Search results for: 'pad line'

-

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More -

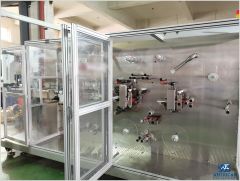

M-5168 COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5168 (121218GTB11U) L COTTON PADS MAKING MACHINE MODEL: M-A COTTON PADS MAKING MACHINE PADS TYPE: ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS: OUR MACHINE COULD MAKE MULTILAYER PADS (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKAGING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More

M-5168 COTTON PADS MAKING MACHINEREFERENCE NUMBER: M-5168 (121218GTB11U) L COTTON PADS MAKING MACHINE MODEL: M-A COTTON PADS MAKING MACHINE PADS TYPE: ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS: OUR MACHINE COULD MAKE MULTILAYER PADS (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKAGING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More -

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More -

TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986 THE LINE COMPOSED BY: 1. TRUTZSCHLER MODEL MWS 1000, FIBRE OPENER WITH WEIGHING DEVICE (2 PIECES) 2. TRUTZSCHLER MODEL FBM 1000, FIBRE BLENDER WITH CONVEYOR BELT 3. TEMAFA MODEL FFO, FINE OPENER 4. TRUTZSCHLER MODEL FBK 2500, EXACTAFEED CHUTE FEED 5. SPINNBAU CARD DOUBLE DOFFER MODEL 2000 6. RAMISCH KLEINEWEFERS CALENDER TYPE: 2 ROLL CALENDER 7. AURA THERMAL OIL BOILER (ELECTRIC) MODEL E 10 – 220 8. EDELMANN SLITTING - WINDING MACHINE, MODEL 620 – 08 LINES ARE WORKING POLYPROPYLENE POLYESTER POLYAMID, VISCOSE COTTON COVERSTOK, HIGYENE NONWOVENS, DRAPES GOWNS, FILTERS, DRAY WIPES. THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON (UP TO 30% COTTON), COVERSTOK, HIGYENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY. PES OR PET 30GSM AT 80 M/MIN 230 °C WIDTH 2000mm = PRODUCING ABOUT 10,000 SQUARE METERS PER HOUR, UTILIZING 320 KG OF POLYESTER FIBERS PER HOUR. CAPACITY OF LINE 120000mm/MIN KG PER HOUR OUTPUT IN KG/HR DEPEND ON GSM: G/SQUARE METER SPEED, ROLERS TEMPERATURES: EG: 44GSM PRODUCTION 250KG/H TO INCREASE PRODUCTION MORE AND MORE. IT DEPENDS ON THE TYPE OF PROCESSING MIN AND MAXIMUM GSM 16 TO 50 GSM MAXIMUM OUTPUT WIDTH OF THE FINISHED PRODUCT 2200mm HOW IS THE HEATING OF CALENDERING DONE: ELECTRIC POW Learn More

TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986 THE LINE COMPOSED BY: 1. TRUTZSCHLER MODEL MWS 1000, FIBRE OPENER WITH WEIGHING DEVICE (2 PIECES) 2. TRUTZSCHLER MODEL FBM 1000, FIBRE BLENDER WITH CONVEYOR BELT 3. TEMAFA MODEL FFO, FINE OPENER 4. TRUTZSCHLER MODEL FBK 2500, EXACTAFEED CHUTE FEED 5. SPINNBAU CARD DOUBLE DOFFER MODEL 2000 6. RAMISCH KLEINEWEFERS CALENDER TYPE: 2 ROLL CALENDER 7. AURA THERMAL OIL BOILER (ELECTRIC) MODEL E 10 – 220 8. EDELMANN SLITTING - WINDING MACHINE, MODEL 620 – 08 LINES ARE WORKING POLYPROPYLENE POLYESTER POLYAMID, VISCOSE COTTON COVERSTOK, HIGYENE NONWOVENS, DRAPES GOWNS, FILTERS, DRAY WIPES. THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON (UP TO 30% COTTON), COVERSTOK, HIGYENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY. PES OR PET 30GSM AT 80 M/MIN 230 °C WIDTH 2000mm = PRODUCING ABOUT 10,000 SQUARE METERS PER HOUR, UTILIZING 320 KG OF POLYESTER FIBERS PER HOUR. CAPACITY OF LINE 120000mm/MIN KG PER HOUR OUTPUT IN KG/HR DEPEND ON GSM: G/SQUARE METER SPEED, ROLERS TEMPERATURES: EG: 44GSM PRODUCTION 250KG/H TO INCREASE PRODUCTION MORE AND MORE. IT DEPENDS ON THE TYPE OF PROCESSING MIN AND MAXIMUM GSM 16 TO 50 GSM MAXIMUM OUTPUT WIDTH OF THE FINISHED PRODUCT 2200mm HOW IS THE HEATING OF CALENDERING DONE: ELECTRIC POW Learn More -

