Search results for: 'Bag machine'

- Related search terms

- machine tr'A=0

- Machine op

- Machine ope

- Machine+ope

- machine de''

-

M-5282 COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGSREFERENCE NUMBER: M-5282 (1313121ANW12RX) L COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS NEW IN STOCK COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS FULLY AUTOMATIC MACHINE FOR PACKAGING ROUND PADS MADE OF COTTON OR SYNTHETIC FIBERS FOR COSMETIC USE IN DRAWSTRING BAGS AND BAGS WITH ZIPPER/ZIP-LOCK MADE OF PLASTIC MATERIAL. THE MACHINE REACHES THE MAXIMUM PERFORMANCE OF ABOUT 30 BAGS PER MINUTE. QUANTITY AVAILABLE: 1 Learn More

M-5282 COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGSREFERENCE NUMBER: M-5282 (1313121ANW12RX) L COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS NEW IN STOCK COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS FULLY AUTOMATIC MACHINE FOR PACKAGING ROUND PADS MADE OF COTTON OR SYNTHETIC FIBERS FOR COSMETIC USE IN DRAWSTRING BAGS AND BAGS WITH ZIPPER/ZIP-LOCK MADE OF PLASTIC MATERIAL. THE MACHINE REACHES THE MAXIMUM PERFORMANCE OF ABOUT 30 BAGS PER MINUTE. QUANTITY AVAILABLE: 1 Learn More -

P-3321 LEMO CAPMAT ST-TU 1100 DIAPER BAG MACHINE, YEAR 1995

P-3321 LEMO CAPMAT ST-TU 1100 DIAPER BAG MACHINE, YEAR 1995P-3321 LEMO CAPMAT ST-TU 1100 DIAPER BAG MACHINE, YEAR 1995

MAKE: LEMO CAPMAT

MODEL: ST-TU 1100

DIAPER BAG MACHINE

YEAR: 1995QUANTITY: 1

Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

M-5139 COTTON GAUZE PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5139 (1212MNTQXX11) L COTTON GAUZE PAD PRODUCTION MACHINE GAUZE PAD 100% BLEACHED WOVEN COTTON GAUZE FOR SINGLE USE MODEL G-630 STERILE/NON-STERILE X-RAY WITH/WITHOUT MODEL FOLDED EDGE/UNFOLDED EDGE YARN 40S/21S/32S MESH 7/9/11/13/15/17/20 THREAD, 19X9/18X10/20X12/19X15/24X20/26X18/30X20 SIZE 2”X2”/3”X3”/4”X4”/4”X8”/8”X16”, 5X5CM/7.5X7.5CM/10X10CM/10X20CM/20X40CM PLY 4/8/12/16/24/32 PACKAGING- STERILE: 1/2/5/10 PCS PER INDIVIDUAL BAG NON-STERILE: 100/200 PCS PER BAG STERILIZATION: RAY GAMMA / EO STANDARD: ISO 13485/CE/FDA PRODUCTION CAPACITY: 150,000 PCS PER DAY MOQ: 20,000 PACKS FOR EACH SHIPMENT EXPIRY DATE: 3 YEARS FOR STERILE, 5 YEARS FOR NON-STERILE THE 4X4 GAUZE SPONGES ARE HIGHLY ABSORBENT MATERIAL, IDEAL FOR OINTMENT AND ANTISEPTIC APPLICATION GOOD FOR PREPPING INJECTION SITES AND CLEANING, PACKING, AND DRESSING WOUNDS 8-PLY- PACK OF 200 QUANTITY: 1 Learn More

M-5139 COTTON GAUZE PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5139 (1212MNTQXX11) L COTTON GAUZE PAD PRODUCTION MACHINE GAUZE PAD 100% BLEACHED WOVEN COTTON GAUZE FOR SINGLE USE MODEL G-630 STERILE/NON-STERILE X-RAY WITH/WITHOUT MODEL FOLDED EDGE/UNFOLDED EDGE YARN 40S/21S/32S MESH 7/9/11/13/15/17/20 THREAD, 19X9/18X10/20X12/19X15/24X20/26X18/30X20 SIZE 2”X2”/3”X3”/4”X4”/4”X8”/8”X16”, 5X5CM/7.5X7.5CM/10X10CM/10X20CM/20X40CM PLY 4/8/12/16/24/32 PACKAGING- STERILE: 1/2/5/10 PCS PER INDIVIDUAL BAG NON-STERILE: 100/200 PCS PER BAG STERILIZATION: RAY GAMMA / EO STANDARD: ISO 13485/CE/FDA PRODUCTION CAPACITY: 150,000 PCS PER DAY MOQ: 20,000 PACKS FOR EACH SHIPMENT EXPIRY DATE: 3 YEARS FOR STERILE, 5 YEARS FOR NON-STERILE THE 4X4 GAUZE SPONGES ARE HIGHLY ABSORBENT MATERIAL, IDEAL FOR OINTMENT AND ANTISEPTIC APPLICATION GOOD FOR PREPPING INJECTION SITES AND CLEANING, PACKING, AND DRESSING WOUNDS 8-PLY- PACK OF 200 QUANTITY: 1 Learn More -

