Search results for: 'Warp c'

- Related search terms

- warpin

- warping ma

- warping machin

- warp e

- Warp ch

-

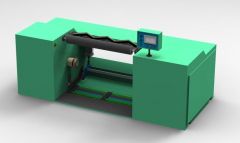

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

J-4692 VTA CREEL FOR WARPING MACHINE, CAPACITY 660 BOBBINS, YEAR 1990J-4692 VTA CREEL FOR WARPING MACHINE, CAPACITY 660 BOBBINS, YEAR 1990 QUANTITY: 1 Learn More

J-4692 VTA CREEL FOR WARPING MACHINE, CAPACITY 660 BOBBINS, YEAR 1990J-4692 VTA CREEL FOR WARPING MACHINE, CAPACITY 660 BOBBINS, YEAR 1990 QUANTITY: 1 Learn More -

J-4190 KARL MAYER DSE 21/30 NC LYCRA WARPER, 700 CREEL ENDS, YEAR 1992J-4190 KARL MAYER DSE 21/30 NC LYCRA WARPER, 700 CREEL ENDS, YEAR 1992 QUANTITY: 1 Learn More

J-4190 KARL MAYER DSE 21/30 NC LYCRA WARPER, 700 CREEL ENDS, YEAR 1992J-4190 KARL MAYER DSE 21/30 NC LYCRA WARPER, 700 CREEL ENDS, YEAR 1992 QUANTITY: 1 Learn More -

TT-6967 COMEZ WARPING MACHINE, YEAR 1999TT-6967 COMEZ WARPING MACHINE, YEAR 1999 QUANTITY: 1 Learn More

TT-6967 COMEZ WARPING MACHINE, YEAR 1999TT-6967 COMEZ WARPING MACHINE, YEAR 1999 QUANTITY: 1 Learn More -

KARL MAYER DIRECT WARPING MACHINE AND BENNINGER V-CREEL, WORKING WIDTH 1600mm, YEAR 2007REFERENCE NUMBER: T-6976 KARL MAYER DIRECT WARPING MACHINE AND BENNINGER V-CREEL, WORKING WIDTH 1600mm, YEAR 2007 KARL MAYER DIRECT WARPING MACHINE TYPE ZM-SP1800 DNC YEAR OF CONSTRUCTION 2007 WORKING WIDTH 1600mm Ø BEAMS 1000mm WITH 17 WARP BEAMS BENNINGER V-CREEL YEAR OF CONSTRUCTION +/- 1998 998 POSITIONS ON THE CREEL GAUGE 260mm REMARK: THE ORIGINAL MACHINE WAS WORKING WIDTH 1800mm BUT HAS BEEN TRANSFORMED BY K. MAYER TO WORKING WIDTH 1600mm QUANTITY: 1 Learn More

KARL MAYER DIRECT WARPING MACHINE AND BENNINGER V-CREEL, WORKING WIDTH 1600mm, YEAR 2007REFERENCE NUMBER: T-6976 KARL MAYER DIRECT WARPING MACHINE AND BENNINGER V-CREEL, WORKING WIDTH 1600mm, YEAR 2007 KARL MAYER DIRECT WARPING MACHINE TYPE ZM-SP1800 DNC YEAR OF CONSTRUCTION 2007 WORKING WIDTH 1600mm Ø BEAMS 1000mm WITH 17 WARP BEAMS BENNINGER V-CREEL YEAR OF CONSTRUCTION +/- 1998 998 POSITIONS ON THE CREEL GAUGE 260mm REMARK: THE ORIGINAL MACHINE WAS WORKING WIDTH 1800mm BUT HAS BEEN TRANSFORMED BY K. MAYER TO WORKING WIDTH 1600mm QUANTITY: 1 Learn More -

