Search results for: 'cont''

- Related search terms

- cont'[0]

- cont'[0]'123

- cont''

- cont'''

- cont''''

-

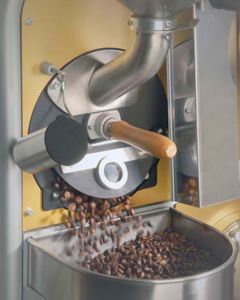

R-7066 COFFEE BAKING MACHINE (INDUSTRIAL) 803N

R-7066 COFFEE BAKING MACHINE (INDUSTRIAL) 803NR-7066 COFFEE BAKING MACHINE (INDUSTRIAL) 803N

1 PS PACKAGE VOLUME (L X W X H): 1240 X 1180 X 1180mm

1 PS PACKAGE TOTAL WEIGHT: 370 KG

POWER CONSUMPTION: 450 WATTS

BAKING CAPACITY: 4 KG

NUMBER OF BAKING DRUMS: FREE TO ADJUST (UP TO 100 RPM)

NUMBER OF COOLING SLOTS: 15 TURNS

HEATING METHOD: BARREL GAS (LPG) OR NATURAL GAS (LNG)

BAKING METHOD: SEMI-HOT AIR TYPE

BAKING TIME: GENERALLY ABOUT 15 MINUTES

PRODUCT DIMENSIONS (L X W X H): 1700 X 600 X 1700mm

PRODUCT WEIGHT: ABOUT 240 KG

CAST IRON INNER POT

STRONG COOLING TROUGH

CAN ACCURATELY CONTROL THE GAS FLOW

BUILT-IN AUTOMATIC SAFETY IGNITION SYSTEM (OVER-TEMPERATURE. POWER OFF. WHEN THE FLAME CAN AUTOMATICALLY CUT OFF THE GAS SOURCE

BUILT-IN USB OUTPUT CABLE, CAN BE CONNECTED TO THE COMPUTER AND RECORD BAKING INFORMATION

BUILT-IN BAKING DRUM SPEED DISPLAY TABLE

13-STAGE DAMPER FINE-TUNINGQUANTITY: 1

Learn More -

R-7067 COFFEE ROASTING MACHINE (FOR INDUSTRIAL USE) 805N

R-7067 COFFEE ROASTING MACHINE (FOR INDUSTRIAL USE) 805NR-7067 COFFEE ROASTING MACHINE (FOR INDUSTRIAL USE) 805N

MECHANICAL DIMENSIONS (L X W X H): 1580 X 1310 X 1850mm

MECHANICAL WEIGHT: ABOUT 420 KG

1 PS PACKAGE VOLUME (L X W X H): 2300 X 900 X 1900mm

1 PS PACKAGE TOTAL WEIGHT: 570 KG

POWER CONSUMPTION: 1200 WATT

BAKING CAPACITY: 6 KG

NUMBER OF BAKING DRUMS: FREE TO ADJUST (UP TO 120 RPM)

NUMBER OF COOLING SLOTS: 15 TURNS

HEATING METHOD: BARREL GAS OR NATURAL GAS

BAKING METHOD: SEMI-HOT AIR TYPE

BAKING TIME: GENERALLY ABOUT 15 MINUTES

CAST IRON INNER POT

STRONG COOLING TROUGH

CAN ACCURATELY CONTROL THE GAS FLOW

BUILT-IN AUTOMATIC SAFETY IGNITION SYSTEM (OVER-TEMPERATURE. POWER OFF. WHEN THE FLAME CAN AUTOMATICALLY CUT OFF THE GAS SOURCE

BUILT-IN USB OUTPUT CABLE, CAN BE CONNECTED TO THE COMPUTER AND RECORD BAKING INFORMATION

BUILT-IN BAKING DRUM SPEED DISPLAY TABLE

13-STAGE DAMPER FINE-TUNINGQUANTITY: 1

Learn More -

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

R-6857 TORREFACTO ROASTING MACHINES

R-6857 TORREFACTO ROASTING MACHINESR-6857 TORREFACTO ROASTING MACHINES

THOR FKT

THE ROASTING MACHINE THOR FKT MB FOR ROASTED COFFEE WITH SUGAR IS BOUND AT HIGH HOURLY PRODUCTION. SINCE GREEN COFFEE IS ABLE TO OBTAIN A HOMOGENEOUS BAKING OF THE COFFEE IN 20 MINUTES FOR EACH CYCLE, WORKING IN AUTOMATIC MODE OR SEMI-AUTOMATIC.

