Search results for: 'Machine+f'

- Related search terms

- machine+foam

- machine+fly

- Machine+fiber

- machine+foam'

- Machine+fla'

-

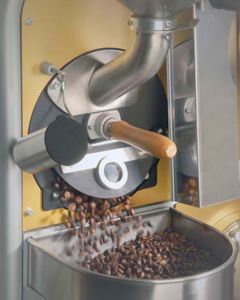

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

R-6857 TORREFACTO ROASTING MACHINES

R-6857 TORREFACTO ROASTING MACHINESR-6857 TORREFACTO ROASTING MACHINES

THOR FKT

THE ROASTING MACHINE THOR FKT MB FOR ROASTED COFFEE WITH SUGAR IS BOUND AT HIGH HOURLY PRODUCTION. SINCE GREEN COFFEE IS ABLE TO OBTAIN A HOMOGENEOUS BAKING OF THE COFFEE IN 20 MINUTES FOR EACH CYCLE, WORKING IN AUTOMATIC MODE OR SEMI-AUTOMATIC.

THE ROASTING THOR FKT MB IS EQUIPPED WITH A STOVE DETACHED, BUILT IN STEEL AND REFRACTORY MATERIAL; THE BURNER, CAN BE GAS (TYPE MODULATING) OR OIL-IN 2/3 FLAME LEVELS, DEPENDING ON THE APPLICATIONS.

THE COOLING DRUM RECEIVES THE PRODUCT DIRECTLY FROM THE DISCHARGE OF THE ROASTING MACHINE.

THE INTERNAL MIXERS WERE DESIGNED AND TESTED IN ORDER TO GUARANTEE AN OPTIMAL COOLING OF THE PRODUCT.

THE DISCHARGE OF THE PRODUCT IS MADE BY REVERSING THE DIRECTION OF ROTATION OF THE DRUM; ON THE COOLING DRUM DOORS FOR THE INSPECTION AND CLEANING OF THE DRUM ARE PROVIDED.

ADDITIONAL FUNCTIONS OF ROASTING MACHINE THOR FKT MB:POSSIBILITY OF TOTALLY OR PARTIALLY AUTOMATIC CONTROLLING BY PLC + TOUCH SCREEN AND SAVING PARAMETERS ROASTING PERFORMED BY ELECTROMECHANICAL/ELECTROPNEUMATIC DEVICES.

PLC WITH OPERATOR INTERFACE;

DISPLAY TO MONITOR THE FUNCTIONS OF ROASTING TIME AND TEMPERATURE;

AUDIBLE AND VISUAL ALARM ON THE MOTOR ALARM INSTALLED AND ON THE BURNER BLOCK.

COLOR: AVAILABLE ACCORDING TO CUSTOMER SPECIFICATIONS

OPTIONAL COMPONENTS:ELECTRICAL CONNECTION MANAGEMENT SYSTEM WITH PC AND TOUCH-SCREEN

Learn More

HEAT RECOVERY UNIT

POST-COMBUSTOR MODEL KAT

BRIQUETTE PRESS -

R-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOS

R-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOSR-3270 SAMIAC CAST-IRON ROASTER COMPLETE SYSTEM - 60 KILOS

5.8 KW/H ELECTRICAL - 220 VAC, 60HZ. 3 PHASE - 30 AMP BREAKER.

NATURAL GAS

INCLUDES: LOADER, ROASTER COOLER, DE-STONER, DUAL CHAFF COLLECTORS INCLUDING INCINERATING STYLE COLLECTOR, AFTERBURNER. ALL AUTOMATED CONTROLS FROM YOUR CONTROL PANEL. THIS IS EXTREME INDUSTRIAL IN EVERY WAY.

