Search results for: 'Complete Te'

- Related search terms

- Complete

- Complete p

- Complete ca

- Complete+p

- Complete+p'

-

TT-4958 COMPLETE TEXTURIZING & TWISTING PLANT, YEAR 1997 TO 2002TT-4958 COMPLETE TEXTURIZING & TWISTING PLANT, YEAR 1997 TO 2002 ITEM 001 MENEGATTO TMA43 TEXTURIZING MACHINES 168 POSITIONS (84 PER SIDE) QUANTITY: 2 ITEM 002 GIUDICI TG30 FA TEXTURIZING MACHINE YEAR 2002 QUANTITY: 1 ITEM 003 RPR 3SDX 4 TEXTURIZING MACHINE TAKE-UP POSITIONS: 240 MAX QUANTITY: 1 ITEM 004 RPR GC-96 TWISTING MACHINES QUANTITY: 5 ITEM 005 GIUDICI TG3 DUPLEX TWISTING MACHINE QUANTITY: 1 ITEM 006 VEMATEX TWISTING MACHINES QUANTITY: 10 ITEM 007 OBEM STEAM AUTOCLAVE YEAR 1997 QUANTITY: 1 ITEM 008 NOVOPAC PACKING & PALLETIZING LINE QUANTITY: 1 Learn More

TT-4958 COMPLETE TEXTURIZING & TWISTING PLANT, YEAR 1997 TO 2002TT-4958 COMPLETE TEXTURIZING & TWISTING PLANT, YEAR 1997 TO 2002 ITEM 001 MENEGATTO TMA43 TEXTURIZING MACHINES 168 POSITIONS (84 PER SIDE) QUANTITY: 2 ITEM 002 GIUDICI TG30 FA TEXTURIZING MACHINE YEAR 2002 QUANTITY: 1 ITEM 003 RPR 3SDX 4 TEXTURIZING MACHINE TAKE-UP POSITIONS: 240 MAX QUANTITY: 1 ITEM 004 RPR GC-96 TWISTING MACHINES QUANTITY: 5 ITEM 005 GIUDICI TG3 DUPLEX TWISTING MACHINE QUANTITY: 1 ITEM 006 VEMATEX TWISTING MACHINES QUANTITY: 10 ITEM 007 OBEM STEAM AUTOCLAVE YEAR 1997 QUANTITY: 1 ITEM 008 NOVOPAC PACKING & PALLETIZING LINE QUANTITY: 1 Learn More -

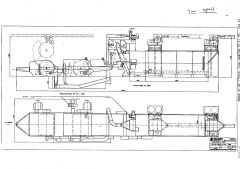

TT-1138 MARGASA COMPLETE TEARING LINE, CAPACITY 300 TO 400 KG – HTT-1138 MARGASA COMPLETE TEARING LINE, CAPACITY 300 TO 400 KG – H POWER: 420 KW QUANTITY: 1 Learn More

TT-1138 MARGASA COMPLETE TEARING LINE, CAPACITY 300 TO 400 KG – HTT-1138 MARGASA COMPLETE TEARING LINE, CAPACITY 300 TO 400 KG – H POWER: 420 KW QUANTITY: 1 Learn More -

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mmM-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

2 ROTARY CUTTERS TYPE CMT-900, WORKING WIDTH 900mm, INCLUDING FEEDING CONVEYORS.

Learn More

1 ELECTRONIC METAL DETECTOR, MOUNTED ON FEEDING CONVEYOR OF THE 1ST CUTTER.

1 PNEUMATIC MATERIAL TRANSPORT WITH SPECIAL FAN FOR RAGS ETC.

1 STATIONARY ZIG-ZAG HUMP MAGNET MOUNTED IN TUBE FOR MATERIAL TRANSPORT.

2 MIXING/ RELAXING STORAGE BINS FOR CUTTED RAGS WITH SPRAYING ROOM

IN FRONT OF:

1 FEEDING MACHINE TYPE CCS-1500, WORKING WIDTH 1500mm, AUTOMATIC PNEUMATIC FEEDING FROM STORAGE BINS, ELECTRONIC LEVEL CONTROL AND DOSING CONVEYOR TO TEARING LINE.

1 RAG TEARING LINE WITH 4 SECTIONS TYPE MASTER MCM-1550-DD, WORKING WIDTH 1500mm, TAMBOUR DIAM. 1000mm.

1 ELECTRONIC CONTROL PANEL FOR THE WHOLE LINE INCL. TOUCH SCREEN AND INVERTER DRIVER FOR SEVERAL MOTORS.

6 FILTER UNITS.

- ALL EQUIPMENT “AS NEW” SINCE RUNNING ONLY A FEW HOURS.

