Search results for: 'roll+pack+mac'

- Related search terms

- roll+pack+machine

- roll+pack+machine'

-

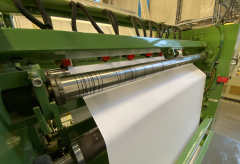

TT-3177 EDELMANN WINDER, WORKING WIDTH 7000mm, YEAR 1993TT-3177 EDELMANN WINDER, WORKING WIDTH 7000mm, YEAR 1993 QUANTITY: 1 Learn More

TT-3177 EDELMANN WINDER, WORKING WIDTH 7000mm, YEAR 1993TT-3177 EDELMANN WINDER, WORKING WIDTH 7000mm, YEAR 1993 QUANTITY: 1 Learn More -

TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012 SLITTER FOR FABRIC ON THE WINDING UNIT CLOTH ROLLS UP ON A 60” TUBE UPGRADED CREEL WITH AIR FEED FROM PACKAGE TO FEEDER Learn More

TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012 SLITTER FOR FABRIC ON THE WINDING UNIT CLOTH ROLLS UP ON A 60” TUBE UPGRADED CREEL WITH AIR FEED FROM PACKAGE TO FEEDER Learn More -

C-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mm

C-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mmC-4358 FULL-AUTO SINGLE LINE WET TISSUE MACHINE Y-2035 (A), CAPACITY 5 TO 30 PCS/PACKAGE, WIDTH 1100mm

Y-2035 (A) FULL-AUTO SINGLE LINE WET TISSUE MACHINE

MAIN TECHNICAL PARAMETER (SUITABLE FOR 5 TO 30 PCS /PACK)

PRODUCTION FLOW:

UNROLLING - FOLDING – WETTING – CUTTING – PILING – PACKING – DELIVERING

PRODUCTION SPEED: 300 TO 400 PCS/MIN

SUITABLE RAW MATERIAL: AIR-LAID PAPER, SPUNLACE /HOT-ROLLING NON-WOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80 G/㎡

WET TISSUE UNFOLDED SIZE: (150 TO 200) × (150 TO 250) (mm, L×W)

WET TISSUE FOLDED SIZE: (75 TO 100) × (45 TO 80) (mm, L×W)QUANTITY: 1

Learn More -

T-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESS

T-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESST-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESS

20 TONS PER DAYPP STAPLE FIBER SYSTEM

Learn More

6000 MTA (LINE-1+LINE-2)

EXTRUTION & SPINNING PACKAGE -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW)REFERENCE NUMBER: G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW) QUANTITY AVAILABLE: 1 Learn More

G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW)REFERENCE NUMBER: G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW) QUANTITY AVAILABLE: 1 Learn More -

YY-3193 USED TETRA PAK TETRA TOP 170 V, YEAR 2003YY-3193 USED TETRA PAK TETRA TOP 170 V, YEAR 2003 MACHINE TYPE: TETRA PAK TETRA TOP 170 V FILLING PLANT MANUFACTURER: TETRA PAK MODEL: TETRA TOP 170 V YEAR OF CONSTRUCTION: 2003 CONDITION: GOOD (USED) OPERATING HOURS: 13.772 H QUANTITY: 1 Learn More

YY-3193 USED TETRA PAK TETRA TOP 170 V, YEAR 2003YY-3193 USED TETRA PAK TETRA TOP 170 V, YEAR 2003 MACHINE TYPE: TETRA PAK TETRA TOP 170 V FILLING PLANT MANUFACTURER: TETRA PAK MODEL: TETRA TOP 170 V YEAR OF CONSTRUCTION: 2003 CONDITION: GOOD (USED) OPERATING HOURS: 13.772 H QUANTITY: 1 Learn More -

TT-2369 DUSENBERY PAPER CONVERTING MACHINE, WEB WIDTH MINIMUM 900mm TO MAXIMUM 1920mm, YEAR 2000TT-2369 DUSENBERY PAPER CONVERTING MACHINE, WEB WIDTH MINIMUM 900mm TO MAXIMUM 1920mm, YEAR 2000 MACHINE IS PRODUCED DUSENBERY EUROPE LTD. YEAR 2000 SPECIFICATION FOR MODEL 375 QUANTITY: 1 Learn More

