Search results for: 'AUTOMATIC P'

- Related search terms

- automatic V

- automatic V''

- AUTOMATIC'

- Automatic 4

- Automatic 4 s

-

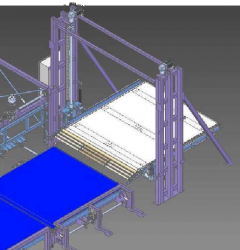

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More -

TT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVERTT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVER UTM TESTING MACHINE KEY SPECIFICATIONS: MAX. CAPACITY: 30KN, 50KN, 100KN, 150KN,200KN,300KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.01mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. STANDARD ACCESSORIES: GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC OPTION ACCESSORIES: HP DESKTOP COMPUTER QUANTITY: 1 Learn More

TT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVERTT-1042 UNIVERSAL TESTING MACHINE WITH PROTECTIVE COVER UTM TESTING MACHINE KEY SPECIFICATIONS: MAX. CAPACITY: 30KN, 50KN, 100KN, 150KN,200KN,300KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.01mm TEST SPEED: 0.001-500mm/MIN, CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W POWER SUPPLY: 220V 50/60Hz 10A STANDARDS: BS EN ISO 13934-1, 13934-2, 13937-2, 13937-3, 13937-4, 13935-1, 13935-2, BS 3320, 4303. ASTM D 434, 558, 2256, 2261, 2731, 3936, 4533, 4964, 5034, 5035, 5735. ISO 2062, 5082, 9073.4, 10321, 13919. STANDARD ACCESSORIES: GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC OPTION ACCESSORIES: HP DESKTOP COMPUTER QUANTITY: 1 Learn More -

TT-1036 ELECTROMECHANICAL UNIVERSAL TESTING MACHINETT-1036 ELECTROMECHANICAL UNIVERSAL TESTING MACHINE KEY SPECIFICATION: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm STROKE RANGE: 1200mm TEST SPEED: 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 76 X 60 X 175 (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A QUANTITY: 1 Learn More

TT-1036 ELECTROMECHANICAL UNIVERSAL TESTING MACHINETT-1036 ELECTROMECHANICAL UNIVERSAL TESTING MACHINE KEY SPECIFICATION: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm STROKE RANGE: 1200mm TEST SPEED: 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 76 X 60 X 175 (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A QUANTITY: 1 Learn More -

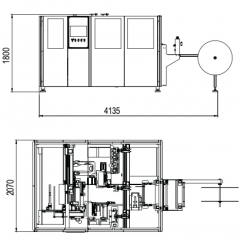

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

YY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mmYY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mm TECHNICAL PARAMETERS: SEWING WIDTH: 120 TO 450mm (4.7 INCHES TO 17.7 INCHES) SEWING THICKNESS: ≤25mm (ONE INCH) PRODUCTION CAPACITY: 4~6M/MIN (7 TO 8 YARDS PER MINUTE) TOTAL POWER: 8KW POWER SUPPLY: 220V QUANTITY: 1 Learn More

YY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mmYY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mm TECHNICAL PARAMETERS: SEWING WIDTH: 120 TO 450mm (4.7 INCHES TO 17.7 INCHES) SEWING THICKNESS: ≤25mm (ONE INCH) PRODUCTION CAPACITY: 4~6M/MIN (7 TO 8 YARDS PER MINUTE) TOTAL POWER: 8KW POWER SUPPLY: 220V QUANTITY: 1 Learn More -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

J-3638 POCKET SPRING ROLL PACKING MACHINEJ-3638 POCKET SPRING ROLL PACKING MACHINE CAPACITY: 14 ROLLS PER HOUR MAXIMUM ROLL DIAMETER: 800mm AUTOMATIC FEEDING SYSTEM CENTERING UNIT ON AUTOMATIC FEEDING SYSTEM COUNTER FOR NUMBER OF PRODUCTS TO BE WRAPPED QUANTITY: 1 Learn More

J-3638 POCKET SPRING ROLL PACKING MACHINEJ-3638 POCKET SPRING ROLL PACKING MACHINE CAPACITY: 14 ROLLS PER HOUR MAXIMUM ROLL DIAMETER: 800mm AUTOMATIC FEEDING SYSTEM CENTERING UNIT ON AUTOMATIC FEEDING SYSTEM COUNTER FOR NUMBER OF PRODUCTS TO BE WRAPPED QUANTITY: 1 Learn More -

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More -

TT-5031 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL, YEAR 1983 TO 2006TT-5031 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL, YEAR 1983 TO 2006 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL COMPACT SYSTEM FROM NM.1/40 UP TO NM.1/80 PRODUCTION CAPACITY 3,500 KG PER 24 HOURS Learn More

TT-5031 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL, YEAR 1983 TO 2006TT-5031 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL, YEAR 1983 TO 2006 WORSTED SPINNING AND RE-COMBING INSTALLATION FOR FINE COUNT OF WOOL COMPACT SYSTEM FROM NM.1/40 UP TO NM.1/80 PRODUCTION CAPACITY 3,500 KG PER 24 HOURS Learn More -

TT-7737 KOMORI LITHRONE LS 40-5 HC, YEAR 2003TT-7737 KOMORI LITHRONE LS 40-5 HC, YEAR 2003 1. BRAND: KOMORI 2. MODEL: LITHRONE LS 40-5 HC 3. YEAR OF CONSTRUCTION: 2003 4. NUMBER OF IMPRESSIONS: 130 MIO. QUANTITY: 1 Learn More

TT-7737 KOMORI LITHRONE LS 40-5 HC, YEAR 2003TT-7737 KOMORI LITHRONE LS 40-5 HC, YEAR 2003 1. BRAND: KOMORI 2. MODEL: LITHRONE LS 40-5 HC 3. YEAR OF CONSTRUCTION: 2003 4. NUMBER OF IMPRESSIONS: 130 MIO. QUANTITY: 1 Learn More