Search results for: 'roll-mac'

- Related search terms

- roll-mac'

-

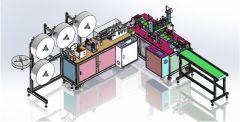

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

OUTER EARLOOP MASK PRODUCTION LINEREFERENCE NUMBER: A-2489 OUTER EARLOOP MASK PRODUCTION LINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, WITH BEAUTIFUL STYLE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm ULTRASONIC: 3 PCS, 20 K 2000W NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.4 TO 0.7 MPA USAGE FLOW: 300 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 70 PCS/min ACCURACY: ≥99% EXCLUDING RAW MATERIAL DEFECTS AND MISOPERATION FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EAR BELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More

M-5146 ROUND COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5146 (1212KKBCXX11) L ROUND COTTON PADS MAKING MACHINE AUTOMATIC ROUND MAKE UP COTTON PADS MACHINE RAW MATERIAL ROLL AUTOMATIC DELIVER EMBOSSING CUTTING OUTPUT IN ARRANGEMENT WASTE MATERIAL ROLLING AUTOMATIC COUNTING FROM LOADING THE RAW MATERIAL TO FINISHED PRODUCT, ALL AUTOMATIC MECHANICAL DRIVE CUTTING, RUNNING STABILITY, EFFICIENCY CAN MAKE FLAT COTTON PADS AND EMBOSSING COTTON PADS MODEL: HZM-1 PRODUCT DIAMETER: 58mm OR ACCORDING TO CUSTOMER RAW MATERIAL: ABSORBENT COTTON, NON-WOVEN FABRICS WEIGHT: 2300KG VOLTAGE: AC 380V 50/60HZ POWER: 5.5KW CAPACITY 400 PIECES PER MINUTE DIMENSION: 5000x1000x2000mm QUANTITY: 1 Learn More -

M-5143 ROUND COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5143 (1212YJJGXX11) L ROUND COTTON PAD MAKING MACHINE NONWOVEN ROUND COTTON PAD MAKING MACHINE MODEL: RD MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: DERANGEMENT PERMUTATION ROUND MOULD PUNCHING EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE EMBOSSING PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: CUSTOMIZED COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITION MATERIAL PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: PLC SERVO CONTROL OF MOTOR SPEED MOTOR: SERVO MOTOR PARAMETER-SETTING: COLOR TOUCH SCREEN PRODUCTION SPEED: 400 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 5.5KW WEIGHT: ABOUT 2300KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More

M-5143 ROUND COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5143 (1212YJJGXX11) L ROUND COTTON PAD MAKING MACHINE NONWOVEN ROUND COTTON PAD MAKING MACHINE MODEL: RD MATERIAL WIDTH: 95CM; DIAMETER: 70CM SLITTING DEVICE: DERANGEMENT PERMUTATION ROUND MOULD PUNCHING EMBOSSING DEVICE: STEEL ROLL EMBOSSING, THE EMBOSSING PATTERN CAN BE CUSTOMIZED PRODUCT SIZE: CUSTOMIZED COUNTING WAY: LEFT AND RIGHT COUNTING SLITTING MATERIAL: COTTON, NONWOVEN, COTTON COMPOSITION MATERIAL PRODUCT FEATURE: EDGE OPEN OR NOT CONTROL SYSTEM: PLC SERVO CONTROL OF MOTOR SPEED MOTOR: SERVO MOTOR PARAMETER-SETTING: COLOR TOUCH SCREEN PRODUCTION SPEED: 400 PIECES PER MINUTE AIR COMPRESSOR: PROVIDED BY YOURSELF PACKING SIZE: DEPENDING ON THE CONFIGURATION POWER: 380V / 50HZ / 5.5KW WEIGHT: ABOUT 2300KG DEPENDING ON THE CONFIGURATION QUANTITY: 1 Learn More -

AA-1153 MASK FILM PACKING MACHINE, UP TO 110 MASKS PER MINUTEAA-1153 MASK FILM PACKING MACHINE, UP TO 110 MASKS PER MINUTE 1. MAXIMUM PRODUCT LENGTH: 220mm 2. MAXIMUM PRODUCT WIDTH: 120mm 3. PACKAGING PRODUCT HEIGHT: 45mm 4. PACKING SPEED: 30 TO 110 BAGS PER MINUTE 5. PACKAGING FILM MAXIMUM WIDTH: 440mm 6. WEIGHT: 900 KGS QUANTITY: 1 Learn More

AA-1153 MASK FILM PACKING MACHINE, UP TO 110 MASKS PER MINUTEAA-1153 MASK FILM PACKING MACHINE, UP TO 110 MASKS PER MINUTE 1. MAXIMUM PRODUCT LENGTH: 220mm 2. MAXIMUM PRODUCT WIDTH: 120mm 3. PACKAGING PRODUCT HEIGHT: 45mm 4. PACKING SPEED: 30 TO 110 BAGS PER MINUTE 5. PACKAGING FILM MAXIMUM WIDTH: 440mm 6. WEIGHT: 900 KGS QUANTITY: 1 Learn More -

V-1471 AUTOMATIC CORELESS ROLL WINDER

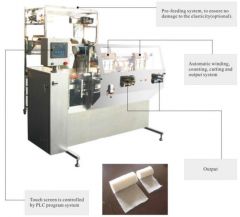

V-1471 AUTOMATIC CORELESS ROLL WINDERREFERENCE NUMBER: V-1471

AUTOMATIC CORELESS ROLL WINDER

THE MACHINE IS SUITABLE TO PROCESS CORELESS ELASTIC BANDAGE ROLLS.

HAS PRE-FEEDING SYSTEM, TO ENSURE NO DAMAGE TO THE ELASTICITY (OPTIONAL).

WITH AUTOMATIC WINDING, COUNTING, CUTTING, AND OUTPUT SYSTEM.

TOUCH SCREEN IS CONTROLLED BY PLC PROGRAM SYSTEM.

WORKING SPEED: 7 TO 11 BEATS PER MINUTE

END SURFACE TOLERANCE OF FINAL ROLLS (DEPENDS ON MATERIAL): ±2 TO 3.5mm

ROLLING TENSION: ADJUSTABLE

MAX. DIAMETER OF FINISHED BANDAGE: 6cm

QUANTITY: 1

Learn More