Search results for: 'PRODUCT+MO'

- Related search terms

- PRODUCT+MODEL

- PRODUCT+MODEL+SERIAL+NO

- PRODUCT+MODEL+SERIAL+NO.

- PRODUCT+MODEL+SERIAL

- PRODUCT+MODE'

-

TT-6348 WESTAL ONE SHOT CHOCOLATE MOULDING LINE, MOULD SIZE PLAIN 600mm X 220mmTT-6348 WESTAL ONE SHOT CHOCOLATE MOULDING LINE, MOULD SIZE PLAIN 600mm X 220mm 1. BRAND WESTAL 2. TYPE 600 ONE SHOT CHOCOLATE MOULDING LINE 3. CURRENTLY SET UP FOR BOOK MOULDING & PRODUCING 7GRAMMES SOLID CHOCOLATE EGGS. 4. CAN ALSO PRODUCE BARS, SHELL MOULDED PRODUCTS, ONE SHOT PRODUCTS, ETC. 5. LINE WAS NEW IN AROUND YEAR 1980, HAD A COMPLETE OVERHAUL IN YEAR 2009. QUANTITY: 1 Learn More

TT-6348 WESTAL ONE SHOT CHOCOLATE MOULDING LINE, MOULD SIZE PLAIN 600mm X 220mmTT-6348 WESTAL ONE SHOT CHOCOLATE MOULDING LINE, MOULD SIZE PLAIN 600mm X 220mm 1. BRAND WESTAL 2. TYPE 600 ONE SHOT CHOCOLATE MOULDING LINE 3. CURRENTLY SET UP FOR BOOK MOULDING & PRODUCING 7GRAMMES SOLID CHOCOLATE EGGS. 4. CAN ALSO PRODUCE BARS, SHELL MOULDED PRODUCTS, ONE SHOT PRODUCTS, ETC. 5. LINE WAS NEW IN AROUND YEAR 1980, HAD A COMPLETE OVERHAUL IN YEAR 2009. QUANTITY: 1 Learn More -

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More -

T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011 THE PLANT IS FOR THE TRANSFORMATION OF THE TOW ON TOPS FOR ACRYLIC DOES NOT PRODUCE YARNS EQUIPMENT IS STILL RUNNING THE PLANT PRODUCE 15600 KGS HOURLY PRODUCTION PER MONTH IS 468 TONS Learn More

T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011 THE PLANT IS FOR THE TRANSFORMATION OF THE TOW ON TOPS FOR ACRYLIC DOES NOT PRODUCE YARNS EQUIPMENT IS STILL RUNNING THE PLANT PRODUCE 15600 KGS HOURLY PRODUCTION PER MONTH IS 468 TONS Learn More -

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More -

M-5128 FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITSREFERENCE NUMBER: M-5128 (121285KMN11UF) L FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITS FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITS MODEL: FC-90 PRODUCTION: 12 SPRING UNITS PER HOUR (SPRING UNIT SIZE 1.5 M X 2 M) SPRING TYPE: BONNELL SPRING DIAMETER: 67 TO 90mm STEEL WIRE DIAMETER: 1.9 TO 2.5mm SPRING HEIGHT (CAN BE CUSTOMIZED): 100 TO 180mm (<80mm NEEDS TO BE CUSTOMIZED) SPRING COILS: 4 TO 7 COILS HELICAL WIRE DIAMETER: 1.3 TO 1.4mm MAXIMUM SPRING UNIT WIDTH: 2050mm QUANTITY AVAILABLE: 1 Learn More

M-5128 FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITSREFERENCE NUMBER: M-5128 (121285KMN11UF) L FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITS FULL AUTOMATIC TRANSFER LINE FOR INNER SPRING UNITS MODEL: FC-90 PRODUCTION: 12 SPRING UNITS PER HOUR (SPRING UNIT SIZE 1.5 M X 2 M) SPRING TYPE: BONNELL SPRING DIAMETER: 67 TO 90mm STEEL WIRE DIAMETER: 1.9 TO 2.5mm SPRING HEIGHT (CAN BE CUSTOMIZED): 100 TO 180mm (<80mm NEEDS TO BE CUSTOMIZED) SPRING COILS: 4 TO 7 COILS HELICAL WIRE DIAMETER: 1.3 TO 1.4mm MAXIMUM SPRING UNIT WIDTH: 2050mm QUANTITY AVAILABLE: 1 Learn More -

TT-7588 TETRA PAK® TETRA ALCIP 1, YEAR 2010TT-7588 TETRA PAK® TETRA ALCIP 1, YEAR 2010 1. MACHINE TYPE: VARIOUS EQUIPMENT 2. BRAND: TETRA PAK® 3. MODEL: TETRA ALCIP 1 4. YEAR OF CONSTRUCTION: 2010 5. UPDATE: 29.04.2025 6. CONDITION: USED QUANTITY: 1 Learn More

