Search results for: 'air compress'

- Related search terms

- Air))),),"')(

- air pr

- air press

- Air'

- air+con

-

TT-3447 ATLAS COPCO RD20II AND T3W OIL RIG, YEAR 2013TT-3447 ATLAS COPCO RD20II AND T3W OIL RIG, YEAR 2013 ITEM 001 ATLAS COPCO RD20 RANGER II YEAR: 2013 HOURS: 86 HOURS ITEM 002 ATLAS COPCO T3W YEAR: 2013 HOURS: 57.3 HOURS KMS: 1418.6 KM Learn More

TT-3447 ATLAS COPCO RD20II AND T3W OIL RIG, YEAR 2013TT-3447 ATLAS COPCO RD20II AND T3W OIL RIG, YEAR 2013 ITEM 001 ATLAS COPCO RD20 RANGER II YEAR: 2013 HOURS: 86 HOURS ITEM 002 ATLAS COPCO T3W YEAR: 2013 HOURS: 57.3 HOURS KMS: 1418.6 KM Learn More -

T-7951 PRE AND FINISH – NEEDLER, WIDTH 2800mm TO 2900mmT-7951PRE AND FINISH – NEEDLER, WIDTH 2800mm TO 2900mm ITEM 001 PRE - NEEDLER QUANTITY: 1 ITEM 002 FINISH - NEEDLER QUANTITY: 1 Learn More

T-7951 PRE AND FINISH – NEEDLER, WIDTH 2800mm TO 2900mmT-7951PRE AND FINISH – NEEDLER, WIDTH 2800mm TO 2900mm ITEM 001 PRE - NEEDLER QUANTITY: 1 ITEM 002 FINISH - NEEDLER QUANTITY: 1 Learn More -

T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018 QUANTITY: 2 Learn More

T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018 QUANTITY: 2 Learn More -

K-8416 G1 TONELLO 330 "CENTRIFUGING" INDUSTRIAL WASHING MACHINE-USED

K-8416 G1 TONELLO 330 "CENTRIFUGING" INDUSTRIAL WASHING MACHINE-USEDREFERENCE NUMBER: K-8416

G1 TONELLO 330 "CENTRIFUGING" INDUSTRIAL WASHING MACHINE-USED

G1 TONELLO 330

“CENTRIFUGING” INDUSTRIAL WASHING MACHINE

FRONTAL TYPE

FOR CHEMICAL “STONE WASH”

CAPACITY LIT. 3.300

MOD. TONELLO G1 330

GENERAL DESCRIPTION:

TONELLO G1 IS A MACHINE WITH HIGH-SPEED HYDRO-EXTRACTION (600 R.P.M.) AND IT IS EQUIPPED WITH AUTOMATIC SELF-BALANCING SYSTEM

TONELLO G1 IS SUPPLIED WITH “SETTABLE INVERTER”

ROTATION SPEED FROM 0 TO 55 R.P.M

ALSO SETTING THE CENTRIFUGING SPEED FROM 0 TO 600 R.P.M.

WITH TIME OF CENTRIFUGE PROGRAMMABLE BY INDUSTRIAL PC

THE ACCESS MAIN DOOR TO THE DRUM IS VERY WIDE, IN ORDER TO EASY GARMENTS LOADING AND UNLOADING OPERATION

OPENING AND CLOSING ARE PNEUMATIC

DOUBLE TILTING SYSTEM FOR GARMENTS LOADING AND UNLOADING

DRIVING SYSTEM IS SITUATED ON THE UPPER PART OF THE MACHINE

WITH PROPER MATERIAL AND MOTORS SUITABLE TO WORK AT LOW AND HIGH R.P.M.

