Search results for: 'sewing'

- Related search terms

- sewing ma

- Sewing machine

- Sewing t

- sewing machine 0

- sewıng machıne

-

GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998REFERENCE NUMBER: V-1855 GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998 PFAFF SEWING HEAD HOURS: 1127 YEAR: 1998 LENGTH X WIDTH: QUEEN 81.5 x 62 MAXIMUM MATTRESS HEIGHT: 4 INCHES TO 22 INCHES VERY GOOD CONDITION Learn More

GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998REFERENCE NUMBER: V-1855 GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998 PFAFF SEWING HEAD HOURS: 1127 YEAR: 1998 LENGTH X WIDTH: QUEEN 81.5 x 62 MAXIMUM MATTRESS HEIGHT: 4 INCHES TO 22 INCHES VERY GOOD CONDITION Learn More -

GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998REFERENCE NUMBER: V-1856 GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998 HOURS: 1630 GOOD CONDITION YEAR: 1998 WIDTH X LENGTH: QUEEN 81.5 x 62 PFAFF SEWING HEAD MAXIMUM MATTRESS HEIGHT: 4 INCHES TO 22 INCHES Learn More

GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998REFERENCE NUMBER: V-1856 GRIBETZ QUEEN TAPE EDGE, TE22, HIGH LIFT, YEAR 1998 HOURS: 1630 GOOD CONDITION YEAR: 1998 WIDTH X LENGTH: QUEEN 81.5 x 62 PFAFF SEWING HEAD MAXIMUM MATTRESS HEIGHT: 4 INCHES TO 22 INCHES Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

BIRCH BROTHERS INSPECTION STATIONS, ROLL WIDTH 84”, CLOTH WIDTH 80”, YEAR 1994REFERENCE NUMBER: T-3396 BIRCH BROTHERS INSPECTION STATIONS, ROLL WIDTH 84”, CLOTH WIDTH 80”, YEAR 1994 BIRCH BROTHERS INSPECTION STATIONS ROLL WIDTH: 84” CLOTH WIDTH: 80” YEAR 1994 LIGHTED INSPECTION BOARD TRUE METER MEASURING SYSTEM MERROW SEWING MACHINE ON RAILS ASSISTED DOFF FUNCTION AND CONNECTING CONVEYOR SYSTEM QUANTITY: 4 Learn More

BIRCH BROTHERS INSPECTION STATIONS, ROLL WIDTH 84”, CLOTH WIDTH 80”, YEAR 1994REFERENCE NUMBER: T-3396 BIRCH BROTHERS INSPECTION STATIONS, ROLL WIDTH 84”, CLOTH WIDTH 80”, YEAR 1994 BIRCH BROTHERS INSPECTION STATIONS ROLL WIDTH: 84” CLOTH WIDTH: 80” YEAR 1994 LIGHTED INSPECTION BOARD TRUE METER MEASURING SYSTEM MERROW SEWING MACHINE ON RAILS ASSISTED DOFF FUNCTION AND CONNECTING CONVEYOR SYSTEM QUANTITY: 4 Learn More -

RAMISCH KLEINEWEFERS CALENDER, WORKING WIDTH 1800mm, YEAR 1991REFERENCE NUMBER: T-6919 RAMISCH KLEINEWEFERS CALENDER, WORKING WIDTH 1800mm, YEAR 1991 RAMISCH KLEINEWEFERS CALENDER YEAR 1991 WORKING WIDTH 1800mm 3 CYLINDERS 2 STEEL 1 RACOLAN UPPER AND LOWER CYLINDERS ARE ELECTRIC HEATED WITH METAL AND SEWING DETECTOR TEMP. 190 °C WORKING PRESS 50 BAR MACHINES ARE IN EXCELLENT RUNNING CONDITION QUANTITY: 1 Learn More

RAMISCH KLEINEWEFERS CALENDER, WORKING WIDTH 1800mm, YEAR 1991REFERENCE NUMBER: T-6919 RAMISCH KLEINEWEFERS CALENDER, WORKING WIDTH 1800mm, YEAR 1991 RAMISCH KLEINEWEFERS CALENDER YEAR 1991 WORKING WIDTH 1800mm 3 CYLINDERS 2 STEEL 1 RACOLAN UPPER AND LOWER CYLINDERS ARE ELECTRIC HEATED WITH METAL AND SEWING DETECTOR TEMP. 190 °C WORKING PRESS 50 BAR MACHINES ARE IN EXCELLENT RUNNING CONDITION QUANTITY: 1 Learn More -

D-2388 What’s the Best Material for a Mask?

