Search results for: 'machine+de+fabri'

-

TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM FOR CONTINUOUS FILAMENT YARN APPLICATIONS (MULTIFILAMENT) YEAR 2020 AVAILABLE FOR IMMEDIATE SALE QUANTITY: 1 Learn More

TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM FOR CONTINUOUS FILAMENT YARN APPLICATIONS (MULTIFILAMENT) YEAR 2020 AVAILABLE FOR IMMEDIATE SALE QUANTITY: 1 Learn More -

TT-7201 REGGIANI ROTARY PRINTING MACHINE UNICA 320, WIDTH 3200mmTT-7201 REGGIANI ROTARY PRINTING MACHINE UNICA 320, WIDTH 3200mm 1. REGGIANI ROTARY PRINTING MACHINE 2. MODEL: UNICA 320 3. MAX. PRINTING WIDTH: 3200mm QUANTITY: 1 Learn More

TT-7201 REGGIANI ROTARY PRINTING MACHINE UNICA 320, WIDTH 3200mmTT-7201 REGGIANI ROTARY PRINTING MACHINE UNICA 320, WIDTH 3200mm 1. REGGIANI ROTARY PRINTING MACHINE 2. MODEL: UNICA 320 3. MAX. PRINTING WIDTH: 3200mm QUANTITY: 1 Learn More -

TT-8132 SULZER P7300 HP PROJECTILE LOOM, WORKING WIDTH 3600mm, YEAR 2006, CAMTT-8132 SULZER P7300 HP PROJECTILE LOOM, WORKING WIDTH 3600mm, YEAR 2006, CAM 1. SULZER P7300 HP PROJECTILE 2. BRAND: SULZER 3. MODEL: P7300 4. TYPE OF FABRIC: DENIM MACHINES RUNNING VERY GOOD CONDITION QUANTITY: 11 Learn More

TT-8132 SULZER P7300 HP PROJECTILE LOOM, WORKING WIDTH 3600mm, YEAR 2006, CAMTT-8132 SULZER P7300 HP PROJECTILE LOOM, WORKING WIDTH 3600mm, YEAR 2006, CAM 1. SULZER P7300 HP PROJECTILE 2. BRAND: SULZER 3. MODEL: P7300 4. TYPE OF FABRIC: DENIM MACHINES RUNNING VERY GOOD CONDITION QUANTITY: 11 Learn More -

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More -

C-4359 FULL-AUTOMATIC DOUBLE LINES WET TISSUE MACHINE Y-2035(B), CAPACITY 5 TO 30 PCS /PACK, WIDTH 1300mm

C-4359 FULL-AUTOMATIC DOUBLE LINES WET TISSUE MACHINE Y-2035(B), CAPACITY 5 TO 30 PCS /PACK, WIDTH 1300mmC-4359 FULL-AUTOMATIC DOUBLE LINES WET TISSUE MACHINE Y-2035(B), CAPACITY 5 TO 30 PCS /PACK, WIDTH 1300mm

Y-2035(B) FULL-AUTOMATIC DOUBLE LINES WET TISSUE MACHINE

MAIN TECHNICAL PARAMETER (SUITABLE FOR 5 TO 30 PCS /PACK)

PRODUCTION FLOW:

UNROLLING - FOLDING – WETTING – CUTTING – PILING– PACKING – DELIVERING

PRODUCTION SPEED: 700 TO 800 PCS/MIN

SUITABLE RAW MATERIAL: AIR-LAID PAPER, SPUNLACE /HOT-ROLLING NON-WOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80G/㎡QUANTITY: 1

Learn More -

C-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mm

C-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mmC-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mm

Y-2035 (A) FULL-AUTO SINGLE LINE WET TISSUE MACHINE

MAIN TECHNICAL PARAMETER (SUITABLE FOR 5 TO 30 PCS /PACK)

PRODUCTION FLOW:

UNROLLING - FOLDING – WETTING – CUTTING – PILING – PACKING – DELIVERING

PRODUCTION SPEED: 300 TO 400 PCS/MIN

SUITABLE RAW MATERIAL: AIR-LAID PAPER, SPUNLACE /HOT-ROLLING NON-WOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80 G/㎡

WET TISSUE UNFOLDED SIZE: (150 TO 200) × (150 TO 250) (mm, L×W)

WET TISSUE FOLDED SIZE: (75 TO 100) × (45 TO 80) (mm, L×W)QUANTITY: 1

Learn More -

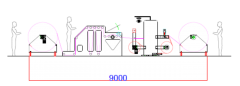

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More -

TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017 1) COMPLETE NONWOVEN NEEDLEPUNCH LINE 2) YEAR 2017 3) CONDITION: USED 4) WORKING WIDTH 2400mm QUANTITY: 1 Learn More

TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017 1) COMPLETE NONWOVEN NEEDLEPUNCH LINE 2) YEAR 2017 3) CONDITION: USED 4) WORKING WIDTH 2400mm QUANTITY: 1 Learn More -

TT-4269 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE, YEAR 1988TT-4269 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE, YEAR 1988 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE YEAR OF PRODUCTION 1988 QUANTITY: 1 Learn More

TT-4269 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE, YEAR 1988TT-4269 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE, YEAR 1988 BEFAMA CR 600 NONWOVEN FABRIC PRODUCTION LINE YEAR OF PRODUCTION 1988 QUANTITY: 1 Learn More -

C-1176 MENSCHER (M-TEC) SUPERFINISH 2, YEAR 2002, WIDTH 2000mm, M-TEC CONTINOUS DECATIZING MACHINEREFERENCE NUMBER: C-1176 MENSCHER (M-TEC) SUPERFINISH 2, YEAR 2002, WIDTH 2000mm, M-TEC CONTINOUS DECATIZING MACHINE COMPOSED OF: MAKE MENSCHNER (BECOME M-TEC) MOD. SUPERFINISH 2 FABRIC ENTRY FRAME + DRIVING GROUP WEFT STRAIGHTNER WITH PINS WHEELS MAKE BIANCO MODEL TRAMATEX SP02 YEAR OF CONSTRUCTION 1990 MACHINE MENSCHNER (M-TEC) MODEL SUPERFINISH YEAR OF CONSTRUCTION 1992 ROLLERS 2000MM WIDTH OF THE SILICON CARPET 1850MM WET DEVICE WEKO YEAR OF CONSTRUCTION 2004 DECATIZING CYLINDER DELIVERY FABRIC IN FOLDING DEVICE QUANTITY AVAILABLE: 1 Learn More

C-1176 MENSCHER (M-TEC) SUPERFINISH 2, YEAR 2002, WIDTH 2000mm, M-TEC CONTINOUS DECATIZING MACHINEREFERENCE NUMBER: C-1176 MENSCHER (M-TEC) SUPERFINISH 2, YEAR 2002, WIDTH 2000mm, M-TEC CONTINOUS DECATIZING MACHINE COMPOSED OF: MAKE MENSCHNER (BECOME M-TEC) MOD. SUPERFINISH 2 FABRIC ENTRY FRAME + DRIVING GROUP WEFT STRAIGHTNER WITH PINS WHEELS MAKE BIANCO MODEL TRAMATEX SP02 YEAR OF CONSTRUCTION 1990 MACHINE MENSCHNER (M-TEC) MODEL SUPERFINISH YEAR OF CONSTRUCTION 1992 ROLLERS 2000MM WIDTH OF THE SILICON CARPET 1850MM WET DEVICE WEKO YEAR OF CONSTRUCTION 2004 DECATIZING CYLINDER DELIVERY FABRIC IN FOLDING DEVICE QUANTITY AVAILABLE: 1 Learn More