Search results for: 'automatic f'

- Related search terms

- automatic+V'

- automatic V''

- AUTOMATIC P

- Automatic+d

- AUTOMATIC''

-

AA-1165 FULLY AUTOMATIC GOOSE DOWN FILLING MACHINE GOOSE FEATHER FILLING MACHINEAA-1165 FULLY AUTOMATIC GOOSE DOWN FILLING MACHINE GOOSE FEATHER FILLING MACHINE MACHINE DIMENSIONS: 1650 x 900 x 2350mm MACHINE WEIGHT: 502KG VOLTAGE: 220V/40Hz Learn More

AA-1165 FULLY AUTOMATIC GOOSE DOWN FILLING MACHINE GOOSE FEATHER FILLING MACHINEAA-1165 FULLY AUTOMATIC GOOSE DOWN FILLING MACHINE GOOSE FEATHER FILLING MACHINE MACHINE DIMENSIONS: 1650 x 900 x 2350mm MACHINE WEIGHT: 502KG VOLTAGE: 220V/40Hz Learn More -

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More -

V-1816 AUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINE

V-1816 AUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINEAUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINE IS ALSO CALLED A PARTICULATE RESPIRATOR FILTER MAKING MACHINE OR HALF FACE RESPIRATOR FILTER MAKING MACHINE, IT’S MADE UNDER MATURE TECHNOLOGY THAT SUPPORTS AUTOMATICALLY MATERIAL FEEDING, WELDING, PUNCHING AND CUTTING, REPLACEMENT FILTER FORMING, THIS MACHINE IS EASY TO OPERATE, BY CHANGING THE ROLLER, IT CAN PRODUCE DIFFERENT SHAPES OF FILTER. THIS MACHINE INCORPORATES ADVANCED ULTRASONIC WELDING AND EQUIPPED WITH CONSTANT TEMPERATURE CONTROLLER WHICH ENSURES THE FILTER FIRMLY AND CLEARLY WELDED.

FEATURES:

1. ADVANCED ULTRASONIC TECHNOLOGY WITH FIRM WELDING EFFECT, IT’S EQUIPPED WITH PULL AND PUSH TYPE MATERIAL FEEDING WHICH MAKES IT EASIER OPERATING.

2. THE MOLD (PATTERN ROLLER) CAN BE CUSTOMIZED TO PRODUCE DIFFERENT FILTERS.

3. THE WELDING LINE IS CLEAR AND FIRM.

ITEM NAME

TECHNICAL PARAMETERS

QTY

REMARK

SPECIFICATION

1800mm X 1200mm X 1800mm

1

HONGDA

WEIGHT

500KG

EFFICIENCY

20 TO 30PCS/MIN

VOLTAGE

220V/380V

AIR PRESSURE

3-6KG/CM²

FREQUENCY

15/20KHZ

POWER

4200W

MOLD SERVO MOTOR

SGM7G-09AFC61 4.4KW

1

YASKAWA

ULTRASONIC POWER SERVO MOTOR

SGM7G-13AFC61 1.3KW

2

YASKAWA

MATERIAL PULLING SERVO MOTOR

SGM7G-09AFC61 0.85KW

2

YASKAWA

MATERIAL FEEDING/CORRECTING/INDENTATION MOTOR

130BYG-350A

4

SONGYANG

POUCHING MOTOR

110BYG-350B

4

SONGYANG

110 STEPPER MOTOR

110BYG-350A

10

SONGYANG

UP AND LOWER MOTOR

90BYG-350A

2

SONGYANG

STEPPER MOTOR 56

SY57STH56-2004A

8

SONGYANG

DIRECT CURRENT MOTOR

0.4KW

2

DIRECT CURRENT MOTOR

0.6KW

1

ASYNCHRONOUS THREE-PHASE MOTOR

90S-6

1

0.75KW

FREQUENCY CONVERTER

AVF200-0152

1

1.5KW

MAIN PNEUMATIC COMPONENTS: AIRTAC (TAIWAN); MAIN ELECTRICAL COMPONENTS: PANASONIC (JAPAN), SICK (GERMANY), DONLIM (CHINA&JAPAN), ETC.

