Search results for: 'conveyor-+F-K'

-

TT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEEDTT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEED MACHINE TECHNICAL SPECIFICATIONS 1. FEEDING METHOD: BY CONVEYOR BELT 2. BELT WIDTH: 600mm 3. BELT LENGTH: 4500mm 4. MOTOR POWER: 2.2KW 380V 50Hz 3-P (OR 440 VOLTS AVAILABLE) 5. MACHINE TYPE: X800 6. CHAMBER VOLUME: 800LITER 7. CHAMBER MATERIAL: 12mm STAINLESS STEEL 8. CAPACITY: 500KG PER HOUR 9. ROTATING KNIFE: 4 PCS, CAN BE ADJUSTABLE 10. FIXED BLADES: 9 PCS 11. KNIFE LIFE TIME: MORE THAN 1000 TONS AT THE FIRST TIME THEN IT CAN BE RE-SHARPENED TO USE AGAIN. 12. BLADE & KNIFE MATERIAL: 9CRSI 13. ROTARY SPEED: 680 RPM 14. MOTOR POWER: 132KW (OR 440 VOLTS AVAILABLE) 380V-50Hz-3P 15. MOTOR MANUFACTURE: WNF FAMOUS 16. DISCHARGE METHOD: PNEUMATIC 17. ELECTRIC CONTROL CASE: SOLID METAL SHEET. 18. CONTACTORS AND SWITCHES: SIEMENS Learn More

TT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEEDTT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEED MACHINE TECHNICAL SPECIFICATIONS 1. FEEDING METHOD: BY CONVEYOR BELT 2. BELT WIDTH: 600mm 3. BELT LENGTH: 4500mm 4. MOTOR POWER: 2.2KW 380V 50Hz 3-P (OR 440 VOLTS AVAILABLE) 5. MACHINE TYPE: X800 6. CHAMBER VOLUME: 800LITER 7. CHAMBER MATERIAL: 12mm STAINLESS STEEL 8. CAPACITY: 500KG PER HOUR 9. ROTATING KNIFE: 4 PCS, CAN BE ADJUSTABLE 10. FIXED BLADES: 9 PCS 11. KNIFE LIFE TIME: MORE THAN 1000 TONS AT THE FIRST TIME THEN IT CAN BE RE-SHARPENED TO USE AGAIN. 12. BLADE & KNIFE MATERIAL: 9CRSI 13. ROTARY SPEED: 680 RPM 14. MOTOR POWER: 132KW (OR 440 VOLTS AVAILABLE) 380V-50Hz-3P 15. MOTOR MANUFACTURE: WNF FAMOUS 16. DISCHARGE METHOD: PNEUMATIC 17. ELECTRIC CONTROL CASE: SOLID METAL SHEET. 18. CONTACTORS AND SWITCHES: SIEMENS Learn More -

G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE)G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE) MODEL: NOVA 26 TECHNICAL DATA: LOADING CONVEYOR: 2100 X 2100mm (82" X 82") UNLOADING CONVEYOR: 2100 X 2100mm (82" X 82") MAXIMUM DRILLING WIDTH: 2100mm (82") MAXIMUM DRILLING HEIGHT: 180mm (7") HOLE DIAMETER: 6 TO 30mm (1/4" TO 1.18") MAXIMUM CONTEMPORANEOUS HOLES NUMBER: 26 MINIMUM DISTANCE BETWEEN THE CHUCKS: 80mm POWER: 11 KW VOLTAGE: AS PER CUSTOMER WORKING PRESSURE BAR: 6 (90 PSI) NET WEIGHT: 2293 KGS (5000 LBS) FLOOR SPACE: 4375 X 3780 H 2204mm Learn More

G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE)G-1535 FOAM DRILLING MACHINE (FOAM PERFORATING MACHINE) MODEL: NOVA 26 TECHNICAL DATA: LOADING CONVEYOR: 2100 X 2100mm (82" X 82") UNLOADING CONVEYOR: 2100 X 2100mm (82" X 82") MAXIMUM DRILLING WIDTH: 2100mm (82") MAXIMUM DRILLING HEIGHT: 180mm (7") HOLE DIAMETER: 6 TO 30mm (1/4" TO 1.18") MAXIMUM CONTEMPORANEOUS HOLES NUMBER: 26 MINIMUM DISTANCE BETWEEN THE CHUCKS: 80mm POWER: 11 KW VOLTAGE: AS PER CUSTOMER WORKING PRESSURE BAR: 6 (90 PSI) NET WEIGHT: 2293 KGS (5000 LBS) FLOOR SPACE: 4375 X 3780 H 2204mm Learn More -

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More -

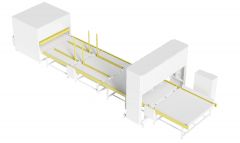

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More -

TT-5001 COMPLETE POWER PLANT, 300 MWT, YEAR 2010, COAL FIREDTT-5001 COMPLETE POWER PLANT, 300 MWT, YEAR 2010, COAL FIRED 300 MWT POWER PLANT BHARAT THERMAL POWER BRAND: ALSTOM COAL PLANT - FUEL COAL FIRE 4 BOILER BY DRUM - DRUM OF SINGLE REQUIRES APPROXIMATELY 300 CONTAINERS TO SHIP Learn More

TT-5001 COMPLETE POWER PLANT, 300 MWT, YEAR 2010, COAL FIREDTT-5001 COMPLETE POWER PLANT, 300 MWT, YEAR 2010, COAL FIRED 300 MWT POWER PLANT BHARAT THERMAL POWER BRAND: ALSTOM COAL PLANT - FUEL COAL FIRE 4 BOILER BY DRUM - DRUM OF SINGLE REQUIRES APPROXIMATELY 300 CONTAINERS TO SHIP Learn More -

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

A-2531 HOT MELT GLUE FOR MATTRESS INDUSTRYQUALITY AND TIDY MATTRESS PRODUCTION WITH AUTOMATIC SYSTEM SAVING TIME AND KEEP CLEAN MATTRESS HEALTHY GLUE MATERIAL USAGE – HOT MELT GLUE PROVIDES HIGH – OUTPUT WITH MINIMUM TRAINING TIME Learn More

A-2531 HOT MELT GLUE FOR MATTRESS INDUSTRYQUALITY AND TIDY MATTRESS PRODUCTION WITH AUTOMATIC SYSTEM SAVING TIME AND KEEP CLEAN MATTRESS HEALTHY GLUE MATERIAL USAGE – HOT MELT GLUE PROVIDES HIGH – OUTPUT WITH MINIMUM TRAINING TIME Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

TT-5702 KHS COMPLETE FILLING LINE FOR CANS, YEAR 2014TT-5702 KHS COMPLETE FILLING LINE FOR CANS, YEAR 2014 KHS COMPLETE FILLING LINE FOR CANS YEAR: 2014 CATEGORY: COMPLETE FILLING LINES BRAND: KHS AVAILABILITY: IMMEDIATELY CAPACITY: 32,000 CPH Learn More

TT-5702 KHS COMPLETE FILLING LINE FOR CANS, YEAR 2014TT-5702 KHS COMPLETE FILLING LINE FOR CANS, YEAR 2014 KHS COMPLETE FILLING LINE FOR CANS YEAR: 2014 CATEGORY: COMPLETE FILLING LINES BRAND: KHS AVAILABILITY: IMMEDIATELY CAPACITY: 32,000 CPH Learn More