1 TANK FOR THE PREPARATION OF AUXILIARY PRODUCTS WITH CAPACITY OF LITTERS 180 EQUIPPED WITH ELECTRO-PUMP AND PNEUMATIC VALVES FOR THE SENT ONE

THE DRAINAGE IN DRAIN AND AUTOMATIC RINSES N° 2 WATER INLETS COMPLETE WITH PNEUMATIC VALVE- MECHANICAL WATER-COUNTER DIRECT HEATING AND COOLING SYSTEM

AUTOMATION WITH MICROPROCESSOR

TECHNICAL DATA TONELLO G1 330

DRUM DIMESION

-DRUM HOLING SHEET mm 4

THICKNESS

-DIAMETER MM 1900

-DEPTH MM 1150

-VOLUME LT. 3300

-DOOR DIAMETER MM 1020

-MAXIMUM LOADING KG. 120/130

CAPACITY

BASKET SPIN SPEED RPM 0-600

DIRECT STEAM CONNECTION Ø 1" 1/4

WATER INLET CONNECTION Ø 2 x 2

COMPRESSED AIR INLET Ø 1/4"

CONNECTION

STEAM IN MAXIMUM PRESSUREBAR BAR 6

WATER IN MAXIMUM PRESSURE BAR 4

COMPRESSED AIR IN MAXIMUM BAR 8

PRESSURE

POWER INSTALLED KW 22

3-PHASE VOLTAGE VOLT/HZ 400/50

PRODUCTS TANK Ø 240 H 400 LT. 80

TANK RINSING VALVE Ø 1/2"

MACHINE SIZE

-WIDTH MM 2500

-WIDTH WITH ELECTRICAL PANEL MM 2980

-DEPTH MM 2710

-HEIGHT MM 3000

Learn More -

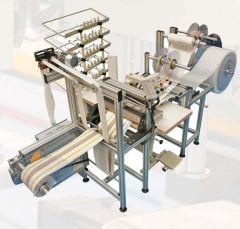

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More -

M-3824 FROZEN FRENCH FRIES LINE 500KG/HREFERENCE NUMBER: M-3824 (990UEWIHH8) L FROZEN FRENCH FRIES LINE 500KG/H QUANTITY AVAILABLE: 1 Learn More

M-3824 FROZEN FRENCH FRIES LINE 500KG/HREFERENCE NUMBER: M-3824 (990UEWIHH8) L FROZEN FRENCH FRIES LINE 500KG/H QUANTITY AVAILABLE: 1 Learn More -

M-5347 LORIS BELLINI YARN DYEING PLANTREFERENCE NUMBER: M-5347 (220MKSFXX1) L LORIS BELLINI YARN DYEING PLANT 1 SCHARER SCHWEITER METTLER 06 SSM HIGH SPEED CROSS WINDER AG SWITZERLAND (MODEL PSM 51 WITH 288 SPINDLES) 1 CAMEL ROBOT ITALY 02 COMPLETE SET OF TRACKS AND ROBOTICS QUANTITY AVAILABLE: 1 Learn More

M-5347 LORIS BELLINI YARN DYEING PLANTREFERENCE NUMBER: M-5347 (220MKSFXX1) L LORIS BELLINI YARN DYEING PLANT 1 SCHARER SCHWEITER METTLER 06 SSM HIGH SPEED CROSS WINDER AG SWITZERLAND (MODEL PSM 51 WITH 288 SPINDLES) 1 CAMEL ROBOT ITALY 02 COMPLETE SET OF TRACKS AND ROBOTICS QUANTITY AVAILABLE: 1 Learn More -

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More

G-0967 PILLOW VACUUM PACKING MACHINEREFERENCE NUMBER: G-0967 PILLOW VACUUM PACKING MACHINE DESCRIPTION: SUITABLE FOR ALL KINDS OF HOME TEXTILE PRODUCS WHICH ARE PACKED WITH PLASTIC BAGS, SUCH AS PILLOWS, CUSHIONS AND PLUSH TOYS, SOFA CUSHION ETC THOSE SOFT STUFFING PRODUCTIONS. THE SUITABLE BAG MATERIAL CAN BE PP, PO & PE, PA, OPP, ETC. HIGH AUTOMATIC LEVEL OF CONTROL IMPORTED. THE SEALING TIME AND COOLING TIME CAN BE ADJUSTED ACCORDING TO THE BAG MATERIAL THICKNESS, NORMALLY IT IS 2 TO 3 SECONDS. EACH SEALING SIDE CAN BE HANDLED BY ONLY ONE OPERATOR. CAPACITY: 3 PIECES PER MINUTE QUANTITY AVAILABLE: 1 Learn More -

