Search results for: 'electric p'

- Related search terms

- Electric di

- Electric d'

- Electrical ma

- Electrical c

- Electrical l

-

TT-3933 JENBACHER GAS GENSET FOR PRODUCTION OF ELECTRICITY, 4.4 MW, YEAR 2012, 50 HzTT-3933 JENBACHER GAS GENSET FOR PRODUCTION OF ELECTRICITY, 4.4 MW, YEAR 2012, 50 Hz JENBACHER GAS MOTOR TYPE JMS 624 GS-NL 4.4 MW POWER (4400 KW) 1500 RPM 24 CYLINDERS BORE 190mm X STROKE 220mm YEAR 2012 TOTAL RUNNING HOURS APPROX. 45000 (APPROX. 5000 STARTS) QUANTITY: 1 Learn More

TT-3933 JENBACHER GAS GENSET FOR PRODUCTION OF ELECTRICITY, 4.4 MW, YEAR 2012, 50 HzTT-3933 JENBACHER GAS GENSET FOR PRODUCTION OF ELECTRICITY, 4.4 MW, YEAR 2012, 50 Hz JENBACHER GAS MOTOR TYPE JMS 624 GS-NL 4.4 MW POWER (4400 KW) 1500 RPM 24 CYLINDERS BORE 190mm X STROKE 220mm YEAR 2012 TOTAL RUNNING HOURS APPROX. 45000 (APPROX. 5000 STARTS) QUANTITY: 1 Learn More -

M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870REFERENCE NUMBER: M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870 YEAR 6X 1996, 2X, 1998 WORKING WIDTH 3900 MM / 153” STAUBLI E-JACQUARD CX-870 YEAR 1998 2688 HOOKS CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More

M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870REFERENCE NUMBER: M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870 YEAR 6X 1996, 2X, 1998 WORKING WIDTH 3900 MM / 153” STAUBLI E-JACQUARD CX-870 YEAR 1998 2688 HOOKS CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More -

M-4110 STORK TRANSFER PRINT RANGE – 1800mm – 72” – ELECTRICALREFERENCE NUMBER: M-4110 (1010STKMXX9) L STORK TRANSFER PRINT RANGE – 1800mm – 72” – ELECTRICAL MILL MADE SCRAY LET-OFF WITH 2 STATIONS 72” WIDE FIFE HYDRAULIC SINGLE ROLL GUIDER MENZEL BRUSH BOX TYPE 78BR 01003, YEAR 8/76 INFRARED UNIT SINGLE SIDED 4-BURNER MOUNTED OVER THE GOODS TO HEAT THEM BEFORE TRANSFER PRINTING STORK 72” HEAT TRANSFER MACHINE, ELECTRICALLY OPERATED GOODS TRAVEL OVER 2-BRUSH ROLLS WITH A VACUUM SYSTEM 54 BAGS WITH 6 DELIVERIES EXIT AND GO INTO A SMALL MILL MADE STEAM CHAMBER HOLDING APPROX. 3 – 5 YARDS ENTERING INTO A HENRY PAULUS BRUSHING UNIT, SINGLE INFRARED UNIT 2-POSITIONS STEAM PLATES FOR THIS UNIT GOODS EXIT AND GO INTO A SMALL ACCUMULATOR APPROX. 50 YARDS THEN OVER ONTO AN AFRAME WINDER QUANTITY AVAILABLE: 1 Learn More

M-4110 STORK TRANSFER PRINT RANGE – 1800mm – 72” – ELECTRICALREFERENCE NUMBER: M-4110 (1010STKMXX9) L STORK TRANSFER PRINT RANGE – 1800mm – 72” – ELECTRICAL MILL MADE SCRAY LET-OFF WITH 2 STATIONS 72” WIDE FIFE HYDRAULIC SINGLE ROLL GUIDER MENZEL BRUSH BOX TYPE 78BR 01003, YEAR 8/76 INFRARED UNIT SINGLE SIDED 4-BURNER MOUNTED OVER THE GOODS TO HEAT THEM BEFORE TRANSFER PRINTING STORK 72” HEAT TRANSFER MACHINE, ELECTRICALLY OPERATED GOODS TRAVEL OVER 2-BRUSH ROLLS WITH A VACUUM SYSTEM 54 BAGS WITH 6 DELIVERIES EXIT AND GO INTO A SMALL MILL MADE STEAM CHAMBER HOLDING APPROX. 3 – 5 YARDS ENTERING INTO A HENRY PAULUS BRUSHING UNIT, SINGLE INFRARED UNIT 2-POSITIONS STEAM PLATES FOR THIS UNIT GOODS EXIT AND GO INTO A SMALL ACCUMULATOR APPROX. 50 YARDS THEN OVER ONTO AN AFRAME WINDER QUANTITY AVAILABLE: 1 Learn More -