THE ROASTING THOR FKT MB IS EQUIPPED WITH A STOVE DETACHED, BUILT IN STEEL AND REFRACTORY MATERIAL; THE BURNER, CAN BE GAS (TYPE MODULATING) OR OIL-IN 2/3 FLAME LEVELS, DEPENDING ON THE APPLICATIONS.

THE COOLING DRUM RECEIVES THE PRODUCT DIRECTLY FROM THE DISCHARGE OF THE ROASTING MACHINE.

THE INTERNAL MIXERS WERE DESIGNED AND TESTED IN ORDER TO GUARANTEE AN OPTIMAL COOLING OF THE PRODUCT.

THE DISCHARGE OF THE PRODUCT IS MADE BY REVERSING THE DIRECTION OF ROTATION OF THE DRUM; ON THE COOLING DRUM DOORS FOR THE INSPECTION AND CLEANING OF THE DRUM ARE PROVIDED.

ADDITIONAL FUNCTIONS OF ROASTING MACHINE THOR FKT MB:POSSIBILITY OF TOTALLY OR PARTIALLY AUTOMATIC CONTROLLING BY PLC + TOUCH SCREEN AND SAVING PARAMETERS ROASTING PERFORMED BY ELECTROMECHANICAL/ELECTROPNEUMATIC DEVICES.

PLC WITH OPERATOR INTERFACE;

DISPLAY TO MONITOR THE FUNCTIONS OF ROASTING TIME AND TEMPERATURE;

AUDIBLE AND VISUAL ALARM ON THE MOTOR ALARM INSTALLED AND ON THE BURNER BLOCK.

COLOR: AVAILABLE ACCORDING TO CUSTOMER SPECIFICATIONS

OPTIONAL COMPONENTS:ELECTRICAL CONNECTION MANAGEMENT SYSTEM WITH PC AND TOUCH-SCREEN

Learn More

HEAT RECOVERY UNIT

POST-COMBUSTOR MODEL KAT

BRIQUETTE PRESS -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

P-6605 PROBAT PRODUCTION ROASTER

P-6605 PROBAT PRODUCTION ROASTERP-6605 PROBAT PRODUCTION ROASTER

HERE IS A CLASSIC PRODUCTION PROBAT ROASTER - BUILT TO RUN 24/7 . . . AND IT HAS BEEN SITTING FOR THE PAST 4 YEARS AS THEY GOT IN TROUBLE FOR NOT HAVING AN AFTERBURNER. NOW THEY ARE REPLACING THE MACHINE WITH A NEW MORE MODERN (AND A LOT MORE EXPENSIVE) SYSTEM. THIS MACHINE IS SCHEDULED TO BE PULLED AND WILL GO INTO STORAGE DURING JULY. EURO LOCATION AND EASY TO LOAD INTO CONTAINER AND ARRIVE AT YOUR NEW LOCATION. MOST ALL THE UTILITIES CAN BE CHANGED TO ACCOMODATE YOUR INDUSTRIAL GAS/PROPANE AND 3 PHASE ELECTRICAL.

GREAT INSTALLATION CONSISTING OF DUAL CYCLONES - ONE FOR ROASTING CHAFF COLLECTION AND THE OTHER FOR THE COOLER - ALL THE ROASTING AND COOLING FOR FINGER TOUCH PNUEMATIC CONTROL (ALL ORIGINAL) AS WELL AS COFFEE DE-STONINGL; EVEN THE CYCLONES ARE EQUIPPED WITH ROTARY VALVES AND SUCTION SYSTEM. VERY SOLID PROBAT INSTALLATION AND THAT MEANS IT IS SUPER TOUGH WITH TOP LINE PARTS.

THIS IS PERFECT MACHINE FOR COFFEE, COCOA AND EVEN MALT ROASTING.

QUANTITY: 1

Learn More -

P-6603 SILOS ROASTED COFFEE STORAGE (STONER FED)

P-6603 SILOS ROASTED COFFEE STORAGE (STONER FED)P-6603 SILOS ROASTED COFFEE STORAGE (STONER FED)

THIS UNIT NEEDS TO BE REMOVED TO MAKE ROOM FOR BIG WALK-IN COOLER - AND IT CAN BE CHANGED RADICALLY TO FIT MOST ANY SITUATION. THE ACTUAL DE-STONER IS SITTING NEXT TO THE COOLER ON A 90 KILO PROBAT (ALTHOUGH THIS STONER/STORAGE SILO IS NOT LIMITED TO ANY SIZE AS THE STONER DOES NOT KNOW HOW BIG THE COOLER - IT ONLY KNOWS TO KEEP GOING TILL IT IS EMPTY.