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More -

TT-4868 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT, WIDTH 1800mm, YEAR INSTALLED 2004TT-4868 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT, WIDTH 1800mm, YEAR INSTALLED 2004 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT FOR MODERN DENIMS INCLUDING MERCERISING, BOTTOMING, TOPPING, SULPHUR DYEING AND CLASSIC INDIGO BLUE, ARRANGED FOR MAXIMUM FLEXIBILITY. ROLLER WIDTH 1800mm, INSTALLED IN 2004 (THE DYE VATS AND PADDERS WERE MANUFACTURED 1994 AND RECONDITIONED BY MASTER WHEN THIS LINE WAS EXTENDED AND INSTALLED IN 2004) QUANTITY: 1 Learn More

TT-4868 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT, WIDTH 1800mm, YEAR INSTALLED 2004TT-4868 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT, WIDTH 1800mm, YEAR INSTALLED 2004 MASTER INDIGO DYEING LINE FOR CONTINUOUS DYEING AND TREATMENT FOR MODERN DENIMS INCLUDING MERCERISING, BOTTOMING, TOPPING, SULPHUR DYEING AND CLASSIC INDIGO BLUE, ARRANGED FOR MAXIMUM FLEXIBILITY. ROLLER WIDTH 1800mm, INSTALLED IN 2004 (THE DYE VATS AND PADDERS WERE MANUFACTURED 1994 AND RECONDITIONED BY MASTER WHEN THIS LINE WAS EXTENDED AND INSTALLED IN 2004) QUANTITY: 1 Learn More -

KNITTING, DYEING, FINISHING MILL #1KNITTING, DYEING, FINISHING MILL #1 Learn More

KNITTING, DYEING, FINISHING MILL #1KNITTING, DYEING, FINISHING MILL #1 Learn More -

TT-4867 BENNINGER MERCERIZING LINE, WORKING WIDTH 2000mm, YEAR 2018TT-4867 BENNINGER MERCERIZING LINE, WORKING WIDTH 2000mm, YEAR 2018 BRAND BENNINGER MODEL: DIMENSA- ML2-2000 WORKING WIDTH: 2000mm QUANTITY: 1 Learn More

TT-4867 BENNINGER MERCERIZING LINE, WORKING WIDTH 2000mm, YEAR 2018TT-4867 BENNINGER MERCERIZING LINE, WORKING WIDTH 2000mm, YEAR 2018 BRAND BENNINGER MODEL: DIMENSA- ML2-2000 WORKING WIDTH: 2000mm QUANTITY: 1 Learn More -

J-2640 DYEING AND FINISHING PLANT FOR SALE

J-2640 DYEING AND FINISHING PLANT FOR SALEREFERENCE NUMBER: J-2640

DYEING AND FINISHING PLANT FOR SALEITEM 001

THIES SAMPLE DYEING MACHINE

MODEL: MINISOFT SAMPLE

CAPACITY: 50 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 002

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

3 PORT SPLIT/SPLIT

CAPACITY: 900 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 003

THIES DYEING MACHINE

MODEL: ECOSOFT PLUS

2 PORT SPLIT/SPLIT

CAPACITY: 600 KGS

YEAR: 1999

MICROPROCESSOR CONTROL

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 004

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

1 PORT SPLIT/SPLIT

CAPACITY: 300 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: A460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 005

GASTON COUNTY DYEING MACHINE

MODEL: AQUAFLOW

2 PORT

CAPACITY; 250 KGS

YEAR: 1987

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING AND UNLOADING REEL

QUANTITY: 1ITEM 006

THIES DYEING MACHINE

MODEL: SOFT TRD

2 TUBE

CAPACITY: 700 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 007 (also our J-2647)

LAFER OPEN WIDTH COMPACTOR MACHINE

MODEL: KSA 500 2400/2200

YEAR: 1998

LAFER TEXEN CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY, VERTICAL PIN CHAIN, WITH PLATE GUIDES, RAIL OPENING, PINNING BRUSHES, PINS ONLY, WITH SUPPORT SECTION FOR THE FABRIC IN THE CENTER, AT 10’ THERE IS A STEAMING SECTION, TOTAL LENGTH OF THE TENTER IS 30’, WITH AUTOMATIC LUBRICATION FOR THE CHAIN