- CAPACITY UP TO 1000KG/HR. -

M-5158 COMPLETE TERRY WEAVING PLANTREFERENCE NUMBER: M-5158 (1212CVPGXX11) L COMPLETE TERRY WEAVING PLANT 1 WEST POINT DIRECT WARPER WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 504 ENDS, 504 SPARE ENDS, PITCH 400 MM, WP ELECTRO SENSE 1 WEST POINT DIRECT WARPER, WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 640 ENDS, 640 SPARE ENDS, PITCH 450 MM, WP ELECTRO SENSE 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 10 DRYING CYLINDERS, TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 8 DRYING CYLINDERS, 7 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 3.0 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 8 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 7 DRYING CYLINDERS, 6 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 SIZE KITCHEN , 5 STAINLESS STEEL MIXING TANKS WITH HEATING 7 MOTOCONO REMAIN WINDERS, 4 POSITIONS EACH 1 WARP BEAM STORAGE, 6 ROWS, 4 LEVELS, 14 M LENGTH 3 SHELVES SINGLE SIDED, 2 SHELVES DOUBLE SIDED WITH HUBTEX WARP BEAM LIFTER, MODEL 20TS 62 SULZER TERRY PROJECTILE LOOMS WITH JACQUARD (8) MODEL P7100 B330 F4 EP J D1, YEAR 4X 1989, 2X 1990, 2X 1991 WORKING WIDTH 3,3 M / 130” (7) STAUBLI E-JACQUARD CX-870, YEAR 1998-2004, 2688 HOOKS, CONTROLLER JC-5 (1) STAUBLI E-JACQUARD CX-860, YEAR 1997, 2688 HOOKS, CONTROLLER JC-4 (M/C 1989) GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7200 B330 F4 J Q D1, YEAR 1X 1991, 1X 1995 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (6) MODEL P7100 B330 F4 J D1, YEAR 1X 1991, 1X 1992, 4X 1994 WORKING WIDTH 3,3 M / 130” (4) STAUBLI E-JACQUARD CX-860, YEAR 1994, 2688 HOOKS, CONTROLLER JC-4 (2) STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 (M/C 1990/91) GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7250 B330 F4 J D1, YEAR 2X 2000, 2X 2001 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2X 2001, 2X 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (5) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1991, 1X 1992, 2X 1994, 1X 1995 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 2003/2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1992 WORKING WIDTH 3,9 M / 153” SCHLEICHER MECHANICAL JACQUARD 3-08, YEAR 1990, 896 HOOKS CAM MOTION, 6 LEVERS INSTALLED, 4 FRAMES GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 3X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1602, YEAR 2006/2008, 3072 HOOKS, CONTROLLER JC-6 GROUND AND PILE WARP BEAM 940 MM DIAMETER (6) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 4X 1993, 1X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520S, YEAR 1993/94, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1994, WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520, YEAR 1995, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7100 B390 F4 EP J D1, YEAR 1995, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2006, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 J D1, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-860, YEAR 1996, 2688 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 J D2, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-960, YEAR 1996, 3072 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (8) MODEL P7200 B390 F4 J Q D1, YEAR 6X 1996, 2X 1997, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 1998, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (8) MODEL P7250 B390 F4 J D1, YEAR 6X 1997, 2X 1998 , WORKING WIDTH 3,9 M / 153” (4) STAUBLI E-JACQUARD LX-1600, YEAR 2000, 3072 HOOKS, CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870, YEAR 2000/01, 2688 HOOKS, CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D2, YEAR 1999 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D3, YEAR 1999, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER ALL MACHINES WITH 4 COLORS, AVERAGE 3 WEFT FEEDERS (ROH CHRONO HS AND SIMILAR), MIN. 3 CENTRAL TUCK IN UNITS PER MACHINE, SIDE TUCK IN UNITS, USTER LOOM DATA E-JACQUARD M/C WITH ELECTRONICALLY CONTROLLED COLOR SELECTION (EXCEPT 8 MECHANICAL M/CS) SPLIT BEAM EXECUTION, 1.5 PILE BEAMS, 1.5 GROUND BEAMS ON-LOOM TAKE-UP, 1.5 CLOTH ROLLS, 4 WEFT FEEDERS, 4 DROP WIRE BARS APPROX. 9000 DROP WIRES AND 4500 HEDDLES, LOOMDATA APPROX. 80% PLATINES INSTALLED STARTES OR STAUBLI HARNESS, ONE LIETTY GANTRY FOR TWO MACHINES LOOM POWER 5 OR 6 KW, JACQUARD POWER 2 KW 5 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G510, YEAR: 1 X 2002, 2 X 2003, 1 X 2004, 1 X 2007, TEMPERATURE 98C , CAPACITY 500 KG.EACH, TONELLO CONTROLS DIRECT STEAM OPERATED, CURRENTLY ALL ARE CONNECTED TO A CENTRAL DOSING SYSTEM (BUT EACH HAS ITS OWN DOSING SYSTEM AND CAN WORK AS INDEPENDENT M/C) FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 1 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G1 50 HS, YEAR 2007, TEMPERATURE 98°C, CAPACITY 50 KG. TONELLO CONTROLS, DIRECT STEAM OPERATED, AIR PRESSURE 7 BAR, HYDRAULICS 3 BAR, STEAM 10 BAR, FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 2 TRIVENETA GARMENT DRYERS, TYPE E550 PV YEAR 2001 MODEL 550 P CAPACITY 500 KG. EACH, DRYING CYCLE TIME IS HALF OF THE TONELLO = EACH MACHINE CAN SERVE 2 TONELLO MACHINES - SEMI AUTOMATIC LOADING AND DISCHARGING, STEAM OPERATED ITEMIZED SALE IS POSSIBLE – AGAINST OFFERS AVAILABLE IMMEDIATELY – STOPPED ON MILL FLOOR Learn More

