Search results for: 'Machine op'

- Related search terms

- machine tr

- machine''[0]''

- machine cap

- Machine+op

- machine de''

-

G-7433 MULTIFUNCTION MACHINE FOR SHREDDING FOAM, POLYESTER OR COTTON FIBER OPENING, MIXING AND PILLOW FILLINGMODEL 1600-H2Y-1360-1710-C7H SPECIFICATION 1.MIXING BOX: 1400 X 1200 X 2200mm 2.FOAM GRINDER: 2500 X 680 X 860mm 3.FIBER OPENER (1710-A7H): 2200 X 1080 X 1070mm VOLTAGE 220 VOLTS 60Hz POWER 0.75 X 2+5.5+4 +2.2 X 3 KW = 16.2 OUTPUT 100 TO 300 KG/H MIX PERCENTAGE ABOVE 98% LABOR 3 PERSONS WEIGHT 1530 KG LABOR 3 PERSONS WEIGHT 1530KG MACHINE DETAILS ONE FOAM SHREDDING MACHINE , ONE FIBER OPENING MACHINE, ONE FEEDING MACHINE, ONE MIXING BOX, TWO FIBER OR FOAM STUFFING NOZZLES (WITH FANS) STATIONS PRODUCT INTRODUCTION : THIS MACHINE IS A NEW MACHINE TO FILL PILLOWS, CUSHIONED SOFA SECTIONS, ETC. ITS GREAT ADVANTAGE IS THAT IT WILL NOT PRODUCE GRANULES AND BALL GRAINS WHEN MIXING CELLUCOTTON AND FOAM, PRODUCING A PRODUCT THAT FILLS WITH EXCELLENT ELASTICITY AND A SMOOTH SURFACE (FOR PILLOWS, A SMOOTH SURFACE IS ESPECIALLY IMPORTANT.) MAIN FUNCTION : IT CONSISTS OF A FOAM SHREDDER, A FIBER OPENER, A MIXING STATION AND TWO FILLING NOZZLES. BY SIMPLY PUTTING THE FOAM (INCLUDING SCRAP ),RAW COTTON (NON-CARDED AND CELLUCOTTON) INTO THE MACHINE, IT WILL AUTOMATICALLY OPEN THE CELLUCOTTON AND SHRED THE FOAM. THE DOSAGE RATIO OF EACH RAW MATERIAL CAN BE ADJUSTED OPTIONALLY, EVENLY MIX THEM AND THEN FILL INTO THE PRODUCT. QUANTITY: 1 Learn More

G-7433 MULTIFUNCTION MACHINE FOR SHREDDING FOAM, POLYESTER OR COTTON FIBER OPENING, MIXING AND PILLOW FILLINGMODEL 1600-H2Y-1360-1710-C7H SPECIFICATION 1.MIXING BOX: 1400 X 1200 X 2200mm 2.FOAM GRINDER: 2500 X 680 X 860mm 3.FIBER OPENER (1710-A7H): 2200 X 1080 X 1070mm VOLTAGE 220 VOLTS 60Hz POWER 0.75 X 2+5.5+4 +2.2 X 3 KW = 16.2 OUTPUT 100 TO 300 KG/H MIX PERCENTAGE ABOVE 98% LABOR 3 PERSONS WEIGHT 1530 KG LABOR 3 PERSONS WEIGHT 1530KG MACHINE DETAILS ONE FOAM SHREDDING MACHINE , ONE FIBER OPENING MACHINE, ONE FEEDING MACHINE, ONE MIXING BOX, TWO FIBER OR FOAM STUFFING NOZZLES (WITH FANS) STATIONS PRODUCT INTRODUCTION : THIS MACHINE IS A NEW MACHINE TO FILL PILLOWS, CUSHIONED SOFA SECTIONS, ETC. ITS GREAT ADVANTAGE IS THAT IT WILL NOT PRODUCE GRANULES AND BALL GRAINS WHEN MIXING CELLUCOTTON AND FOAM, PRODUCING A PRODUCT THAT FILLS WITH EXCELLENT ELASTICITY AND A SMOOTH SURFACE (FOR PILLOWS, A SMOOTH SURFACE IS ESPECIALLY IMPORTANT.) MAIN FUNCTION : IT CONSISTS OF A FOAM SHREDDER, A FIBER OPENER, A MIXING STATION AND TWO FILLING NOZZLES. BY SIMPLY PUTTING THE FOAM (INCLUDING SCRAP ),RAW COTTON (NON-CARDED AND CELLUCOTTON) INTO THE MACHINE, IT WILL AUTOMATICALLY OPEN THE CELLUCOTTON AND SHRED THE FOAM. THE DOSAGE RATIO OF EACH RAW MATERIAL CAN BE ADJUSTED OPTIONALLY, EVENLY MIX THEM AND THEN FILL INTO THE PRODUCT. QUANTITY: 1 Learn More -

