Search results for: 'mac o'

- Related search terms

- machine

- machine tr

- machine''''

- machine de''

- mach+3

-

SPINNBAU DOUBLE DOFFER NONWOVEN CARDREFERENCE NUMBER: T-6847 SPINNBAU DOUBLE DOFFER NONWOVEN CARD BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER NONWOVEN CARD NEW HIGH CAPACITY HOPPER FEEDER WITH CHUTE DELIVERY ELECTRONIC WEIGH SYSTEM “TS MICROFEED” NEW AC INVERTER DRIVE SYSTEM WITH TOUCH SCREEN CONTROL NEW AC GEARED MOTOR UNITS NEW DRIVE BELTS AS REQUIRED NEW SAFETY CIRCUIT, E-STOPS AND GUARD INTERLOCKS INCLUDING MACHINE REFURBISHMENT AND RE-PAINT TO RAL 7035 (LIGHT GREY) THE 2500mm SPINNBAU CARD CAN BE SPECIFIED FOR YOUR PRODUCTION REQUIREMENTS TOGETHER WITH A NEW CROSSLAPPER, OVENS AND NEEDLE LOOMS. RE-CONDITIONED QUANTITY: 1 Learn More

SPINNBAU DOUBLE DOFFER NONWOVEN CARDREFERENCE NUMBER: T-6847 SPINNBAU DOUBLE DOFFER NONWOVEN CARD BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER NONWOVEN CARD NEW HIGH CAPACITY HOPPER FEEDER WITH CHUTE DELIVERY ELECTRONIC WEIGH SYSTEM “TS MICROFEED” NEW AC INVERTER DRIVE SYSTEM WITH TOUCH SCREEN CONTROL NEW AC GEARED MOTOR UNITS NEW DRIVE BELTS AS REQUIRED NEW SAFETY CIRCUIT, E-STOPS AND GUARD INTERLOCKS INCLUDING MACHINE REFURBISHMENT AND RE-PAINT TO RAL 7035 (LIGHT GREY) THE 2500mm SPINNBAU CARD CAN BE SPECIFIED FOR YOUR PRODUCTION REQUIREMENTS TOGETHER WITH A NEW CROSSLAPPER, OVENS AND NEEDLE LOOMS. RE-CONDITIONED QUANTITY: 1 Learn More -

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More

AUTOMATEX, SPINNBAU NEEDLE PUNCH LINEREFERENCE NUMBER: T-6840 AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE BRAND: AUTOMATEX, SPINNBAU NEEDLE PUNCH LINE CONSISTING OF: BLEND LINE, 60” WIDE, 4 HOPPERS WITH 12 HEAVY DUTY EXTENDED APRONS & NEW ELECTRONIC WEIGHING SYSTEM (2016). ALL MACHINES COMPLETELY RECONDITIONED IN 2016. OMMI STACK RESERVE, AUTOMATIC COMBO 332, YEAR 2000 SPINNBAU CARD, 2500mm, DOUBLE DOFFER, YEAR 1995, REPORTED ~1500 TO 1800 PPH CAPACITY DEPENDING UPON PRODUCT. AUTOMATEX FA/3000 TC CROSSLAPPER, YEAR 1997, AC DRIVES. BATT DRAFTER, 12 ROLLS. AUTOMATEX PR-100/T PRE-NEEDLER, 60mm STROKE, YEAR 1997 DRAFTER, 5 ROLLS. AUTOMATEX AG 154/TB NEEDLE LOOM, QUAD PUNCH, 50mm STROKE, YEAR 1997 FOUR ROLL STRETCH. METAL DETECTOR. ENTEX TENTER WITH VERTICAL IR HEAT BANKS, YEAR 1997 WINDER, YEAR 1997 PERKINS 4 ROLL CALENDER, NO STEEL ROLLS OR HEAT SYSTEM INCLUDED BUT MIGHT BE NEGOTIATED. EHHARDT+LEIMER GUIDER MODEL SE 11062, YEAR 2013 ENTEC WINDER, YEAR 1997 FINISHED WIDTH REPORTED OF 210" BUT COULD GO WIDER. LINE RAN PRIMARILY GEOTEXTILE & BEDDING PRODUCTS FROM 4.5 TO 10 OZ/YD. QUANTITY: 1 Learn More -