M-5158 COMPLETE TERRY WEAVING PLANTREFERENCE NUMBER: M-5158 (1212CVPGXX11) L COMPLETE TERRY WEAVING PLANT 1 WEST POINT DIRECT WARPER WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 504 ENDS, 504 SPARE ENDS, PITCH 400 MM, WP ELECTRO SENSE 1 WEST POINT DIRECT WARPER, WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 640 ENDS, 640 SPARE ENDS, PITCH 450 MM, WP ELECTRO SENSE 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 10 DRYING CYLINDERS, TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 8 DRYING CYLINDERS, 7 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 3.0 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 8 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 7 DRYING CYLINDERS, 6 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 SIZE KITCHEN , 5 STAINLESS STEEL MIXING TANKS WITH HEATING 7 MOTOCONO REMAIN WINDERS, 4 POSITIONS EACH 1 WARP BEAM STORAGE, 6 ROWS, 4 LEVELS, 14 M LENGTH 3 SHELVES SINGLE SIDED, 2 SHELVES DOUBLE SIDED WITH HUBTEX WARP BEAM LIFTER, MODEL 20TS 62 SULZER TERRY PROJECTILE LOOMS WITH JACQUARD (8) MODEL P7100 B330 F4 EP J D1, YEAR 4X 1989, 2X 1990, 2X 1991 WORKING WIDTH 3,3 M / 130” (7) STAUBLI E-JACQUARD CX-870, YEAR 1998-2004, 2688 HOOKS, CONTROLLER JC-5 (1) STAUBLI E-JACQUARD CX-860, YEAR 1997, 2688 HOOKS, CONTROLLER JC-4 (M/C 1989) GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7200 B330 F4 J Q D1, YEAR 1X 1991, 1X 1995 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (6) MODEL P7100 B330 F4 J D1, YEAR 1X 1991, 1X 1992, 4X 1994 WORKING WIDTH 3,3 M / 130” (4) STAUBLI E-JACQUARD CX-860, YEAR 1994, 2688 HOOKS, CONTROLLER JC-4 (2) STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 (M/C 1990/91) GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7250 B330 F4 J D1, YEAR 2X 2000, 2X 2001 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2X 2001, 2X 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (5) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1991, 1X 1992, 2X 1994, 1X 1995 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 2003/2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1992 WORKING WIDTH 3,9 M / 153” SCHLEICHER MECHANICAL JACQUARD 3-08, YEAR 1990, 896 HOOKS CAM MOTION, 6 LEVERS INSTALLED, 4 FRAMES GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 3X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1602, YEAR 2006/2008, 3072 HOOKS, CONTROLLER JC-6 GROUND AND PILE WARP BEAM 940 MM DIAMETER (6) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 4X 1993, 1X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520S, YEAR 1993/94, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1994, WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520, YEAR 1995, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7100 B390 F4 EP J D1, YEAR 1995, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2006, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 J D1, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-860, YEAR 1996, 2688 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 J D2, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-960, YEAR 1996, 3072 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (8) MODEL P7200 B390 F4 J Q D1, YEAR 6X 1996, 2X 1997, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 1998, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (8) MODEL P7250 B390 F4 J D1, YEAR 6X 1997, 2X 1998 , WORKING WIDTH 3,9 M / 153” (4) STAUBLI E-JACQUARD LX-1600, YEAR 2000, 3072 HOOKS, CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870, YEAR 2000/01, 2688 HOOKS, CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D2, YEAR 1999 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D3, YEAR 1999, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER ALL MACHINES WITH 4 COLORS, AVERAGE 3 WEFT FEEDERS (ROH CHRONO HS AND SIMILAR), MIN. 3 CENTRAL TUCK IN UNITS PER MACHINE, SIDE TUCK IN UNITS, USTER LOOM DATA E-JACQUARD M/C WITH ELECTRONICALLY CONTROLLED COLOR SELECTION (EXCEPT 8 MECHANICAL M/CS) SPLIT BEAM EXECUTION, 1.5 PILE BEAMS, 1.5 GROUND BEAMS ON-LOOM TAKE-UP, 1.5 CLOTH ROLLS, 4 WEFT FEEDERS, 4 DROP WIRE BARS APPROX. 9000 DROP WIRES AND 4500 HEDDLES, LOOMDATA APPROX. 80% PLATINES INSTALLED STARTES OR STAUBLI HARNESS, ONE LIETTY GANTRY FOR TWO MACHINES LOOM POWER 5 OR 6 KW, JACQUARD POWER 2 KW 5 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G510, YEAR: 1 X 2002, 2 X 2003, 1 X 2004, 1 X 2007, TEMPERATURE 98C , CAPACITY 500 KG.EACH, TONELLO CONTROLS DIRECT STEAM OPERATED, CURRENTLY ALL ARE CONNECTED TO A CENTRAL DOSING SYSTEM (BUT EACH HAS ITS OWN DOSING SYSTEM AND CAN WORK AS INDEPENDENT M/C) FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 1 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G1 50 HS, YEAR 2007, TEMPERATURE 98°C, CAPACITY 50 KG. TONELLO CONTROLS, DIRECT STEAM OPERATED, AIR PRESSURE 7 BAR, HYDRAULICS 3 BAR, STEAM 10 BAR, FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 2 TRIVENETA GARMENT DRYERS, TYPE E550 PV YEAR 2001 MODEL 550 P CAPACITY 500 KG. EACH, DRYING CYCLE TIME IS HALF OF THE TONELLO = EACH MACHINE CAN SERVE 2 TONELLO MACHINES - SEMI AUTOMATIC LOADING AND DISCHARGING, STEAM OPERATED ITEMIZED SALE IS POSSIBLE – AGAINST OFFERS AVAILABLE IMMEDIATELY – STOPPED ON MILL FLOOR Learn More

