Search results for: 'Machine+card+ro'

-

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More -

C-1144 CARDING MACHINE HOUGET REKORD, YEAR 1972, WIDTH 2500MM, DELIVERY OF CANSREFERENCE NUMBER: C-1144 CARDING MACHINE HOUGET REKORD, YEAR 1972, WIDTH 2500MM, DELIVERY OF CANS SPECIFICATIONS: CARDING MACHINE HOUGET REKORD 2500 MM WORKING WIDTH YEAR OF CONSTRUCTION 1972 VOLUMETRIC FEEDER 3 TAMBOURS DIAMETER 1500 AND 1270 MM WORKER/STRIPPER 1 PRE TAMBOUR 1000 MM DIAMETER 1 TAKE-OFF 1270 MM DIAMETER SLIVER EXIT, CALENDER ROLLERS WITH 2 BELTS EXIT INTO CANS. AUTOMATIC CAN CHANGER SUITABLE FOR CANS 1000 MM QUANTITY AVAILABLE: 1 Learn More

C-1144 CARDING MACHINE HOUGET REKORD, YEAR 1972, WIDTH 2500MM, DELIVERY OF CANSREFERENCE NUMBER: C-1144 CARDING MACHINE HOUGET REKORD, YEAR 1972, WIDTH 2500MM, DELIVERY OF CANS SPECIFICATIONS: CARDING MACHINE HOUGET REKORD 2500 MM WORKING WIDTH YEAR OF CONSTRUCTION 1972 VOLUMETRIC FEEDER 3 TAMBOURS DIAMETER 1500 AND 1270 MM WORKER/STRIPPER 1 PRE TAMBOUR 1000 MM DIAMETER 1 TAKE-OFF 1270 MM DIAMETER SLIVER EXIT, CALENDER ROLLERS WITH 2 BELTS EXIT INTO CANS. AUTOMATIC CAN CHANGER SUITABLE FOR CANS 1000 MM QUANTITY AVAILABLE: 1 Learn More -

C-1143 HOUGET CARDING MACHINE REKORD, YEAR 1979, WIDTH 2500MM, DELIVERY OF CANSREFERENCE NUMBER: C-1143 HOUGET CARDING MACHINE REKORD, YEAR 1979, WIDTH 2500MM, DELIVERY OF CANS SPECIFICATIONS: CARDING MACHINE HOUGET REKORD 2500 MM WORKING WIDTH YEAR OF CONSTRUCTION 1979 USED VOLUMETRIC FEEDER. 3 TAMBOURS DIAMETER 1500 1270MM WORKER &STRIPPER. 1 PRE TAMBOUR 1000 MM DIAMETER 1 TAKE-OFF 1270 MM DIAMETER. SLIVER EXIT, CALENDER ROLLERS WITH 2 BELTS. EXIT INTO CANS. AUTOMATIC CAN CHANGER SUITABLE FOR CANS 1000 MM. GOOD METAL CLOTHING FOR PES, PAX, SYNTHETICS, WOOL AND THEIR BLENDS. QUANTITY AVAILABLE: 1 Learn More

C-1143 HOUGET CARDING MACHINE REKORD, YEAR 1979, WIDTH 2500MM, DELIVERY OF CANSREFERENCE NUMBER: C-1143 HOUGET CARDING MACHINE REKORD, YEAR 1979, WIDTH 2500MM, DELIVERY OF CANS SPECIFICATIONS: CARDING MACHINE HOUGET REKORD 2500 MM WORKING WIDTH YEAR OF CONSTRUCTION 1979 USED VOLUMETRIC FEEDER. 3 TAMBOURS DIAMETER 1500 1270MM WORKER &STRIPPER. 1 PRE TAMBOUR 1000 MM DIAMETER 1 TAKE-OFF 1270 MM DIAMETER. SLIVER EXIT, CALENDER ROLLERS WITH 2 BELTS. EXIT INTO CANS. AUTOMATIC CAN CHANGER SUITABLE FOR CANS 1000 MM. GOOD METAL CLOTHING FOR PES, PAX, SYNTHETICS, WOOL AND THEIR BLENDS. QUANTITY AVAILABLE: 1 Learn More -

M-2022 COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNINGREFERENCE NUMBER: M-2022 (77052WHPOY6RL) COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNING QUANTITY AVAILABLE: 1 Learn More

M-2022 COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNINGREFERENCE NUMBER: M-2022 (77052WHPOY6RL) COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNING QUANTITY AVAILABLE: 1 Learn More -