D-2388 What’s the Best Material for a Mask?Federal health officials have now recommended that we cover our faces with fabric during the coronavirus pandemic. But what material offers the most protection?

The Centers for Disease Control and Prevention has posted a no-sew mask pattern using a bandanna and a coffee filter as well as a video on making masks using rubber bands and folded fabrics found at home.

While a simple face covering can reduce the spread of coronavirus by blocking outgoing germs from coughs or sneezes of an infected person, experts say there is more variation in how much homemade masks might protect the wearer from incoming germs, depending on the fit and quality of the material used.

Scientists around the country have taken it upon themselves to identify everyday materials that do a better job of filtering microscopic particles. In recent tests, HEPA furnace filters scored well, as did vacuum cleaner bags, layers of 600-count pillowcases and fabric similar to flannel pajamas. Stacked coffee filters had medium scores. Scarves and bandanna material had the lowest scores, but still captured a small percentage of particles.

If you don’t have any of the materials that were tested, a simple light test can help you decide whether a fabric is a good candidate for a mask.

“Hold it up to a bright light,” said Dr. Scott Segal, chairman of anesthesiology at Wake Forest Baptist Health who recently studied homemade masks. “If light passes really easily through the fibers and you can almost see the fibers, it’s not a good fabric. If it’s a denser weave of thicker material and light doesn’t pass through it as much, that’s the material you want to use.”

Researchers say it’s important to remember that lab studies are conducted under perfect conditions with no leaks or gaps in the mask, but the test methods give us a way to compare materials. And while the degree of filtration for some homemade masks seems low, most of us — who are staying home and practicing social distancing in public — don’t need the high level of protection required for medical workers. More important, any face covering is better than none, especially if worn by a person who has the virus but doesn’t know it.

The biggest challenge of choosing a homemade mask material is to find a fabric that is dense enough to capture viral particles, but breathable enough that we can actually wear it. Some items being touted online promise high filtration scores, but the material would be unwearable.

Dressing Up for Work … at Home

Yang Wang, an assistant professor of environmental engineering at Missouri University of Science and Technology, worked with his graduate students to study various combinations of layered materials — including both air filters and fabric. “You need something that is efficient for removing particles, but you also need to breathe,” said Dr. Wang, who last fall won an international award for aerosol research.To test everyday materials, scientists are using methods similar to those used to test medical masks, which everybody agrees should be saved for medical workers who are exposed to high doses of virus from seeing infected patients. The best medical mask — called the N95 respirator — filters out at least 95 percent of particles as small as 0.3 microns. By comparison, a typical surgical mask — made using a rectangular piece of pleated fabric with elastic ear loops — has a filtration efficiency ranging from 60 to 80 percent.

Dr. Wang’s group tested two types of air filters. An allergy-reduction HVAC filter worked the best, capturing 89 percent of particles with one layer and 94 percent with two layers. A furnace filter captured 75 percent with two layers, but required six layers to achieve 95 percent. To find a filter similar to those tested, look for a minimum efficiency reporting value (MERV) rating of 12 or higher or a microparticle performance rating of 1900 or higher.

The problem with air filters is that they potentially could shed small fibers that would be risky to inhale. So if you want to use a filter, you need to sandwich the filter between two layers of cotton fabric. Dr. Wang said one of his grad students made his own mask by following the instructions in the C.D.C. video, but adding several layers of filter material inside a bandanna.