NOTE: THE COLOR ON ALL EXTERIOR SURFACES LOOKS NEW - THE FRONT PANEL OF THE ROASTER HAS BE LEFT "NATURAL" SHOWING THE GRAIN OF THE CAST IRON - THIS WAS DONE ON PURPOSE - AS ENGINEERING AND THE ORIGINAL OWNER WANTED TO OIL THE SURFACE IN ORDER TO DEMONSTRATE THE TEXTURE OF THE CAST IRON. SORT OF A HIGH-TECH APPEAL.HERE IS A MOST UNUSUAL 60 KILO ROASTER THAT HAS COME UP. THIS IS A CLOSE TO NEW AS YOU WILL EVER SEE - AS IT HAS BEEN USED SPARINGLY SINCE NEW IN 2008 AND IT IS NOW GOING TO BE REMOVED TO MAKE WAY FOR A PLANT REMODEL. SAMIAC WAS A GREAT MAKER OF CAST IRON ROASTERS - DOUBLE DRUM TOO. EVERYTHING IN THE ROASTER IS "OFF THE SHELF" AND THE FACT THAT SAMIAC IS NO LONGER AROUND IS A NON ISSUE AS ALL OF THE COMPONENTS LIKE MOTORS, CONTROLS, SWITCHES, BURNER ARE ALL EITHER US OR CANADA SUPPLIED AND ARE ALL UL, CSA, AGA ETC, ETC. PERHAPS YOU GET THE IDEA THAT I LIKE THIS ROASTER.

STUDY THE PHOTOS (TAKEN END OF MAY 2016. AND YOU WILL SEE HOW CLEAN THIS MACHINE REALLY IS. IT IS TOTALLY CLEANED EVERY DAY OF USE (NOT USED EVERY DAY EITHER) AS PART OF THE SHUT DOWN - THERE IS NEVER EVEN A SPECK OF CRUD LEFT ON THIS MACHINE, EVER. I KNOW OF NO OTHER PLANT THAT IS KEPT THIS CLEAN. WE COULD EAT OFF THIS MACHINE - TOTALLY SUPER CLEAN!

QUANTITY: 1

Learn More -

R-6855 STA IMPIANTI MILLENNIUM 3 ROASTING MACHINES

R-6855 STA IMPIANTI MILLENNIUM 3 ROASTING MACHINESR-6855 STA IMPIANTI MILLENNIUM 3 ROASTING MACHINES

THE ROASTING MACHINES SERIES MILLENNIUM 3 REALIZED BY STA IMPIANTI SRL CONFIRM THEMSELVES CAPABLES OF A WORLD LEADING TRADE MARK IN DESIGN AND PROJECTATION OF INDUSTRIAL AUTOMATIC ROASTING MACHINES FOR COFFEE AND OTHER SIMILAR PRODUCTS. THESE MACHINES, ALLOWING HIGHLY INTEGRATED TECHNOLOGICAL SOLUTIONS, ANTICIPATE THE MOST ADVANCED MARKET DEMANDS.

THANKS TO THE CONSTANT PURSUIT OF HIGH QUALITY STANDARD AND THE COMPANY’S DESIRE TO PROVIDE AT THE SAME TIME A PRODUCT TAILORED TO THE NEEDS OF EACH CLIENT COMPANY, STA IMPIANTI SRL IS ABLE TO OFFER THE BEST SOLUTION IN THE MARKET.THE ROASTING MACHINES SERIES MILLENNIUM 3 ARE GUARANTEE OF THE HIGHEST STANDARDS OF TECHNOLOGY DECLINED

ON CONCEPS OF HIGH PRODUCTION, MAXIMUM PERFORMANCE, RELIABILITY TOTAL SAFETY WITH LOW NOISE AND ENVIRONMENTAL EMISSIONS.

STANDARD EQUIPMENT:

ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN FOR FULL AUTOMATIC OR PARTIAL DRIVE.

AUTOMATIC ROASTING PROCESS WITH RECORDING – STORAGE OF ROASTING PARAMETERS

SYSTEM CONTROL THROUGH PLC + TOUCH SCREEN

FITTINGS FOR PC

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP WITH DISPLAY ANOMALIES.

