Search results for: 'set+800'

-

L-3886 CHICKEN FEED PRODUCTION LINE

L-3886 CHICKEN FEED PRODUCTION LINEREFERENCE NUMBER: L-3886

Learn More

1) RECEIVING PROCESS

HEIGHT: 12 METERS

POWER: 1.5 KW

2) GRINDING AND MIXING PROCESS

LENGTH: 1.5 METERS

POWER: 1.5 KW

3) PELLETIZING AND BAGGING PROCESS

CAPACITY: 2 TO 3 TONS PER HOUR, PER UNIT

POWER: 37 KW

4) AUXILIARY PROCESS

POWE: 1.5 KW

5) ELECTRIC CONTROL SYSTEM

POWER: 3 PHASE, 380 VOLTS, 50 Hz -

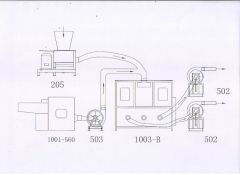

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINE

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINEREFERENCE NUMBER: L-2926

Learn More

1 X FIBER CARDING MACHINE

MODEL: 1001-560

1 X FIBER FEEDING MACHINE

MODEL: 503

1 X MIXING MACHINE

MODEL: 1003-B

2 X FILLING MACHINES

MODEL: 502

QUANTITY: 1 SET

FOAM SHREDDER

MODEL: 205

QUANTITY: 1 -

R-6969 GAMATEX SIZING MACHINE, YEAR 1988

R-6969 GAMATEX SIZING MACHINE, YEAR 1988REFERENCE NUMBER: R-6969

Learn More

MAKE: GAMATEX

TYPE: BM 85

QUANTITY: 1 -

R-7054 GR30 COFFEE ROASTING MACHINE

R-7054 GR30 COFFEE ROASTING MACHINER-7054 GR30 COFFEE ROASTING MACHINE

MODEL: GR30

30 KG ROASTING CAPACITY

16-22 MIN. ROASTING TIME

4 MOTORS

220V SINGLE PHASE POWER SUPPLY

DELIVERED WITH SHELL SILOS ON THE BODY

THE TEMPERATURE IS DECLARED BY AUDIBLE WARNING WHEN IT REACHES THE SET TEMPERATURE

CE CERTIFIED GAS CUTTER IS USED

DIMENSIONS: 1550X2600X2250mm

WEIGHT: 800 KG

3.67 KW = 4.92 HP

FUEL TYPE: NATURAL GAS / LPGQUANTITY: 1

Learn More -

C-2576 CATERPILLAR GENERATORS, YEAR 1988 TO 2014

C-2576 CATERPILLAR GENERATORS, YEAR 1988 TO 2014C-2576 CATERPILLAR GENERATORS, YEAR 1988 TO 2014

ITEM 001

CATERPILLAR G3616 - NEW

QUANTITY: 1ITEM 002

CATERPILLAR G 3616 WITH ARIEL JGC4 COMPRESSOR

QUANTITY: 2ITEM 003

CATERPILLAR CAT 3612

QUANTITY: 1ITEM 004

CATERPILLAR MAK 8M25

QUANTITY: 4ITEM 005

CATERPILLAR 3516C-HD

QUANTITY: 1ITEM 006

CATERPILLAR G3520

QUANTITY: 4ITEM 007

CATERPILLAR G3520C

QUANTITY: 1ITEM 008

CATERPILLAR G3520

QUANTITY: 2ITEM 009

CATERPILLAR G3520C

QUANTITY: 6ITEM 010

CATERPILLAR 3516, GS3411

QUANTITY: 2ITEM 011

CATERPILLAR 3516-G

QUANTITY: 3ITEM 012

CATERPILLAR G3512E

QUANTITY: 2ITEM 013

CATERPILLAR G3516

QUANTITY: 2ITEM 014

CATERPILLAR 3520C/3516

QUANTITY: 4ITEM 015

CATERPILLAR 3516B

QUANTITY: 4ITEM 016

CATERPILLAR 3516

QUANTITY: 1ITEM 017

CATERPILLAR G3508B

QUANTITY: 1ITEM 018

CATERPILLAR G 3516 - NEW

QUANTITY: 8ITEM 019

CATERPILLAR CAT 3512

QUANTITY: 3ITEM 020

CATERPILLAR 3412 C 900F

QUANTITY: 1ITEM 021

CATERPILLAR C18

QUANTITY: 1ITEM 022

CATERPILLAR CAT 3412

QUANTITY: 1ITEM 023

CATERPILLAR CAT 3412

QUANTITY: 1ITEM 024

Learn More

CATERPILLAR 3406

QUANTITY: 1 -

F-1427 FEATHER FILLING MACHINE MODEL SR-1

F-1427 FEATHER FILLING MACHINE MODEL SR-1REFERENCE NUMBER: F-1427

FEATHER FILLING MACHINE MODEL SR-1

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• PRODUCT NAME: WEIGHING DOWN & FEATHER FILLING MACHINE

• TYPE: SR-1

• DIMENSION: 7500 x 2500 x 3500MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 11KW

• FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.5G,±1.0G,±1.5G,DEPENDING ON THE FILLING WEIGHT

• AIR SUPPLY: 0.5 TO 0.8MPA

• WEIGHT: APPROX. 800KG

• THE AUTOMATIC DOWN AND FEATHER FILLING MACHINE IS MAINLY USED TO PRODUCE JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS AND COMFORTERS THAT MADE WITH DOWN AND FEATHER MATERIAL BY COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM( FOR ONE FILLING PIPE) FOR CONSTANT SUPPLY

• THE SYSTEM IS THE VACUUM FILLING FUNCTION AND DOES NOT HURT THE MATERIAL; IT KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT AND CHOOSE TOTAL ERROR OR SINGLE ERROR FROM THE CONTROL PANEL. THIS CONTROLS FOR THE PRODUCTION QUALITY AND MATERIAL WASTE

• ONE FILLING PIPE CAN BE HANDLED BY 1 OPERATOR BY VERY SIMPLE OPERATION WHICH SAVES YOU A BIG AMOUNT OF LABOR COSTS..

• THE KEY ELECTRICAL COMPONENTS ARE IMPORTED, SO THAT THE QUALITY IS RELIABLE AND STABLE.

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 DIFFERENT RECIPES AND EACH RECIPE CAN BE 80 SETS DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS

• AVERAGE FILLING TIME CAN BE 2 TO 5 SECONDS (DEPENDING ON THE WEIGHT AND FABRIC) AND THE FILLING TIME CAN BE ADJUSTED

• DIFFERENT CUSTOMER REQUIREMENTS CAN BE CONSIDERED BY OUR PROFESSIONAL ENGINEERS TO WORK ON OUR MACHINES TO MATCH THE CUSTOMER’S NEED.

• MATERIAL HOPPER: DIA. 1700 x 2500MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 3 PCS(6SETS)

• FILLING TABLE :1200 x 550 x 1500 2 PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 2 SETS

• AIR OUTPUT BOX: 1200 x 1800 x 1700MM 1 PCS

• MATERIAL FEEDING BOX: 1200x1200x2500MM 1 PCS

• BLOWER: 6PCS

• PIPE SYSTEM: 1SET

Learn More -

K-3941 LABORATORY COTTON FANCY YARN TWISTER

K-3941 LABORATORY COTTON FANCY YARN TWISTERREFERENCE NUMBER: K-3941

LABORATORY COTTON FANCY YARN TWISTER

TWO SETS OF THICK YARN FEEDING, WITH CORN YARN ROLLER, TO SPIN COTTON LOOP YARN, SLUB/KNOP YARN, 2 COLOR FANCY YARN

CONTROL:TOUCH SCREEN+ PLC

4 SPINDLES

TWISTING DEGREE:ABOUT 200-2000 TIMES/METER

DRAFTING RANGE:ABOUT 2-50

FIBER LENGTH:22mm TO 42mm

OUTPUT:ABOUT 0.25KG-0.5KG

SPINDLE SPEED:12000 RPM

ROLLER SIZE:Φ25/25/25mm

RING SIZE:Φ38-45 mm

TOTAL POWER:750W

VOLTAGE:220/3×380V AC 50/60Hz

MACHINE DIMENSIONS 1000mm×800mm×1600mm

QUANTITY: 1

Learn More -

V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAMREFERENCE NUMBER: V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAM MODEL SRM-P-1200 1067mm WIDE (42 INCHES) 2032mm LONG (80 INCHES) 560mm TALL (22 INCHES) THE MATERIAL IS 225 KGS PER CUBIC METER DENSITY (14 LBS/CUBIC FOOT) QUANTITY AVAILABLE: 1 Learn More

V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAMREFERENCE NUMBER: V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAM MODEL SRM-P-1200 1067mm WIDE (42 INCHES) 2032mm LONG (80 INCHES) 560mm TALL (22 INCHES) THE MATERIAL IS 225 KGS PER CUBIC METER DENSITY (14 LBS/CUBIC FOOT) QUANTITY AVAILABLE: 1 Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More