Search results for: 'bolt m'

-

BRUCKNER BOPP EXTRUSION LINE WIDTH 8200mm YEAR 1992BRUCKNER BOPP EXTRUSION LINE, WIDTH 8200mm, THREE LAYERS, BUILT 1992, COMPLETED WITH AN ATLAS SLITTER/REWINDER, MODEL CW, WIDTH 8200mm. AND FURTHER AUXILIARIES, INCLUDING SPARE PARTS. NAMEPLATE CAPACITY 20,000 T/Y. RAW MATERIALS SECTION - 4 SILOS 250 M3 ALUMINIUM - 2 SILOS 100 M3 ALUMINIUM - 2 SILOS 50 M3 ALUMINIUM - PNEUMATIC TRANSPORT SYSTEM; COMPUTERIZED DOSING SYSTEM, HOPPERS AND SCALES FOR THE THREE EXTRUDERS EXTRUSION SECTION - MAIN EXTRUDERS: 2 MITSUBISHI CASCADE EXTRUDERS Ø 300 mm AND 250 mm - CO-EXTRUDERS: 2 BANDERA EXTRUDERS Ø 100 mm, EQUIPPED WITH MELT PIPES - DIE: SIMPLAST, WIDTH 1,140 mm, GAP 2 - 3.75 mm, 40 PUSH/PULL BOLTS - CHILL ROLL: Ø 3 M, 1,900,000 KJ/H COOLING CAPACITY - WATER BATH: 1.500.000 KJ/H CAPACITY MDO (MACHINE DIRECTION ORIENTATION) SECTION - PREHEATING INFRARED 130 KW - PREHEATING: 16 CHROMIUM PLATED ROLLS Ø 614 mm - STRETCHING: 6 CHROMIUM PLATED ROLLS Ø 180 mm, EQUIPPED WITH RUBBER NIP ROLLS Ø 150 mm - ANNEALING: 2 CHROMIUM PLATED ROLLS Ø 614 mm TDO (TRANSVERSE DIRECTION ORIENTATION) SECTION - TOTAL LENGTH: 66 METER - PREHEATING: 5 SECTIONS - STRETCHING : 5 SECTIONS - ANNEALING : 5 SECTIONS - NEUTRAL : 1 SECTION - COOLING : 2 SECTIONS - INLET 850 – 1,050 mm WIDTH - OUTLET 7,600 – 8,600 mm WIDTH PRS (PULL ROLL STAND) SECTION - EDGE TRIM CUTTERS - ESSECI FLAME TREATER, BURNER, CHROMIUM PLATE ROLL, RUBBER NIP ROLL - CORONA TREATER 1: 3 DISCHARGE BARS, SILICON ROLL, RUBBER NIP ROLL - CORONA TREATER 2: 2 DISCHARGE BARS, EDGE BAR, SILICON ROLL, RUNNER NIP ROLL MEASUREX/HONEYWELL GAUGE CONTROL SYSTEMS - 8.5 M SCANNER FOR FILM - 1.2 M SCANNER FOR CAST SHEET - MAIN THICKNESS CONTROL UNIT