M-5118 LABORATORY CARDING MACHINE YEAR 1970 WIDTH 600mmREFERENCE NUMBER: M-5118 (1212PPSTXX11) L LABORATORY CARDING MACHINE YEAR 1970 WIDTH 600mm LABORATORY CARDING MACHINE YEAR ABOUT 1970 WORKING WIDTH 600mm PRE-TAMBOUR WITH 2 PAIRS WORKER/STRIPPER TAMBOUR WITH 4 PAIRS WORKER/STRIPPER INLET ROLLERS FLY COMB QUANTITY AVAILABLE: 1 Learn More

M-5118 LABORATORY CARDING MACHINE YEAR 1970 WIDTH 600mmREFERENCE NUMBER: M-5118 (1212PPSTXX11) L LABORATORY CARDING MACHINE YEAR 1970 WIDTH 600mm LABORATORY CARDING MACHINE YEAR ABOUT 1970 WORKING WIDTH 600mm PRE-TAMBOUR WITH 2 PAIRS WORKER/STRIPPER TAMBOUR WITH 4 PAIRS WORKER/STRIPPER INLET ROLLERS FLY COMB QUANTITY AVAILABLE: 1 Learn More -

TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995 RIETER COMPLETE SPINNING PLANT 16,128 SPINDLES YEAR 1991 TO 1995 QUANTITY: 1 PLANT Learn More

TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995TT-2155 RIETER COMPLETE SPINNING PLANT WITH 16,128 SPINDLES, YEAR 1991 TO 1995 RIETER COMPLETE SPINNING PLANT 16,128 SPINDLES YEAR 1991 TO 1995 QUANTITY: 1 PLANT Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015REFERENCE NUMBER: T-6868 NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015 NEEDLE PUNCH LINE EXIT WIDTH 2200/2500mm OVERHAULED AND UPDATED IN 2012/2015 TECHNOLOGY CONTROL BY S7 DESIGNED AND USED FOR NATURAL FIBRES, GLASS FIBRES, RECYCLED FIBRES 100% OR MIXED WITH PP FOR BASIC MATERIALS OF THE AUTOMOTIVE INDUSTRY CAPACITY: 400 KGS ITEM 001 2 BALE OPENER BRAND TEMAFA WORKING WIDTH: 1400mm WOODEN LATICE BELTS WOODEN TRANSPORT LATTICE VERY GOOD CONDITION INDIVIDUAL CONTROL OF OPENING AND MIXING ITEM 002 WILLOW BRAND TEMAFA 4 PAIRS STRIPPING AND WORKING ROLLERS WORKING WIDTH: 1400mm WITH VENTILATOR AND PIPE SYSTEM TO CHUTE FEED AND HOPPER FEEDER ITEM 003 CHUTE FEED BRAND TEMAFA WORKING WIDTH: 2700mm CONTROL OF FILLING HEIGHT BY ULTRASOUND SENSORS ITEM 004 HOPPER FEEDER BRAND OCTIR (RSP) GROUND BELT BY WOODEN LATTICE AND DRIVEN BY SEPARATE DRIVE VIA ECCENTRIC VIBRATION WALL MOBILE FRON WALL ITEM 005 CARDING MACHINE WORKING WIDTH: 2500mm 5 PAIRD STRIPPER AND WORKER INSTALLED 1 PAIR STRIPPER/WORKER SEPARATE DELIVERY INDIVIDUAL DRIVE SYSTEMS RIGID CARD CLOTHING MAIN DRUM 1600mm DIAMETER DOFFER DRUM 1200mm AND FLY COMB ITEM 006 CROSS LAPPER WEB FEEDING BY TRANSILON-BELTS EXIT BELT AS WOODEN LATTICE BELT ITEM 007 PRE-NEEDLE MACHINE BRAND DILO MODI DVM25 WORKING WIDTH: 2500mm ALL BELT SYSTEMS USE WOODEN LATTICE BELTS 1 NEEDLE BOARD NEEDLING FROM TOP TO BOTTOM ITEM 008 NEEDLE MACHINE BRAND ASSELIN WORKING WIDTH: 2200mm 4 NEEDLE BAR MACHINE (2 TOP/2 BOTTOM) ALTERNATING AND SIMULTANEOUS WORKING METHODS BY MODIFICATION OF DRIVING BELT WAYS PULL-OUT ROLLERS AT EXIT STROKE HEIGHT 40mm ITEM 009 ROLLING MACHINE 3 LONGITUDINAL CUTTER (TOP AND BOTTOM DRIVEN) 1 CROSS CUTTER CONTROL OF THE LINE: SEPARATE SYSTEM FOR BALE OPENING AND MIXING S7 CONTROL FOR COMPLETE LINE UPR TO DATE LEVEL, AIRCONDITIONED, CONTROL CABINETS CLOSE TO MACHINE OR SEPARATE MACHINES ARE IN VERY GOOD AND UPDATED CONDITION Learn More

NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015REFERENCE NUMBER: T-6868 NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015 NEEDLE PUNCH LINE EXIT WIDTH 2200/2500mm OVERHAULED AND UPDATED IN 2012/2015 TECHNOLOGY CONTROL BY S7 DESIGNED AND USED FOR NATURAL FIBRES, GLASS FIBRES, RECYCLED FIBRES 100% OR MIXED WITH PP FOR BASIC MATERIALS OF THE AUTOMOTIVE INDUSTRY CAPACITY: 400 KGS ITEM 001 2 BALE OPENER BRAND TEMAFA WORKING WIDTH: 1400mm WOODEN LATICE BELTS WOODEN TRANSPORT LATTICE VERY GOOD CONDITION INDIVIDUAL CONTROL OF OPENING AND MIXING ITEM 002 WILLOW BRAND TEMAFA 4 PAIRS STRIPPING AND WORKING ROLLERS WORKING WIDTH: 1400mm WITH VENTILATOR AND PIPE SYSTEM TO CHUTE FEED AND HOPPER FEEDER ITEM 003 CHUTE FEED BRAND TEMAFA WORKING WIDTH: 2700mm CONTROL OF FILLING HEIGHT BY ULTRASOUND SENSORS ITEM 004 HOPPER FEEDER BRAND OCTIR (RSP) GROUND BELT BY WOODEN LATTICE AND DRIVEN BY SEPARATE DRIVE VIA ECCENTRIC VIBRATION WALL MOBILE FRON WALL ITEM 005 CARDING MACHINE WORKING WIDTH: 2500mm 5 PAIRD STRIPPER AND WORKER INSTALLED 1 PAIR STRIPPER/WORKER SEPARATE DELIVERY INDIVIDUAL DRIVE SYSTEMS RIGID CARD CLOTHING MAIN DRUM 1600mm DIAMETER DOFFER DRUM 1200mm AND FLY COMB ITEM 006 CROSS LAPPER WEB FEEDING BY TRANSILON-BELTS EXIT BELT AS WOODEN LATTICE BELT ITEM 007 PRE-NEEDLE MACHINE BRAND DILO MODI DVM25 WORKING WIDTH: 2500mm ALL BELT SYSTEMS USE WOODEN LATTICE BELTS 1 NEEDLE BOARD NEEDLING FROM TOP TO BOTTOM ITEM 008 NEEDLE MACHINE BRAND ASSELIN WORKING WIDTH: 2200mm 4 NEEDLE BAR MACHINE (2 TOP/2 BOTTOM) ALTERNATING AND SIMULTANEOUS WORKING METHODS BY MODIFICATION OF DRIVING BELT WAYS PULL-OUT ROLLERS AT EXIT STROKE HEIGHT 40mm ITEM 009 ROLLING MACHINE 3 LONGITUDINAL CUTTER (TOP AND BOTTOM DRIVEN) 1 CROSS CUTTER CONTROL OF THE LINE: SEPARATE SYSTEM FOR BALE OPENING AND MIXING S7 CONTROL FOR COMPLETE LINE UPR TO DATE LEVEL, AIRCONDITIONED, CONTROL CABINETS CLOSE TO MACHINE OR SEPARATE MACHINES ARE IN VERY GOOD AND UPDATED CONDITION Learn More -

TT-7507 COMPLETE OPEN END SPINNING PLANT, 4400 ROTORS, YEAR 2015 TO 2019TT-7507 COMPLETE OPEN END SPINNING PLANT, 4400 ROTORS, YEAR 2015 TO 2019 1. COMPLETE OPEN END SPINNING PLANT 2. 4400 ROTORS 3. YEAR 2019, 2018, 2017, 2015 4. PRODUCTION IN 24 HOURS X 30 DAYS NE 24: 1000 TONS Learn More

TT-7507 COMPLETE OPEN END SPINNING PLANT, 4400 ROTORS, YEAR 2015 TO 2019TT-7507 COMPLETE OPEN END SPINNING PLANT, 4400 ROTORS, YEAR 2015 TO 2019 1. COMPLETE OPEN END SPINNING PLANT 2. 4400 ROTORS 3. YEAR 2019, 2018, 2017, 2015 4. PRODUCTION IN 24 HOURS X 30 DAYS NE 24: 1000 TONS Learn More -

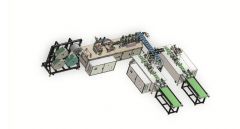

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More