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More -

M-4892 HIGH-SPEED NEEDLE PUNCHING MACHINE

M-4892 HIGH-SPEED NEEDLE PUNCHING MACHINEM-4892 HIGH-SPEED NEEDLE PUNCHING MACHINE

MACHINE WIDTH: 2000mm TO 9200mm

NEEDLE DENSITY: 4000 TO 8000N/M

NEEDLE STROKE 30mm TO 60mm

PUNCHING FREQUENCY: 800 TO 1200S/MINQUANTITY: 1

Learn More -

M-5335 DELL’ORCO & VILLANI RAG TEARING LINES + BALE PRESSREFERENCE NUMBER: M-5335 (220DSHLXX1) L DELL’ORCO & VILLANI RAG TEARING LINES + BALE PRESS (2) X DELL’ORCO & VILLANI CUTTERS YEAR 1989 (2) X DELL’ORCO & VILLANI MIXING ROOMS + BIN EMPTIER TYPE FA / 3030 / T. (1) X DELL’ORCO & VILLANI VOLUMATIC FEEDER, MODEL CARICATORE TYPE CS / 1600, YEAR 1999 (1) X DELL’ORCO & VILLANI RAG TEARING MACHINE, 4 CYLINDERS YEAR 1999, WIDTH 1500mm, EACH DRUM MODEL M/1500, TYPE SFILACCIATRICE (1) X DELL’ORCO & VILLANI VOLUMATIC FEEDER, MODEL CARICATORE TYPE CS / 1600, YEAR 1989 (1) X DELL’ORCO & VILLANI RAG TEARING MACHINE, 3 CYLINDERS YEAR 1989, WIDTH 1500mm, EACH DRUM MODEL M/1500, TYPE SFILACCIATRICE (1) X DELL’ORCO & VILLANI BALE PRESS, TYPE RA / 100, WITH 2 CHAMBERS (ROTATIVE SYSTEM) WITH WEIGHING DEVICE (SCALE FOR KG OF EACH BALE) (1) X DELL’ORCO & VILLANI DUST COLLECTING INSTALLATION, WITH BAGS TO COLLECT THE DUST QUANTITY AVAILABLE: 10 Learn More

M-5335 DELL’ORCO & VILLANI RAG TEARING LINES + BALE PRESSREFERENCE NUMBER: M-5335 (220DSHLXX1) L DELL’ORCO & VILLANI RAG TEARING LINES + BALE PRESS (2) X DELL’ORCO & VILLANI CUTTERS YEAR 1989 (2) X DELL’ORCO & VILLANI MIXING ROOMS + BIN EMPTIER TYPE FA / 3030 / T. (1) X DELL’ORCO & VILLANI VOLUMATIC FEEDER, MODEL CARICATORE TYPE CS / 1600, YEAR 1999 (1) X DELL’ORCO & VILLANI RAG TEARING MACHINE, 4 CYLINDERS YEAR 1999, WIDTH 1500mm, EACH DRUM MODEL M/1500, TYPE SFILACCIATRICE (1) X DELL’ORCO & VILLANI VOLUMATIC FEEDER, MODEL CARICATORE TYPE CS / 1600, YEAR 1989 (1) X DELL’ORCO & VILLANI RAG TEARING MACHINE, 3 CYLINDERS YEAR 1989, WIDTH 1500mm, EACH DRUM MODEL M/1500, TYPE SFILACCIATRICE (1) X DELL’ORCO & VILLANI BALE PRESS, TYPE RA / 100, WITH 2 CHAMBERS (ROTATIVE SYSTEM) WITH WEIGHING DEVICE (SCALE FOR KG OF EACH BALE) (1) X DELL’ORCO & VILLANI DUST COLLECTING INSTALLATION, WITH BAGS TO COLLECT THE DUST QUANTITY AVAILABLE: 10 Learn More -

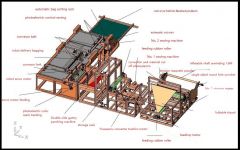

M-5221 NONWOVEN LINE WIDTH 2500mm

M-5221 NONWOVEN LINE WIDTH 2500mmREFERENCE NUMBER: M-5221 (1313565TNY12RX) L

NONWOVEN LINE WIDTH 2500mmCARD FEEDING

CARDINGQUANTITY AVAILABLE: 1

Learn More -

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSION

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSIONREFERENCE NUMBER: L-1760

Learn More

FOR PUNCHING HOLES IN PU FOAM

WORKING WIDTH: 2100mm

QUANTITY: 1