CONNECTED TO THE BOLT OF THE EXTRUSION DIE FOR LIP ADJUSTMENT WINDER - 2 TURRETS KAMPF WINDER - AUTOMATIC CUT / TURRET / MILL-ROLL CHANGE - WINDING CORES: 108 STEEL WINDING CORES Ø 500 mm CONTROL UNIT - THE LINE IS EQUIPPED WITH A FULLY INTEGRATED CONTROL SYSTEM SUPPLIED BY BRUCKNER MILL ROLL STAND (SEMI-FINISHED PRODUCTS WAREHOUSE) - 150 TOTAL POSITIONS, OF WHICH 50 IN HEATED CLOSED ROOM - 1 PICK-UP FOR LOADING / UNLOADING WINDER AND SLITTER - 1 MANUAL EMERGENCY PICK-UP FOR LOADING/UNLOADING WI NDER AND SLITTER AND MAINTENANCE - 1 SHUTTLE TO MOVE MILL ROLLS IN AND OUT OF THE WAREHOUSE - 1 MAIN CRANE FOR MOVING MILL ROLLS / EMPTY CORES RECYCLING - HERBOLD GRINDER FOR SCRAP RECOVERY - 4 FLUFF SILOS - 1 EREMA MACHINE FOR REGRANULATION, APPROX. 700 KG/H SLITTER - ATLAS CW MACHINE, BUILT 1992, MAJOR UPGRADE 2010 - INLET MILL-ROLLS MAX Ø 1.2 M, WIDTH 8.2 M - 16 REWINDING STATIONS, WIDTHS FROM 400 mm TO 2450 mm, MAX Ø 1,000 mm - AUTOMATIC KNIVES AND RE-WINDING ARMS POSITIONING PACKING - SEMI-AUTOMATIC BALLOTTI LINE FOR CONDITIONING OF ROLLS AND PALLETS, BUILT 2000 - CONVEYORS - SCALING - STRAPPING - STRETCHING UTILITIES - 3 COMPRESSORS 3 BARS FOR COMPRESSED AIR CIRCUIT FOR RAW MATERIALS HANDLING - 2 COMPRESSORS 6 BARS FOR COMPRESSED AIR - 2 CHILLERS FOR CHILLED WATER PRODUCTION - 2 WATER COOLING TOWERS - 1 BOILER FOR THERMAL OIL PRODUCTION - 3 TRANSFORMERS 15 KV TO 380 V ADDITIONAL EQUIPMENT - SPARE PARTS FOR ALL OF THE ABOVE - TECHNICAL CONSUMABLES - IT EQUIPMENT FOR CONTROLLING THE MANUFACTURING EQUIPMENT AND DATA TRAFFIC, SUCH AS SERVERS, SWITCHES AND CABLING - LABORATORY EQUIPMENT FOR QUALITY CONTROL PURPOSES Line was producing 20 to 40 microns , line can produce down to 10 to 12 microns Learn More