M-5158 COMPLETE TERRY WEAVING PLANTREFERENCE NUMBER: M-5158 (1212CVPGXX11) L COMPLETE TERRY WEAVING PLANT 1 WEST POINT DIRECT WARPER WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 504 ENDS, 504 SPARE ENDS, PITCH 400 MM, WP ELECTRO SENSE 1 WEST POINT DIRECT WARPER, WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 640 ENDS, 640 SPARE ENDS, PITCH 450 MM, WP ELECTRO SENSE 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 10 DRYING CYLINDERS, TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 8 DRYING CYLINDERS, 7 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 3.0 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 8 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 7 DRYING CYLINDERS, 6 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 SIZE KITCHEN , 5 STAINLESS STEEL MIXING TANKS WITH HEATING 7 MOTOCONO REMAIN WINDERS, 4 POSITIONS EACH 1 WARP BEAM STORAGE, 6 ROWS, 4 LEVELS, 14 M LENGTH 3 SHELVES SINGLE SIDED, 2 SHELVES DOUBLE SIDED WITH HUBTEX WARP BEAM LIFTER, MODEL 20TS 62 SULZER TERRY PROJECTILE LOOMS WITH JACQUARD (8) MODEL P7100 B330 F4 EP J D1, YEAR 4X 1989, 2X 1990, 2X 1991 WORKING WIDTH 3,3 M / 130” (7) STAUBLI E-JACQUARD CX-870, YEAR 1998-2004, 2688 HOOKS, CONTROLLER JC-5 (1) STAUBLI E-JACQUARD CX-860, YEAR 1997, 2688 HOOKS, CONTROLLER JC-4 (M/C 1989) GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7200 B330 F4 J Q D1, YEAR 1X 1991, 1X 1995 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (6) MODEL P7100 B330 F4 J D1, YEAR 1X 1991, 1X 1992, 4X 1994 WORKING WIDTH 3,3 M / 130” (4) STAUBLI E-JACQUARD CX-860, YEAR 1994, 2688 HOOKS, CONTROLLER JC-4 (2) STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 (M/C 1990/91) GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7250 B330 F4 J D1, YEAR 2X 2000, 2X 2001 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2X 2001, 2X 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (5) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1991, 1X 1992, 2X 1994, 1X 1995 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 2003/2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1992 WORKING WIDTH 3,9 M / 153” SCHLEICHER MECHANICAL JACQUARD 3-08, YEAR 1990, 896 HOOKS CAM MOTION, 6 LEVERS INSTALLED, 4 FRAMES GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 3X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1602, YEAR 2006/2008, 3072 HOOKS, CONTROLLER JC-6 GROUND AND PILE WARP BEAM 940 MM DIAMETER (6) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 4X 1993, 1X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520S, YEAR 1993/94, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1994, WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520, YEAR 1995, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7100 B390 F4 EP J D1, YEAR 1995, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2006, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 J D1, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-860, YEAR 1996, 2688 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 J D2, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-960, YEAR 1996, 3072 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (8) MODEL P7200 B390 F4 J Q D1, YEAR 6X 1996, 2X 1997, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 1998, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (8) MODEL P7250 B390 F4 J D1, YEAR 6X 1997, 2X 1998 , WORKING WIDTH 3,9 M / 153” (4) STAUBLI E-JACQUARD LX-1600, YEAR 2000, 3072 HOOKS, CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870, YEAR 2000/01, 2688 HOOKS, CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D2, YEAR 1999 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D3, YEAR 1999, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER ALL MACHINES WITH 4 COLORS, AVERAGE 3 WEFT FEEDERS (ROH CHRONO HS AND SIMILAR), MIN. 3 CENTRAL TUCK IN UNITS PER MACHINE, SIDE TUCK IN UNITS, USTER LOOM DATA E-JACQUARD M/C WITH ELECTRONICALLY CONTROLLED COLOR SELECTION (EXCEPT 8 MECHANICAL M/CS) SPLIT BEAM EXECUTION, 1.5 PILE BEAMS, 1.5 GROUND BEAMS ON-LOOM TAKE-UP, 1.5 CLOTH ROLLS, 4 WEFT FEEDERS, 4 DROP WIRE BARS APPROX. 9000 DROP WIRES AND 4500 HEDDLES, LOOMDATA APPROX. 80% PLATINES INSTALLED STARTES OR STAUBLI HARNESS, ONE LIETTY GANTRY FOR TWO MACHINES LOOM POWER 5 OR 6 KW, JACQUARD POWER 2 KW 5 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G510, YEAR: 1 X 2002, 2 X 2003, 1 X 2004, 1 X 2007, TEMPERATURE 98C , CAPACITY 500 KG.EACH, TONELLO CONTROLS DIRECT STEAM OPERATED, CURRENTLY ALL ARE CONNECTED TO A CENTRAL DOSING SYSTEM (BUT EACH HAS ITS OWN DOSING SYSTEM AND CAN WORK AS INDEPENDENT M/C) FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 1 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G1 50 HS, YEAR 2007, TEMPERATURE 98°C, CAPACITY 50 KG. TONELLO CONTROLS, DIRECT STEAM OPERATED, AIR PRESSURE 7 BAR, HYDRAULICS 3 BAR, STEAM 10 BAR, FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 2 TRIVENETA GARMENT DRYERS, TYPE E550 PV YEAR 2001 MODEL 550 P CAPACITY 500 KG. EACH, DRYING CYCLE TIME IS HALF OF THE TONELLO = EACH MACHINE CAN SERVE 2 TONELLO MACHINES - SEMI AUTOMATIC LOADING AND DISCHARGING, STEAM OPERATED ITEMIZED SALE IS POSSIBLE – AGAINST OFFERS AVAILABLE IMMEDIATELY – STOPPED ON MILL FLOOR Learn More -

