Search results for: 'can sew'

-

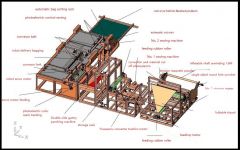

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More -

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More -

BABY DIAPER SEWING SYSTEM YEAR 1998TOTAL AUTOMATIC FOR PRE-FOLDED BABY DIAPERS PRE-FOLDED BABY DIAPERS AT RATES OF UP TO 35 PIECES PER MINUTE FEEDS FROM A HEAVY-DUTY CRADLE INFEED CAPABLE OF ROLL DIAMETERS OF 48” AND WEIGHTS OF 1,000LBS. BASIC SINGLE-STAGE FOLDERS CAN PRODUCE DIAPERS IN THE 2-3-2 STYLE, WITH AND WITHOUT SOAKER INSERTION THE OPTIONAL DUAL-STAGE FOLDERS CAN PRODUCE 2-3-2, 2-4-2, AND 2-5-2 STYLES, WITH AND WITHOUT SOAKER INSERTION THE FOLDER KITS ARE DELIVERED FOR TWO WIDTHS AS PER CUSTOMER SPECIFICATIONS ADDITIONAL FOLDERS CAN BE ADDED AN OPTIONAL PRINTER ATTACHMENT IS AVAILABLE FOR PRINTING A COMPANY LOGO OR TRADEMARK ON THE DIAPERS A STACKER IS ALSO AVAILABLE FOR STACKING THE FINISHED DIAPERS INTO BATCHES. THE BATCH SIZE CAN BE SELECTED ON A COUNTER SS-1BD SEWING SYSTEM THE SS-1BD SEWING SYSTEM DETAILED BELOW HAS BEEN DESIGNED ESPECIALLY FOR THE PRODUCTION OF FOLDED BABY DIAPERS WITH DOUBLE-STAGE FOLD. THE SYSTEM IS ALSO CAPABLE OF USING A STANDARD FELT-TYPE INSERT. THE STANDARD FEATURES ARE: POWERED INFEED CRADLE FOR ONE ROLL OF FABRIC WITH A MAXIMUM WIDTH OF 48”, DIAMETER OF 36”, AND WEIGHT OF 750LB (MASTER ROLL), AND ONE ROLL WITH MAXIMUM WIDTH OF 6”, DIAMETER OF 36”, AND WEIGHT OF 30LB. (SOAKER ROLL). COMPLETE WITH EDGE GUIDE LENGTH FOLDER TO CREATE OVERLAPPING, CONTINUOUS FOLD WITH POSSIBILITY OF INSERTING SOAKER. CAN BE ENTIRELY BYPASSED WHEN FOLDING IS NOT REQUIRED. FIRST SEWING STATION WITH TWO RIGHT HAND CHAIN STITCH SEWING HEADS (TYPE 401) TO SEW THE FOLD IN PLACE. DUAL STAGE PULL ROLLS FEED FROM ITEM 2 INTO A DANCER-BAR ACCUMULATOR MEASURING AND CUTOFF STATION (TRAVERSING ROTARY KNIFE) CUTS DIAPER TO LENGTH WITH +/- 1/8” REPEATABILITY. OUTFEED CONVEYOR WITH RIGHT-ANGLE TRANSFER STATION FOR TRANSFER OF CUT PIECES INTO SECOND SEWING SATION. SECOND SEWING STATION WITH LEFT AND RIGHT HAND SERGERS (TYPE 514) AND UPPER AND LOWER CONVEYOR BELTS TO CARRY THE DIAPER BETWEEN THE SERGERS. LEFT AND RIGHT HAND MECHANICAL CHAIN CUTTERS TO CUT THE THREAD CHAIN BETWEEN DIAPERS ELECTRONIC THREAD MOTION DETECTORS ON ALL SEWING HEADS. FOR SHIPPING: REQUIRES ONE CONTAINER -40 FEET TOTAL WEIGHT- 4,525 KGS Learn More