EMAIL US FOR PRICE & PICTURES

INCLUDE OUR REFERENCE NUMBER

Learn More -

J-2778 SEMI-AUTOMATIC FACE MASK MACHINE FOR MASS 175 x 95mm – 200 PER MINUTE (Air Freight Available)

J-2778 SEMI-AUTOMATIC FACE MASK MACHINE FOR MASS 175 x 95mm – 200 PER MINUTE (Air Freight Available)SEMI-AUTOMATIC FACE MASK MACHINE

PRODUCES BLANK MASKS WITH NO EAR STRAPS (see our J-2779 for ear strap machine)

MASK DIMENSIONS: 175 x 95mm

CAPACITY: 150 TO 200 PIECES PER MINUTE

WEIGHT: 650 KGS

DIMENSIONS (L x W x H): 3400 x 800 x 2020mm

MATERIAL: NONWOVEN/ MELT-BLOWN FABRIC

VOLTAGE: 220 VOLTS / 380 VOLTS

POWER: 6 KWWITH ADJUSTABLE SPEED

CONSISTENT PRODUCT QUALITY

CONVENIENT OPERATION

USES ULTRASONIC WELDING TO FORM MASKSLEAD TIME: 5 DAYS FROM RECEIPT OF PAYMENT

PACKAGE 1 BY WOODEN BOX: 2400 X 1000 X 1300mm

Learn More

PACKAGE 2 BY WOODEN BOX: 2150 X 700 X 2300 mm

TOTAL WEIGHT IS EXPECTED TO BE AROUND 650KGS -

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTE

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTECAPACITY: 30-35 MASKS PER MINUTE

HIGH STABILITY, LOW FAILURE RATE

COMPUTER CONTROLLED OPERATIONS DRIVEN BY PLC

WITH AUTOMATIC TENSION CONTROL

VOLTAGE: 380 VOLTS, +5%, 50 Hz (OR AS PER CUSTOMER)

TOTAL POWER: ABOUT 15 KW

DIMENSIONS: L 10500 x W 1500 x H 2200mmQUANTITY: 1

Learn More -

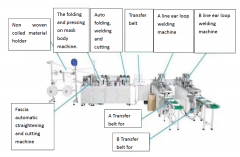

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPE

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPEI. FUNCTION

Learn More

THE MACHINE IS FULLY AUTOMATIC EAR TO LOOP MASK MAKING MACHINE. THIS MACHINE INCLUDES ONE SET OF CS-175 AND 2 SETS CS-WD175 AND BY A UNIT OF AUTOMATED DISPENSER. MASK BODIES PRODUCED ON THE MASK MACHINE CAN BE ALLOCATED ONTO 2 SETS OF SUBSEQUENT MACHINES CONTROLLED BY PLC AT THE SPEED OF 0 TO 120 PIECES PER MINUTE. ALL OF OPERATIONS OF THE MACHINE ARE CONTROLLED THROUGH TOUCH SCREEN OR PLCS.

II. PROCESS

AFTER THE MACHINE MAKES THE MASK BODY, THE CONVEYOR BELT STRUCTURE TRANSPORTS THE MASK BODY PIECE TO THE CONNECTING CONVEYOR. THROUGH THE CONNECTION CONVEYOR MASK PLATE TO THE CONVEYOR BELT, AGAIN THROUGH THE CONVEYOR BELT THE MASK IS TRANSPORTED TO THE EAR PIECE SECTION TO THE FRONT OF THE MACHINE ABOVE THE FIRST MASK PLATE, FINALLY THROUGH THE CYLINDER DOWN THE MASK ONTO MASK EAR MACHINE DISC, FOLLOWED UP BY EAR MASKS FOR THE EARS OF THE BELT WELDING MACHINE AND THEN IT’S COMPLETE.

III. FEATURES:

1. MACHINE FRAME IS MADE OF ALUMINUM ALLOY, PREVENTED FROM RUST;

2. THE MACHINE CAN MAKE 1 TO 3 TYPES OF MASK BLANKS ACCORDING TO WHAT THE CUSTOMER REQUIRES.

3. THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION CAN BE ADJUSTED;

4. THE DIRECTION OF THE EAR LOOP IS OUTSIDE;

5. A COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION ACHIEVES A HIGH RELIABILITY AND LOW FAILURE RATE. -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINE

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINEMAKES MASKS WITH 3 PLIES FROM WHITE MELT-BLOWN FABRIC, AND BLUE NONWOVEN FABRIC & WHITE NONWOVEN FABRIC (SEE OFFER PICTURES)