STONER LIFTS COFFEE UP TO A SURGE HOPPER ABOVE - THEN GRAVITY FEEDS DOWN TO THE BIN THAT YOU TOLD IT TO GO . . . HOWEVER, THERE ARE SEVERAL OPTIONS ON HOW SUCH A SILO GETS LOADED - EVERYTHING FROM A SUCTION WAND TO OTHER CONFIGURATIONS OF THE GRAVITY ONE PICTURED . . . AS THIS IS A DISCUSSION TOPIC. THE TOP SECTION STANDS ALONE AND CAN EASILY BE REMOVED. THE ACTUAL STORAGE SILOS STAND ALONE AND THEY CAN BE EASILY REMOVED - OR EVEN BE MADE TALLER SHORTER TO FIT YOUR BUILDING. THEN THE BASE CAN BE ALTERED ACCORDINGLY. NOTICE THE CONTROL BOX ON THE LEFT SIDE - THAT IS 21 INCHES WIDE X 24 INCHES TALL AND 10 INCHES DEEP AND THAT CAN BE MOUNTED ON ANY WALL OR RIGHT WHERE IT IS . . . TOTALLY MOVABLE.

92.5 INCHES WIDE - THAT IS JUST SHORT OF 8 FEET OVERALL LENGTH.

8 FEET TALL FOR THE MAIN STORAGE PLUS THE STUFF ON TOP THAT MAY END UP BEING CHANGED.

36 INCHES WIDE ON THE STAND - BUT ACTUAL STORAGE IS 32 INCHES

19.5 CUBIC FEET OR 400 POUNDS ROASTED COFFEE

CAN BE USED FOR GREEN COFFEE - 850 POUNDS+

YOU CAN INSTALL ANY SPACE SAVING LOADING BLOWER, VACUUM OR EVEN AUGAR . . . GREEN OR ROASTED WHOLE BEAN

BASICALLY THERE ARE SO MANY CONFIGURATIONS OR WAYS TO USE THIS UNIT - IT IS JUST GREAT TO FIND SOMETHING SO WELL PRESERVED, AS THIS HAS BEEN SITTING UNUSED FOR AT LEAST 15 YEARS EVEN THOUGH THE ACTUAL COFFEE OPERATION IS VERY ACTIVE - JUST DID NOT USE THIS PARTICULAR CONFIGURATION.QUANTITY: 1

Learn More -

P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009

P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009P-5043 PROBAT (P5) ROASTER 5 KILOS YEAR 2009

PROBAT

MODEL: P5

ROASTER

YEAR: 2009

5 KILOS

NICE FULL CONTROL PANEL MOUNTED ON LEFT SIDE

AVERAGE 33 POUNDS PER HOUR. MAXIMUM 10 POUNDS PER BATCH

PROBAT HAS RETURNED TO THEIR CLASSIC, NOSTALGIC DESIGN CONTACT COMPONENTS MADE OF HIGH-QUALITY CAST IRON

SIMULTANEOUS ROASTING AND COOLING HAS JUST BEEN ADDED WITH SUCTION FOR COOLING AND ROASTING EXHAUST AIR

SEPARATE MOTORS FOR DRUM DRIVE, COOLING SIEVE STIRRING ARM AS WELL AS ROASTER AND COOLER FANS – NO MORE BELTS AND CHAINS, A GREAT IMPROVEMENT.

SIMPLIFIED CLEANING BY REMOVABLE LATERAL WALLS

SEPARATE ROASTING CYCLONE FOR AN EFFECTIVE CHAFF ASPIRATION WHICH CAN BE LOCATED IN DIFFERENT LOCATIONS AS NEEDED

CLEAR OPERATION WITH DIGITAL TIME AND TEMPERATURE DISPLAY

EMERGENCY DISCHARGE IN CASE OF POWER OUTAGE USING SUPPLIED CRANK. ADAPTER MAKES POSSIBLE THE USE OF A CORDLESS SCREWDRIVER

OPTIONAL (PROBATONE 5 / PROBATONE 12): PS NASED CONTROL SYSTEM WITH VISUALISATION OF PRODUCT TEMPERATURE CURVE AND RECIPE MEMORYQUANTITY: 1