J-4672 COMPLETE TETRAPAK A3 SPEED 100V 1000ml BASE FILLING LINE, YEAR 2008J-4672 COMPLETE TETRAPAK A3 SPEED 100V 1000ml BASE FILLING LINE, YEAR 2008 STATUS: DISMANTLED QUANTITY: 1 Learn More

J-4672 COMPLETE TETRAPAK A3 SPEED 100V 1000ml BASE FILLING LINE, YEAR 2008J-4672 COMPLETE TETRAPAK A3 SPEED 100V 1000ml BASE FILLING LINE, YEAR 2008 STATUS: DISMANTLED QUANTITY: 1 Learn More -

YY-2216 COMPLETE USED TETRA PAK A3 FLEX C/1000SQ FILLING LINE, YEAR 2005YY-2216 COMPLETE USED TETRA PAK A3 FLEX C/1000SQ FILLING LINE, YEAR 2005 MAIN INSPECTIONS WERE PERFORMED BY TETRA PAK SERVICE, SERVICE REPORTS ARE AVAILABLE. QUANTITY: 1 Learn More

YY-2216 COMPLETE USED TETRA PAK A3 FLEX C/1000SQ FILLING LINE, YEAR 2005YY-2216 COMPLETE USED TETRA PAK A3 FLEX C/1000SQ FILLING LINE, YEAR 2005 MAIN INSPECTIONS WERE PERFORMED BY TETRA PAK SERVICE, SERVICE REPORTS ARE AVAILABLE. QUANTITY: 1 Learn More -

A-1292 COMPLETE TERRY PLANTREFERENCE NUMBER: A-1292 (010113GHBWQ12UL) A COMPLETE TERRY PLANT QUANTITY AVAILABLE: 1 Learn More