M-5158 COMPLETE TERRY WEAVING PLANTREFERENCE NUMBER: M-5158 (1212CVPGXX11) L COMPLETE TERRY WEAVING PLANT 1 WEST POINT DIRECT WARPER WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 504 ENDS, 504 SPARE ENDS, PITCH 400 MM, WP ELECTRO SENSE 1 WEST POINT DIRECT WARPER, WORKING WIDTH 1.8M, FLANGE DIAMETER BEAM OUTPUT 940 MM, PRESSURE ROLLER 1 WEST POINT V-CREEL, 640 ENDS, 640 SPARE ENDS, PITCH 450 MM, WP ELECTRO SENSE 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 10 DRYING CYLINDERS, TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 10 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 8 DRYING CYLINDERS, 7 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 3.0 M, FLANGE 1250 MM 1 WEST POINT SIZING UNIT, 8 POSITION CREEL, WORKING WIDTH 1.8M, DIAMETER 940 MM SINGLE SIZE BOX, ROLLER WIDTH 1.8 M, SINGLE SQUEEZING 7 DRYING CYLINDERS, 6 TEFLON COATED, PARRAFIN WEST POINT HEAD STOCK, WORKING WIDTH 2.7 M, FLANGE 1250 MM 1 SIZE KITCHEN , 5 STAINLESS STEEL MIXING TANKS WITH HEATING 7 MOTOCONO REMAIN WINDERS, 4 POSITIONS EACH 1 WARP BEAM STORAGE, 6 ROWS, 4 LEVELS, 14 M LENGTH 3 SHELVES SINGLE SIDED, 2 SHELVES DOUBLE SIDED WITH HUBTEX WARP BEAM LIFTER, MODEL 20TS 62 SULZER TERRY PROJECTILE LOOMS WITH JACQUARD (8) MODEL P7100 B330 F4 EP J D1, YEAR 4X 1989, 2X 1990, 2X 1991 WORKING WIDTH 3,3 M / 130” (7) STAUBLI E-JACQUARD CX-870, YEAR 1998-2004, 2688 HOOKS, CONTROLLER JC-5 (1) STAUBLI E-JACQUARD CX-860, YEAR 1997, 2688 HOOKS, CONTROLLER JC-4 (M/C 1989) GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7200 B330 F4 J Q D1, YEAR 1X 1991, 1X 1995 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (6) MODEL P7100 B330 F4 J D1, YEAR 1X 1991, 1X 1992, 4X 1994 WORKING WIDTH 3,3 M / 130” (4) STAUBLI E-JACQUARD CX-860, YEAR 1994, 2688 HOOKS, CONTROLLER JC-4 (2) STAUBLI E-JACQUARD CX-870, YEAR 2004, 2688 HOOKS, CONTROLLER JC-5 (M/C 1990/91) GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7250 B330 F4 J D1, YEAR 2X 2000, 2X 2001 WORKING WIDTH 3,3 M / 130” STAUBLI E-JACQUARD CX-870, YEAR 2X 2001, 2X 2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (5) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1991, 1X 1992, 2X 1994, 1X 1995 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 2003/2004, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1992 WORKING WIDTH 3,9 M / 153” SCHLEICHER MECHANICAL JACQUARD 3-08, YEAR 1990, 896 HOOKS CAM MOTION, 6 LEVERS INSTALLED, 4 FRAMES GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 3X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1602, YEAR 2006/2008, 3072 HOOKS, CONTROLLER JC-6 GROUND AND PILE WARP BEAM 940 MM DIAMETER (6) MODEL P7100 B390 F4 EP J D1, YEAR 1X 1992, 4X 1993, 1X 1994 WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520S, YEAR 1993/94, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 EP J D1, YEAR 1994, WORKING WIDTH 3,9 M / 153” STAUBLI MECHANICAL JACQUARD CR-520, YEAR 