PRE-HEATING SYSTEM FOR RAW COFFEE IN STAND-BY

TEMPERATURE COFFEE CONTROL BOTH DURING ROASTING AND COOLING CYCLE.

HOT AIR GENERATOR (STA IMPIANTI‘ PATENTED SYSTEM)

“LOW INERTIA” DEVICE FOR IMMEDIATE STARTING OF PRODUCTION

INDUSTRIAL GAS BURNER TYPE MODULATING OR GASOIL BURNER AT MULTI STAGES OF FLAME ACCORDING APPLICATION.

PROCESS AIR ADMITTANCE CONTROL SYSTEM

FITTINGS FOR CLEAN AIR BY AIR EXCHANGER

CONTROL BOARD COMPLETE WITH LIGHTING DEVICE

SCREENER WITH PNEUMATIC DRAWING

WATER PUMP COMPLETE WITH TANK AND SAFETY BY PASS DEVICE

PRE COOLING SYSTEM OVER ROASTING DRUM

PRE COOLING SYSTEM CONNECTED TO THE COOLER

FIRE PREVENTION SYSTEM LINKED TO THE CYCLONE-CHAFFS COLLECTOR.

CYCLONE-CHAFFS COLLECTOR WITH DRIVEN STAR VALVE

CYCLONE FOR COOLER AND DESTONER

SELF CLEANING COOLING TANK

ADDITIONAL EMERGENCY UNLOADING FOR COOLER

INTEGRATED DESTONER

SERVOCONTROL DEVICE FOR REMOTE ADJUSTMENT OF DESTONER

SOUND PROOFING SYSTEM

GLOBAL SAFETY PROTECTION

OPTIONAL EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

CLEAN AIR BY AIR GENERATOR-EXCHANGING SYSTEM

POST COMBUSTOR TYPE THERMAL BURNER OR CATALYTIC

EXTERNAL DRAWING AIR (QUICK FRESH) SYSTEM

DESTONER WEIGHING CELLS

CHAFFS COMPACTOR.

HEATING ADDUCTION SYSTEM:PATENTED SYSTEM BY STA IMPIANTI SRL SPECIFICALLY STUDIED FOR ROASTING LINE APPLICATIONS. THIS SYSTEM ALLOWS SHORTER AND HOMOGENEOUS ROASTING TIME:

BY CONVECTION HOT AIR FLOWING THROUGH THE COFFEE IN THE DRUM

BY CONDUCTION DUE TO THE HEATED ROASTING DRUM

BY IRRADIANCE FROM THE GRATE LOCATED BETWEEN THE FLAME AND THE ROASTING DRUM (INFRARED RAYS)

HOT AIR GENERATOR:THREE ARE THE POSSIBILITIES OF SETTLEMENT TO THE OVER INDICATED SYSTEM:

AIR BY AIR EXCHANGING SYSTEM WITH RECOVERY DEVICE (100% CLEAN AIR)

Learn More

CONVENTIONAL GENERATOR

HEATING GENERATOR WITH PARTIAL OR TOTAL RECYCLE -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

R-3259 PRIMO 35 ROASTER TOP CONDITION 2009 - 15 KILOS

R-3259 PRIMO 35 ROASTER TOP CONDITION 2009 - 15 KILOSR-3259 PRIMO 35 ROASTER TOP CONDITION 2009 - 15 KILOS

35 # PER BATCH

35 LBS. CAPACITY, CARBON STEEL DRUM, INFRARED CERAMIC BURNERS.

ROAST AND COOL AT THE SAME TIME - AS EACH FUNCTION HAS INDEPENDENT FANS, MOTORS AND CONTROL.

EXTRA SET OF BURNERS INCLUDED AS SPARES FOR FUTURE USE WHEN NEEDED

PROPANE HEAT - 96,000 BTU

220 VOLT 60HZ SINGLE PHASE ELECTRICAL

WIRED FOR CROPSTER OR ARTISEN PROFILE TRACKING

REMOTE CHAFF COLLECTOR

MAIN ROASTER BODY - 30" X 66" X 73" TALL - PLUS ROOM FOR PIPES AND MOTOR SERVICE IN THE BACK.

ALLOW ANOTHER 36" SQUARE AREA FOR CHAFF COLLECTION - AND KEEP IN MIND THAT THE LOCATION IS VERY USABE TO FIT YOUR FACILITY.THIS PRIMO 35 IS A GOOD LOOKING ROASTER - AND IT HAS BEEN USED SPARINGLY SINCE 2009 AS THIS IS A "SMALL BATCH" USE BY A MUCH LARGER INSTITUTIONAL-TYPE OPERATION - BUT HIS WHOLE BEAN BUSINESS HAS GROWN AND IT IS NOT COST EFFECTIVE TO HAVE A DEDICATED ROASTMASTER JUST DOING 15 KILO PER BATCH. SO A LARGE MACHINE IS BEING INSTALLED. GOOD NEWS FOR THE BUYER.

ANYBODY LIKING DIEDRICH ROASTERS WILL BE HAPPY WITH THIS AS THEY ARE INTERNALLY SIMILAR AS THE OWNER OF PRIMO USED TO BE SHOP FOREMAN BACK WHEN DIEDRICH WAS LOCATED IN CALIFORNIA. ANOTHER THING THAT IS NICE ABOUT THIS MACHINE IS THE EASE OF WORKING ON IT IF AND WHEN IT REQUIRES ATTENTION. MOST EVERY PART IN THE MACHINE IS "OFF THE SHELF" AND THAT MAKES REPAIRS AND MAINTENANCE REAL EASY. MAKE SURE YOU LUBE ON SCHEDULE AND MAKE SURE YOU USE HIGH TEMP GREASE (LINK) AS EXAMPLE, ALTHOUGH THERE ARE OTHER SELECTIONS IN THAT SAME AREA OF THE WEB STORE.

LOTS OF PEOPLE USE THIS MACHINE AS A "STARTER MACHINE" SINCE IT IS SO EASY TO OPERATE. EVEN IF YOU DO NOT USE FANCY PROFILE TRACKING - IT IS STILL GREAT FOR MANUAL ROASTING AND HANDS-ON DEVELOPMENT.

QUANTITY: 1

Learn More -

R-3243 COFFEE ROASTERS COMPLETE PLANT TAKE OVER, CAPACITY 4,200 LBS PER HOUR

R-3243 COFFEE ROASTERS COMPLETE PLANT TAKE OVER, CAPACITY 4,200 LBS PER HOURR-3243 COFFEE ROASTERS COMPLETE PLANT TAKE OVER, CAPACITY 4,200 LBS PER HOUR

TWO (2) COMPLETELY AUTOMATIC AND DIGITAL JABEZ BURNS 23R 4 BAG ROASTERS, PROGRAMMED RECIPES, AUTOMATED BUCKET ELEVATORS, DESTONER, MICRO FILTER GREEN BEAN CLEANER, AFTERBURNER FOR BOTH ROASTERS INCLUDES:

- FIRST ROASTER: JABEZ BURNS GAS-FIRED BATCH COFFEE ROASTER, MODEL 23R ACO THERMALO, (MODEL 23R-02309 ON CONTROL PANEL), C/W MAXON OVENPAK GAS BURNER, MODEL 400, SIZE 422M, (ROASTER REBUILT 2013), C/W JABEZ BURNS AUTOMATIC CONTROL CONSOLE C/W ALLEN-BRADLEY PLC MODEL MICROLOGIX 1500, ALLEN-BRADLEY HMI CONTROL MODEL PANELVIEW 550, PRINTER, & WORKSTATION, (ROASTER "A")

