANGEMENT PERMUTATION ROUND MOULD PUNCHING EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE EMBOSSING PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: CUSTOMIZED COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITION MATERIAL PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: PLC SERVO CONTROL OF MOTOR SPEED MOTOR: SERVO MOTOR PARAMETER-SETTING: COLOR TOUCH SCREEN PRODUCTION SPEED: 400 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 5.5KW WEIGHT: ABOUT 2300KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More

M-5143 ROUND COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5143 (1212YJJGXX11) L ROUND COTTON PAD MAKING MACHINE NONWOVEN ROUND COTTON PAD MAKING MACHINE MODEL: RD MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: DERANGEMENT PERMUTATION ROUND MOULD PUNCHING EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE EMBOSSING PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: CUSTOMIZED COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITION MATERIAL PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: PLC SERVO CONTROL OF MOTOR SPEED MOTOR: SERVO MOTOR PARAMETER-SETTING: COLOR TOUCH SCREEN PRODUCTION SPEED: 400 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 5.5KW WEIGHT: ABOUT 2300KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More -

M-5141 COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5141 (1212TTPCXX11) L COTTON PAD PRODUCTION MACHINE COTTON PAD SLICES CUTTING MACHINE MODEL: RC RAW MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: SHEAR TYPE ROUND KNIVES EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: WIDTH DEPENDS ON THE MOULD AND THE LENGTH CAN BE ADJUSTED WITHIN 10CM FREELY COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITES PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: FREQUENCY CONTROL OF MOTOR SPEED MOTOR: STEPPING MOTOR PARAMETER-SETTING: MAN-MACHINE INTERFACE PRODUCTION SPEED: 300 TO 1600 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 4.5KW WEIGHT: ABOUT 1800KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More

M-5141 COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5141 (1212TTPCXX11) L COTTON PAD PRODUCTION MACHINE COTTON PAD SLICES CUTTING MACHINE MODEL: RC RAW MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: SHEAR TYPE ROUND KNIVES EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: WIDTH DEPENDS ON THE MOULD AND THE LENGTH CAN BE ADJUSTED WITHIN 10CM FREELY COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITES PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: FREQUENCY CONTROL OF MOTOR SPEED MOTOR: STEPPING MOTOR PARAMETER-SETTING: MAN-MACHINE INTERFACE PRODUCTION SPEED: 300 TO 1600 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 4.5KW WEIGHT: ABOUT 1800KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More