T-6391 GUILLOTINE CUTTING MACHINE FOR NON-WOVEN, WIDTH 2400mm, YEAR 1997 TO 1998

T-6391 GUILLOTINE CUTTING MACHINE FOR NON-WOVEN, WIDTH 2400mm, YEAR 1997 TO 1998KNEE LEVER SCISSORS

Learn More

MAKE MOHR / FLEISSNER

CUTTING WIDTH: 2400mm

YEAR 1997 - EXCHANGE THE WHOLE CUTTING BARK AND BACKING KNIFES

YEAR 1998 - HYDRAULIC UNIT COMPLETELY NEW

YEAR 1998 - KNIFE BAR SYSTEM AND LOWER KNIFE COMPLETELY NEW

KNIFE BAR HAS TWO-SIDED HOLD DOWN WITH KNIFE GUIDE, KNIFE AND LOWER KNIFE AS NEW

HYDRAULIC CYLINDER SEAL KIT - NEW

HYDRAULIC OIL - NEW

MACHINE IS IN GOOD CONDITION

BLADE IS IN GOOD CONDITION

WE ARE CUTTING WOOL FLEECE UP TO 4000 GR/M² WITHOUT ANY PROBLEMS

POWER: 400 V, 50 HZ, 8.0 KW

SPACE REQUIREMENTS: L: 4250mm X B 1900mm X H 2600mm

THIS MACHINE IS AVAILABLE IMMEDIATELY -

L-3203 FOAM PEELING MACHINE MODEL 2150 CUTTING WIDTH 2150mm – FOR REBOND FOAM BLOCKS

L-3203 FOAM PEELING MACHINE MODEL 2150 CUTTING WIDTH 2150mm – FOR REBOND FOAM BLOCKSREFERENCE NUMBER: L-3203

Learn More

MODEL: 2150

MACHINE EXTERNAL SIZE: 5000mm LONG X 2500mm WIDE X 2000mm HIGH

QUANTITY: 1 -

L-1824 FOAM PILLOW PUNCHING MACHINE HOLE DIAMETER 8mm

L-1824 FOAM PILLOW PUNCHING MACHINE HOLE DIAMETER 8mmREFERENCE NUMBER: L-1824

Learn More

MACHINE SIZE: 4500 X 1200 X 2250mm

QUANTITY: 1 -

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSION

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSIONREFERENCE NUMBER: L-1760

Learn More

FOR PUNCHING HOLES IN PU FOAM

WORKING WIDTH: 2100mm

QUANTITY: 1 -

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)REFERENCE NUMBER: L-1502

Learn More

MODEL: UE2410

QUANTITY: 1 -

L-4271 WEST POINT SIZING MACHINE, WITH DOUBLE SIZE BOX, WIDTH 108”, YEAR 1998

L-4271 WEST POINT SIZING MACHINE, WITH DOUBLE SIZE BOX, WIDTH 108”, YEAR 1998REFERENCE NUMBER: L-4271

Learn More

BRAND: WEST POINT

YEAR: 1998

QUANTITY: 1 -

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mmM-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

2 ROTARY CUTTERS TYPE CMT-900, WORKING WIDTH 900mm, INCLUDING FEEDING CONVEYORS.

Learn More

1 ELECTRONIC METAL DETECTOR, MOUNTED ON FEEDING CONVEYOR OF THE 1ST CUTTER.

1 PNEUMATIC MATERIAL TRANSPORT WITH SPECIAL FAN FOR RAGS ETC.

1 STATIONARY ZIG-ZAG HUMP MAGNET MOUNTED IN TUBE FOR MATERIAL TRANSPORT.

2 MIXING/ RELAXING STORAGE BINS FOR CUTTED RAGS WITH SPRAYING ROOM

IN FRONT OF:

1 FEEDING MACHINE TYPE CCS-1500, WORKING WIDTH 1500mm, AUTOMATIC PNEUMATIC FEEDING FROM STORAGE BINS, ELECTRONIC LEVEL CONTROL AND DOSING CONVEYOR TO TEARING LINE.

1 RAG TEARING LINE WITH 4 SECTIONS TYPE MASTER MCM-1550-DD, WORKING WIDTH 1500mm, TAMBOUR DIAM. 1000mm.

1 ELECTRONIC CONTROL PANEL FOR THE WHOLE LINE INCL. TOUCH SCREEN AND INVERTER DRIVER FOR SEVERAL MOTORS.

6 FILTER UNITS.

- ALL EQUIPMENT “AS NEW” SINCE RUNNING ONLY A FEW HOURS.

- CAPACITY UP TO 1000KG/HR. -

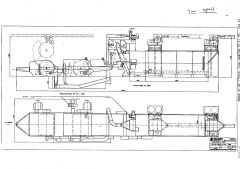

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm