Search results for: 'double need'

-

SPINNBAU DOUBLE DOFFER NONWOVEN CARDREFERENCE NUMBER: T-6847 SPINNBAU DOUBLE DOFFER NONWOVEN CARD BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER NONWOVEN CARD NEW HIGH CAPACITY HOPPER FEEDER WITH CHUTE DELIVERY ELECTRONIC WEIGH SYSTEM “TS MICROFEED” NEW AC INVERTER DRIVE SYSTEM WITH TOUCH SCREEN CONTROL NEW AC GEARED MOTOR UNITS NEW DRIVE BELTS AS REQUIRED NEW SAFETY CIRCUIT, E-STOPS AND GUARD INTERLOCKS INCLUDING MACHINE REFURBISHMENT AND RE-PAINT TO RAL 7035 (LIGHT GREY) THE 2500mm SPINNBAU CARD CAN BE SPECIFIED FOR YOUR PRODUCTION REQUIREMENTS TOGETHER WITH A NEW CROSSLAPPER, OVENS AND NEEDLE LOOMS. RE-CONDITIONED QUANTITY: 1 Learn More

SPINNBAU DOUBLE DOFFER NONWOVEN CARDREFERENCE NUMBER: T-6847 SPINNBAU DOUBLE DOFFER NONWOVEN CARD BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER NONWOVEN CARD NEW HIGH CAPACITY HOPPER FEEDER WITH CHUTE DELIVERY ELECTRONIC WEIGH SYSTEM “TS MICROFEED” NEW AC INVERTER DRIVE SYSTEM WITH TOUCH SCREEN CONTROL NEW AC GEARED MOTOR UNITS NEW DRIVE BELTS AS REQUIRED NEW SAFETY CIRCUIT, E-STOPS AND GUARD INTERLOCKS INCLUDING MACHINE REFURBISHMENT AND RE-PAINT TO RAL 7035 (LIGHT GREY) THE 2500mm SPINNBAU CARD CAN BE SPECIFIED FOR YOUR PRODUCTION REQUIREMENTS TOGETHER WITH A NEW CROSSLAPPER, OVENS AND NEEDLE LOOMS. RE-CONDITIONED QUANTITY: 1 Learn More -

BB-1111 AUTOMATIC COMPUTERIZED BORDER SEWING MACHINE

BB-1111 AUTOMATIC COMPUTERIZED BORDER SEWING MACHINESEWING MACHINES: 64 NEEDLES HIGH SPEED CHAINSTITCH SEWING HEAD

MAX SEWING SPEED:

3000RPM FOR DOUBLE HEAD CNC SEWING SYSTEM

1800RPM FOR MULTINEEDLE SEWING SYSTEM

NUMBER OF SEWING HEADS: 3

STITCH TYPE: CHAIN STITCH

MAX BORDER SEWING WIDTH:

400mm FOR MULTINEEDLE SYSTEM

270mm FOR DOUBLE HEAD CNC SEWING

MAX STITCH LENGTH: 6mm

NUMBER OF PATTERN MEMORY: UNLIMITED

AUTO BORDER ROLLER: YES

THREAD BREAK AND MATERIAL - OUT DETECTION: YES

AUTO STOP AT PRESET YARDAGE: YES

EDGE HEMMING: YES

DISTANCE ADJUSTMENT BETWEEN THE SEWING HEADS: YES

POWER REQUIREMENT: 6.5 KW

VOLTAGE TYPE: 380 VAC (III+N+TT)

COMPRESSED AIR: 6-8 BAR

POWER REQUIREMENT: 30 KWQUANTITY: 1

Learn More -

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More

V-1041 AIRLAY- FELT LINE 2400mmINDEX 1. Technical specification pag.2 2. Line composition pag.3 3. Machines description pag.4 4. Total price of the turn-key plant pag.25 5. Sale terms pag.26 6. Payment terms pag.28 7. General selling terms and conditions pag.29 Learn More -

K-4385 COMERIO ERCOLE MODEL CE-15/120-S EMBROIDERING MACHINE YEAR 1990REFERENCE NUMBER: K-4385 COMERIO ERCOLE MODEL CE-15/120-S EMBROIDERING MACHINE YEAR 1990 MAKE: COMERIO ERCOLE MODEL: CE-15/120-S YEAR 1990- RECONDITIONED IN 2000 "FUTURA" SYSTEM 15YARDS LENGTH FIELD HIGH 1200mm 2 COLORS QUANTITY AVAILABLE: 1 Learn More

K-4385 COMERIO ERCOLE MODEL CE-15/120-S EMBROIDERING MACHINE YEAR 1990REFERENCE NUMBER: K-4385 COMERIO ERCOLE MODEL CE-15/120-S EMBROIDERING MACHINE YEAR 1990 MAKE: COMERIO ERCOLE MODEL: CE-15/120-S YEAR 1990- RECONDITIONED IN 2000 "FUTURA" SYSTEM 15YARDS LENGTH FIELD HIGH 1200mm 2 COLORS QUANTITY AVAILABLE: 1 Learn More -

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More -

E-9863 PILLOW VACUUM PACKING COMPRESSING MACHINEINVENTORY NUMBER: E-9863 PILLOW VACUUM PACKING COMPRESSING MACHINE SIMPLE TO OPERATE. LOW MAINTENANCE DOUBLE CYLINDER GUIDANCE SYSTEM. THE MACHINE IS CONTROLLED BY PHOTO ELECTRICS. THE TEMPERATURE AND RUNNING SPEED CAN BE ADJUSTED AS NEEDED. VERY EASY TO REPAIR. EVERY SPARE PART CAN BE REMOVED AND RE-INSTALLED EASILY. DOUBLE COMPRESSING CYLINDER. QUANTITY AVAILABLE: 1 Learn More

E-9863 PILLOW VACUUM PACKING COMPRESSING MACHINEINVENTORY NUMBER: E-9863 PILLOW VACUUM PACKING COMPRESSING MACHINE SIMPLE TO OPERATE. LOW MAINTENANCE DOUBLE CYLINDER GUIDANCE SYSTEM. THE MACHINE IS CONTROLLED BY PHOTO ELECTRICS. THE TEMPERATURE AND RUNNING SPEED CAN BE ADJUSTED AS NEEDED. VERY EASY TO REPAIR. EVERY SPARE PART CAN BE REMOVED AND RE-INSTALLED EASILY. DOUBLE COMPRESSING CYLINDER. QUANTITY AVAILABLE: 1 Learn More -

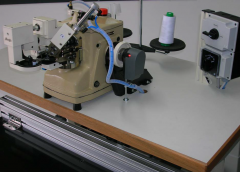

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

M-1020-F SPECIAL SEWING MACHINE MODEL 164CSPECIAL SEWING MACHINE FOR CLOSING PILLOWS, CUSHIONS FOR FURNISHING AND UPHOLSTERY PRODUCTS THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDER CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBERS, ALL KIND OF CUSHIONS. THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA Learn More

M-1020-F SPECIAL SEWING MACHINE MODEL 164CSPECIAL SEWING MACHINE FOR CLOSING PILLOWS, CUSHIONS FOR FURNISHING AND UPHOLSTERY PRODUCTS THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDER CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBERS, ALL KIND OF CUSHIONS. THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA Learn More -

M-5157 ETON SYSTEMS YEAR 1988

M-5157 ETON SYSTEMS YEAR 1988REFERENCE NUMBER: M-5157 (1212PTKRXX11) L

ETON SYSTEMS YEAR 1988

ETON 2001

YEAR OF MANUFACUTRE: AROUND 1988

ABOUT 70 STATIONS, MAYBE MORE

TWO SEPARATE LINES, EACH AROUND 50 METERS LONG

TWO LINES ARE ASSEMBLED AND WORKING

LOTS OF SPARE PARTS FROM DISMANTLED ETONS SYSTEMS AND LOTS OF HANGERS

QUANTITY AVAILABLE: 2

Learn More -

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More