1995, 1344 HOOKS GROUND AND PILE WARP BEAM 940 MM DIAMETER (2) MODEL P7100 B390 F4 EP J D1, YEAR 1995, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2006, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940 MM DIAMETER (4) MODEL P7100 B390 F4 J D1, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-860, YEAR 1996, 2688 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (1) MODEL P7100 B390 F4 J D2, YEAR 1995 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-960, YEAR 1996, 3072 HOOKS, CONTROLLER JC-4 GROUND AND PILE WARP BEAM 940 MM DIAMETER (8) MODEL P7200 B390 F4 J Q D1, YEAR 6X 1996, 2X 1997, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD CX-870, YEAR 1998, 2688 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (8) MODEL P7250 B390 F4 J D1, YEAR 6X 1997, 2X 1998 , WORKING WIDTH 3,9 M / 153” (4) STAUBLI E-JACQUARD LX-1600, YEAR 2000, 3072 HOOKS, CONTROLLER JC-5 (M/C 1997) (4) STAUBLI E-JACQUARD CX-870, YEAR 2000/01, 2688 HOOKS, CONTROLLER JC-5 (M/C 1997/98) GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D2, YEAR 1999 , WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER (1) MODEL P7250 B390 F4 J D3, YEAR 1999, WORKING WIDTH 3,9 M / 153” STAUBLI E-JACQUARD LX-1600, YEAR 2002, 3072 HOOKS, CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER ALL MACHINES WITH 4 COLORS, AVERAGE 3 WEFT FEEDERS (ROH CHRONO HS AND SIMILAR), MIN. 3 CENTRAL TUCK IN UNITS PER MACHINE, SIDE TUCK IN UNITS, USTER LOOM DATA E-JACQUARD M/C WITH ELECTRONICALLY CONTROLLED COLOR SELECTION (EXCEPT 8 MECHANICAL M/CS) SPLIT BEAM EXECUTION, 1.5 PILE BEAMS, 1.5 GROUND BEAMS ON-LOOM TAKE-UP, 1.5 CLOTH ROLLS, 4 WEFT FEEDERS, 4 DROP WIRE BARS APPROX. 9000 DROP WIRES AND 4500 HEDDLES, LOOMDATA APPROX. 80% PLATINES INSTALLED STARTES OR STAUBLI HARNESS, ONE LIETTY GANTRY FOR TWO MACHINES LOOM POWER 5 OR 6 KW, JACQUARD POWER 2 KW 5 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G510, YEAR: 1 X 2002, 2 X 2003, 1 X 2004, 1 X 2007, TEMPERATURE 98C , CAPACITY 500 KG.EACH, TONELLO CONTROLS DIRECT STEAM OPERATED, CURRENTLY ALL ARE CONNECTED TO A CENTRAL DOSING SYSTEM (BUT EACH HAS ITS OWN DOSING SYSTEM AND CAN WORK AS INDEPENDENT M/C) FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 1 TONELLO AT GARMENT WASHING AND BLEACHING MACHINES MODEL G1 50 HS, YEAR 2007, TEMPERATURE 98°C, CAPACITY 50 KG. TONELLO CONTROLS, DIRECT STEAM OPERATED, AIR PRESSURE 7 BAR, HYDRAULICS 3 BAR, STEAM 10 BAR, FULL DRUM (NOT DIVIDED), 4 WATER ENTRIES AND 2 DRAINING OPENINGS CAPABLE OF WASHING, BLEACHING AND WATER EXTRACTION, HEAVY DUTY (SUITABLE FOR JEANS) 2 TRIVENETA GARMENT DRYERS, TYPE E550 PV YEAR 2001 MODEL 550 P CAPACITY 500 KG. EACH, DRYING CYCLE TIME IS HALF OF THE TONELLO = EACH MACHINE CAN SERVE 2 TONELLO MACHINES - SEMI AUTOMATIC LOADING AND DISCHARGING, STEAM OPERATED ITEMIZED SALE IS POSSIBLE – AGAINST OFFERS AVAILABLE IMMEDIATELY – STOPPED ON MILL FLOOR Learn More -