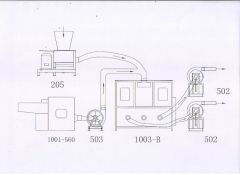

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINE

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINEREFERENCE NUMBER: L-2926

Learn More

1 X FIBER CARDING MACHINE

MODEL: 1001-560

1 X FIBER FEEDING MACHINE

MODEL: 503

1 X MIXING MACHINE

MODEL: 1003-B

2 X FILLING MACHINES

MODEL: 502

QUANTITY: 1 SET

FOAM SHREDDER

MODEL: 205

QUANTITY: 1 -

TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006 1. USED VECOPLAN SHREDDER, MODEL RG52-75 SPK 2. SINGLE-SHAFT DESIGN POWERED BY A 75 HP MOTOR AND IS EQUIPPED WITH 20 CUTTERS. 3. IT OFFERS A 52" X 58" FEED OPENING, 4. A 15" ROTOR, AND A 1.25" SCREEN. 5. BOTH THE FEED AND DISCHARGE CONVEYORS ARE INCLUDED. 6. YEAR 2006 7. REPORTEDLY LESS THAN 500 OPERATING HOURS. USED EXCLUSIVELY FOR SHREDDING 100% HARD DRIVES QUANTITY: 1 Learn More

TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006 1. USED VECOPLAN SHREDDER, MODEL RG52-75 SPK 2. SINGLE-SHAFT DESIGN POWERED BY A 75 HP MOTOR AND IS EQUIPPED WITH 20 CUTTERS. 3. IT OFFERS A 52" X 58" FEED OPENING, 4. A 15" ROTOR, AND A 1.25" SCREEN. 5. BOTH THE FEED AND DISCHARGE CONVEYORS ARE INCLUDED. 6. YEAR 2006 7. REPORTEDLY LESS THAN 500 OPERATING HOURS. USED EXCLUSIVELY FOR SHREDDING 100% HARD DRIVES QUANTITY: 1 Learn More -

TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022 VECOPLAN SHREDDER VAZ 1300-M – NEW (IN PLANT - COMPANY DECIDED NOT TO USE IT - AVAILABLE IMMEDIATELY - STILL IN WRAPPER) QUANTITY: 1 Learn More

TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022 VECOPLAN SHREDDER VAZ 1300-M – NEW (IN PLANT - COMPANY DECIDED NOT TO USE IT - AVAILABLE IMMEDIATELY - STILL IN WRAPPER) QUANTITY: 1 Learn More -

G-7287 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXING WITH SHREDDED FOAMPRODUCT INTRODUCTION : SPECIALLY DESIGNED FOR THE STUFFING PRODUCTS SUCH AS SOFA, SEAT CUSHION, PILLOW ETC. ITS GREASTEST ADVANTAGE IS THAT THE MIX OF COTTON FIBER WON'T FORM GRANULES. THE PRODUCTS HAVE A PLAIN & TIDY APPEARANCE WITH GOOD FLEXIBILITY (ESPECIALLY IMPORTANT TO PILLOWS AND SOFAS) Learn More