- SECOND ROASTER: JABEZ BURNS GAS-FIRED BATCH COFFEE ROASTER, MODEL 23R ACO THERMALO (MODEL 23R-04307 ON CONTROL PANEL), C/W MAXON OVENPAK GAS BURNER, MODEL 400, SIZE 422M, (ROASTER REBUILT 2013), C/W JABEZ BURNS AUTOMATIC CONTROL CONSOLE C/W ALLEN-BRADLEY PLC MODEL MICROLOGIX 1500, ALLEN-BRADLEY HMI CONTROL MODEL PANELVIEW 550, PRINTER, & WORKSTATION, (ROASTER "B")

- TWO: JABEZ BURNS COOLER/STIRRER/DE-STONER MODEL STIRFLEX C/W AIRVEYING DISCHARGE DUCT, ERIEZ MAGNET MODEL 20" RE RPS, STYLE 9706716, W/ S/S ENCLOSURE, & S/S HOOD W/ LIGHTING

- S/S EXHAUST HOOD OVER COFFEE DUMP BIN C/W EXHAUST FAN & DUCTING

- UNIVERSAL BUCKET ELEVATOR W/ AIRVEYING PIPE TO GREEN BEAN CLEANER

- HAMATEC ROTARY SCREEN GREEN BEAN CLEANER, TYPE KSD500/1200AM, (2007), C/W LEESON AC VARIABLE SPEED MOTOR CONTROL

- MACTIFLO DUST COLLECTOR W/ DRUM DISCHARGE, C/W NATIONAL CONTROLS INTELLIGENT DUST CONTROL MODEL DNC-T2310-A10

- UNIVERSAL BUCKET ELEVATOR (FROM GREEN BEAN CLEANER), MODEL D3-100ED, C/W PNEUMATIC DISCHARGE GATE, (2) BEAN LOADING CONTROL PANELS, & (2) AIRVEYING PIPES TO ROASTER "A" & ROASTER "B"

- TWO: ROASTED COFFEE BEAN ELEVATED HOLDING BIN C/W PNEUMATIC DISCHARGE GATE & AIRVEYING DISCHARGE PIPE

- CIRCULATING BLOWER FOR ROASTING LINE "A" C/W SUPPORT PLATFORM

- ELEVATED CHAFF COLLECTION CYCLONE W/ DRUM DISCHARGE

- CIRCULATING BLOWER FOR ROASTING LINE "B" C/W SUPPORT PLATFORM

- MARS 4' X 4' FLOOR PLATFORM SCALE C/W DIGITAL WEIGHT INDICATOR, MODEL MSF-445, 5,000 LB. CAP. (SUBJECT TO CONFIRMATION) 24" X 30" PLATFORM SCALE C/W DIGITAL WEIGHT INDICATOR

- INPROHEAT INDUSTRIES NATURAL GAS THERMAL OXIDIZER AFTERBURNER, MAX. INPUT 1.4MM BTU/HR C/W MAXON OVENPAK-II GAS BURNER, SIZE 425, CONTROL PANEL C/W TEMPERATURE RECORDER AND HONEYWELL BURNER CONTROL

Learn More -

P-5077 PROBAT L25 ROASTER 25 KILOS

P-5077 PROBAT L25 ROASTER 25 KILOSP-5077 PROBAT L25 ROASTER 25 KILOS

PROBAT 25 FOLLOWS YEARS OF TRADITION IN BUILDING REALLY TOUGH EASY TO REPAIR TYPE MACHINERY. THIS NEW MODEL IS EVEN MORE FRIENDLY AS IT HAS ELIMINATED ALL THE CHAINS AND BELTS OF YEARS GONE BY . . . AND HOW IS TOTALLY DIRECT DRIVE MOTORS - 4 OF THEM . . . ONE FOR EACH FUNCTION OF THE MACHINE. DON'T FORGET THAT THIS MACHINE IS TALL ENOUGH TO REQUIRE A LOADER AND THIS BASIC MODEL DOES NOT INCLUDE THE LOADER OR A DESTONER OR AN AFTERBURNER . . . AS ALL THESE ITEMS MUST BE ADDED TO THE BASIC MACHINE.