TT-2369 DUSENBERY PAPER CONVERTING MACHINE, WEB WIDTH MINIMUM 900mm TO MAXIMUM 1920mm, YEAR 2000TT-2369 DUSENBERY PAPER CONVERTING MACHINE, WEB WIDTH MINIMUM 900mm TO MAXIMUM 1920mm, YEAR 2000 MACHINE IS PRODUCED DUSENBERY EUROPE LTD. YEAR 2000 SPECIFICATION FOR MODEL 375 QUANTITY: 1 Learn More -

E-8929 SPLITTERINVENTORY NUMBER: E-8929 SPLITTER MODEL: 1650 64" WIDTH MATERIAL (1650mm) QUANTITY AVAILABLE: 1 Learn More

E-8929 SPLITTERINVENTORY NUMBER: E-8929 SPLITTER MODEL: 1650 64" WIDTH MATERIAL (1650mm) QUANTITY AVAILABLE: 1 Learn More -

M-5102 NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICSREFERENCE NUMBER: M-5102 (1212FPDWXX11) L NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICS NEGATIVE & POSITIVE RAPIER HERCULES H5500 WEAVING MACHINES 20 SHAFTS NOMINAL WIDTH 5500mm MAXIMUM REED WIDTH 5500mm MINIMUM REED WIDTH 4400mm STANDARD BASIC MACHINE FOR VOLTAGE 440 V AND FREQUENCY OF 60 HZ DIRECT DRIVE MOTOR, SPEED CONTROLLED BY MICROPROCESSOR WITHOUT CHANGE OF PULLEY, WITHOUT CLUTCH SYSTEM, WITH (15%-40%) ELECTRIC POWER SAVING DEPENDING FROM TYPE OF WOVEN FABRIC SHEDDING MACHINE: STAUBLI DOBBY MODEL 2668 20 RODS SHAFTS TYPE GROB HEALD FRAME WITH UNDER MOTION 20 LEVER DRC CASTLE ELECTRIC CABINET WITH MICROPROCESSOR, ELECTRONIC PICK FINDING, ELECTRONIC LET-OFF, ELECTRONIC TAKE-UP UNIT WITH INDEPENDENT MOTOR ELECTRONIC WEFT COLOUR SELECTOR IN EXECUTION FOR 8 COLORS TAKE-UP WITH ROLLER DIAMETER 219mm 6 TWIN BEAM DIAMETER 219mm WITH FLANGE 1000mm Q3 JUMBO BACK REST BAR FOR HERCULES WEFT DENSITY VARIABLE PROGRAMMABLE BY THE OPERATOR AT YOUR CHOICE HORIZONTAL CREEL 4 COLOURS AND SUPPORT FOR 8 CONE 4 WEFT FEEDERS ROJ CHRONO X3 3 WEFT BRAKES FOR EVERY CHRONO X3 (TOTAL 12 PCS) TO BE SELECT AS PER CUSTOMER WEFT YARN WEFT CONTROLLING UNIT ELTEX MODEL G3W. DEROULÈ LATERAL MINI CREELS SUPPORT FOR 24 CONES LATERAL MOTORIZED LENO SYSTEM HEATING SCISSOR-CUTTING LATERAL TEMPLES: TO BE DEFINED DEPENDING THE FABRIC CHARACTERISTIC 20 FRAMES GROB TYPE 331 C TYPE DRC S227 GROBTEX ALFIX-U 14.000 GROB HEALDS TYPE 8 X 3.8 TYPE GROZ AETEX SP 0.38 331 8.0X3.8 I CR (7000PCS PER PACK) 1 WARP STOP MOTION 6-30 GROB FKW LED 14.000 GROB DROP WIRE TYPE GROZ EOU 1405 180X11X0.50 ZN (2000PCS PER PACK) SETS OF NEGATIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) SETS OF POSITIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) POSITIVE RAPIER KIT (FULL COMPONENT) CENTRAL GEARBOX ALREADY INSTALLED AND COLOR SELECTOR ALREADY ASSEMBLED FOR POSITIVE VERSION APPLICATION (TO REDUCE TIME OF CONVERSION) SETS AND EQUIPMENT OF LOOM TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDING NR. 2 TORQUE TOOL EXTRA SPARE PARTS THE TOTAL MACHINE SUPPLY WILL ALSO INCLUDE 2 SETS OF NEGATIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF NEGATIVE TAPES (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE TAPES (LEFT AND RIGHT SIDE) 1 POSITIVE RAPIER KIT (FULL COMPONENT) 1 SET AND EQUIPMENT OF LOOM 1 TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDE 2 TORQUE TOOLS EXTRA SPARE PARTS 1500EUR/MACHINE WARRANTY: ONE YEAR FROM MACHINE ERECTION OR AFTER 3 MONTHS DELIVERY DATE QUANTITY: 1 Learn More