Dr. Wang’s group also found that when certain common fabrics were used, two layers offered far less protection than four layers. A 600 thread count pillow case captured just 22 percent of particles when doubled, but four layers captured nearly 60 percent. A thick woolen yarn scarf filtered 21 percent of particles in two layers, and 48.8 percent in four layers. A 100 percent cotton bandanna did the worst, capturing only 18.2 percent when doubled, and just 19.5 percent in four layers.

The group also tested Brew Rite and Natural Brew basket-style coffee filters, which, when stacked in three layers, showed 40 to 50 percent filtration efficiency — but they were less breathable than other options.

If you are lucky enough to know a quilter, ask them to make you a mask. Tests performed at the Wake Forest Institute for Regenerative Medicine in Winston-Salem, N.C., showed good results for homemade masks using quilting fabric. Dr. Segal, of Wake Forest Baptist Health, who led the study, noted that quilters tend to use high-quality, high-thread count cotton. The best homemade masks in his study were as good as surgical masks or slightly better, testing in the range of 70 to 79 percent filtration. Homemade masks that used flimsier fabric tested as low as 1 percent filtration, Dr. Segal said.

The best-performing designs were a mask constructed of two layers of high-quality, heavyweight “quilter’s cotton,” a two-layer mask made with thick batik fabric, and a double-layer mask with an inner layer of flannel and outer layer of cotton.

Bonnie Browning, executive show director for the American Quilter’s Society, said that quilters prefer tightly woven cottons and batik fabrics that stand up over time. Ms. Browning said most sewing machines can handle only two layers of fabric when making a pleated mask, but someone who wanted four layers of protection could wear two masks at a time.

Ms. Browning said she recently reached out to quilters on Facebook and heard from 71 people who have made a combined total of nearly 15,000 masks. “We quilters are very much in the thick of what’s going on with this,” said Ms. Browning, who lives in Paducah, Ky. “One thing most of us have is a stash of fabric.”

People who don’t sew could try a folded origami mask, created by Jiangmei Wu, assistant professor of interior design at Indiana University. Ms. Wu, who is known for her breathtaking folded artwork, said she began designing a folded mask out of a medical and building material called Tyvek, as well as vacuum bags, after her brother in Hong Kong, where mask wearing is common, suggested it. (DuPont, the maker of Tyvek, said in a statement that Tyvek is intended for medical apparel, not masks.) The folded mask pattern is free online, as is a video demonstrating the folding process. In tests at Missouri University and University of Virginia, scientists found that vacuum bags removed between 60 percent and 87 percent of particles. But some brands of vacuum bags may contain fiberglass or are harder to breathe through than other materials, and shouldn’t be used. Ms. Wu used a bag by EnviroCare Technologies, which has said it does not use fiberglass in its paper and synthetic cloth bags.

“I wanted to create an alternative for people who don’t sew,” said Ms. Wu, who said she is talking to various groups to find other materials that will be effective in a folded mask. “Given the shortage of all kinds of materials, even vacuum bags might run out.”

The scientists who conducted the tests used a standard of 0.3 microns because that is the measure used by the National Institute for Occupational Safety and Health for medical masks.

Linsey Marr, a Virginia Tech aerosol scientist and an expert in the transmission of viruses, said the certification method for respirators and HEPA filters focuses on 0.3 microns because particles around that size are the hardest to catch. While it seems counterintuitive, particles smaller than 0.1 microns are actually easier to catch because they have a lot of random motion that makes them bump into the filter fibers, she said.

“Even though coronavirus is around 0.1 microns, it floats around in a wide range of sizes, from around 0.2 to several hundred microns, because people shed the virus in respiratory fluid droplets that also contain lots of salts and proteins and other things,” said Dr. Marr. “Even if the water in the droplets fully evaporates, there’s still a lot of salt and proteins and other gunk that stays behind as solid or gel-like material. I think 0.3 microns is still useful for guidance because the minimum filtration efficiency will be somewhere around this size, and it’s what NIOSH uses.”