M-0479 ROBOT TUFT CARPET TUFTING MACHINE AND BOORIA 3D DESIGN SOFTWAREREFERENCE NUMBER: M-0479 ROBOT TUFT CARPET TUFTING MACHINE AND BOORIA 3D DESIGN SOFTWARE ROBOT TUFT CARPET WEAVING MACHINES AND BOORIA 3D DESIGN SOFTWARE FOR SALE (2009) (THERE ARE TWO TUFTING MACHINES) QUANTITY AVAILABLE: 1 Learn More

M-0479 ROBOT TUFT CARPET TUFTING MACHINE AND BOORIA 3D DESIGN SOFTWAREREFERENCE NUMBER: M-0479 ROBOT TUFT CARPET TUFTING MACHINE AND BOORIA 3D DESIGN SOFTWARE ROBOT TUFT CARPET WEAVING MACHINES AND BOORIA 3D DESIGN SOFTWARE FOR SALE (2009) (THERE ARE TWO TUFTING MACHINES) QUANTITY AVAILABLE: 1 Learn More -

BRUCKNER BOPP EXTRUSION LINE WIDTH 8200mm YEAR 1992BRUCKNER BOPP EXTRUSION LINE, WIDTH 8200mm, THREE LAYERS, BUILT 1992, COMPLETED WITH AN ATLAS SLITTER/REWINDER, MODEL CW, WIDTH 8200mm. AND FURTHER AUXILIARIES, INCLUDING SPARE PARTS. NAMEPLATE CAPACITY 20,000 T/Y. RAW MATERIALS SECTION - 4 SILOS 250 M3 ALUMINIUM - 2 SILOS 100 M3 ALUMINIUM - 2 SILOS 50 M3 ALUMINIUM - PNEUMATIC TRANSPORT SYSTEM; COMPUTERIZED DOSING SYSTEM, HOPPERS AND SCALES FOR THE THREE EXTRUDERS EXTRUSION SECTION - MAIN EXTRUDERS: 2 MITSUBISHI CASCADE EXTRUDERS Ø 300 mm AND 250 mm - CO-EXTRUDERS: 2 BANDERA EXTRUDERS Ø 100 mm, EQUIPPED WITH MELT PIPES - DIE: SIMPLAST, WIDTH 1,140 mm, GAP 2 - 3.75 mm, 40 PUSH/PULL BOLTS - CHILL ROLL: Ø 3 M, 1,900,000 KJ/H COOLING CAPACITY - WATER BATH: 1.500.000 KJ/H CAPACITY MDO (MACHINE DIRECTION ORIENTATION) SECTION - PREHEATING INFRARED 130 KW - PREHEATING: 16 CHROMIUM PLATED ROLLS Ø 614 mm - STRETCHING: 6 CHROMIUM PLATED ROLLS Ø 180 mm, EQUIPPED WITH RUBBER NIP ROLLS Ø 150 mm - ANNEALING: 2 CHROMIUM PLATED ROLLS Ø 614 mm TDO (TRANSVERSE DIRECTION ORIENTATION) SECTION - TOTAL LENGTH: 66 METER - PREHEATING: 5 SECTIONS - STRETCHING : 5 SECTIONS - ANNEALING : 5 SECTIONS - NEUTRAL : 1 SECTION - COOLING : 2 SECTIONS - INLET 850 – 1,050 mm WIDTH - OUTLET 7,600 – 8,600 mm WIDTH PRS (PULL ROLL STAND) SECTION - EDGE TRIM CUTTERS - ESSECI FLAME TREATER, BURNER, CHROMIUM PLATE