Search results for: 'Production+cap'

- Related search terms

- Production+capacity

- Production+capa

- Production+capacity'

- Production+capa'

-

TT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVESTTT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVEST SUGAR AND ALCOHOL MILL QUANTITY: 1 Learn More

TT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVESTTT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVEST SUGAR AND ALCOHOL MILL QUANTITY: 1 Learn More -

TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996 LAROCHE BRAND: LAROCHE YEAR: 1996 STATE: USED FULLY OPERATIVE LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING. QUANTITY: 1 Learn More

TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996 LAROCHE BRAND: LAROCHE YEAR: 1996 STATE: USED FULLY OPERATIVE LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING. QUANTITY: 1 Learn More -

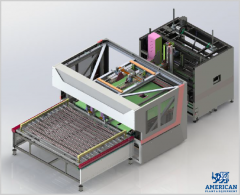

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More -

T-7427 EPSON ROBUSTELLI DIGITAL PRINTING MACHINES, YEAR 2017T-7427 EPSON ROBUSTELLI DIGITAL PRINTING MACHINES, YEAR 2017 HEAD PIECES: 32 HEAD BRAND: EPSON PRECISION CORE COLOR PIECES: 8 WORKING WIDTH: 1800mm INK TANK CAPACITY: 3 LITERS MAX PRINT SPEED: 450 LINEAR METER / H INSTALLED ELECTRIC POWER: 19 KW BELT HEATER: AVAILABLE BELT BLOWER: AVAILABLE DRIVEN FABRIC UNIT: EFFE FABRIC ENTRY UNIT: EFFE DRYER UNIT: EFFE 3 PHASE DRYER DRYER HEATING CAPACITY: NATURAL GAS NAM BURNER 125 KW POWER SUPPLY UNIT: İNFORM 30 KVA QUANTITY: 2 Learn More

T-7427 EPSON ROBUSTELLI DIGITAL PRINTING MACHINES, YEAR 2017T-7427 EPSON ROBUSTELLI DIGITAL PRINTING MACHINES, YEAR 2017 HEAD PIECES: 32 HEAD BRAND: EPSON PRECISION CORE COLOR PIECES: 8 WORKING WIDTH: 1800mm INK TANK CAPACITY: 3 LITERS MAX PRINT SPEED: 450 LINEAR METER / H INSTALLED ELECTRIC POWER: 19 KW BELT HEATER: AVAILABLE BELT BLOWER: AVAILABLE DRIVEN FABRIC UNIT: EFFE FABRIC ENTRY UNIT: EFFE DRYER UNIT: EFFE 3 PHASE DRYER DRYER HEATING CAPACITY: NATURAL GAS NAM BURNER 125 KW POWER SUPPLY UNIT: İNFORM 30 KVA QUANTITY: 2 Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

V-1188 I TECH SINGLE NEEDLE QUILTING MACHINE

V-1188 I TECH SINGLE NEEDLE QUILTING MACHINETWO SETS OF MOTORS X & Y.

Learn More

ADJUSTABLE FRAME

VOLTAGE: 220 V

Widths 80 x 90 and 105 x 93 inches -

M-3824 FROZEN FRENCH FRIES LINE 500KG/HREFERENCE NUMBER: M-3824 (990UEWIHH8) L FROZEN FRENCH FRIES LINE 500KG/H QUANTITY AVAILABLE: 1 Learn More

M-3824 FROZEN FRENCH FRIES LINE 500KG/HREFERENCE NUMBER: M-3824 (990UEWIHH8) L FROZEN FRENCH FRIES LINE 500KG/H QUANTITY AVAILABLE: 1 Learn More -

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More -

THIES AIR STREAM HT DYEING MACHINES – 2 AND 4 ROPES – YEAR 1998THIES AIR STREAM 2 ROPES HT 140 °C 2 x ROPE DYEING MACHINE THIES AIR STREAM 4 ROPES HT 140 °C 3 x ROPE DYEING MACHINE Learn More

THIES AIR STREAM HT DYEING MACHINES – 2 AND 4 ROPES – YEAR 1998THIES AIR STREAM 2 ROPES HT 140 °C 2 x ROPE DYEING MACHINE THIES AIR STREAM 4 ROPES HT 140 °C 3 x ROPE DYEING MACHINE Learn More