THE 3 MASK LAYERS ARE COMPOSED OF:

NONWOVEN WHITE: T/ ONE MILLION MASKS 195 TO 200mm 25g 2800m

NONWOVEN BLUE: T/ ONE MILLION MASKS 175mm 25g 2800mm

MELT-BLOWN WHITE: T/ TWO MILLION MASKS 175 25g N95

MAIN MACHINE PARTS CONSTRUCTED WITH STAINLESS STEEL

MITSUBISHI BRAND PLCs

ULTRASONIC HEAD BRAND: HUIZHUAN

ULTRASONIC GENERATOR WATTAGE CAPACITY: 1500 TO 2000 WATTS

ULTRASONIC GENERATOR FREQUENCY: 20K

MIDDLE FABRIC LAYER IS SPUNBOND, MELTBLOWN AND SPUNBOND

ACTIVATED CARBON FABRIC NOT POSSIBLE, YET

OVERALL EQUIPMENT LAYOUT:

3. INTERMEDIATE WELDING AND SLICING

2. HEMMING, NASAL, WELDING

4. MASK CONVEYOR LINE

5. EARBAND MACHINE (1 CONVEYOR LINE)

6. EARBAND MACHINE (2 CONVEYOR LINE)

7. EAR STRAP MACHINE (1 ASSEMBLY WELDING)

8. EAR STRAP MACHINE (2 ASSEMBLY WELDING)

9. MASK LINE

10. MASK LINEPRODUCT DETAILS:

VOLTAGE: 220V, 50/60HZ

AUTOMATIC MASK MACHINE

POWER: 85KW

PRODUCTION OUTPUT: 100 MASKS PER MINUTE, THE MAXIMUM ACTUAL OUTPUT IS 5000 PER HOUR.

DIMENSIONS: 6500mm X 4500mm X 2000mm120 TO 150 MASKS PER MINUTE, ACTUAL DETECTION DATA

Learn More

DELIVERY TIME: 20 DAYS -

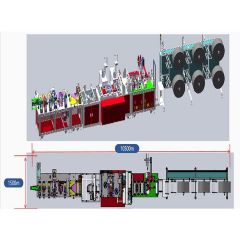

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAY

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAYPRODUCES FLAT MASKS AUTOMATICALLY: COILS STOCK, FOLDS AND PRESSES, MOLDS MASK, CUTS, LOADS AND WELDS EAR LOOPS, FINISHED PRODUCTS EXIT THE MACHINE

Learn More

MASKS ARE COMFORTABLE, NO PRESSURE, EASY TO WEAR AND PROVIDE GOOD FILTRATION

LINE FEATURES

ULTRASONIC WELDING MACHINE

HIGH SPEED PRODUCTION: 120,000 TO 140,000 PIECES PER 24-HOUR DAY

-APPROXIMATELY 90 TO 110 PIECES PER MINUTE

MODULAR AND PERSONNEL-FRIENDLY DESIGN WITH EASY MAINTENANCE

AUTOMATIC STOP AND ALARM FEATURE FOR MATERIAL BREAKAGE AND OTHER EXCEPTIONS, WITH ON-SCREEN HELP FOR CORRECTING THE BREAKAGE/EXCEPTIONS

DIMENSIONS: 6500mm LENGTH x 2500mm WIDTH x 1950mm HEIGHT

WEIGHT: </= 5000 KG

POWER: 220 VOLTS +/- 5% , 50 Hz, GROUND PROTECTION (OR AS PER CUSTOMER)

TOTAL KW: APPROXIMATELY 8.8 KW

AIR: 0.4 TO 0.6 MP (CLEAN AIR AFTER DEWATER, OIL-LESS, FILTRATION AND PRESSURE)

MAIN ACCESSORY: AIRTAC AIR CYLINDER

QUANTITY: 1 COMPLETE LINE (2 SETS CURRENTLY AVAILABLE MARCH 17TH) -

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

L-5827 AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINEREFERENCE NUMBER: L-5827

AUTOMATIC MECHANICAL POLYSTYRENE FAST FOOD CONTAINER MACHINE

EFFECTIVE FORMING AREA: 1100 X 1400mm

HEATING OVEN LENGTH: 4400mm

HYDRAULIC CYLINDER BORE: 220mm

QUANTITY: 1

Learn More