Search results for: 'cylinders'

-

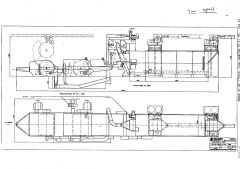

J-2364 LAROCHE SUPER OLYMPIC TEARING LINES, WW 1500mm, 6 CYLINDERS – NEW CONTROLS

J-2364 LAROCHE SUPER OLYMPIC TEARING LINES, WW 1500mm, 6 CYLINDERS – NEW CONTROLSMAKE: LAROCHE

MODEL: SUPER OLYMPIC

WIDTH: 1500mm

YEAR: MID 1980’S

6 CYLINDERS EACH LINE

CYLINDER DIAMETER: 1000mm

ALL CYLINDERS ARE DESIGNED FOR PINNED LAGS AND THERE IS LIFE LEFT IN MOST OF THE LAGS SETS.

LAGS: (1) 8mm x 135, (1) 10mm x 160, (1) 12 x 166, (3) 13mm x 174

EACH CYLINDER FED BY A FEED ROLL TO FEED DISH COMBINATION AND THE FIBER IS TRANSFERRED TO THE FOLLOWING CYLINDER VIA A CONDENSING SECTION.

MOTORS: 3 x 150 HP 575 VOLT

TOTAL REQUIRED POWER: 875 AMPS

NEW CONTROLS WITH ABB DRIVES

FEED CHUTES

LUMMUS BALERS

PINNED CYLINDERS

TEMAFA BLENDING BINS

EXIT CONVEYORS

EACH SECTION EQUIPPED WITH ANSUL DRY POWDER FIRE PROTECTION SYSTEM THAT IS ACTIVATED FROM EMBER DETECTED IN THE DUCT REMOVAL PIPING.

LINES INCLUDE ALL NECESSARY FANS, MAGNETS, DUCTING AND WIRINGIN PERFECT WORKING ORDER

QUANTITY: 2 LINES

Learn More -

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm -

XL CLEANERS, WIDTH 56 INCHES, 6 DOUBLE XL CYLINDERS

XL CLEANERS, WIDTH 56 INCHES, 6 DOUBLE XL CYLINDERSWIDTH: 56 INCHES

Learn More

THERE ARE THREE SETS OF DOUBLE XL or 6 TOTAL CYLINDERS

PLEASE SEE PHOTO FOR CONFIGURATION -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

R-6969 GAMATEX SIZING MACHINE, YEAR 1988

R-6969 GAMATEX SIZING MACHINE, YEAR 1988REFERENCE NUMBER: R-6969

Learn More

MAKE: GAMATEX

TYPE: BM 85

QUANTITY: 1 -

L-4752 SUCKER MULLER HACOBA SIZING MACHINE, TYPE C-40, WIDTH OF PANS 1800mm, WIDTH OF EXIT 3500mm YEAR 1999

L-4752 SUCKER MULLER HACOBA SIZING MACHINE, TYPE C-40, WIDTH OF PANS 1800mm, WIDTH OF EXIT 3500mm YEAR 1999REFERENCE NUMBER: L-4752

Learn More

TYPE: C-40

WORKING WIDTH: 1800mm

YEAR: 1999 -

A-1548 (0707GHBAV06) A SUCKER MULLER HACOBA SIZING MACHINE, YEAR 1999, EXIT DELIVERY, WIDTH 3400mm

A-1548 (0707GHBAV06) A SUCKER MULLER HACOBA SIZING MACHINE, YEAR 1999, EXIT DELIVERY, WIDTH 3400mmREFERENCE NUMBER: A-1548 (0707GHBAV06) A

Learn More

BRAND: SUCKER MULLER HACOBA

WIDTH 3400mm

YEAR: 1999

QUANTITY: 1 -

R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999

R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999R-1170 DELL’ ORCO VILLANI RAG TEARING LINE + BALE PRESS, YEAR 1989 TO 1999

DETAILS:

DELL’ ORCA VILLANI RAG TEARING LINE + BALLING MACHINE

COMPOSED BY:

ITEM 001

DELL’ ORCA VILLANI CUTTERS

YEAR: 1989

QUANTITY: 2ITEM 002

DELL’ ORCA VILLANI MIXING ROOMS + BIN EMPTIER

TYPE: FA/3030/T

QUANTITY: 2ITEM 003

DELL’ ORCA VILLANI VOLUMATIC FEEDER

MODEL: CARICATORE

TYPE: CS/1600

YEAR: 1999

QUANTITY: 1ITEM 004

DELL’ ORCA VILLANI RAG TEARING MACHINE

4 CYLINDERS

YEAR: 1999

WIDTH: 1500mm

EACH DRUM MODEL: M/1500

TYPE: SFILACCIATRICE

QUANTITY: 1ITEM 005

DELL’ ORCA VILLANI VOLUMATIC FEEDER

MODEL: CARICATORE

TYPE: CS/1600

YEAR: 1989

QUANTITY: 1ITEM 006

DELL’ ORCA VILLANI RAG TEARING MACHINE

3 CYLINDERS

YEAR: 1989

WIDTH: 1500mm

EACH DRUM MODEL: M/1500

TYPE: SFILACCIATRICE

QUANTITY: 1ITEM 007

DELL’ ORCA VILLANI BALE PRESS

TYPE: RA/100

WITH 2 CHAMBERS (ROTATIVE SYSTEM)

WITH WEIGHING DEVICE (SCALE FOR KG OF EACH BALE)

QUANTITY: 1ITEM 008

DELL’ ORCA VILLANI DUST COLLECTING INSTALLATION

WITH BAGS TO COLLECT THE DUST

QUANTITY: 1QUANTITY: 1 LINE

Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More