ROLL, RUBBER NIP ROLL - CORONA TREATER 1: 3 DISCHARGE BARS, SILICON ROLL, RUBBER NIP ROLL - CORONA TREATER 2: 2 DISCHARGE BARS, EDGE BAR, SILICON ROLL, RUNNER NIP ROLL MEASUREX/HONEYWELL GAUGE CONTROL SYSTEMS - 8.5 M SCANNER FOR FILM - 1.2 M SCANNER FOR CAST SHEET - MAIN THICKNESS CONTROL UNIT CONNECTED TO THE BOLT OF THE EXTRUSION DIE FOR LIP ADJUSTMENT WINDER - 2 TURRETS KAMPF WINDER - AUTOMATIC CUT / TURRET / MILL-ROLL CHANGE - WINDING CORES: 108 STEEL WINDING CORES Ø 500 mm CONTROL UNIT - THE LINE IS EQUIPPED WITH A FULLY INTEGRATED CONTROL SYSTEM SUPPLIED BY BRUCKNER MILL ROLL STAND (SEMI-FINISHED PRODUCTS WAREHOUSE) - 150 TOTAL POSITIONS, OF WHICH 50 IN HEATED CLOSED ROOM - 1 PICK-UP FOR LOADING / UNLOADING WINDER AND SLITTER - 1 MANUAL EMERGENCY PICK-UP FOR LOADING/UNLOADING WI NDER AND SLITTER AND MAINTENANCE - 1 SHUTTLE TO MOVE MILL ROLLS IN AND OUT OF THE WAREHOUSE - 1 MAIN CRANE FOR MOVING MILL ROLLS / EMPTY CORES RECYCLING - HERBOLD GRINDER FOR SCRAP RECOVERY - 4 FLUFF SILOS - 1 EREMA MACHINE FOR REGRANULATION, APPROX. 700 KG/H SLITTER - ATLAS CW MACHINE, BUILT 1992, MAJOR UPGRADE 2010 - INLET MILL-ROLLS MAX Ø 1.2 M, WIDTH 8.2 M - 16 REWINDING STATIONS, WIDTHS FROM 400 mm TO 2450 mm, MAX Ø 1,000 mm - AUTOMATIC KNIVES AND RE-WINDING ARMS POSITIONING PACKING - SEMI-AUTOMATIC BALLOTTI LINE FOR CONDITIONING OF ROLLS AND PALLETS, BUILT 2000 - CONVEYORS - SCALING - STRAPPING - STRETCHING UTILITIES - 3 COMPRESSORS 3 BARS FOR COMPRESSED AIR CIRCUIT FOR RAW MATERIALS HANDLING - 2 COMPRESSORS 6 BARS FOR COMPRESSED AIR - 2 CHILLERS FOR CHILLED WATER PRODUCTION - 2 WATER COOLING TOWERS - 1 BOILER FOR THERMAL OIL PRODUCTION - 3 TRANSFORMERS 15 KV TO 380 V ADDITIONAL EQUIPMENT - SPARE PARTS FOR ALL OF THE ABOVE - TECHNICAL CONSUMABLES - IT EQUIPMENT FOR CONTROLLING THE MANUFACTURING EQUIPMENT AND DATA TRAFFIC, SUCH AS SERVERS, SWITCHES AND CABLING - LABORATORY EQUIPMENT FOR QUALITY CONTROL PURPOSES Line was producing 20 to 40 microns , line can produce down to 10 to 12 microns Learn More