Learn More -

P-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOS

P-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOSP-5042 JOPER CAST IRON SMALL BATCH ROASTER 5 KILOS

JOPER

CAST IRON SMALL BATCH ROASTER

5 KILOS

JOPER 5 KILOS AUTOMATIC PROFILING CONTROLS. SHIPS WITH YOUR ELECTRICAL AND GAS SPECIFICATIONS. FEATURES THE SAME CAST IRON ATTRIBUTES OF THE OLD PROBAT SCHOOL. THE DRUM ROASTING MACHINE RUNS QUIETLY DUE TO THE HIGH FIBER INSULATION AND NO PULLEYS OR CHAINS IN ITS DESIGN. CHAFF REMOVAL IS QUICK AND EFFICIENT DUE TO THE FREE STANDING DESING. THE POWERFUL SELF CLEANING ROASTING AND COOLING FANS ALLOWS THE SEPARATE AIRFLOW. TWO MODELS: MANUAL AND PROFILE (AUTOMATIC)DATA:

LOAD CAPACITY 11/POUUNDS BATCH 44 POUNDS PER HOUR

ROASTING TIME 15 MINUTES COOLING 3 MINUTES

NATURAL GAS OR PROPANE

ELECTRICAL REQUIREMENTS CAN NE BEUILT TO YOUR SPECIFICATIONS.

220v 3 PHASE IS THE MOST QUIET, BUT THE ELECTRICAL CAN BE BUILT TO YOUR NEEDED VOLTAGE AND PHASE.

LOW NOX PRECISE BURNER ADJUSTMENT

WEIGHT WITH COOLOR AND CHAFF 992 POUNDS

DIRECT DRIVE SEPARATE MOTORS (4 OF THEM)

REQUIRED FLOOR SPACE: 56 INCHES WIDE 84 INCHES FRONT TO BACK, 79 INCHES HIGH

(DIMS INCLUDE EXTERNAL CHAFF COLLECTOR)

BURNER POWER: 95,000 BTU

BUILT TO UL295 STANDARDSQUANTITY: 1

Learn More -

L-4532 DATGEN ROASTERS

L-4532 DATGEN ROASTERSL-4532 DATGEN ROASTERS

MODELS AVAILABLE: DR 1, 3, 5, 12, 25, & 35

MODEL DR-1

CAPACITY: 0.5 TO 1.25 KGSMODEL DR-3

CAPACITY: 0.1 KGS TO 2.5 KGS

HOURLY ROAST OUTPUT: 10 KGS

VOLTAGE: 230 VOLTS @ 60 Hz OR 400 VOLTS @ 50 Hz

40,000 BTU, 26.2 KW

FUEL: PROPANE OR NATURAL GAS

ROASTER WEIGHT: 100 KGS

ROASTER DIMENSIONS: 1400mm TALL X 1200mm LONG X 1100mm WIDE

EXHAUST PIPE DIAMETER: 130mm

COMPUTER CONNECTION: RS 485

DRIVE: 4 MOTORS

MOTOR POWER: 1 KW PER HOURMODEL DR-5

CAPACITY: 0.5 KGS TO 5 KGS

HOURLY ROAST OUTPUT: 15 KGS

VOLTAGE: 230 VOLTS @ 60 Hz OR 400 VOLTS @ 50 Hz

90,000 BTU, 26.2 KW

FUEL: PROPANE OR NATURAL GAS

ROASTER WEIGHT: 300 KGS

DIMENSIONS: 1470mm TALL x 1750mm LONG X 1140mm WIDE

EXHAUST PIPE DIAMETER: 150mm

DRIVE: 4 MOTORS

MOTOR POWER: 2 KW PER HOURMODEL: DR-12

CAPACITY: 0.5 TO 12 KGS PER BATCH (MAX 15 KGS OF GREEN BEANS)

OPERATING TIME: 5 TO 18 MINUTES PER BATCH, DEPENDING ON ROASTING PROFILES

ROASTER DIMENSIONS: 1160mm WIDE X 1430mm LONG X 1800mm TALL

WEIGHT: 410 KGS

POWER: 230 VOLTS @ 60 Hz OR 400 VOLTS @ 50 Hz

FUEL: PROPANE OR NATURAL GAS

GAS PRESSURE: NATURAL GAS ABOVE 2 KPA / PROPANE ABOVE 2.9 KPA

90,000 BTU PER HOUR

EXHAUST PIPE DIAMETER: 150mm

ROAST AIR SCFM/SCMH: 380 SCFM / 650 SCMHMODEL: DR-30

CAPACITY: 2.5 TO 37.5 KGSMODEL: DR-60

CAPACITY: 2.5 TO 75 KGS

Learn More