Search results for: 'Power equi'

- Related search terms

- equi

- equipment'

- equi'

- equip'

- POWER HE

-

TT-2241 SIEMENS AND ROLLS ROYCE GAS POWER PLANT, 75 MW, YEAR 2018TT-2241 SIEMENS AND ROLLS ROYCE GAS POWER PLANT, 75 MW, YEAR 2018 QUANTITY: 1 Learn More

TT-2241 SIEMENS AND ROLLS ROYCE GAS POWER PLANT, 75 MW, YEAR 2018TT-2241 SIEMENS AND ROLLS ROYCE GAS POWER PLANT, 75 MW, YEAR 2018 QUANTITY: 1 Learn More -

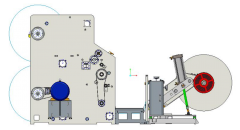

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

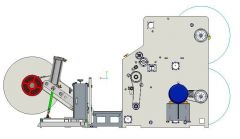

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More -

TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN)TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN) KEY SPECIFICATIONS MAX. CAPACITY: 5KN,10KN, 20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm EXTENSOMETER RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN, 0.001-1000mm/MIN WALKING SPACE: 1500mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER SUPPLY: AC 220V 50/60Hz 10A DIMENSIONS: 750 X 700 X 1700mm (W X D X H) WEIGHT: 170KG QUANTITY: 1 Learn More

TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN)TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN) KEY SPECIFICATIONS MAX. CAPACITY: 5KN,10KN, 20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm EXTENSOMETER RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN, 0.001-1000mm/MIN WALKING SPACE: 1500mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER SUPPLY: AC 220V 50/60Hz 10A DIMENSIONS: 750 X 700 X 1700mm (W X D X H) WEIGHT: 170KG QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINE

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1000MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:1000M/H ● OUTPUT:45KG/H ● TOTAL POWER:50KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:65MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 15KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : ONE-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:160MM (3) FILTER INSIDE DIA: 65MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1050MM (4) WIDTH ADJUSTMENT: UT-BLOCK TYPE, SINGLE SIDE IS 200MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1050MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT) AND 8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 1.5KW (6) THREE TRACTION ROLLER: 1050MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND15KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER. SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC

Learn More -

TT-7948 LM2500/1600/6000 GAS TURBINE PARTS: PROCESS EQUIPMENT AND PIPING, YEAR 2025TT-7948 LM2500/1600/6000 GAS TURBINE PARTS: PROCESS EQUIPMENT AND PIPING, YEAR 2025 CONDITION: NEW Learn More

TT-7948 LM2500/1600/6000 GAS TURBINE PARTS: PROCESS EQUIPMENT AND PIPING, YEAR 2025TT-7948 LM2500/1600/6000 GAS TURBINE PARTS: PROCESS EQUIPMENT AND PIPING, YEAR 2025 CONDITION: NEW Learn More -

YY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONSYY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONS 2 OPTIONS FOR FOAM AIR PERMEABILITY TESTER THIS INSTRUMENT IS COMPLETELY BASED ON THE NATIONAL STANDARD TEST REQUIREMENTS, RESEARCH AND DEVELOPMENT OF CUSTOM DEVELOPMENT, A COMPLETE REPLACEMENT FOR THE STANDARD RECOMMENDED RXQ-1 TYPE OF FOAM AIR PERMEABILITY TESTER, THE INSTRUMENT HAS A HIGH DEGREE OF INTEGRATION, THE USE OF THE LATEST MEASUREMENT AND CONTROL TECHNOLOGY, TO ACHIEVE THE AUTOMATION OF THE TEST PROCESS, INTELLIGENT, AND IMPROVE THE TESTING ACCURACY. THROUGH THE 7-INCH TOUCH SCREEN, THE ENTIRE TESTING PROCESS OF ONE-KEY OPERATION, SIMPLE OPERATION, INTELLIGENT AND CONVENIENT, IS A MAJOR RESEARCH INSTITUTIONS, SCIENTIFIC RESEARCH INSTITUTES, QUALITY INSPECTION UNITS FOR THE DETERMINATION OF SPONGE AIR PERMEABILITY OF THE NECESSARY INSTRUMENTS. QUANTITY: 1 Learn More

YY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONSYY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONS 2 OPTIONS FOR FOAM AIR PERMEABILITY TESTER THIS INSTRUMENT IS COMPLETELY BASED ON THE NATIONAL STANDARD TEST REQUIREMENTS, RESEARCH AND DEVELOPMENT OF CUSTOM DEVELOPMENT, A COMPLETE REPLACEMENT FOR THE STANDARD RECOMMENDED RXQ-1 TYPE OF FOAM AIR PERMEABILITY TESTER, THE INSTRUMENT HAS A HIGH DEGREE OF INTEGRATION, THE USE OF THE LATEST MEASUREMENT AND CONTROL TECHNOLOGY, TO ACHIEVE THE AUTOMATION OF THE TEST PROCESS, INTELLIGENT, AND IMPROVE THE TESTING ACCURACY. THROUGH THE 7-INCH TOUCH SCREEN, THE ENTIRE TESTING PROCESS OF ONE-KEY OPERATION, SIMPLE OPERATION, INTELLIGENT AND CONVENIENT, IS A MAJOR RESEARCH INSTITUTIONS, SCIENTIFIC RESEARCH INSTITUTES, QUALITY INSPECTION UNITS FOR THE DETERMINATION OF SPONGE AIR PERMEABILITY OF THE NECESSARY INSTRUMENTS. QUANTITY: 1 Learn More