Search results for: 'roll pa'

- Related search terms

- roll p

- Roll e

- roller d

- roll-m

- roller p''

-

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More -

T-4865 BENNINGER BLEACHING PLANT, WORKING WIDTH:2000mm, YEAR 2018T-4865 BENNINGER BLEACHING PLANT, WORKING WIDTH:2000mm, YEAR 2018 BLEACHING PLANT BRAND: BENNINGER MODEL: AP-DL070B2E-(LTDB)-LK-2000 WORKING WIDTH: 2000mm YEAR: 2018 QUANTITY: 1 Learn More

T-4865 BENNINGER BLEACHING PLANT, WORKING WIDTH:2000mm, YEAR 2018T-4865 BENNINGER BLEACHING PLANT, WORKING WIDTH:2000mm, YEAR 2018 BLEACHING PLANT BRAND: BENNINGER MODEL: AP-DL070B2E-(LTDB)-LK-2000 WORKING WIDTH: 2000mm YEAR: 2018 QUANTITY: 1 Learn More -

TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES)TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES) DOUBLE SHAFT SLITTING & REWINDING MACHINE FOR PAPER, ADHENSIVE TAPE, LABEL ETC. EFFECTIVE WIDTH: 1300mm (51 INCHES) UNWIND DIAMETER: 1000mm (40 INCHES) MINIMUM SLITTING WIDTH: 5mm (0.196 INCHES) REWIND DIAMETER: 650mm (25.5 INCHES) MACHINE SPEED: 300 METERS/MIN. POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KGS (SUPPLIED BY USER) QUANTITY: 1 Learn More

TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES)TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES) DOUBLE SHAFT SLITTING & REWINDING MACHINE FOR PAPER, ADHENSIVE TAPE, LABEL ETC. EFFECTIVE WIDTH: 1300mm (51 INCHES) UNWIND DIAMETER: 1000mm (40 INCHES) MINIMUM SLITTING WIDTH: 5mm (0.196 INCHES) REWIND DIAMETER: 650mm (25.5 INCHES) MACHINE SPEED: 300 METERS/MIN. POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KGS (SUPPLIED BY USER) QUANTITY: 1 Learn More -

C-2319 LAMPERTI TRICOMBINED BRUSH TIGERING, LUSTRING AND SHEARING LINE LC/SF, WIDTH 2600mm TO 2680mm, YEAR 1980REFERENCE NUMBER: C-2319 LAMPERTI TRICOMBINED BRUSH TIGERING, LUSTRING AND SHEARING LINE LC/SF, WIDTH 2600mm TO 2680mm, YEAR 1980 DETAILS: MADE: LAMPERTI TYPE: LC/SF YEAR: 1980 ROLLER WIDTH: 2600mm QUANTITY AVAILABLE: 1 Learn More

C-2319 LAMPERTI TRICOMBINED BRUSH TIGERING, LUSTRING AND SHEARING LINE LC/SF, WIDTH 2600mm TO 2680mm, YEAR 1980REFERENCE NUMBER: C-2319 LAMPERTI TRICOMBINED BRUSH TIGERING, LUSTRING AND SHEARING LINE LC/SF, WIDTH 2600mm TO 2680mm, YEAR 1980 DETAILS: MADE: LAMPERTI TYPE: LC/SF YEAR: 1980 ROLLER WIDTH: 2600mm QUANTITY AVAILABLE: 1 Learn More -

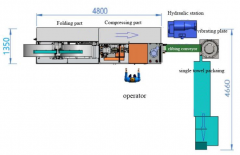

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

TT-8642 MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP, WORKING WIDTH 2400mm, YEAR 2008TT-8642 MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP, WORKING WIDTH 2400mm, YEAR 2008 1. MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP 2. WORKING WIDTH 2400mm 3. YEAR 2008 Learn More

TT-8642 MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP, WORKING WIDTH 2400mm, YEAR 2008TT-8642 MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP, WORKING WIDTH 2400mm, YEAR 2008 1. MONFORTS ECO-APPLICATOR/SOFTCOATING EVO SOFT NEO & HSP 2. WORKING WIDTH 2400mm 3. YEAR 2008 Learn More -

TT-7603 AUTOMATIC PAPER COTTON SWABS STICKS MAKING MACHINE, 4.5KW, 50HzTT-7603 AUTOMATIC PAPER COTTON SWABS STICKS MAKING MACHINE, 4.5KW, 50Hz 1. WARRANTY: 1 YEAR 2. CONDITION: NEW 3. WEIGHT: 2000KG 4. POWER SUPPLY: 380V/50Hz 5. TOTAL POWER: 4.5KW QUANTITY: 1 Learn More

TT-7603 AUTOMATIC PAPER COTTON SWABS STICKS MAKING MACHINE, 4.5KW, 50HzTT-7603 AUTOMATIC PAPER COTTON SWABS STICKS MAKING MACHINE, 4.5KW, 50Hz 1. WARRANTY: 1 YEAR 2. CONDITION: NEW 3. WEIGHT: 2000KG 4. POWER SUPPLY: 380V/50Hz 5. TOTAL POWER: 4.5KW QUANTITY: 1 Learn More -

TT-3460 CARU SUEDING MACHINE AND LASER ENGRAVING MACHINE, TABLE WIDTH 2400mm TO 3200mm, YEAR 2017TT-3460 CARU SUEDING MACHINE AND LASER ENGRAVING MACHINE, TABLE WIDTH 2400mm TO 3200mm, YEAR 2017 CARU SUEDING MACHINE TYPE “S 330” YEAR: 2017 Learn More

TT-3460 CARU SUEDING MACHINE AND LASER ENGRAVING MACHINE, TABLE WIDTH 2400mm TO 3200mm, YEAR 2017TT-3460 CARU SUEDING MACHINE AND LASER ENGRAVING MACHINE, TABLE WIDTH 2400mm TO 3200mm, YEAR 2017 CARU SUEDING MACHINE TYPE “S 330” YEAR: 2017 Learn More -

T-9576 COMPLETE BABCOCK BLEACHING LINE, WORKING WIDTH 3400mm, YEAR 1998T-9576 COMPLETE BABCOCK BLEACHING LINE, WORKING WIDTH 3400mm, YEAR 1998 QUANTITY: 1 Learn More

T-9576 COMPLETE BABCOCK BLEACHING LINE, WORKING WIDTH 3400mm, YEAR 1998T-9576 COMPLETE BABCOCK BLEACHING LINE, WORKING WIDTH 3400mm, YEAR 1998 QUANTITY: 1 Learn More -

J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM)J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM) REQUIRES 1 TO 2 OPERATORS WITH PLC CONTROLS WEIGHT: 1600 KGS VOLTAGE: 220 VOLTS POWER: 6 KW ULTRASONIC FREQUENCY: 20 kHz GAS PRESSURE: 6 KG PER cm2 QUANTITY: 1 Learn More

J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM)J-3392 AUTOMATIC 3-PLEAT HEADBAND FISH-STYLE FACE MASK MACHINE -CAPACITY: 45 TO 50 PIECES PER MINUTE -INCLUDES PRINTING ON MASKS -INCLUDES NOSE FOAM INSERTION (CLOSED CELL FOAM) REQUIRES 1 TO 2 OPERATORS WITH PLC CONTROLS WEIGHT: 1600 KGS VOLTAGE: 220 VOLTS POWER: 6 KW ULTRASONIC FREQUENCY: 20 kHz GAS PRESSURE: 6 KG PER cm2 QUANTITY: 1 Learn More