BABY DIAPER SEWING SYSTEM YEAR 1998TOTAL AUTOMATIC FOR PRE-FOLDED BABY DIAPERS PRE-FOLDED BABY DIAPERS AT RATES OF UP TO 35 PIECES PER MINUTE FEEDS FROM A HEAVY-DUTY CRADLE INFEED CAPABLE OF ROLL DIAMETERS OF 48” AND WEIGHTS OF 1,000LBS. BASIC SINGLE-STAGE FOLDERS CAN PRODUCE DIAPERS IN THE 2-3-2 STYLE, WITH AND WITHOUT SOAKER INSERTION THE OPTIONAL DUAL-STAGE FOLDERS CAN PRODUCE 2-3-2, 2-4-2, AND 2-5-2 STYLES, WITH AND WITHOUT SOAKER INSERTION THE FOLDER KITS ARE DELIVERED FOR TWO WIDTHS AS PER CUSTOMER SPECIFICATIONS ADDITIONAL FOLDERS CAN BE ADDED AN OPTIONAL PRINTER ATTACHMENT IS AVAILABLE FOR PRINTING A COMPANY LOGO OR TRADEMARK ON THE DIAPERS A STACKER IS ALSO AVAILABLE FOR STACKING THE FINISHED DIAPERS INTO BATCHES. THE BATCH SIZE CAN BE SELECTED ON A COUNTER SS-1BD SEWING SYSTEM THE SS-1BD SEWING SYSTEM DETAILED BELOW HAS BEEN DESIGNED ESPECIALLY FOR THE PRODUCTION OF FOLDED BABY DIAPERS WITH DOUBLE-STAGE FOLD. THE SYSTEM IS ALSO CAPABLE OF USING A STANDARD FELT-TYPE INSERT. THE STANDARD FEATURES ARE: POWERED INFEED CRADLE FOR ONE ROLL OF FABRIC WITH A MAXIMUM WIDTH OF 48”, DIAMETER OF 36”, AND WEIGHT OF 750LB (MASTER ROLL), AND ONE ROLL WITH MAXIMUM WIDTH OF 6”, DIAMETER OF 36”, AND WEIGHT OF 30LB. (SOAKER ROLL). COMPLETE WITH EDGE GUIDE LENGTH FOLDER TO CREATE OVERLAPPING, CONTINUOUS FOLD WITH POSSIBILITY OF INSERTING SOAKER. CAN BE ENTIRELY BYPASSED WHEN FOLDING IS NOT REQUIRED. FIRST SEWING STATION WITH TWO RIGHT HAND CHAIN STITCH SEWING HEADS (TYPE 401) TO SEW THE FOLD IN PLACE. DUAL STAGE PULL ROLLS FEED FROM ITEM 2 INTO A DANCER-BAR ACCUMULATOR MEASURING AND CUTOFF STATION (TRAVERSING ROTARY KNIFE) CUTS DIAPER TO LENGTH WITH +/- 1/8” REPEATABILITY. OUTFEED CONVEYOR WITH RIGHT-ANGLE TRANSFER STATION FOR TRANSFER OF CUT PIECES INTO SECOND SEWING SATION. SECOND SEWING STATION WITH LEFT AND RIGHT HAND SERGERS (TYPE 514) AND UPPER AND LOWER CONVEYOR BELTS TO CARRY THE DIAPER BETWEEN THE SERGERS. LEFT AND RIGHT HAND MECHANICAL CHAIN CUTTERS TO CUT THE THREAD CHAIN BETWEEN DIAPERS ELECTRONIC THREAD MOTION DETECTORS ON ALL SEWING HEADS. FOR SHIPPING: REQUIRES ONE CONTAINER -40 FEET TOTAL WEIGHT- 4,525 KGS Learn More -

YY-2725 48 MW POWER BARGEYY-2725 48 MW POWER BARGE 48 MW POWER BARGE INCLUDES FUEL BARGE FOR SALE 1996 BUILT FUEL AND POWER BARGE QUANTITY: 1 Learn More

YY-2725 48 MW POWER BARGEYY-2725 48 MW POWER BARGE 48 MW POWER BARGE INCLUDES FUEL BARGE FOR SALE 1996 BUILT FUEL AND POWER BARGE QUANTITY: 1 Learn More -