BRUCKNER BOPP EXTRUSION LINE WIDTH 8200mm YEAR 1992BRUCKNER BOPP EXTRUSION LINE, WIDTH 8200mm, THREE LAYERS, BUILT 1992, COMPLETED WITH AN ATLAS SLITTER/REWINDER, MODEL CW, WIDTH 8200mm. AND FURTHER AUXILIARIES, INCLUDING SPARE PARTS. NAMEPLATE CAPACITY 20,000 T/Y. RAW MATERIALS SECTION - 4 SILOS 250 M3 ALUMINIUM - 2 SILOS 100 M3 ALUMINIUM - 2 SILOS 50 M3 ALUMINIUM - PNEUMATIC TRANSPORT SYSTEM; COMPUTERIZED DOSING SYSTEM, HOPPERS AND SCALES FOR THE THREE EXTRUDERS EXTRUSION SECTION - MAIN EXTRUDERS: 2 MITSUBISHI CASCADE EXTRUDERS Ø 300 mm AND 250 mm - CO-EXTRUDERS: 2 BANDERA EXTRUDERS Ø 100 mm, EQUIPPED WITH MELT PIPES - DIE: SIMPLAST, WIDTH 1,140 mm, GAP 2 - 3.75 mm, 40 PUSH/PULL BOLTS - CHILL ROLL: Ø 3 M, 1,900,000 KJ/H COOLING CAPACITY - WATER BATH: 1.500.000 KJ/H CAPACITY MDO (MACHINE DIRECTION ORIENTATION) SECTION - PREHEATING INFRARED 130 KW - PREHEATING: 16 CHROMIUM PLATED ROLLS Ø 614 mm - STRETCHING: 6 CHROMIUM PLATED ROLLS Ø 180 mm, EQUIPPED WITH RUBBER NIP ROLLS Ø 150 mm - ANNEALING: 2 CHROMIUM PLATED ROLLS Ø 614 mm TDO (TRANSVERSE DIRECTION ORIENTATION) SECTION - TOTAL LENGTH: 66 METER - PREHEATING: 5 SECTIONS - STRETCHING : 5 SECTIONS - ANNEALING : 5 SECTIONS - NEUTRAL : 1 SECTION - COOLING : 2 SECTIONS - INLET 850 – 1,050 mm WIDTH - OUTLET 7,600 – 8,600 mm WIDTH PRS (PULL ROLL STAND) SECTION - EDGE TRIM CUTTERS - ESSECI FLAME TREATER, BURNER, CHROMIUM PLATE ROLL, RUBBER NIP ROLL - CORONA TREATER 1: 3 DISCHARGE BARS, SILICON ROLL, RUBBER NIP ROLL - CORONA TREATER 2: 2 DISCHARGE BARS, EDGE BAR, SILICON ROLL, RUNNER NIP ROLL MEASUREX/HONEYWELL GAUGE CONTROL SYSTEMS - 8.5 M SCANNER FOR FILM - 1.2 M SCANNER FOR CAST SHEET - MAIN THICKNESS CONTROL UNIT CONNECTED TO THE BOLT OF THE EXTRUSION DIE FOR LIP ADJUSTMENT WINDER - 2 TURRETS KAMPF WINDER - AUTOMATIC CUT / TURRET / MILL-ROLL CHANGE - WINDING CORES: 108 STEEL WINDING CORES Ø 500 mm CONTROL UNIT - THE LINE IS EQUIPPED WITH A FULLY INTEGRATED CONTROL SYSTEM SUPPLIED BY BRUCKNER MILL ROLL STAND (SEMI-FINISHED PRODUCTS WAREHOUSE) - 150 TOTAL POSITIONS, OF WHICH 50 IN HEATED CLOSED ROOM - 1 PICK-UP FOR LOADING / UNLOADING WINDER AND SLITTER - 1 MANUAL EMERGENCY PICK-UP FOR LOADING/UNLOADING WI NDER AND SLITTER AND MAINTENANCE - 1 SHUTTLE TO MOVE MILL ROLLS IN AND OUT OF THE WAREHOUSE - 1 MAIN CRANE FOR MOVING MILL ROLLS / EMPTY CORES RECYCLING - HERBOLD GRINDER FOR SCRAP RECOVERY - 4 FLUFF SILOS - 1 EREMA MACHINE FOR REGRANULATION, APPROX. 700 KG/H SLITTER - ATLAS CW MACHINE, BUILT 1992, MAJOR UPGRADE 2010 - INLET MILL-ROLLS MAX Ø 1.2 M, WIDTH 8.2 M - 16 REWINDING STATIONS, WIDTHS FROM 400 mm TO 2450 mm, MAX Ø 1,000 mm - AUTOMATIC KNIVES AND RE-WINDING ARMS POSITIONING PACKING - SEMI-AUTOMATIC BALLOTTI LINE FOR CONDITIONING OF ROLLS AND PALLETS, BUILT 2000 - CONVEYORS - SCALING - STRAPPING - STRETCHING UTILITIES - 3 COMPRESSORS 3 BARS FOR COMPRESSED AIR CIRCUIT FOR RAW MATERIALS HANDLING - 2 COMPRESSORS 6 BARS FOR COMPRESSED AIR - 2 CHILLERS FOR CHILLED WATER PRODUCTION - 2 WATER COOLING TOWERS - 1 BOILER FOR THERMAL OIL PRODUCTION - 3 TRANSFORMERS 15 KV TO 380 V ADDITIONAL EQUIPMENT - SPARE PARTS FOR ALL OF THE ABOVE - TECHNICAL CONSUMABLES - IT EQUIPMENT FOR CONTROLLING THE MANUFACTURING EQUIPMENT AND DATA TRAFFIC, SUCH AS SERVERS, SWITCHES AND CABLING - LABORATORY EQUIPMENT FOR QUALITY CONTROL PURPOSES Line was producing 20 to 40 microns , line can produce down to 10 to 12 microns Learn More -

