Search results for: 'pillow'

- Related search terms

- pillow+b

- pillow co

- pillow+fi

- pillow machine

- pillow c

-

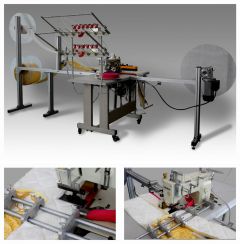

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINE

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINEREFERENCE NUMBER: L-5049

Learn More

AUTO SEWING MACHINE

MAX. STITCH LENGTH: 6mm

PRESSER FOOT HEIGHT: 10mm

QUANTITY: 1 -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More -

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More -

G-8019 VAUX-P PROGRAMMABLE COMPUTER STITCHER FOR PILLOW AND DIWANREFERENCE NUMBER: G-8019 VAUX-P PROGRAMMABLE COMPUTER STITCHER FOR PILLOW AND DIWAN QUANTITY AVAILABLE: 1 Learn More

G-8019 VAUX-P PROGRAMMABLE COMPUTER STITCHER FOR PILLOW AND DIWANREFERENCE NUMBER: G-8019 VAUX-P PROGRAMMABLE COMPUTER STITCHER FOR PILLOW AND DIWAN QUANTITY AVAILABLE: 1 Learn More -

X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS THIS MACHINE IS SPECIFIC FOR THE SEWING OF ANY KIND OF SYNTHETIC FIBRES AND FOAM, RESIN OR SIMILAR IN ANY THICKNESS AND WEIGHT USED TO COVER THE WOODEN FRAME QUANTITY AVAILABLE: 1 Learn More

X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS THIS MACHINE IS SPECIFIC FOR THE SEWING OF ANY KIND OF SYNTHETIC FIBRES AND FOAM, RESIN OR SIMILAR IN ANY THICKNESS AND WEIGHT USED TO COVER THE WOODEN FRAME QUANTITY AVAILABLE: 1 Learn More