TT-7588 TETRA PAK® TETRA ALCIP 1, YEAR 2010TT-7588 TETRA PAK® TETRA ALCIP 1, YEAR 2010 1. MACHINE TYPE: VARIOUS EQUIPMENT 2. BRAND: TETRA PAK® 3. MODEL: TETRA ALCIP 1 4. YEAR OF CONSTRUCTION: 2010 5. UPDATE: 29.04.2025 6. CONDITION: USED QUANTITY: 1 Learn More -

TT-1882 HFO MITSUBISHI 18KU30A POWER PLANT, 45MW 50Hz, 5.6MW, YEAR 1998TT-1882 HFO MITSUBISHI 18KU30A POWER PLANT, 45MW 50Hz, 5.6MW, YEAR 1998 MAIN SPECIFICATIONS: ENGINE MODEL: 18KU30A BRAND: MITSUBISHI CONTINUOUS OUTPUT: 5,600KWE X 750 RPM FREQUENCY & VOLTAGE: 50HZ & 11,000V YEAR OF PRODUCTION: 1998 FUEL OIL: HFO / DO PLANT AUXILIARY EQUIPMENT: 1 SET RUNNING HOURS: ABT. 21,000 HOURS QUANTITY: 8 Learn More

TT-1882 HFO MITSUBISHI 18KU30A POWER PLANT, 45MW 50Hz, 5.6MW, YEAR 1998TT-1882 HFO MITSUBISHI 18KU30A POWER PLANT, 45MW 50Hz, 5.6MW, YEAR 1998 MAIN SPECIFICATIONS: ENGINE MODEL: 18KU30A BRAND: MITSUBISHI CONTINUOUS OUTPUT: 5,600KWE X 750 RPM FREQUENCY & VOLTAGE: 50HZ & 11,000V YEAR OF PRODUCTION: 1998 FUEL OIL: HFO / DO PLANT AUXILIARY EQUIPMENT: 1 SET RUNNING HOURS: ABT. 21,000 HOURS QUANTITY: 8 Learn More -

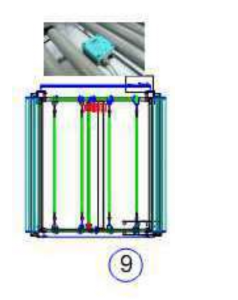

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More -

YY-2441 AUTO VERTICAL STITCH SEWING MACHINE, MATTRESS BORDER WIDTH 560mm (22 INCHES)YY-2441 AUTO VERTICAL STITCH SEWING MACHINE, MATTRESS BORDER WIDTH 560mm (22 INCHES) APPLICATION: THIS MACHINE IS USE FOR VERTICAL STITCH SEWING MATTRESS DECORATIVE BORDER, THE MACHINE IS EQUIPPED HIGH QUALITY SEWING HEAD, THE SPEED OF SEWING CAN REACH 3.5M/MINUTES, SEWING THICKNESS CAN REACH 15MM. ACCORDING TO USER’S REQUESTS TO CHOOSE DIFFERENT WIDTH MATTRESS BORDER FOR ARISE QUALITY LEVEL OF MATTRESS. THE ADVANCED PLC CONTROL SYSTEM TO ENSURE ACCURATE SEWING AND NICE RESULT. IT EQUIPPED SPECIAL DESIGNED MATERIAL FEEDING AND WINDER SYSTEM WITH SMART SENSOR. IT IS SUCCESSFULLY ACCOMPLISH COMPLETE AUTOMATION PRODUCTION. THIS IS THE PERFECT AND PROFESSIONAL SEWING EQUIPMENT FOR THE PRODUCTION OF LUXURY MATTRESSES. Learn More

YY-2441 AUTO VERTICAL STITCH SEWING MACHINE, MATTRESS BORDER WIDTH 560mm (22 INCHES)YY-2441 AUTO VERTICAL STITCH SEWING MACHINE, MATTRESS BORDER WIDTH 560mm (22 INCHES) APPLICATION: THIS MACHINE IS USE FOR VERTICAL STITCH SEWING MATTRESS DECORATIVE BORDER, THE MACHINE IS EQUIPPED HIGH QUALITY SEWING HEAD, THE SPEED OF SEWING CAN REACH 3.5M/MINUTES, SEWING THICKNESS CAN REACH 15MM. ACCORDING TO USER’S REQUESTS TO CHOOSE DIFFERENT WIDTH MATTRESS BORDER FOR ARISE QUALITY LEVEL OF MATTRESS. THE ADVANCED PLC CONTROL SYSTEM TO ENSURE ACCURATE SEWING AND NICE RESULT. IT EQUIPPED SPECIAL DESIGNED MATERIAL FEEDING AND WINDER SYSTEM WITH SMART SENSOR. IT IS SUCCESSFULLY ACCOMPLISH COMPLETE AUTOMATION PRODUCTION. THIS IS THE PERFECT AND PROFESSIONAL SEWING EQUIPMENT FOR THE PRODUCTION OF LUXURY MATTRESSES. Learn More -

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More