REACTORREFERENCE NUMBER: P-8841-H REACTOR NOMINAL CAPACITY(L): 50 ELECTRIC HEATING POWER CONSUMPTION(KW): 4X2 DIAMETER OF INSIDE BARREL (mm): 400 DIAMETER OF JACKET (mm): 600 MODEL OF REDUCER: 0.8 TO 1 ELECTRIC MOTOR: 1450 PER 0.8 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 100 ELECTRIC HEATING POWER CONSUMPTION: 6X2 DIAMETER OF INSIDE BARREL (mm): 500 DIAMETER OF JACKET (mm): 700 MODEL OF REDUCER: 1.1 TO 1 ELECTRIC MOTOR: 1450 PER 1.1 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 300 ELECTRIC HEATING POWER CONSUMPTION: 6X4 DIAMETER OF INSIDE BARREL (mm): 800 DIAMETER OF JACKET (mm): 1000 MODEL OF REDUCER: 1000 ELECTRIC MOTOR: 2.2 TO 2 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 500 ELECTRIC HEATING POWER CONSUMPTION: 9X4 DIAMETER OF INSIDE BARREL (mm): 900 DIAMETER OF JACKET (mm): 1100 MODEL OF REDUCER: 3 TO 2 ELECTRIC MOTOR: 1450 PER 3 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 1000 ELECTRIC HEATING POWER CONSUMPTION: 12X4 DIAMETER OF INSIDE BARREL (mm): 1200 DIAMETER OF JACKET (mm): 1400 MODEL OF REDUCER: 4 TO 3 ELECTRIC MOTOR: 1450 PER 4 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 2000 ELECTRIC HEATING POWER CONSUMPTION: 15X5 DIAMETER OF INSIDE BARREL (mm): 1400 DIAMETER OF JACKET (mm): 1600 MODEL OF REDUCER: 4 TO 3 ELECTRIC MOTOR: 1450 PER 4 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 3000 ELECTRIC HEATING POWER CONSUMPTION: 15X6 DIAMETER OF INSIDE BARREL (mm): 1800 DIAMETER OF JACKET (mm): 1800 MODEL OF REDUCER: 5.5 TO 3 ELECTRIC MOTOR: 1450 PER 5.5 AGITATOR REVOLUTION: 60 TO 100 QUANTITY: 1 Learn More

REACTORREFERENCE NUMBER: P-8841-H REACTOR NOMINAL CAPACITY(L): 50 ELECTRIC HEATING POWER CONSUMPTION(KW): 4X2 DIAMETER OF INSIDE BARREL (mm): 400 DIAMETER OF JACKET (mm): 600 MODEL OF REDUCER: 0.8 TO 1 ELECTRIC MOTOR: 1450 PER 0.8 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 100 ELECTRIC HEATING POWER CONSUMPTION: 6X2 DIAMETER OF INSIDE BARREL (mm): 500 DIAMETER OF JACKET (mm): 700 MODEL OF REDUCER: 1.1 TO 1 ELECTRIC MOTOR: 1450 PER 1.1 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 300 ELECTRIC HEATING POWER CONSUMPTION: 6X4 DIAMETER OF INSIDE BARREL (mm): 800 DIAMETER OF JACKET (mm): 1000 MODEL OF REDUCER: 1000 ELECTRIC MOTOR: 2.2 TO 2 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 500 ELECTRIC HEATING POWER CONSUMPTION: 9X4 DIAMETER OF INSIDE BARREL (mm): 900 DIAMETER OF JACKET (mm): 1100 MODEL OF REDUCER: 3 TO 2 ELECTRIC MOTOR: 1450 PER 3 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 1000 ELECTRIC HEATING POWER CONSUMPTION: 12X4 DIAMETER OF INSIDE BARREL (mm): 1200 DIAMETER OF JACKET (mm): 1400 MODEL OF REDUCER: 4 TO 3 ELECTRIC MOTOR: 1450 PER 4 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 2000 ELECTRIC HEATING POWER CONSUMPTION: 15X5 DIAMETER OF INSIDE BARREL (mm): 1400 DIAMETER OF JACKET (mm): 1600 MODEL OF REDUCER: 4 TO 3 ELECTRIC MOTOR: 1450 PER 4 AGITATOR REVOLUTION: 60 TO 100 NOMINAL CAPACITY(L) 3000 ELECTRIC HEATING POWER CONSUMPTION: 15X6 DIAMETER OF INSIDE BARREL (mm): 1800 DIAMETER OF JACKET (mm): 1800 MODEL OF REDUCER: 5.5 TO 3 ELECTRIC MOTOR: 1450 PER 5.5 AGITATOR REVOLUTION: 60 TO 100 QUANTITY: 1 Learn More -