TT-7645 SOLAR TITAN130, 50Hz, YEAR 2013TT-7645 SOLAR TITAN130, 50Hz, YEAR 2013 1. SOLAR TITAN130 2. YEAR: 2013 3. HOURS: 7112 AFTER OVERHAULED BY SOLAR 4. 10.5KV 5. 50Hz 6. TOTAL HOURS: 37112 7. FUEL: NATURAL GAS 8. GENERATOR: ABB Learn More

TT-7645 SOLAR TITAN130, 50Hz, YEAR 2013TT-7645 SOLAR TITAN130, 50Hz, YEAR 2013 1. SOLAR TITAN130 2. YEAR: 2013 3. HOURS: 7112 AFTER OVERHAULED BY SOLAR 4. 10.5KV 5. 50Hz 6. TOTAL HOURS: 37112 7. FUEL: NATURAL GAS 8. GENERATOR: ABB Learn More -

TT-6767 CUMBERLAND MODEL 37B 3 KN GRANULATOR - NEWTT-6767 CUMBERLAND MODEL 37B 3 KN GRANULATOR - NEW CUMBERLAND GRANULATOR MODEL 37B 3 KN INFEED: CONVEYOR FEED CUTTING CHAMBER: 2-BED KNIFE ROTOR: OPEN, 3-KNIFE, HIGH SHEAR ROTOR KNIVES: (3) HCHC, HIGH SHEAR BED KNIVES: (2) HCHC SCREEN: 3/8” DIAMETER OR LARGER, END REMOVABLE BASE: PLATE BASE DISCHARGE: AIRVEYOR CHUTE, 8” O.D. MOTOR: 100 HP, 1800 RPM, 3/60/230/460, TEFC DRIVE PARTS: V-BELT - FLYWHEEL ELECTRICAL COMPONENTS: NEMA 12, WITH SAFETY INTERLOCKS CONTROLS: CUSTOMER SUPPLIED LABELS: WARNING LABELS/PLATES AS REQUIRED BY OSHA Learn More

TT-6767 CUMBERLAND MODEL 37B 3 KN GRANULATOR - NEWTT-6767 CUMBERLAND MODEL 37B 3 KN GRANULATOR - NEW CUMBERLAND GRANULATOR MODEL 37B 3 KN INFEED: CONVEYOR FEED CUTTING CHAMBER: 2-BED KNIFE ROTOR: OPEN, 3-KNIFE, HIGH SHEAR ROTOR KNIVES: (3) HCHC, HIGH SHEAR BED KNIVES: (2) HCHC SCREEN: 3/8” DIAMETER OR LARGER, END REMOVABLE BASE: PLATE BASE DISCHARGE: AIRVEYOR CHUTE, 8” O.D. MOTOR: 100 HP, 1800 RPM, 3/60/230/460, TEFC DRIVE PARTS: V-BELT - FLYWHEEL ELECTRICAL COMPONENTS: NEMA 12, WITH SAFETY INTERLOCKS CONTROLS: CUSTOMER SUPPLIED LABELS: WARNING LABELS/PLATES AS REQUIRED BY OSHA Learn More -

TT-6298 EREMA PC 1007T RECLAIM LINE, YEAR 2012TT-6298 EREMA PC 1007T RECLAIM LINE, YEAR 2012 1. EREMA FILM RECLAIM LINE 2. BRAND: EREMA 3. MODEL: PC 1007T QUANTITY: 1 Learn More

TT-6298 EREMA PC 1007T RECLAIM LINE, YEAR 2012TT-6298 EREMA PC 1007T RECLAIM LINE, YEAR 2012 1. EREMA FILM RECLAIM LINE 2. BRAND: EREMA 3. MODEL: PC 1007T QUANTITY: 1 Learn More -

TT-3350 CARDING MACHINE FOR DEHAIRED ALPACA FIBER, DIMENSION 3300 X 1800 X 1800mm, POWER 1.8 KWTT-3350 CARDING MACHINE FOR DEHAIRED ALPACA FIBER, DIMENSION 3300 X 1800 X 1800mm, POWER 1.8 KW FOR ALPACA FIBER DEHAIRED CONDITION: NEW QUANTITY: 1 Learn More