BRUCKNER BOPP EXTRUSION LINE WIDTH 8200mm YEAR 1992BRUCKNER BOPP EXTRUSION LINE, WIDTH 8200mm, THREE LAYERS, BUILT 1992, COMPLETED WITH AN ATLAS SLITTER/REWINDER, MODEL CW, WIDTH 8200mm. AND FURTHER AUXILIARIES, INCLUDING SPARE PARTS. NAMEPLATE CAPACITY 20,000 T/Y. RAW MATERIALS SECTION - 4 SILOS 250 M3 ALUMINIUM - 2 SILOS 100 M3 ALUMINIUM - 2 SILOS 50 M3 ALUMINIUM - PNEUMATIC TRANSPORT SYSTEM; COMPUTERIZED DOSING SYSTEM, HOPPERS AND SCALES FOR THE THREE EXTRUDERS EXTRUSION SECTION - MAIN EXTRUDERS: 2 MITSUBISHI CASCADE EXTRUDERS Ø 300 mm AND 250 mm - CO-EXTRUDERS: 2 BANDERA EXTRUDERS Ø 100 mm, EQUIPPED WITH MELT PIPES - DIE: SIMPLAST, WIDTH 1,140 mm, GAP 2 - 3.75 mm, 40 PUSH/PULL BOLTS - CHILL ROLL: Ø 3 M, 1,900,000 KJ/H COOLING CAPACITY - WATER BATH: 1.500.000 KJ/H CAPACITY MDO (MACHINE DIRECTION ORIENTATION) SECTION - PREHEATING INFRARED 130 KW - PREHEATING: 16 CHROMIUM PLATED ROLLS Ø 614 mm - STRETCHING: 6 CHROMIUM PLATED ROLLS Ø 180 mm, EQUIPPED WITH RUBBER NIP ROLLS Ø 150 mm - ANNEALING: 2 CHROMIUM PLATED ROLLS Ø 614 mm TDO (TRANSVERSE DIRECTION ORIENTATION) SECTION - TOTAL LENGTH: 66 METER - PREHEATING: 5 SECTIONS - STRETCHING : 5 SECTIONS - ANNEALING : 5 SECTIONS - NEUTRAL : 1 SECTION - COOLING : 2 SECTIONS - INLET 850 – 1,050 mm WIDTH - OUTLET 7,600 – 8,600 mm WIDTH PRS (PULL ROLL STAND) SECTION - EDGE TRIM CUTTERS - ESSECI FLAME TREATER, BURNER, CHROMIUM PLATE ROLL, RUBBER NIP ROLL - CORONA TREATER 1: 3 DISCHARGE BARS, SILICON ROLL, RUBBER NIP ROLL - CORONA TREATER 2: 2 DISCHARGE BARS, EDGE BAR, SILICON ROLL, RUNNER NIP ROLL MEASUREX/HONEYWELL GAUGE CONTROL SYSTEMS - 8.5 M SCANNER FOR FILM - 1.2 M SCANNER FOR CAST SHEET - MAIN THICKNESS CONTROL UNIT CONNECTED TO THE BOLT OF THE EXTRUSION DIE FOR LIP ADJUSTMENT WINDER - 2 TURRETS KAMPF WINDER - AUTOMATIC CUT / TURRET / MILL-ROLL CHANGE - WINDING CORES: 108 STEEL WINDING CORES Ø 500 mm CONTROL UNIT - THE LINE IS EQUIPPED WITH A FULLY INTEGRATED CONTROL SYSTEM SUPPLIED BY BRUCKNER MILL ROLL STAND (SEMI-FINISHED PRODUCTS WAREHOUSE) - 150 TOTAL POSITIONS, OF WHICH 50 IN HEATED CLOSED ROOM - 1 PICK-UP FOR LOADING / UNLOADING WINDER AND SLITTER - 1 MANUAL EMERGENCY PICK-UP FOR LOADING/UNLOADING WI NDER AND SLITTER AND MAINTENANCE - 1 SHUTTLE TO MOVE MILL ROLLS IN AND OUT OF THE WAREHOUSE - 1 MAIN CRANE FOR MOVING MILL ROLLS / EMPTY CORES RECYCLING - HERBOLD GRINDER FOR SCRAP RECOVERY - 4 FLUFF SILOS - 1 EREMA MACHINE FOR REGRANULATION, APPROX. 700 KG/H SLITTER - ATLAS CW MACHINE, BUILT 1992, MAJOR UPGRADE 2010 - INLET MILL-ROLLS MAX Ø 1.2 M, WIDTH 8.2 M - 16 REWINDING STATIONS, WIDTHS FROM 400 mm TO 2450 mm, MAX Ø 1,000 mm - AUTOMATIC KNIVES AND RE-WINDING ARMS POSITIONING PACKING - SEMI-AUTOMATIC BALLOTTI LINE FOR CONDITIONING OF ROLLS AND PALLETS, BUILT 2000 - CONVEYORS - SCALING - STRAPPING - STRETCHING UTILITIES - 3 COMPRESSORS 3 BARS FOR COMPRESSED AIR CIRCUIT FOR RAW MATERIALS HANDLING - 2 COMPRESSORS 6 BARS FOR COMPRESSED AIR - 2 CHILLERS FOR CHILLED WATER PRODUCTION - 2 WATER COOLING TOWERS - 1 BOILER FOR THERMAL OIL PRODUCTION - 3 TRANSFORMERS 15 KV TO 380 V ADDITIONAL EQUIPMENT - SPARE PARTS FOR ALL OF THE ABOVE - TECHNICAL CONSUMABLES - IT EQUIPMENT FOR CONTROLLING THE MANUFACTURING EQUIPMENT AND DATA TRAFFIC, SUCH AS SERVERS, SWITCHES AND CABLING - LABORATORY EQUIPMENT FOR QUALITY CONTROL PURPOSES Line was producing 20 to 40 microns , line can produce down to 10 to 12 microns Learn More