Search results for: 'quilt+a'

-

K-4933 AUTOMATIC QUILT FIXING HOTMELT MACHINEREFERENCE NUMBER: K-4933 AUTOMATIC QUILT FIXING HOTMELT MACHINE QUANTITY AVAILABLE: 1 Learn More

K-4933 AUTOMATIC QUILT FIXING HOTMELT MACHINEREFERENCE NUMBER: K-4933 AUTOMATIC QUILT FIXING HOTMELT MACHINE QUANTITY AVAILABLE: 1 Learn More -

K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINEREFERENCE NUMBER: K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINE DIMENSIONS: 1462 X 1060 X 1988mm POWER 500W VOLTAGE 220V 50HZ SINGLE PHASE WEIGHT 300KG USED FOR COMFORTER PACKING & BAGGING EASY TO OPERATION WITH 1 OPERATOR ELECTRICITY KEY PARTS ADOPT SIEMENS BRAND, STABLE & THEIR LOCAL SERVICE WILL SUPPORT YOU CHANGEABLE DIFFERENT DIMENSION PLATE MAIN STRUCUTRE MADE BY COMPUTERIZED LASER CUTTING MACHINE, STABLE & DURABLE CHANGEABLE PRESSING PLATES MEET DIFFERENT NEED. DIFFERENT POWER CONDITION AND SAFE STANDARD CAN BE ORDERED ACCORDING TO THE CLIENT’S LOCAL REQUIREMENT. QUANTITY AVAILABLE: 1 Learn More

K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINEREFERENCE NUMBER: K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINE DIMENSIONS: 1462 X 1060 X 1988mm POWER 500W VOLTAGE 220V 50HZ SINGLE PHASE WEIGHT 300KG USED FOR COMFORTER PACKING & BAGGING EASY TO OPERATION WITH 1 OPERATOR ELECTRICITY KEY PARTS ADOPT SIEMENS BRAND, STABLE & THEIR LOCAL SERVICE WILL SUPPORT YOU CHANGEABLE DIFFERENT DIMENSION PLATE MAIN STRUCUTRE MADE BY COMPUTERIZED LASER CUTTING MACHINE, STABLE & DURABLE CHANGEABLE PRESSING PLATES MEET DIFFERENT NEED. DIFFERENT POWER CONDITION AND SAFE STANDARD CAN BE ORDERED ACCORDING TO THE CLIENT’S LOCAL REQUIREMENT. QUANTITY AVAILABLE: 1 Learn More -

24 HEAD QUILTING AND EMBROIDERY CONTINUOUS MACHINE - FOR FULL WIDTH FABRIC ROLL TO ROLL24 HEADS, EACH HEAD 4 NEEDLES (4 COLORS) HEAD GAUGE 135mm CAN WORK ALTERNATE HEADS WORKING WIDTH 270mm WITH TRIMMER SYSTEM IT USES ORIGINAL JAPANESE KOBAN ROTARY HOOK 10” TOUCH SCREEN COMPUTER PUNCHING SOFTWARE Learn More

24 HEAD QUILTING AND EMBROIDERY CONTINUOUS MACHINE - FOR FULL WIDTH FABRIC ROLL TO ROLL24 HEADS, EACH HEAD 4 NEEDLES (4 COLORS) HEAD GAUGE 135mm CAN WORK ALTERNATE HEADS WORKING WIDTH 270mm WITH TRIMMER SYSTEM IT USES ORIGINAL JAPANESE KOBAN ROTARY HOOK 10” TOUCH SCREEN COMPUTER PUNCHING SOFTWARE Learn More -

GRIBETZ PARAGON 4 CHAINSTITCH QUILTING MACHINES 90” (2286mm) YEAR 1998 AND 2001MAKE: GRIBETZ MODEL PARAGON 4 1 IS YEAR 1998, 1 IS YEAR 2001 CHAINSTITCH WITH PANEL CUTTER Learn More

GRIBETZ PARAGON 4 CHAINSTITCH QUILTING MACHINES 90” (2286mm) YEAR 1998 AND 2001MAKE: GRIBETZ MODEL PARAGON 4 1 IS YEAR 1998, 1 IS YEAR 2001 CHAINSTITCH WITH PANEL CUTTER Learn More -