TT-3350 CARDING MACHINE FOR DEHAIRED ALPACA FIBER, DIMENSION 3300 X 1800 X 1800mm, POWER 1.8 KWTT-3350 CARDING MACHINE FOR DEHAIRED ALPACA FIBER, DIMENSION 3300 X 1800 X 1800mm, POWER 1.8 KW FOR ALPACA FIBER DEHAIRED CONDITION: NEW QUANTITY: 1 Learn More -

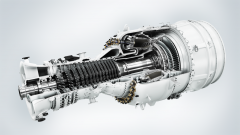

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More -

TT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINETT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINE 6” BRAMPTON MONOLAYER LDPE LINE LINE IS IN STORAGE IN A WAREHOUSE, READY TO SHIP QUANTITY: 1 Learn More

TT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINETT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINE 6” BRAMPTON MONOLAYER LDPE LINE LINE IS IN STORAGE IN A WAREHOUSE, READY TO SHIP QUANTITY: 1 Learn More -

TT-1573 CATERPILLAR 982M WHEEL LOADER, YEAR 2016, 6225 TOTAL HOURSTT-1573 CATERPILLAR 982M WHEEL LOADER, YEAR 2016, 6225 TOTAL HOURS CATERPILLAR 982M WHEEL LOADER YEAR 2016 MATERIAL HANDLER 6,225 TOTAL HOURS QUANTITY: 1 Learn More

TT-1573 CATERPILLAR 982M WHEEL LOADER, YEAR 2016, 6225 TOTAL HOURSTT-1573 CATERPILLAR 982M WHEEL LOADER, YEAR 2016, 6225 TOTAL HOURS CATERPILLAR 982M WHEEL LOADER YEAR 2016 MATERIAL HANDLER 6,225 TOTAL HOURS QUANTITY: 1 Learn More -

T-9532 DMT BOPP LINE, WIDTH 4200mm, YEAR 1995T-9532 DMT BOPP LINE, WIDTH 4200mm, YEAR 1995 QUANTITY: 1 Learn More

T-9532 DMT BOPP LINE, WIDTH 4200mm, YEAR 1995T-9532 DMT BOPP LINE, WIDTH 4200mm, YEAR 1995 QUANTITY: 1 Learn More -

AA-1189 CONTAINER LOADING CRANEAA-1189 CONTAINER LOADING CRANE TECHNICAL PARAMETERS: TYPICAL QUAYSIDE CRANE 1. A: GANTRY SPAN: 15000 TO 35000mm 2. C: BACKREACH: 0 TO 25000mm 3. E: CLEARANCE UNDER SILL BEAM: 12000 TO 18000mm 4. G: TRAVEL WHEEL GAUGE: 18200mm 5. H: BUFFER TO BUFFER: 27000mm 6. WHEEL SPACING: 1000 TO 2000mm 7. WHEELS PER CORNER (DEPENDS ON REQUIRED WHEEL LOADS): 6/12 – SEASIDE 8. WHEELS PER CORNER (DEPENDS ON REQUIRED WHEEL LOADS): 6/12 – LANDSIDE 9. MAX. WIDTH TROLLEY AND MAIN BEAM/BOOM: 7600mm Learn More

AA-1189 CONTAINER LOADING CRANEAA-1189 CONTAINER LOADING CRANE TECHNICAL PARAMETERS: TYPICAL QUAYSIDE CRANE 1. A: GANTRY SPAN: 15000 TO 35000mm 2. C: BACKREACH: 0 TO 25000mm 3. E: CLEARANCE UNDER SILL BEAM: 12000 TO 18000mm 4. G: TRAVEL WHEEL GAUGE: 18200mm 5. H: BUFFER TO BUFFER: 27000mm 6. WHEEL SPACING: 1000 TO 2000mm 7. WHEELS PER CORNER (DEPENDS ON REQUIRED WHEEL LOADS): 6/12 – SEASIDE 8. WHEELS PER CORNER (DEPENDS ON REQUIRED WHEEL LOADS): 6/12 – LANDSIDE 9. MAX. WIDTH TROLLEY AND MAIN BEAM/BOOM: 7600mm Learn More