• KSA 500 COMPACTOR BENCH WITH TEXEN CONTROLS

• TENSIONLESS FABRIC CONVEYOR

• PLAITOR AND FABRIC SCRAY WITH OPTICAL LOAD SENSOR

• INLINE INSPECTION BATCHER MACHINE, WITHH A BACK LIGHTED BOARD, MANUAL CUT

• SCALE TO WEIGHT THE FABRIC

QUANTITY: 1ITEM 008 (also our J-2648)

SANTEX TUBULAR 4-ROLL EXTRACTION PAD

MODEL: SANTASTRETCH PLUS 140

YEAR: 1998

COMPOSED OF TURNTABLE, DETWISTER, TUBULAR 4-ROLL PAD WITH WET SPREADERS, PLAITOR

WITH ADDITION TANKS FOR SOFTENER

REEL FABRIC PLAITOR EXIT

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 009

SANTEX CONVEYOR DRYER FOR OPEN WIDTH AND TUBULAR FABRIC

MODEL: SANTASHRINK 4/5240

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER TO

• (2) SANTEX 2-ROLL PADS, RUBBER OVER RUBBER, 102” WIDE x 12” DIAMETER, STAINLESS STEEL PAN, 10-TON PAD, SWING-AWAY PAN, TENSION BAR WITH 2 STAINLESS STEEL MIXING TANKS, 75 GALLONS EACH

• DRIVEN SCROLL ROLLS WITH EDGE GUIDE CONTROL, WIDTH 95”

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY 45°, YEAR 1998, VERTICAL PIN CHAIN, 30’ LONG WITH TANDEMATIC PLATE GUIDES, RAIL GUIDES, PINNING BRUSHES, GUIDE SUPPORT FOR THE FABRIC, FABRIC CONVEYOR TO ENTER BOTH TUBULAR OR OPEN WIDTH FABRIC TO

• CONVEYOR DRYER 100” WIDE, 5 ZONES, 3-PASS WITH MAXON BURNERS, 5 CIRCULATING FANS TO CONVEYOR BELT TO PLAITOR

• ALL MOTORS AND SANTEX CONTROLS AND MONITORS

QUANTITY: 1ITEM 010

SANTEX AG TUBULAR COMPACTOR MACHINE

MODEL: SANTASPREAD 140

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSIONS BAR ENTRY

• OPERATOR’S PLATFORM

• TENSION DEVICE

• DRIVEN SPREADER BARS

• STEAMING DEVICE

• TUBULAR COMPACTING BENCH

• FELT BLANKET ONTO THE CONVEYOR BELT

• PRECISION PLAITOR

• TABELTOP ELECTRONIC SCALE

QUANTITY: 1ITEM 011

COMET NAPPER

MODEL: PEGSO-X4

YEAR: 1998

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

24 ROLLS WITH TURNING BARS FOR TUBULAR 90” WIDE

XYCOM CONTROLS

12-BAG COLLECTION SYSTEM AND PLAITOR

YEAR: 1996

QUANTITY: 1ITEM 012

STENTEX TENTER FRAME

MODEL: STENTOTHERM 3300

YEAR: 1999

STENTEX CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION ENTRY TO TEXT-STAR TYPE GUIDER TO 2 ROLL PAD

• ADDITION TANK TOP SCRAY PAD TO TEXT-STAR TYPE GUIDER

• TWO ROLL PAD R/R 10 TON

• OPERATOR’S PLATFORM

• WORKING WIDTH 1800mm

• HORIZONTAL PIN CHAIN, KNIT ENTRY

• TANDEMATIC SPLITLEVEL DECURLERS

• OVERFEED

• PINNING BRUSHES

• STEAM BOX

• RAIL GUIDERS, 20 FEET ENTRY, 8 ZONES

• 80 FEET HOUSING

• SCREEN MONITORS

• GAS FIRED, MAXON OVEPAK 408 BURNERS

• HONEYWELL CONTROLS

• 3 FEET COOLING ZONE

• 2 COOLING CANS, SELVEDGE TRIMMERS

• PLIATOR, SCRAY

• ZONE IN LINE INSPECTION BATCHER

QUANTITY: 1ITEM 013

ZIMMER ROTARY SCREEN PRINTING MACHINE

MODEL: R92-S153

YEAR: 1993

COMPOSED OF:

• TENSION BAR SKY ENTRY

• SCRAY

• CORINO BRUSH

• CORINO PRINT GUIDER

• ZIMMER PRINTER, 8 COLOR, 86” BLANEKT

• PRINT CONVEYOR DRYER, 30’ LONG, 3-ZONE, GAS FIRED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 014

Learn More

SAFETY SWITCH BULLET NOSE SLITTER

MODEL: CUTTING

WITH REEL FABRIC PLIATOR

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1 -

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More