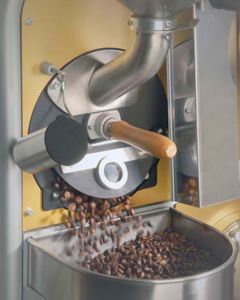

R-6858 LITTLE COFFEE ROASTERS

R-6858 LITTLE COFFEE ROASTERSR-6858 LITTLE COFFEE ROASTERS

ROASTING MACHINE MODEL EXPO 500

THE LITTLE ROASTING MACHINE MODEL EXPO IS USED FOR LABORATORY TESTS OR TO SEARCH FOR NEW BLENDS AND FLAVORS. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL FOR LABORATORYES TEST, LIKE QUALITY CONTROL ON RAW COFFEE.

ROASTER MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, IS AVAILABLE WITH HEATING GENERATOR TYPE ELECTRIC RESISTANCE OR GAS, WITH MANUAL CONTROL SYSTEM.COMPONENTS:

HOPPER OF CHARGE

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

2 ELECTRONIC DISPLAYS TO CONTROL THE PRODUCT TEMPERATURE INSIDE

THE ROASTING DRUM AND HEATING GENERATOR.SAFETY DEVICE FOR ELECTRIC RESISTANCE SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM AND COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

COLOURS AVAILABLE: ACCORDING CLIENTS REQUEST

ROASTING MACHINE MOD.ROAST.1000

ROASTING MACHINE PARTICULARLY SUITABLE FOR SPECIALIZED ACTIVITIES IN SMALL BATCHES OF ROASTED COFFEE OF SUPERIOR QUALITY, SUCH AS THE MARKET “SLOW FOOD”, COFFEE SHOPS, CONFECTIONERY SHOP. TECHNOLOGICALLY ADVANCED, CONFIRMS ITSELF AS IDEAL TOOL SPECIALIZED IN PRODUCTION OF SELECTED ROASTED COFFEES OF HIGH QUALITY. MACHINE MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTERS, IS AVAILABLE WITH HEATING GENERATOR BY ELECTRIC RESISTANCE AND PLC CONTROL SYSTEM OR AUTOMATIC.

COMPONENTS:HOPPER OF CHARGE

Learn More

HEATING GENERATOR BY ELECTRIC RESISTANCE OR GAS BURNER

COOLING TANK

MONITOR TOUCH SCREEN TO SEE AND CONTROL ALL THE ROASTING PROCESS FUNCTIONS.

SAFETY DEVICE FOR ELECTRIC RESISTANCES SWITCHING OFF

DRUM ROTATION BY GEARED MOTOR

ELECTRIC FAN FOR ROASTING DRUM

ELECTRIC FAN FOR COOLING TANK

CYCLONE WITH REMOVABLE CONTAINER

DEVICE FOR AUTOMATIC UNLOADING AT THE END OF ROASTING CYCLE

ACOUSTIC ALARM ADVISING THE ENDING OF ROASTING CYCLE

AVAILABLE COLOURS: ALUMINIUM / BRASS -

G-5886 CHICKEN SLAUGHTER LINE 6000 PER HOURREFERENCE NUMBER: G-5886 CHICKEN SLAUGHTER LINE 6000 PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-5886 CHICKEN SLAUGHTER LINE 6000 PER HOURREFERENCE NUMBER: G-5886 CHICKEN SLAUGHTER LINE 6000 PER HOUR QUANTITY AVAILABLE: 1 Learn More -

G-5233-A CHICKEN SLAUGHTER LINE 3000 BIRDS PER HOURREFERENCE NUMBER: G-5233 CHICKEN SLAUGHTER LINE 3000 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-5233-A CHICKEN SLAUGHTER LINE 3000 BIRDS PER HOURREFERENCE NUMBER: G-5233 CHICKEN SLAUGHTER LINE 3000 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More -

G-5233 CHICKEN SLAUGHTER LINE 2000-2500 BIRDS PER HOURREFERENCE NUMBER: G-5233 CHICKEN SLAUGHTER LINE 2000-2500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-5233 CHICKEN SLAUGHTER LINE 2000-2500 BIRDS PER HOURREFERENCE NUMBER: G-5233 CHICKEN SLAUGHTER LINE 2000-2500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More -

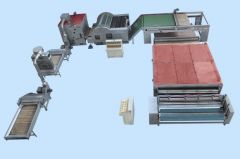

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More