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More -

YY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mmYY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mm APPLICATION: SUITABLE FOR THE SINGLE HEAD QUILTING PATTERNS OF MATTRESS, DUVET, BLANKET, MATTRESS PROTECTOR. QUANTITY: 1 Learn More

YY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mmYY-2261 COMPUTERIZED DOUBLE SADDLES QUILTING MACHINE WITH SUPPORT BELT, MAXIMUM SPEED 3000 RPM PER MINUTE, MAXIMUM QUILTING THICKNESS 50mm APPLICATION: SUITABLE FOR THE SINGLE HEAD QUILTING PATTERNS OF MATTRESS, DUVET, BLANKET, MATTRESS PROTECTOR. QUANTITY: 1 Learn More -

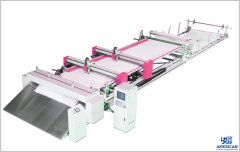

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More -

MULTI NEEDLE QUILTING MACHINE 94 SHUTTLE WIDTH 2450mm (94") -3 BAR (1x3x6) #10 BOBBINPRODUCT MAIN INFORMATION: 1. WITH WINDOWS XP OPERATING SYSTEM, EASY OPERATION 2. CAD PATTERN DESIGNING OR SCANNER-INPUT PATTERN 3. COMPUTERIZED COMPENSATION AND DESIGN AMENDMENT, ENSURING BETTER PRECISION 4. IR THREAD-BREAKING DETECTION, AUTO-STOP; 5. 360°AND 180°SPAN QUILTING AVAILABLE FOR COMPLEX PATTERN; 6. IMPORTED SERVO MOTORS, HIGH PRECISION; 7. QUILTING LENGTH ADJUSTABLE, AUTO STOP WHEN COMPLETED; 8. PATTERN EFFECT PROCESS TRACK, AUTO DETECTION OPERATION. Learn More

MULTI NEEDLE QUILTING MACHINE 94 SHUTTLE WIDTH 2450mm (94") -3 BAR (1x3x6) #10 BOBBINPRODUCT MAIN INFORMATION: 1. WITH WINDOWS XP OPERATING SYSTEM, EASY OPERATION 2. CAD PATTERN DESIGNING OR SCANNER-INPUT PATTERN 3. COMPUTERIZED COMPENSATION AND DESIGN AMENDMENT, ENSURING BETTER PRECISION 4. IR THREAD-BREAKING DETECTION, AUTO-STOP; 5. 360°AND 180°SPAN QUILTING AVAILABLE FOR COMPLEX PATTERN; 6. IMPORTED SERVO MOTORS, HIGH PRECISION; 7. QUILTING LENGTH ADJUSTABLE, AUTO STOP WHEN COMPLETED; 8. PATTERN EFFECT PROCESS TRACK, AUTO DETECTION OPERATION. Learn More -

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More -

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

2 BAR , 150m DISTANCE BETWEEN BARS

WIDTH UP TO 2700mm = 106 INCHESMAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER

YEAR: 2014

96 SEPARATELY CONTROLLABLE NEEDLES

FULLY AUTOMATIC NEEDLE PLAN CHANGE

TOP AND BOTTOM THREAD CUTTER AT EACH SEWING POSITION

MATERIAL WIDTH UP TO 2700mm

TWO NEEDLE BARS

150mm SPACING

HANDWHEEL ADJUSTMENT OF HEIGHT OF PRESSER PLATE

ELECTRONIC THREAD BREAK DETECTOR FOR TOP AND BOTTOM THREADS

MATERIAL UNWIND DEVICE

RACKS FOR TOP AND BOTTOM THREAD

ONE CATWALK EACH ON FRONT AND REAR OPERATING SITE

TROUGH INFEED FOR UPPER MATERIAL WITH MOTOR-DRIVEN ROLLER SYSTEM

AUTOMATIC MARKING AND DETECTING UNIT FOR PATTERN CONFORM LATERAL CUT

ELECTRONICS AND MOTORS 400V, 3 PHASES

CONCRETE BASES AND VIBRATION DAMPERS

Learn More