G-7287 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXING WITH SHREDDED FOAMPRODUCT INTRODUCTION : SPECIALLY DESIGNED FOR THE STUFFING PRODUCTS SUCH AS SOFA, SEAT CUSHION, PILLOW ETC. ITS GREASTEST ADVANTAGE IS THAT THE MIX OF COTTON FIBER WON'T FORM GRANULES. THE PRODUCTS HAVE A PLAIN & TIDY APPEARANCE WITH GOOD FLEXIBILITY (ESPECIALLY IMPORTANT TO PILLOWS AND SOFAS) Learn More -

G-7288 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXINGMODEL: B:SHT1360-1560-C7H-HY MEASURES: 3500x1620x1750mm VOLTAGE PER CUSTOMER REQUEST POWER : 0.75 +4+0.75+4+2.2 KW OUTPUT: 80 TO 150KG/H BLOOMS: 98% OR ABOVE WEIGHT: 800 KG Learn More

G-7288 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXINGMODEL: B:SHT1360-1560-C7H-HY MEASURES: 3500x1620x1750mm VOLTAGE PER CUSTOMER REQUEST POWER : 0.75 +4+0.75+4+2.2 KW OUTPUT: 80 TO 150KG/H BLOOMS: 98% OR ABOVE WEIGHT: 800 KG Learn More -

TT-7952 SHRED-TECH ST-50 SHREDDER, DUAL-SHAFTTT-7952 SHRED-TECH ST-50 SHREDDER, DUAL-SHAFT 1. BRAND: SHRED-TECH 2. MODEL: ST-50 3. MACHINE TYPE: SHREDDER (DUAL-SHAFT) QUANTITY: 1 Learn More

TT-7952 SHRED-TECH ST-50 SHREDDER, DUAL-SHAFTTT-7952 SHRED-TECH ST-50 SHREDDER, DUAL-SHAFT 1. BRAND: SHRED-TECH 2. MODEL: ST-50 3. MACHINE TYPE: SHREDDER (DUAL-SHAFT) QUANTITY: 1 Learn More -

TT-6932 SSI DUAL-SHEAR SHREDDER, YEAR 2013TT-6932 SSI DUAL-SHEAR SHREDDER, YEAR 2013 1. SSI DUAL-SHEAR SHREDDER 2. MODEL M100H (75) 3. HYDRAULIC DRIVE 4. USED QUANTITY: 1 Learn More

TT-6932 SSI DUAL-SHEAR SHREDDER, YEAR 2013TT-6932 SSI DUAL-SHEAR SHREDDER, YEAR 2013 1. SSI DUAL-SHEAR SHREDDER 2. MODEL M100H (75) 3. HYDRAULIC DRIVE 4. USED QUANTITY: 1 Learn More -

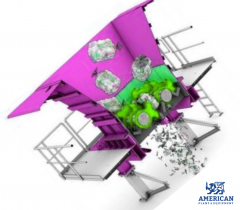

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More -

TT-1017 HOLLINGSWORTH SHRED MASTER, WIDTH 900mm, YEAR 1994TT-1017 HOLLINGSWORTH SHRED MASTER, WIDTH 900mm, YEAR 1994 COMPLETE WITH NEW CONTROL PANEL, EMERGENCY STOPS AND SAFETY TIME OUT SYSTEM MACHINE FOOTPRINT 3500mm LONG FROM CONVEYOR ENTRY TO FAN UNIT 1600mm WIDE QUANTITY: 1 Learn More

TT-1017 HOLLINGSWORTH SHRED MASTER, WIDTH 900mm, YEAR 1994TT-1017 HOLLINGSWORTH SHRED MASTER, WIDTH 900mm, YEAR 1994 COMPLETE WITH NEW CONTROL PANEL, EMERGENCY STOPS AND SAFETY TIME OUT SYSTEM MACHINE FOOTPRINT 3500mm LONG FROM CONVEYOR ENTRY TO FAN UNIT 1600mm WIDE QUANTITY: 1 Learn More