PROFILE EDITION: PLEASE NOTE THAT PROBAT IS OFFERING A PROFILE PACKAGE THAT CAN BE ADDED TO THIS MACHINE.

SPECIFICATIONS:

CAPACITY PER BATCH: 26–55 LBS (11.8–25 KG)

BATCHES PER HOUR: 4

CAPACITY PER HOUR: 220 LBS (100 KG)

NATURAL GAS OR PROPANE: 190,000 BTU / HR

INLET FITTING: ½ INCHES

VOLTAGE: 230 / 460 V

FREQUENCY: 60 HZ

PHASE: 3

MAX. LOAD: 40 / 20 AMPS

DIMENSIONS: 7 FEET 6 INCHES H X 3 FEET 6 INCHES W X 6 FEET D

WEIGHT: 2,500 LBSQUANTITY: 1

Learn More -

R-3245 PROBAT DUETT ROASTER & DEMO UNIT - 1 KILO

R-3245 PROBAT DUETT ROASTER & DEMO UNIT - 1 KILOR-3245 PROBAT DUETT ROASTER & DEMO UNIT - 1 KILO

PROBAT DUETT RESEARCH & DEMO UNIT: 1 KILO

THIS ROASTER IS NOT FOR EVERYBODY AS IT IS TOTALLY SPECIALIZED AND DESIGNED AS A "SAMPLE ROASTER" TO REALLY BIG AND HIGH YIELD ROASTERS ALSO MADE BY PROBAT OR GOTHOT BACK IN THE DAY. TOTALLY GEEK TYPE. ACTUALLY THIS MACHINE WAS ONLY USED IN THE PROBAT SHOWROOM WHEN IT WAS LOCATED IN BURLINGAME CALIFORNIA AND HAS NOT BE USED SINCE. EVEN THEN, IT WAS USED ONLY SEVERAL TIMES A QUARTER PR DURING A CLASS. WE ALWAYS PUT IN A LITTLE OVER 2 POUNDS SO AS TO GET 2 POUNDS OUT. BUT THERE IS A FLEXIBLE RANGE.YOU PUT IN FROM 1.6 POUNDS TO 2.6 POUNDS AND CAN SET UP A PROFILE (OR RUN MANUALLY) SO THAT YOU CAN CONTROL AIR AND HEAT AND THE SPEED OF BOTH ALLOWING FOR AS FAST AS A 2 MINUTE ROAST FOR HIGH YIELD OR ADJUST TO NORMAL RANGES FOR MAKING INTRICATE STUDIES INTO CHANGING CONDITIONS OF PROFILING. EVERY DETAIL OF THE MACHINES INNARDS OR ELECTRICAL BOX IS ALL RELAY DRIVEN AND CONTROLLED. THE TOTAL ROAST PROCESS IS VISIBLE BEFORE YOUR EYES AND AS SOON AS THE ROAST REACHES YOUR SET POINT - THE COFFEE SIMPLY SLIDES AND DROPS INTO THE COOING CHAMBER AND YOU ARE READY FOR THE NEXT STUDY.

REQUIRES AN AIR CONNECTION. RUNS ON ELECTRIC ONLY. HAS LIGHTS ON INSIDE. COMES IN 2 BIG BOXES AND WE HAD IT INSTALLED WITH THE ROASTER ONLY IN THE LAB SHOWROOM AND THE CHAFF AND AIR HANDLING UNIT IN ANOTHER ROOM SO WE DID NOT HAVE TO LISTEN TO IT. YOUR OPTION.

BUILT IN 1995 AT PROBAT. NEEDS 3 PHASE POWER. BEEN IN STORAGE SINCE THOSE SHOWROOM DAYS BACK IN IN 97.

QUANTITY: 1

Learn More