A-1292 COMPLETE TERRY PLANTREFERENCE NUMBER: A-1292 (010113GHBWQ12UL) A COMPLETE TERRY PLANT QUANTITY AVAILABLE: 1 Learn More -

TT-6385 REGGIANI COMPLETE TEXTILE PRINTING LINETT-6385 REGGIANI COMPLETE TEXTILE PRINTING LINE ADVANCED PRINTING LINE: 1. REGGIANI FLEXY 180 PRINTER: FEATURES AN 8-COLOR CAPABILITY (CMYK, BLUE, ORANGE, RED, GRAY) FOR VIBRANT, DETAILED PRINTS. 2. SETEMA WASH-PADDER-DRY-WRAP LINE: ENSURES HIGH-QUALITY FABRIC TREATMENT AND PREPARATION. 3. RIP INEDIT NEOSTAMPA 9HP WITH RUBY UPGRADE: ADVANCED DIGITAL PRINTING CAPABILITIES FOR PRECISION AND VERSATILITY. 4. THE REGGIANI FLEXY 180 PRINTER WAS INSTALLED AT THE END OF 2020, HAS PRINTED 117,000 METERS, IS IN PERFECT CONDITION, AND IS ALWAYS MAINTAINED BY REGGIANI. QUANTITY: 1 Learn More

TT-6385 REGGIANI COMPLETE TEXTILE PRINTING LINETT-6385 REGGIANI COMPLETE TEXTILE PRINTING LINE ADVANCED PRINTING LINE: 1. REGGIANI FLEXY 180 PRINTER: FEATURES AN 8-COLOR CAPABILITY (CMYK, BLUE, ORANGE, RED, GRAY) FOR VIBRANT, DETAILED PRINTS. 2. SETEMA WASH-PADDER-DRY-WRAP LINE: ENSURES HIGH-QUALITY FABRIC TREATMENT AND PREPARATION. 3. RIP INEDIT NEOSTAMPA 9HP WITH RUBY UPGRADE: ADVANCED DIGITAL PRINTING CAPABILITIES FOR PRECISION AND VERSATILITY. 4. THE REGGIANI FLEXY 180 PRINTER WAS INSTALLED AT THE END OF 2020, HAS PRINTED 117,000 METERS, IS IN PERFECT CONDITION, AND IS ALWAYS MAINTAINED BY REGGIANI. QUANTITY: 1 Learn More -

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

M-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERSM-0033 ROLANDO COMPLETE TEARING LINE YEAR 1994 WIDTH 2000mm - 2 CYLINDERS

WORKING WIDTH 2000mm

Learn More

YEAR 1994

CONSISTING OF:

LOADING INSTALLATION

LIQUID RESP. OIL SPRAYING UNIT

AUTOMATIC FEEDING RA1/6mm 2000

TEARING MACHINE RM9 WITH 2 CYLINDERS, 2000mm -

J-0136 COMPLETE LAROCHE RAG TEARING LINE

J-0136 COMPLETE LAROCHE RAG TEARING LINEREFERENCE NUMBER: J-0136

COMPLETE LAROCHE RAG TEARING LINE

A) MACHINE LINE FOR RAGS RECOVERY

BRAND: LAROCHE

MODEL: CADETTE 1000

YEAR: 2001

THE LINE CONTAINS:

2 POWER SILOS

5 SHREDDERS UNITS

1 ENCIMAGEN DIAMETER 350mm

1 CONDENSER FLOW

1 FAN TYPE VT360 FLOW

1 METAL DETECTOR AND DUCTS

FULL ELECTRICAL POWER: 130.4KW – 50HZ

B) ROTARY CUTTER TO CUT WASTE FIBERS

BRAND: LAROCHE

MODEL: 500

TYPE: 231

YEAR: 2001

WORKING WIDTH: 500mm

CUTTING LENGTH: 25mm TO 165mm ADJUSTABLE BY A MOTOR-VARIATOR PIV

400mm DIAMETER WITH TWO BLADES

ROTATION SPEED OF CUTTING HEAD: 200 RPM

FEEDING RATE: ADJUSTABLE FROM 10 TO 68M/mm IN ACCORDANCE WITH THE CUTTING LENGTH

INSTALLED ELECTRIC POWER: MAIN MOTOR: 15HP

CHAIN VARIABLE PIV: 2 HP

OUTPUT CONVEYOR MOTOR: .75 HP

C) PRESS MODEL PRESS PV 25,

BRAND: LAROCHE

YEAR: 2001

Learn MoreQUANTITY: 1