L-4842 DECORATIVE BORDER AUTO-SEWING MACHINE, MODEL TF-4

L-4842 DECORATIVE BORDER AUTO-SEWING MACHINE, MODEL TF-4REFERENCE NUMBER: L-4842

AUTOMATIC BORDER SEWING MACHINE WITH DECORATIVE CAPABILITIES, MODEL TF-4

QUANTITY: 1

Learn More -

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENTCOFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

Learn More -

P-8696 ULTRASONIC SEWING MACHINELearn More

P-8696 ULTRASONIC SEWING MACHINELearn MoreREFERENCE NUMBER: P-8696

ULTRASONIC SEWING MACHINE

CAN BE USED WITH EITHER 20 KHz, 30 KHz OR 40 KHz EQUIPMENT

LED DISPLAY FOR EASY PROCESS MONITORING

19” (483mm) THROAT

INDEPENDENT CONTROLS FOR SLITTING AND ROTARY ANVIL WELDING

DUAL SEALING CAPABILITIES WITH INDEPENDENT ADJUSTMENTS

EDGE GUIDING, REWINDING, AND FEED ROLLS CAN BE USED

CAN BE OPERATOR CONTROLLED AS A BENCHTOP UNIT OR INTEGRATED INTO AN EXISTING LINE

QUANTITY: 1

-

M-4426 KUSTERS CALENDER YEAR 2008 WIDTH 3200mREFERENCE NUMBER: M-4426 (10102MNJHX9RX) K KUSTERS CALENDER YEAR 2008 WIDTH 3200mm KUSTERS CALENDER YEAR 2008 WORKING WIDTH 3200mm PLC CONTROLLED CONTROL PANEL A HYDRAULIC MOTOR DRIVEN ROLLERS POLYAMIDE AUTOMATIC ROLL COOLING SYSTEM METAL DETECTOR AUTOMATIC SEWING CONTROL SYSTEM EDGE HOLDING SYSTEM STATIC ELECTRICITY RECEIVER CLOSED CIRCUIT OIL HEATING SYSTEM ROLLER BEARING SYSTEM ALL CAMERA CONTROLS CAN BE PERFORMED ON DIGITAL SCREEN ALL MALFUNCTIONS THAT MAY OCCUR, CAN BE SEEN ON THE DIGITAL DISPLAY CHROME CYLINDERS INDISE AND OUTSIDE SURFACE TEMPERATURE CAN BE MEASURED AT VARIOUS POINTS POLYAMIDE ROLLERS TEFLON BASED COMPUTER-AIDED SPECIAL GRINDING MACHINES ARE GRIND. 2 ROLLS (CYLINDERS) QUANTITY AVAILABLE: 1 Learn More

M-4426 KUSTERS CALENDER YEAR 2008 WIDTH 3200mREFERENCE NUMBER: M-4426 (10102MNJHX9RX) K KUSTERS CALENDER YEAR 2008 WIDTH 3200mm KUSTERS CALENDER YEAR 2008 WORKING WIDTH 3200mm PLC CONTROLLED CONTROL PANEL A HYDRAULIC MOTOR DRIVEN ROLLERS POLYAMIDE AUTOMATIC ROLL COOLING SYSTEM METAL DETECTOR AUTOMATIC SEWING CONTROL SYSTEM EDGE HOLDING SYSTEM STATIC ELECTRICITY RECEIVER CLOSED CIRCUIT OIL HEATING SYSTEM ROLLER BEARING SYSTEM ALL CAMERA CONTROLS CAN BE PERFORMED ON DIGITAL SCREEN ALL MALFUNCTIONS THAT MAY OCCUR, CAN BE SEEN ON THE DIGITAL DISPLAY CHROME CYLINDERS INDISE AND OUTSIDE SURFACE TEMPERATURE CAN BE MEASURED AT VARIOUS POINTS POLYAMIDE ROLLERS TEFLON BASED COMPUTER-AIDED SPECIAL GRINDING MACHINES ARE GRIND. 2 ROLLS (CYLINDERS) QUANTITY AVAILABLE: 1 Learn More