M-5102 NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICSREFERENCE NUMBER: M-5102 (1212FPDWXX11) L NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICS NEGATIVE & POSITIVE RAPIER HERCULES H5500 WEAVING MACHINES 20 SHAFTS NOMINAL WIDTH 5500mm MAXIMUM REED WIDTH 5500mm MINIMUM REED WIDTH 4400mm STANDARD BASIC MACHINE FOR VOLTAGE 440 V AND FREQUENCY OF 60 HZ DIRECT DRIVE MOTOR, SPEED CONTROLLED BY MICROPROCESSOR WITHOUT CHANGE OF PULLEY, WITHOUT CLUTCH SYSTEM, WITH (15%-40%) ELECTRIC POWER SAVING DEPENDING FROM TYPE OF WOVEN FABRIC SHEDDING MACHINE: STAUBLI DOBBY MODEL 2668 20 RODS SHAFTS TYPE GROB HEALD FRAME WITH UNDER MOTION 20 LEVER DRC CASTLE ELECTRIC CABINET WITH MICROPROCESSOR, ELECTRONIC PICK FINDING, ELECTRONIC LET-OFF, ELECTRONIC TAKE-UP UNIT WITH INDEPENDENT MOTOR ELECTRONIC WEFT COLOUR SELECTOR IN EXECUTION FOR 8 COLORS TAKE-UP WITH ROLLER DIAMETER 219mm 6 TWIN BEAM DIAMETER 219mm WITH FLANGE 1000mm Q3 JUMBO BACK REST BAR FOR HERCULES WEFT DENSITY VARIABLE PROGRAMMABLE BY THE OPERATOR AT YOUR CHOICE HORIZONTAL CREEL 4 COLOURS AND SUPPORT FOR 8 CONE 4 WEFT FEEDERS ROJ CHRONO X3 3 WEFT BRAKES FOR EVERY CHRONO X3 (TOTAL 12 PCS) TO BE SELECT AS PER CUSTOMER WEFT YARN WEFT CONTROLLING UNIT ELTEX MODEL G3W. DEROULÈ LATERAL MINI CREELS SUPPORT FOR 24 CONES LATERAL MOTORIZED LENO SYSTEM HEATING SCISSOR-CUTTING LATERAL TEMPLES: TO BE DEFINED DEPENDING THE FABRIC CHARACTERISTIC 20 FRAMES GROB TYPE 331 C TYPE DRC S227 GROBTEX ALFIX-U 14.000 GROB HEALDS TYPE 8 X 3.8 TYPE GROZ AETEX SP 0.38 331 8.0X3.8 I CR (7000PCS PER PACK) 1 WARP STOP MOTION 6-30 GROB FKW LED 14.000 GROB DROP WIRE TYPE GROZ EOU 1405 180X11X0.50 ZN (2000PCS PER PACK) SETS OF NEGATIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) SETS OF POSITIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) POSITIVE RAPIER KIT (FULL COMPONENT) CENTRAL GEARBOX ALREADY INSTALLED AND COLOR SELECTOR ALREADY ASSEMBLED FOR POSITIVE VERSION APPLICATION (TO REDUCE TIME OF CONVERSION) SETS AND EQUIPMENT OF LOOM TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDING NR. 2 TORQUE TOOL EXTRA SPARE PARTS THE TOTAL MACHINE SUPPLY WILL ALSO INCLUDE 2 SETS OF NEGATIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF NEGATIVE TAPES (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE TAPES (LEFT AND RIGHT SIDE) 1 POSITIVE RAPIER KIT (FULL COMPONENT) 1 SET AND EQUIPMENT OF LOOM 1 TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDE 2 TORQUE TOOLS EXTRA SPARE PARTS 1500EUR/MACHINE WARRANTY: ONE YEAR FROM MACHINE ERECTION OR AFTER 3 MONTHS DELIVERY DATE QUANTITY: 1 Learn More