YY-2598 1 X 2M CRABTREE DIRECT WARPING WITH 150 END CREEL, YEAR (REFURBISHED 2018), WORKING WIDTH 2100mmYY-2598 1 X 2M CRABTREE DIRECT WARPING WITH 150 END CREEL, YEAR (REFURBISHED 2018), WORKING WIDTH 2100mm QUANTITY: 1 Learn More

YY-2598 1 X 2M CRABTREE DIRECT WARPING WITH 150 END CREEL, YEAR (REFURBISHED 2018), WORKING WIDTH 2100mmYY-2598 1 X 2M CRABTREE DIRECT WARPING WITH 150 END CREEL, YEAR (REFURBISHED 2018), WORKING WIDTH 2100mm QUANTITY: 1 Learn More -

R-5953 SUCKER SIZING H340, 3400mm 12 CYLINDER WITH CHINESE WARPER YEAR 2001

R-5953 SUCKER SIZING H340, 3400mm 12 CYLINDER WITH CHINESE WARPER YEAR 2001REFERENCE NUMBER: R-5953

Learn More

SUCKER SIZING H340

YEAR 2001

QUANTITY: 7 -

C-2273 KARL MAYER WARPING MACHINES AND BEAMS WITH 1200 ENDS CREELREFERENCE NUMBER: C-2273 KARL MAYER WARPING MACHINES AND BEAMS WITH 1200 ENDS CREEL DETAILS: KARL MAYER WARPING MACHINES AND BEAMS WARPER MADE BY KARL MAYER TYPE: GSP 50 ( 30" X 50" ) NR : 1510 , 1511 THESE MACHINES CAN SUPPORT BEAMS WIDTH UP TO 50" AND FLANGE DIAMETER UP TO 30".( OR 2 BEAMS 21 X 21 AT SAME TIME ) WITH COMPLETE 1200 ENDS CREEL FULL ACCESSORIES IN COMPLETE CONDITION 200PCS ALUCOLOR BEAMS 21” X 21” QUANTITY AVAILABLE: 2 Learn More

C-2273 KARL MAYER WARPING MACHINES AND BEAMS WITH 1200 ENDS CREELREFERENCE NUMBER: C-2273 KARL MAYER WARPING MACHINES AND BEAMS WITH 1200 ENDS CREEL DETAILS: KARL MAYER WARPING MACHINES AND BEAMS WARPER MADE BY KARL MAYER TYPE: GSP 50 ( 30" X 50" ) NR : 1510 , 1511 THESE MACHINES CAN SUPPORT BEAMS WIDTH UP TO 50" AND FLANGE DIAMETER UP TO 30".( OR 2 BEAMS 21 X 21 AT SAME TIME ) WITH COMPLETE 1200 ENDS CREEL FULL ACCESSORIES IN COMPLETE CONDITION 200PCS ALUCOLOR BEAMS 21” X 21” QUANTITY AVAILABLE: 2 Learn More -

M-2003 BENNINGER BEN-MATIC SECTIONAL WARPER WIDTH 3200mm YEAR 2000 WITH 2 CREELS

M-2003 BENNINGER BEN-MATIC SECTIONAL WARPER WIDTH 3200mm YEAR 2000 WITH 2 CREELSREFERENCE NUMBER: M-2003

BENNINGER BEN-MATIC SECTIONAL WARPER WIDTH 3200mm YEAR 2000 WITH 2 CREELSSECTIONAL WARPER

TYPE BEN-MATIC

MAXIMUM BEAM DIAMETER 1000mm

WAXING DEVICE

WITH 2 CREELS EACH 672 POSITIONS

GAUGE 335mm

EACH CREEL 2 SETS OF TROLLEYS

MAKE BENNINGER

WORKING WIDTH: 3200mm

YEAR 2000

STILL IN PRODUCTIONQUANTITY: 1

Learn More