Learn More -

H-2239 MAMMUT QUILTER – MODEL P2 S240 QS28/PA – YEAR 2011

H-2239 MAMMUT QUILTER – MODEL P2 S240 QS28/PA – YEAR 2011BRAND: MAMMUT

MODEL: P2 S240 QS28/PA

YEAR 2011GENERAL MACHINE DATA

UP TO 3,100 STITCHES / MINUTE

MAX. SEWING AREA 2,400 X 2,600mm

STITCH LENGTH 2-8mmMECHANICAL DATA

DIMENSIONS (L X W): 4100 X 7500mm

WEIGHT: APPROXIMATELY 2,300 KG

AIR CONNECTION: 6 BAR

AIR CONSUMPTION: 250 L / MINELECTRICAL DATA

3 PHASES / 400 V

50-60 HZ

3.5 KWQUANTITY: 1

Learn More -

PP-1128 MAINTENANCE SHOP FROM MATTRESS PLANT

PP-1128 MAINTENANCE SHOP FROM MATTRESS PLANT

Learn MoreDescription

Various Air Hoses, Coil Hoses, Connectors

Various Spools of Wiring

Trash Cans

Various Wheels

Various Shop Fans/AC Units

Various Air Tanks for Welders

Maintenance Shop Racks

Table Top Clamp/Various Other Clamps

Miscellaneous Sewing Machines

Motors for Machines

Various Shop Vacuums

Fire Extinguishers

Dollys/Carts

Belt Sander

Shop Aprons

Various Cooper Coils/Belts

Various Nuts/Bolts/Allen Wrenches

Hammers/Saws/Screw Drivers

Various Drills

Cabinets Full of Miscellaneous Spare Parts/Nuts/Bolts

Lift Genie

Machine Manuals

All Other Miscellaneous Parts/Pieces/Tools/Small Machinery

-

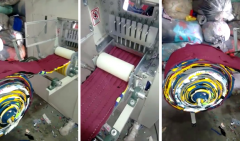

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTER

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERREFERENCE NUMBER: J-2326

QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERQUILTING MACHINE FOR RAGS

SEWS RAGS CONTINUOUSLY

SEW HEAD: 7 NEEDLES AND 7 LOOPERS

MAKES A CHAIN STITCH ON THE CONVEYED RAGS

USES OVERLOCK THREAD

DISTANCE BETWEEN NEEDLES: 250mm (ENSURES THAT EVEN SMALL RAGS ARE SEWN)

1 HP MOTOR, 3-PHASE, 220 VOLT

WITH FREQUENCY INVERTER TO ADJUST THE ROTATION SPEED OF THE MOTOR AS NEEDED

HEIGHT: 1800mm

WIDTH: 960mm

DEPTH; 370mm

CONVEYOR WIDTH: 200mm

CONVEYOR LENGTH: 1560mm

MACHINE TOTAL LENGTH WITH CONVEYOR: 2800mmAFTER SEWING, THE QUILT IS TRANSPORTED OUT INTO ROLLS WHICH CAN BE CUT ACCORDING TO CUSTOMER NEEDS

Learn More

OPERATION: PLACE A LARGER RAG AS THE BOTTOM LAYER, SMALLER RAGS AS FILLING, AND ANOTHER LARGER RAG AS THE TOP LAYER. OPERATION REQUIRES 2 TO 3 OPERATORS.

TO REDUCE THE NUMBER OF OPERATORS REQUIRED, A FIBER ROLL AS CAN BE USED AS THE LOWER LAYER. THIS ALSO INCREASES THE PRODUCTION RATE.

DAILY PRODUCTION: VARIES BETWEEN 300 TO 500 KG PER 8 HOURS OF OPERATION

FOR KNIT FABRICS SUCH AS COTTON, VISCOSE, SWEATSHIRT FLEECE, NYLON STRETCH-FABRIC, PIQUET AND POPELINE

THERE IS NO MATERIAL WASTE AS THE MACHINE USES 100% OF THE RAGS

WORKING WIDTH: 12 INCHES

NEEDLE SPACING: 1 INCH

WITH LOOPER STRUCTURE SIMILAR TO THE DIAGRAM BELOW (REDUCES BOTTOM THREAD BREAKAGE)

MACHINE IS NEW, MADE TO ORDER

LEAD TIME: 10 DAYS